Method for manufacturing composite material based on nano-particle three-dimensional micro-nano structured arrangement

A technology of micro-nano structure and composite materials, which is applied in the direction of nano-structure manufacturing, nano-structure manipulation, and specific nano-structure formation, etc., which can solve the problems that cannot realize three-dimensional micro-nano structure and no structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

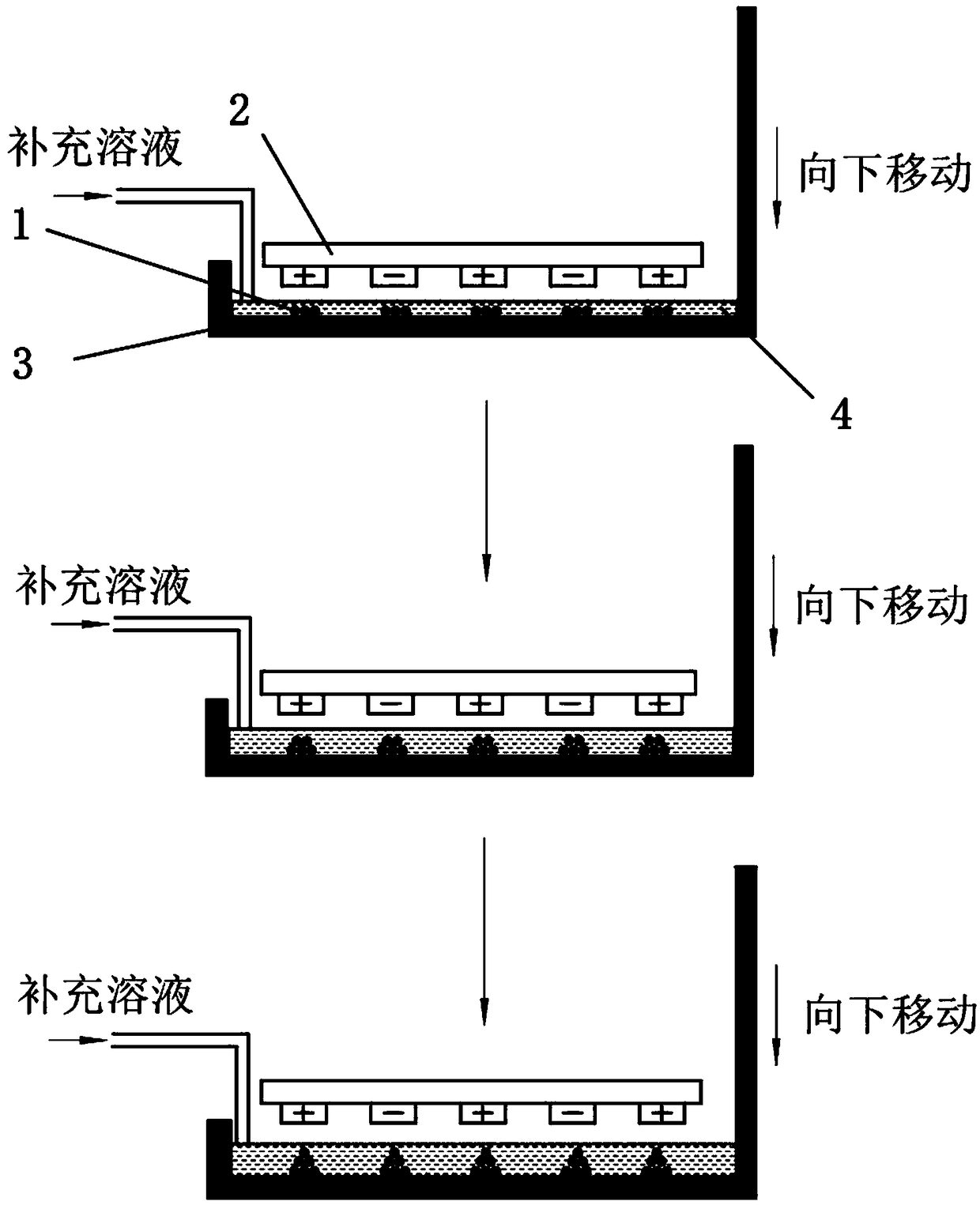

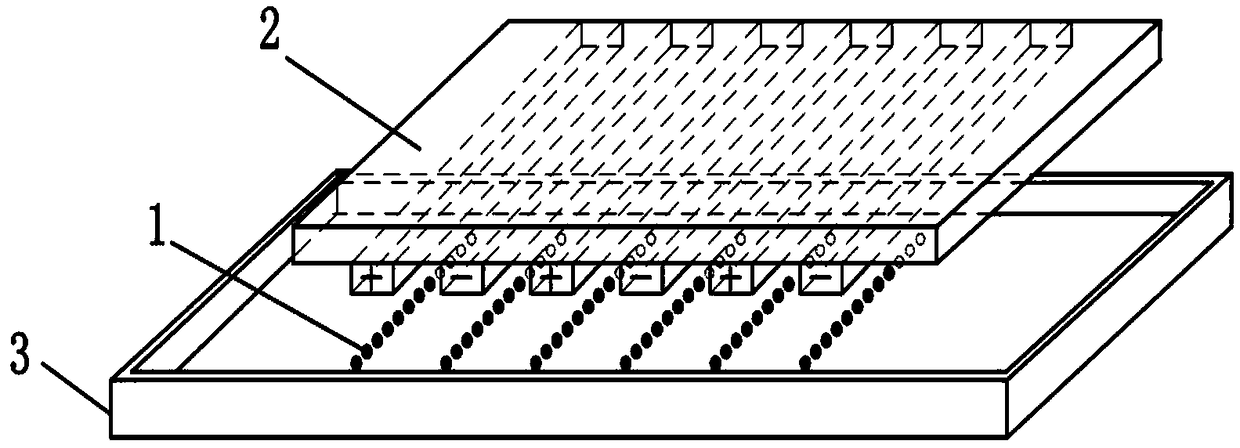

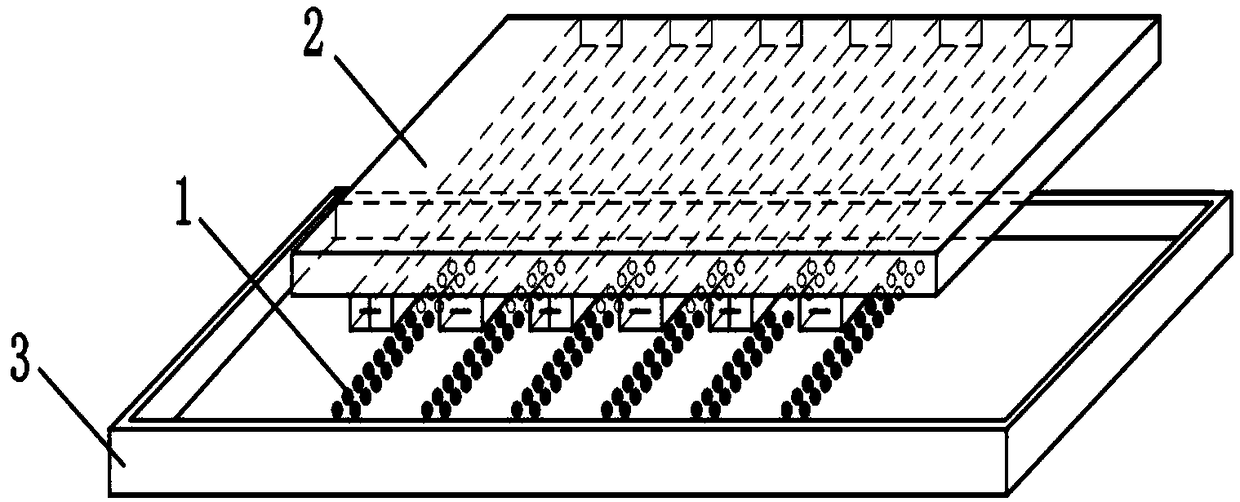

[0036] refer to figure 1 , a method for manufacturing a composite material based on a three-dimensional micro-nano structured arrangement of nanoparticles, comprising the following steps:

[0037] 1) Place the particles of polystyrene beads 1 with a diameter of 5 μm in the PDMS solution, and stir for five minutes to make the particles evenly distributed, and obtain a PDMS solution 4 evenly distributed with polystyrene particles;

[0038] 2) Pour a part of the PDMS solution 4 of polystyrene particles into the container 3, and then scrape it so that the liquid level in the container is 60 μm;

[0039] 3) leveling the PDMS solution 4 of polystyrene particles in the container;

[0040] 4) Apply the first structured electric field with a width of 50 μm and a finger distance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com