Method and device used for manufacturing at least two section beams in one set

A technique of warping and warping in strips, applied in the direction of warping machines, manufacturing tools, and other manufacturing equipment/tools, can solve problems such as huge cost and high cost, and achieve the effect of avoiding poor stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

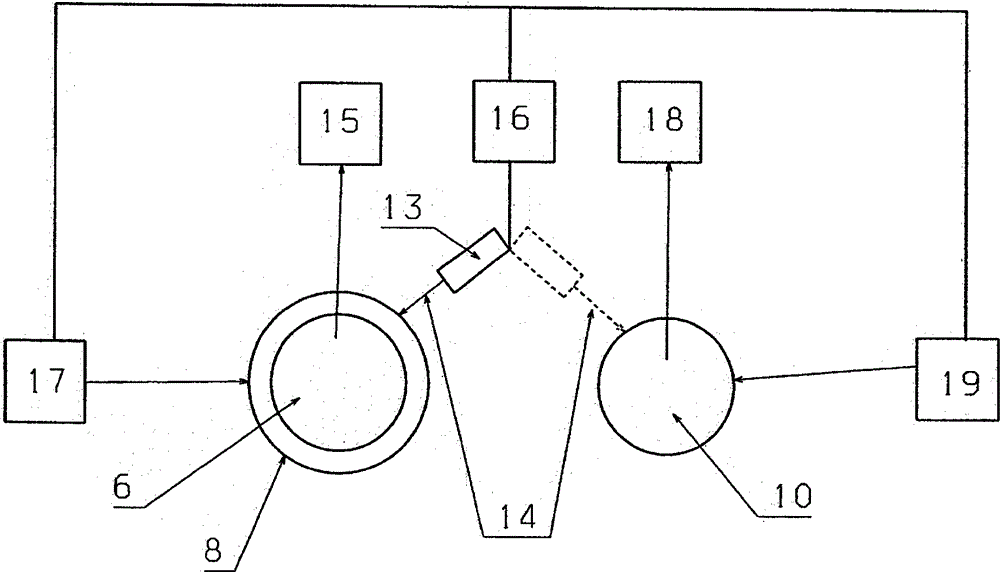

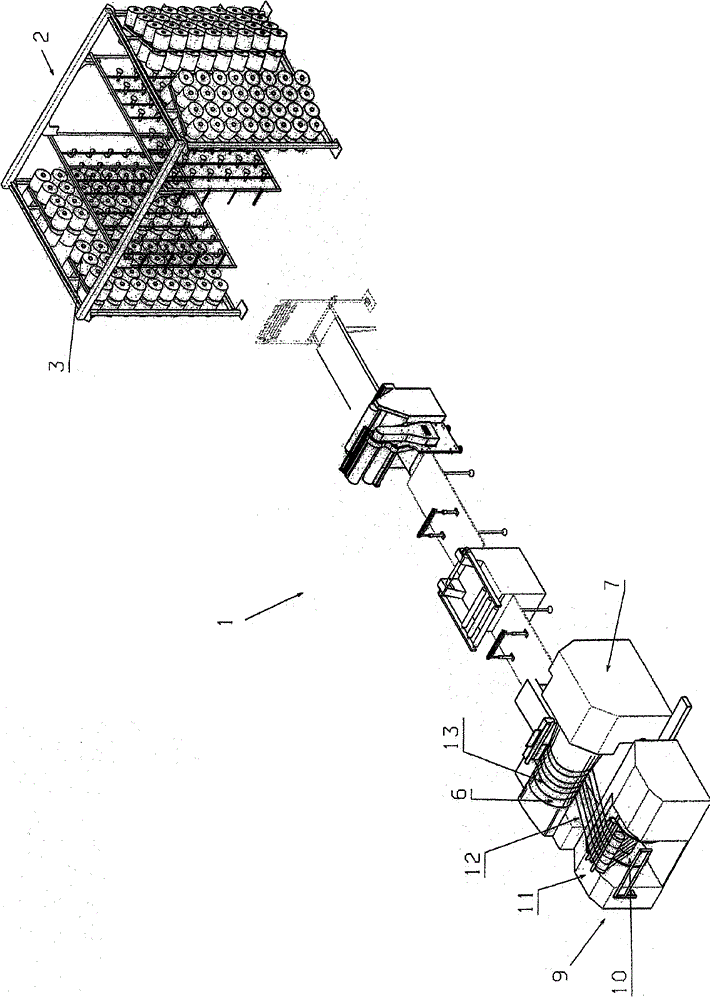

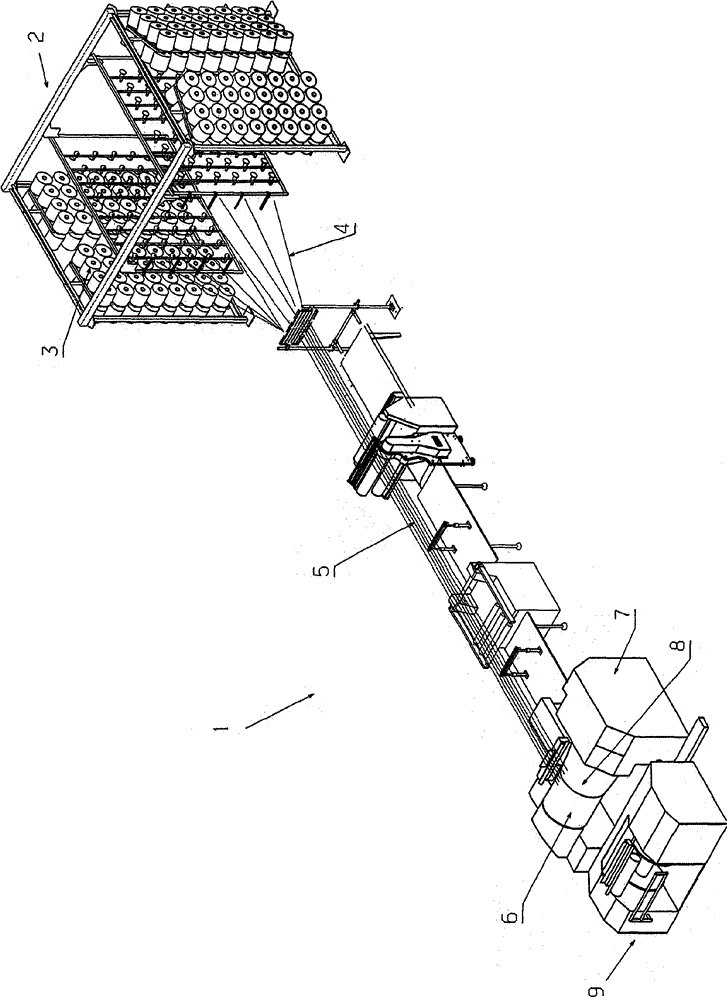

[0025] A device 1 for producing a group of at least two section warp beams for a weaving process has a creel 2 as a yarn source. A plurality of bobbins 3 are arranged in the creel 2 . A yarn 4 can be drawn from each bobbin 3 . The yarns are combined by means of devices known per se into a belt 5 , ie a yarn group, and are then wound on a warping cylinder 6 of a warping device 7 . The warper 7 is configured as a conical warper, ie the warping cylinder 6 is provided with a conical section 8 . Correspondingly, the yarn 4 can be wound on the warping cylinder 6 in the section warping method. First the first tape 5 is wound, precisely with the desired length for the later warp threads. The warping cylinder 6 rotates here. The warping cylinder 6 and the belt 5 are offset laterally by a small distance with each revolution of the warping cylinder 6 , so that the belt 5 moves upward along the conical section 8 during winding. If the tape 5 has been wound with the desired length, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com