Sow feeder with adjustable width passage

A channel width and feeder technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve problems such as unfavorable pig feeding, and achieve the effects of easy disassembly and replacement, simple and practical structure, and fast, convenient and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A sow feeder with adjustable channel width, comprising a front door, a channel 9, and a rear door, the rear door is a one-way door, and the front door and the rear door are communicated through a channel 9 formed by side pipes, sows enter from the front door and pass through the channel 9. Enter the feeding area from the back door.

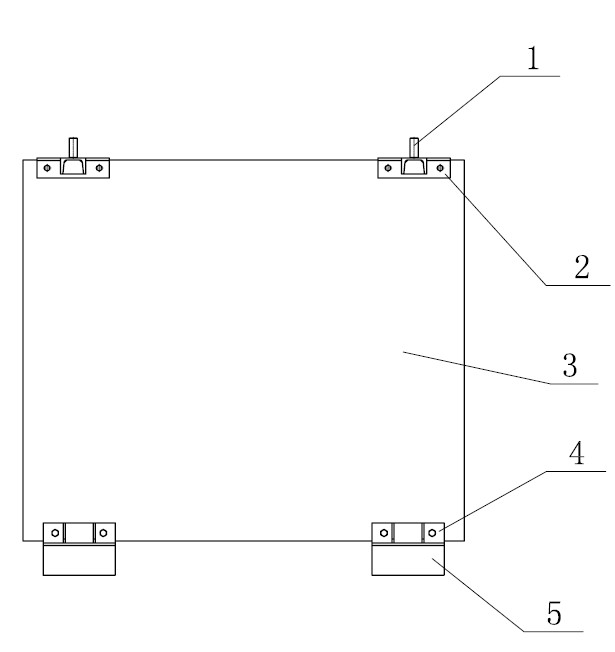

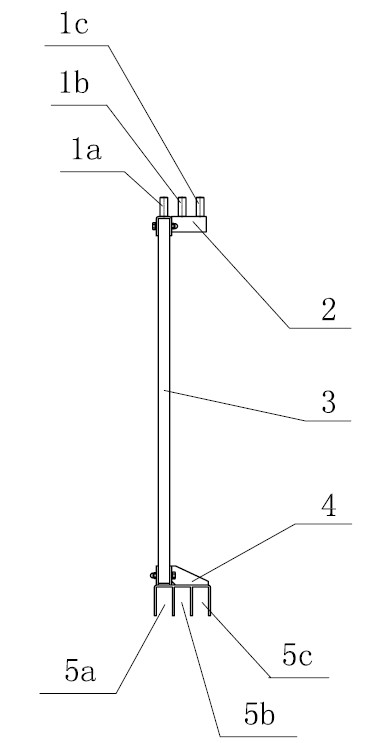

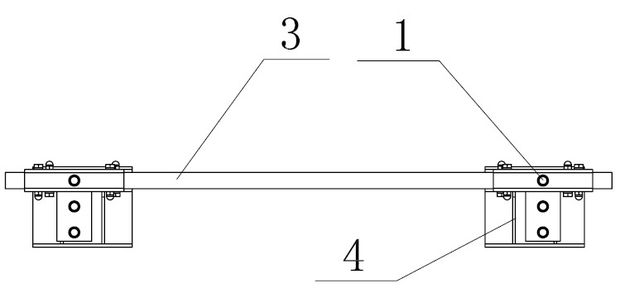

[0032] The side pipe of the feeder channel 9 includes the upper side tube 6 and the lower side tube 7 on the left and right sides, and the door panel 3 is fixedly arranged between the upper side tube 6 and the lower side tube 7 on the same side of the passage 9, the upper side tube 6, the lower side tube 7 and The door panels 3 are combined to form the side walls of the channel 9; as Figure 1-3 As shown, the upper end of the door panel 3 is provided with an upper support 2 extending to the outside of the door panel 3, and the lower end is provided with a lower support 4 extending to the outside of the door panel 3. The upper support 2 is p...

Embodiment 2

[0039] On the basis of the above structure, a pair of upper supports 2 are arranged symmetrically on both sides of the upper end of the door panel 3, and a pair of lower supports 4 are symmetrically arranged on both sides of the lower end of the door panel 3. The positions of the upper supports 2 and the lower supports 4 One to one correspondence.

[0040]According to breeding experience, three bolt positioning sleeves 1a, 1b, 1c can be set on the upper support 2, and three side tube positioning sleeves corresponding to the three bolt positioning sleeves 1a, 1b, 1c can be set on the lower support 4. Grooves 5a, 5b, 5c, by installing the left and right lower side tubes 7 in different side tube positioning grooves and fixing the upper side tube 6 on the corresponding latch positioning sleeve, the width dimension of the channel 9 of the sow feeder is realized. Adjustment.

[0041] A total of five feeder channel 9 width sizes are available using this design, such as Figure 4-9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com