3D (3-dimensional) molding machine

A 3D, mechanical technology, applied in the field of road construction machinery, can solve the problems that the cost, quality and effect cannot reach the best state, the rotating raised plate with large pitch is easy to be damaged, and the power function requirements are large, etc., so as to achieve simple and reasonable structure, Low cost, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

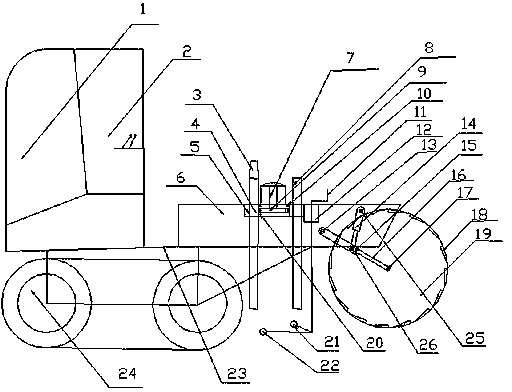

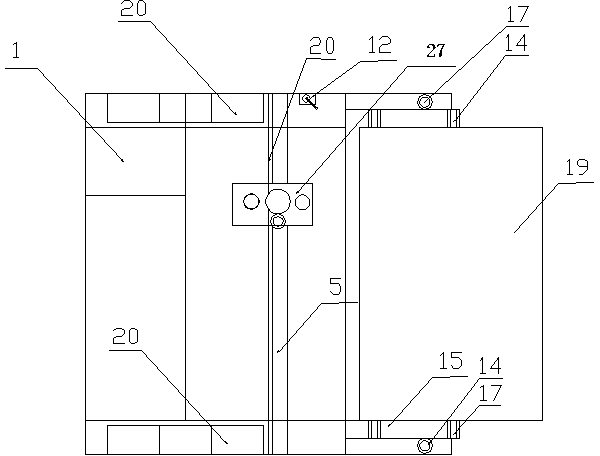

[0021] Such as figure 1 As shown, a 3D molding machine includes a crawler vehicle 1, a pouring device and a road surface forming roller arranged on the crawler vehicle, and a base plate 23 is provided at the bottom of the crawler vehicle. In the present invention, a transverse groove 5 is arranged in the middle of the bottom plate 23 of the tracked vehicle 1, and a guide rail 10 is arranged above the transverse groove 5, and a 3D pouring device with a cover is installed on the guide rail, and the 3D pouring device slides laterally in the transverse groove 5.

[0022] One end (front end) of the base plate is provided with a 3D modeling and programming control room 2, and the road surface forming roll is arranged at the other end (rear end) of the base plate. The 3D modeling and programming control room 2 is equipped with a display module for displaying the road 3D modeling status, a man-machine communication module, and a modeling control and implementation control module.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com