Patents

Literature

56results about How to "Fulfill usage requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

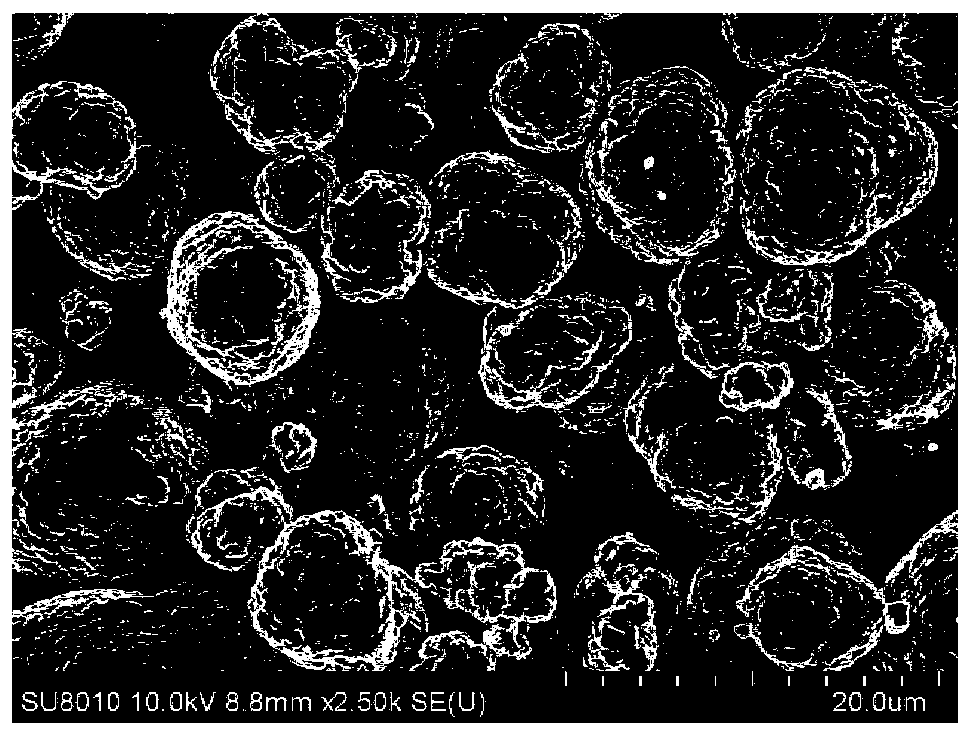

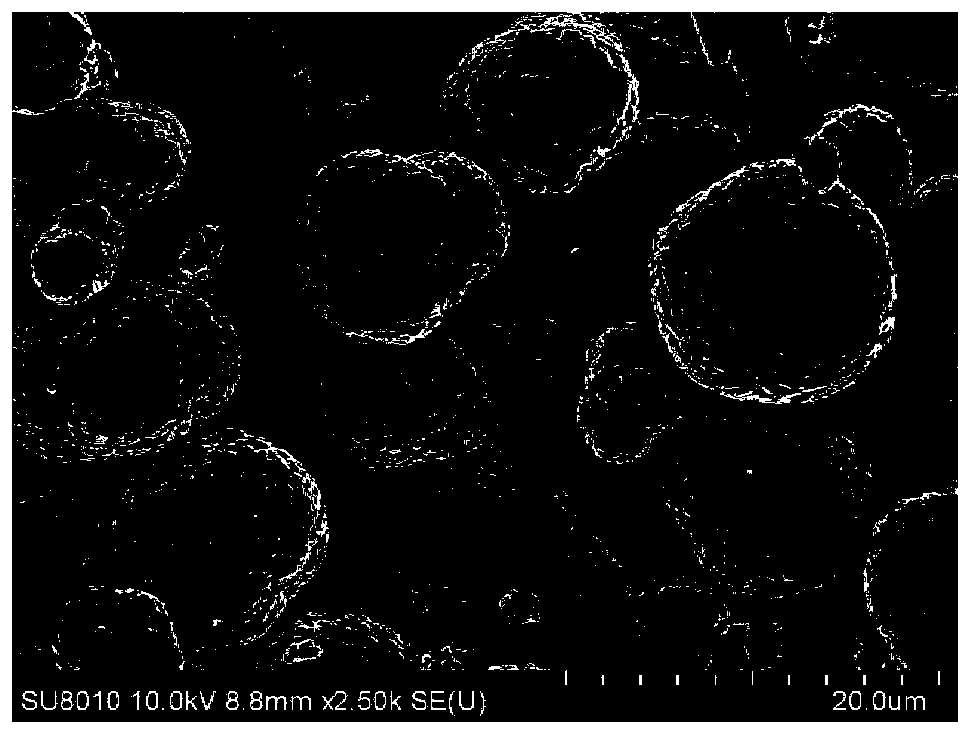

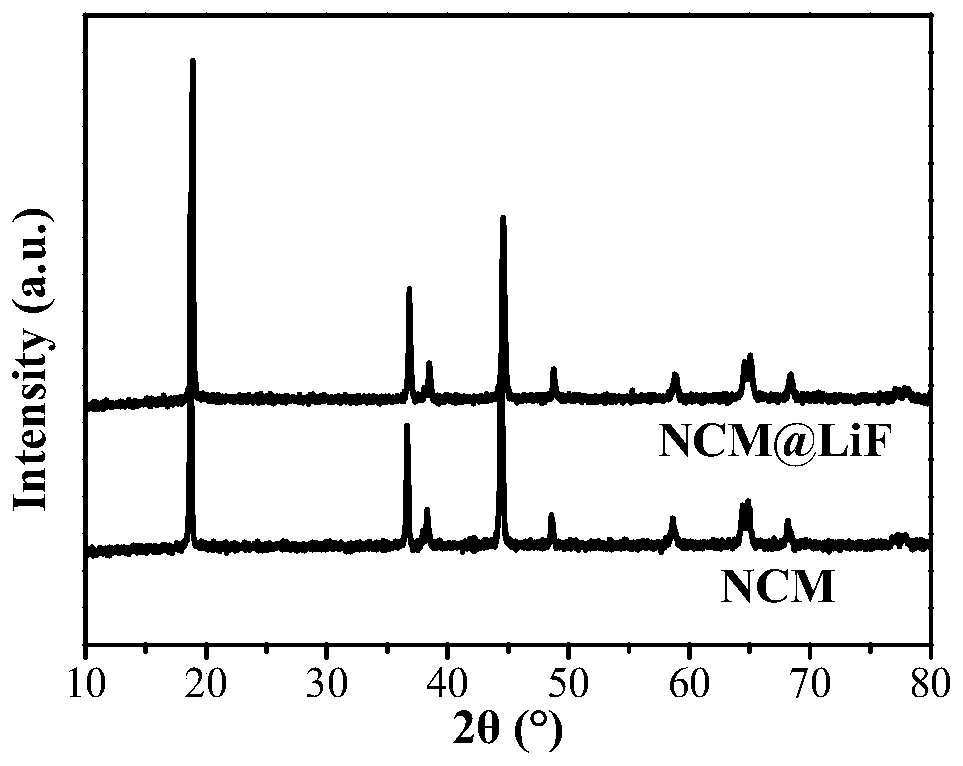

Method for surface modification of ternary cathode material for lithium ion batteries by fluorine-based ionic liquid

PendingCN110137470AThe synthesis process is simpleEasy to operateCell electrodesSecondary cellsTetrafluoroborateEthyl acetate

The invention discloses a method for surface modification of a ternary cathode material for lithium ion batteries by fluorine-based ionic liquid, which comprises the following steps: (1) a ternary cathode material is added into fluorine-based ionic liquid, which includes alkyl imidazole tetrafluoroborate, 1-ethyl acetate-3-methylimidazole tetrafluoroborate, and the like; and (2) stirring, filtering, washing, drying and calcining are carried out. The fluorine-based ionic liquid can interact with the lithium residue on the surface of the ternary cathode material through hydrolysis and form a lithium fluoride coating on the surface. The coating not only can reduce the side reaction between interfaces, but also can solve the problem that the ternary cathode material is sensitive to carbon dioxide / water in air and greatly improve the cycle life and rate performance of the material. The preparation method of the invention is simple, green and environment-friendly, can significantly improve the electrochemical performance of the material, and has a broad application prospect.

Owner:SOUTH CHINA UNIV OF TECH

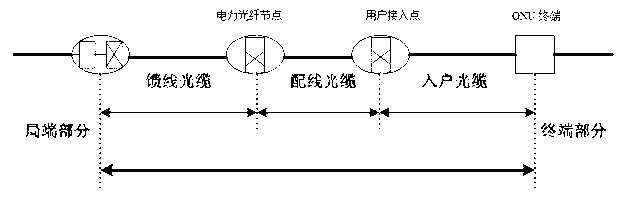

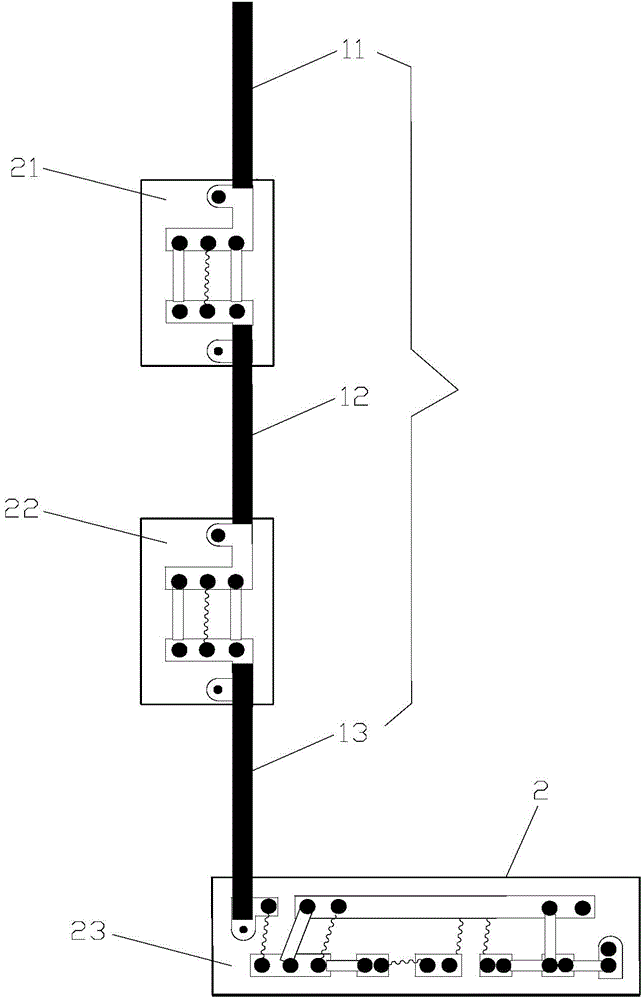

Power fiber to the home (PFTTH) access method based on EPON (Ethernet passive optical network)

InactiveCN103020359AFulfill usage requirementsConvenient on-site constructionSpecial data processing applicationsEngineeringOptical network unit

The invention discloses a power fiber to the home (PFTTH) access method based on an EPON (Ethernet passive optical network), which comprises the following steps: 1) analyzing a building structure and an electrical structure of a building to be accessed; 2) determining a node position of a power fiber; 3) allocating an optical divider; and 4) allocating an ONU (optical network unit) terminal. According to the PFTTH access method based on the EPON, a data model of the PFTTH is established, a plan on the PFTTH is guided, and site operation is convenient, so that the using requirements of different regions and environments on the terminal can be met; and the PFTTH access method has the advantages of high practicability and good prospect.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER +3

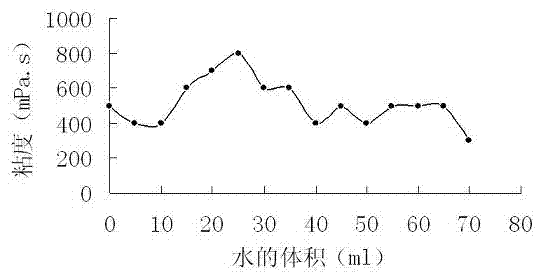

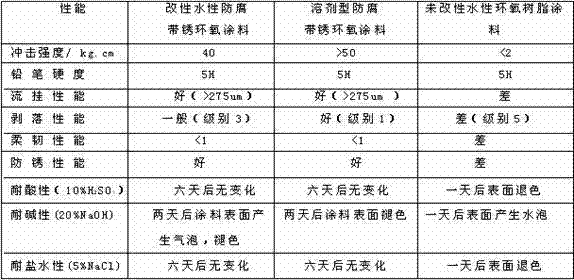

Synthesis of modified aqueous epoxy resin and method for preparing antiseptic rusty paint

ActiveCN101775108AGood water dispersibilityGood storage stabilityAnti-corrosive paintsEpoxySynthesis methods

The invention discloses synthesis of modified aqueous epoxy resin and a method for preparing antiseptic rusty paint, relating to synthesis of epoxy resin and a method for preparing paint. The invention solves the problems of the traditional aqueous epoxy resin antiseptic paint that storing stability of base material resin and water resistance and corrosion resistance of an aqueous epoxy resin antiseptic paint coating film can not be met simultaneously. the synthesis method of modified aqueous epoxy resin comprises the steps of: mixing Span 60 with Tween 20, adding E-51; heating and stirring, and dropwise adding distilled water till the system viscosity is suddenly reduced; and finally dropwise adding an initiating agent and a monomer to carry out heating reaction. The method for preparing antiseptic rusty paint comprises the steps of: mixing the modified aqueous epoxy resin, a corrosion inhibitor and a rust preventing agent, stirring and grinding; adding a defoaming agent, a curing agent and deionized water; and stirring the mixture to obtain the modified aqueous epoxy resin antiseptic rusty paint. The invention simultaneously meets the storing stability of the base material resin of the aqueous epoxy resin antiseptic paint and the water resistance and the corrosion resistance of the aqueous epoxy resin antiseptic paint coating film.

Owner:HARBIN INST OF TECH

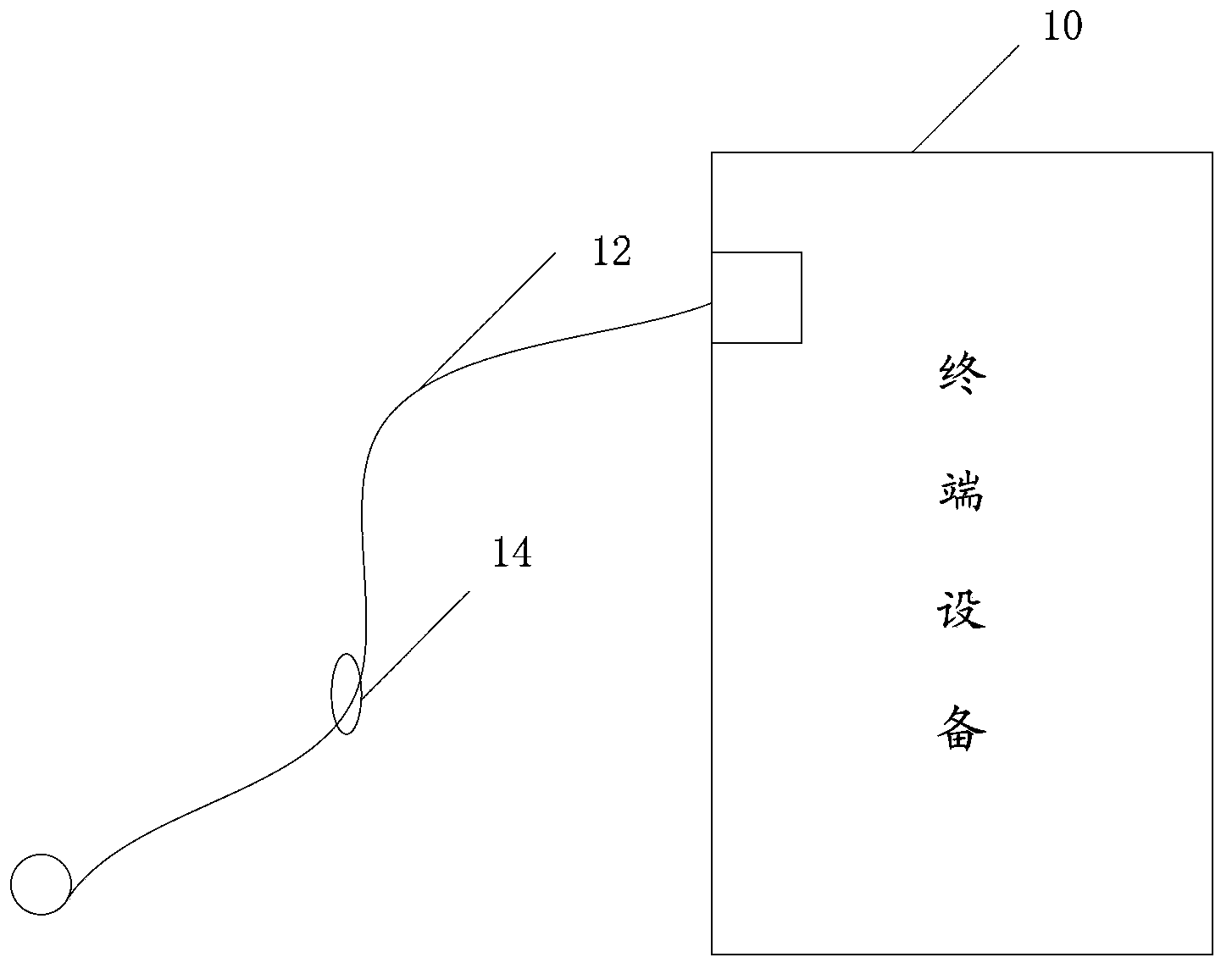

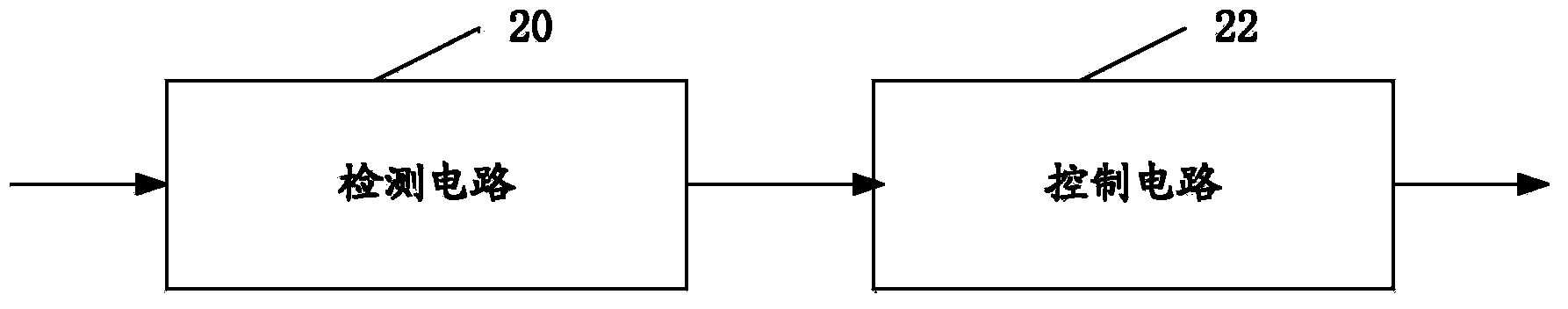

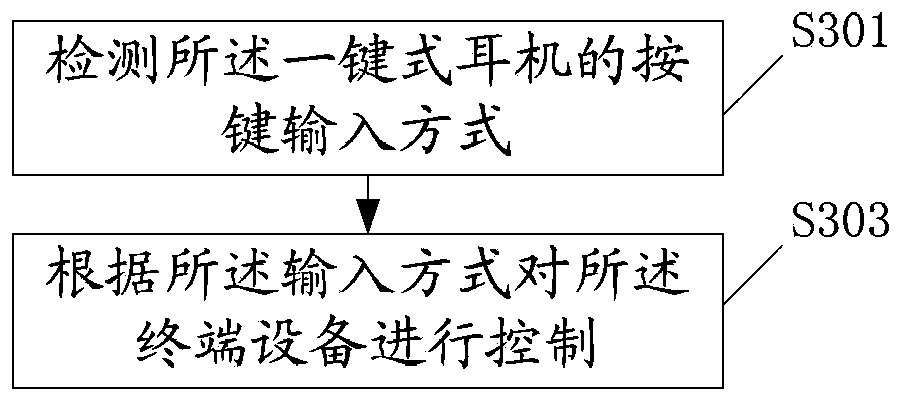

Terminal device and control method thereof

InactiveCN103685708AFulfill usage requirementsImprove experienceSubstation equipmentTerminal equipmentComputer terminal

The invention provides a terminal device and a control method thereof. The terminal device is controlled through a common one-button earphone. The terminal device includes: a detection circuit used for detecting the input method of a button; and a control circuit which is connected with the detection circuit and used for receiving the input method transmitted by the detection circuit and controlling the terminal device according to the input method. The control method includes: detecting the button input method of the one-button earphone; and controlling the terminal device according to the input method. Through adoption of the technical scheme, the terminal device can be controlled through the common one-button earphone so that cost is not increased and at the same time, control of commonly used functions can be realized conveniently and rapidly.

Owner:LENOVO MOBILE COMM TECH

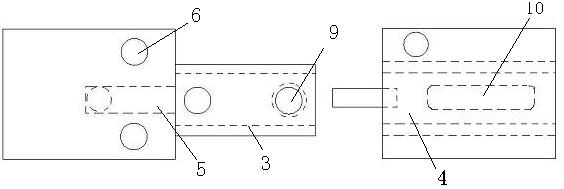

Steel bushing inlay casting method for motor casing front and rear end covers and front and rear end covers

The invention discloses a steel bushing inlay casting method for motor casing front and rear end covers. The method comprises the steps that 1 a steel sleeve is manufactured; 2 the steel sleeve is heated through high-frequency plasma; 3 the steel sleeve is placed into a lower mold of a low-pressure casting apparatus and positioned, molten aluminum is injected into a mold from bottom to top, and the steel sleeve is covered with molten aluminum; and 4 a separation line is formed between the steel sleeve and an end cover. The invention further discloses the motor casing front and rear end covers. Compared with front and rear end covers of a permanent magnet servo motor of an existing new energy automobile, the motor casing front and rear end covers are cast with aluminum alloy under low pressure and are formed at one time, and the motor casing front and rear end covers have smooth appearance and clear arcs; because the steel sleeve is inlaid in a bearing, the problem that a bearing deforms due to heat is solved, the hardness of a bearing position is increased, and weight is reduced by 40% compared with an integrally machined steel part or a ball iron part; and a machine base is made of the same aluminum alloy as the end covers, the aluminum alloy has a better heat dissipation effect than steel parts, the motor has an attractive appearance, and labor cost is reduced by 20%.

Owner:HUIZHOU WEISHENG IND

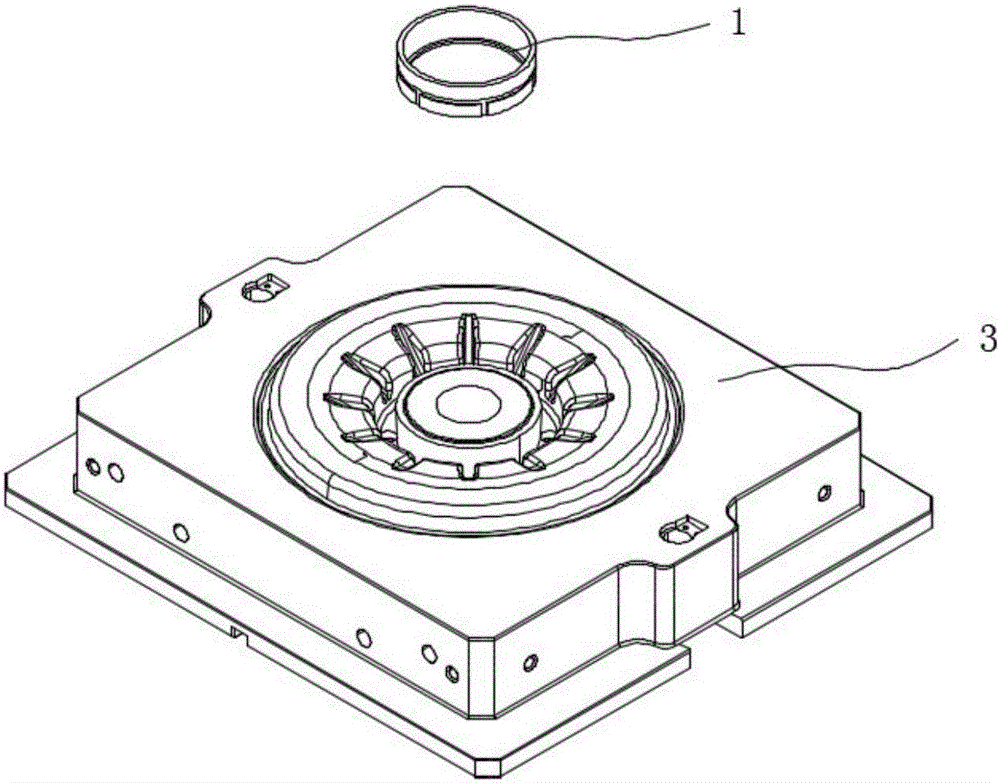

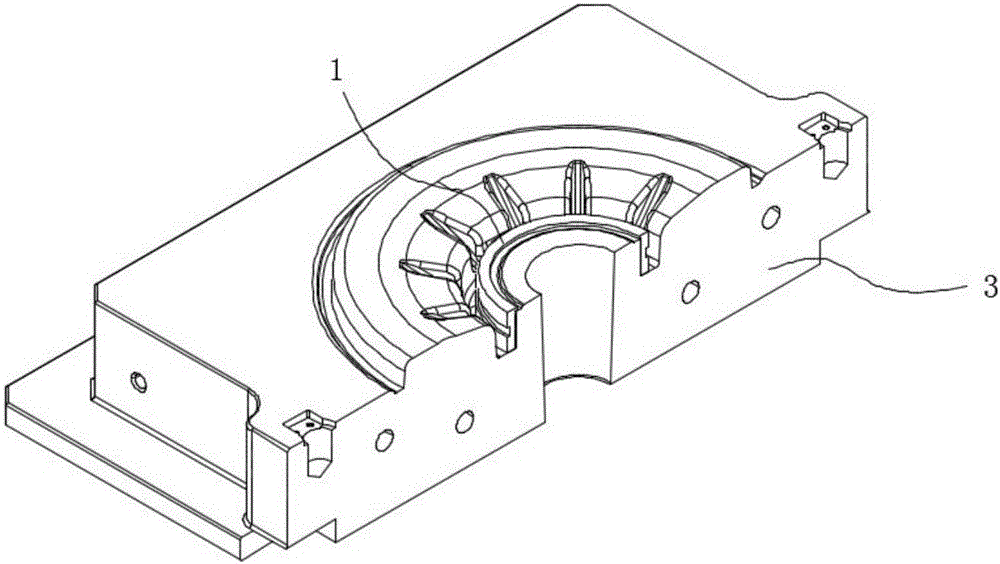

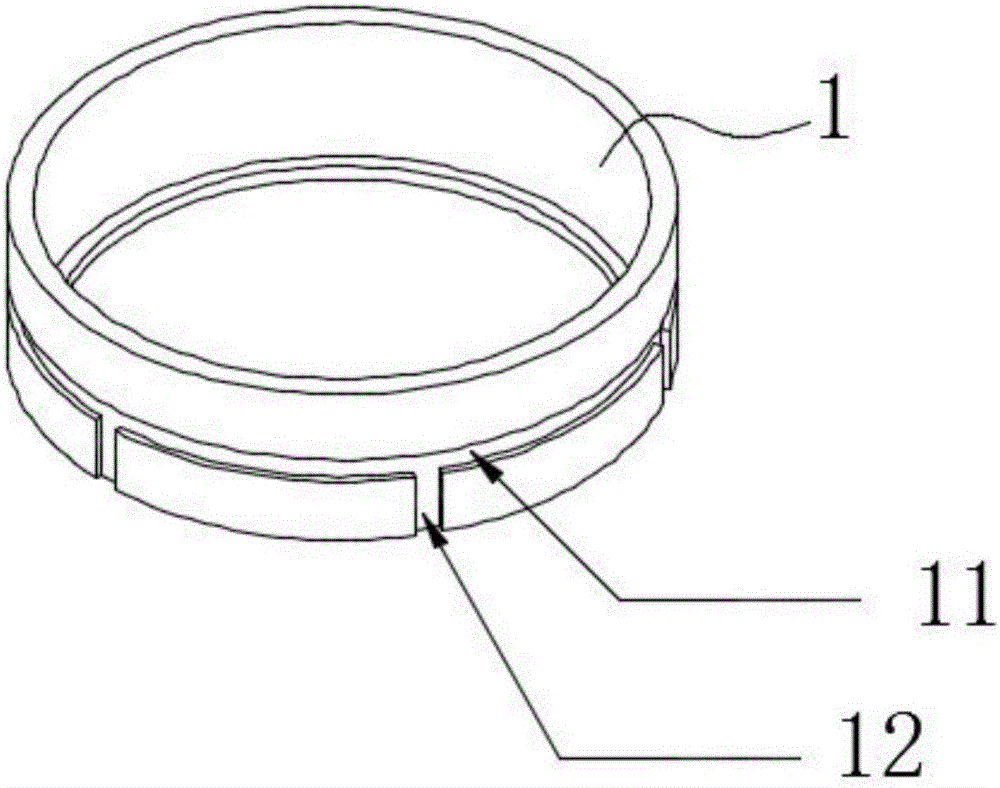

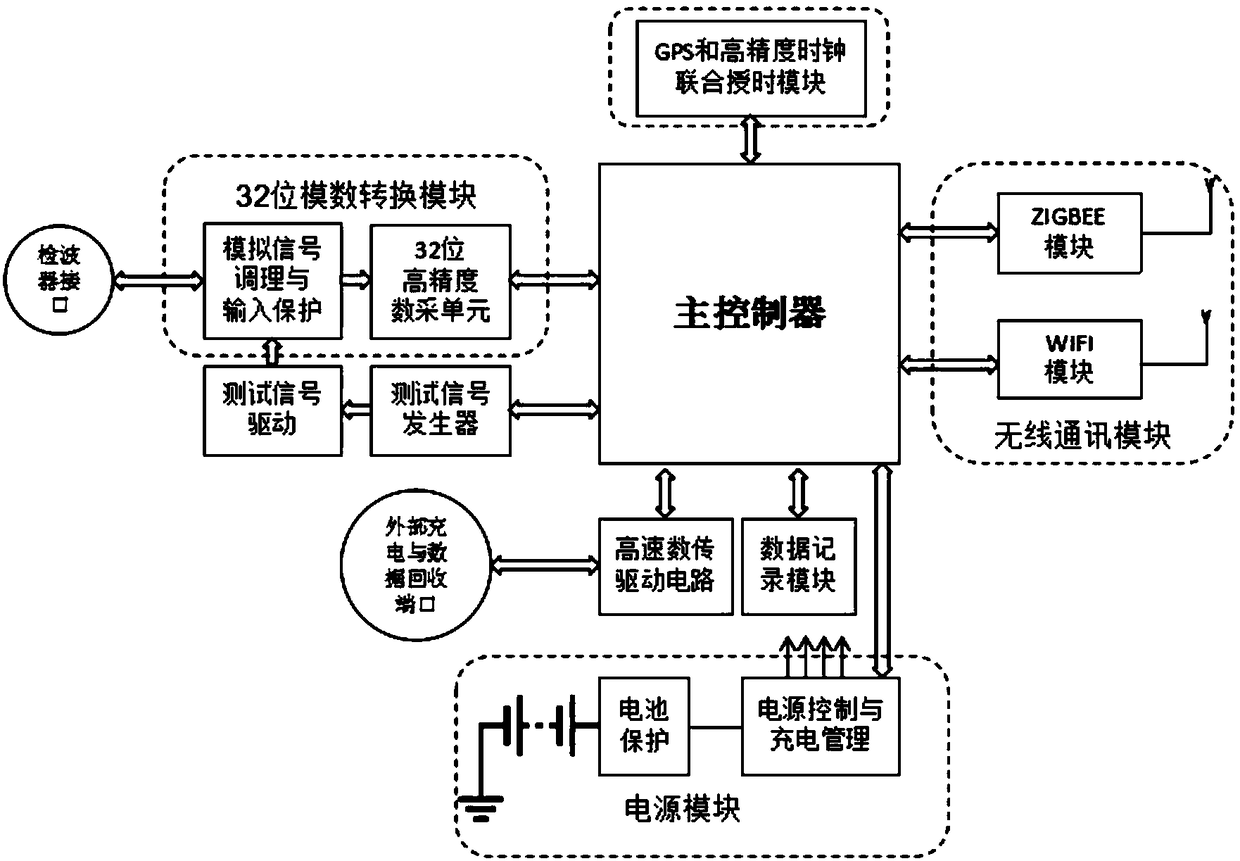

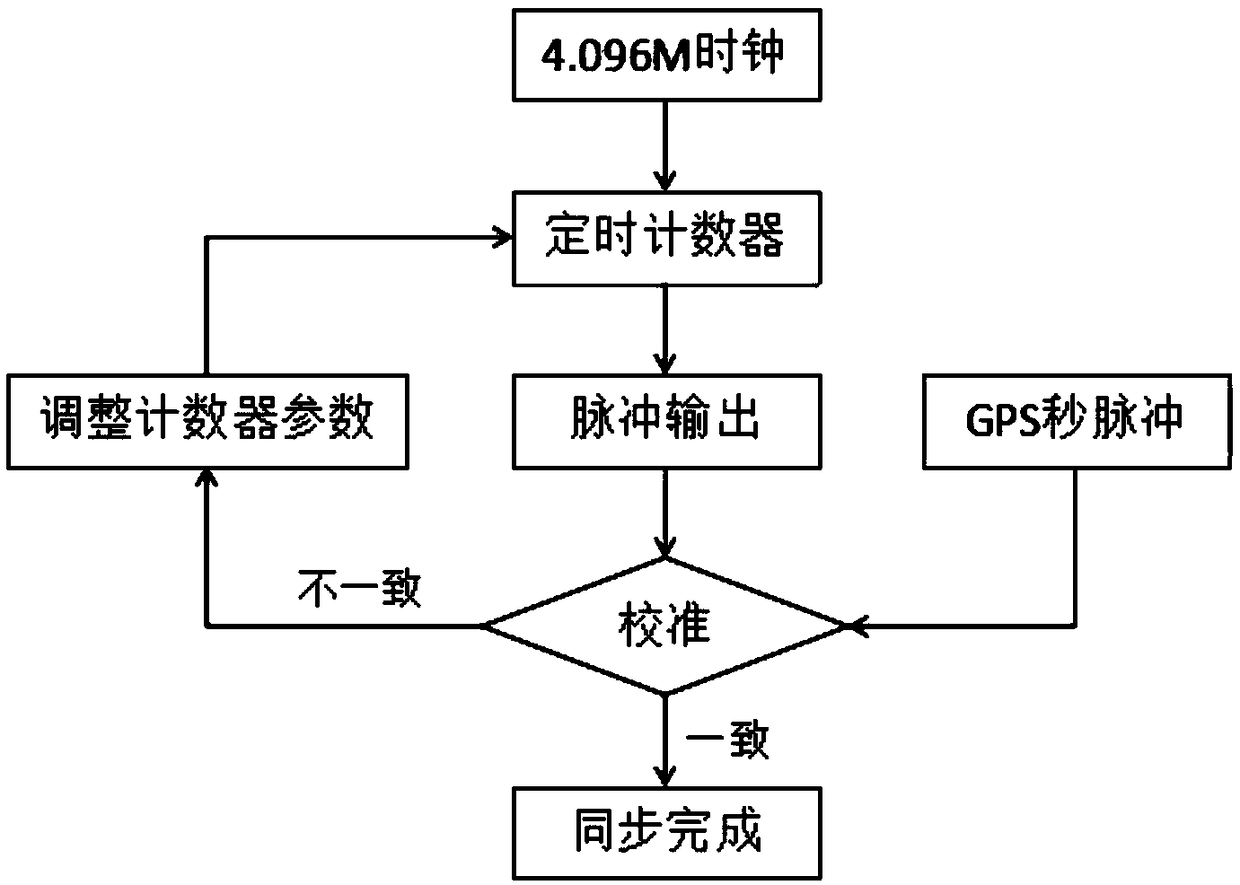

Seismic exploration wireless automatic collection system

PendingCN108761525AReasonable designReduce weightSeismic signal receiversCollection systemSoftware system

The present invention discloses a seismic exploration wireless automatic collection system. The system comprises a field collection node, a relay, a handheld data recovery test terminal, a centralizeddata recovery charge cabinet and a seismic data fusion processing software system. The field collection node is internally provided with a high-sensitive detector movement, the field collection nodeis electrically connected with a detector interface, the detector interface is electrically connected with the detector, the centralized data recovery charge cabinet is electrically connected with thefield collection node through an external charge and data recovery port, the field collection node is in wireless connection with the relay, and the relay is in wireless connection with the handhelddata recovery test terminal. The seismic exploration wireless automatic collection system is reasonable in design, light in weight, low in cost, high in precision, large in dynamic range, stable and reliable in seismic signal collection and digitization and convenient and rapid in installation arrangement, can achieve seamless collection in real meaning and can meet the usage requirement.

Owner:CHINA PETROCHEMICAL CORP +3

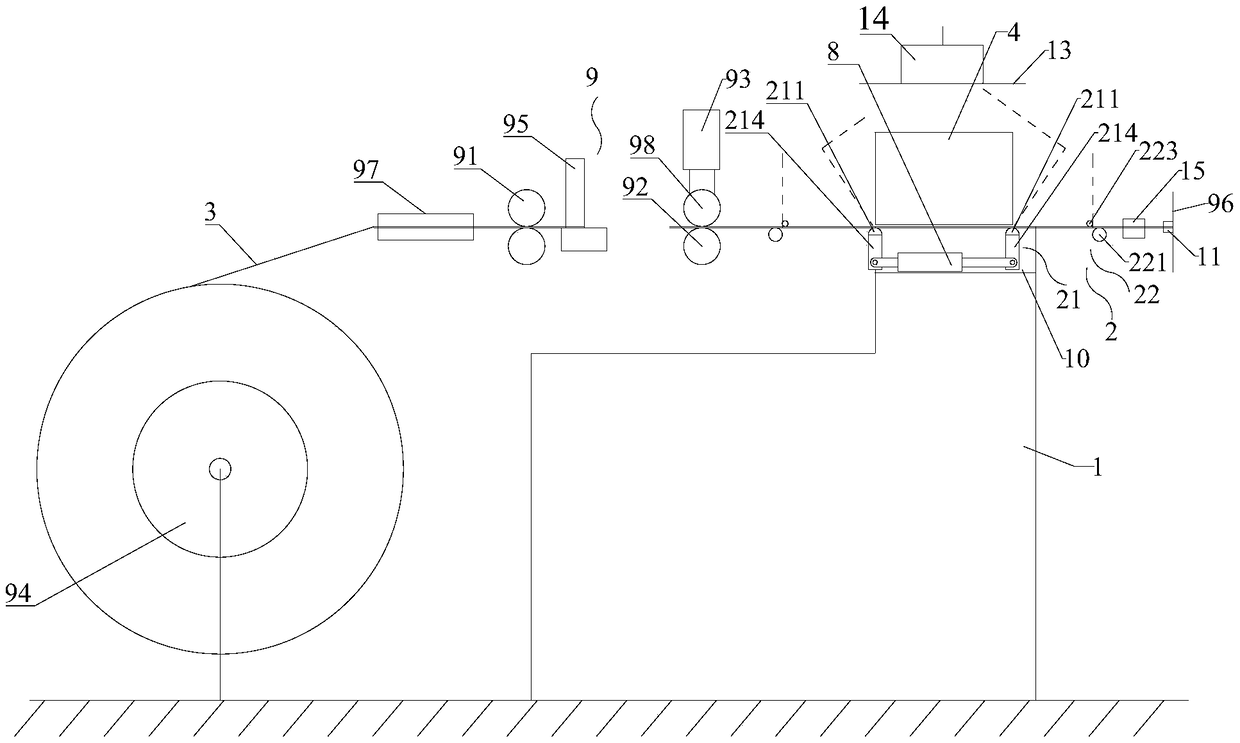

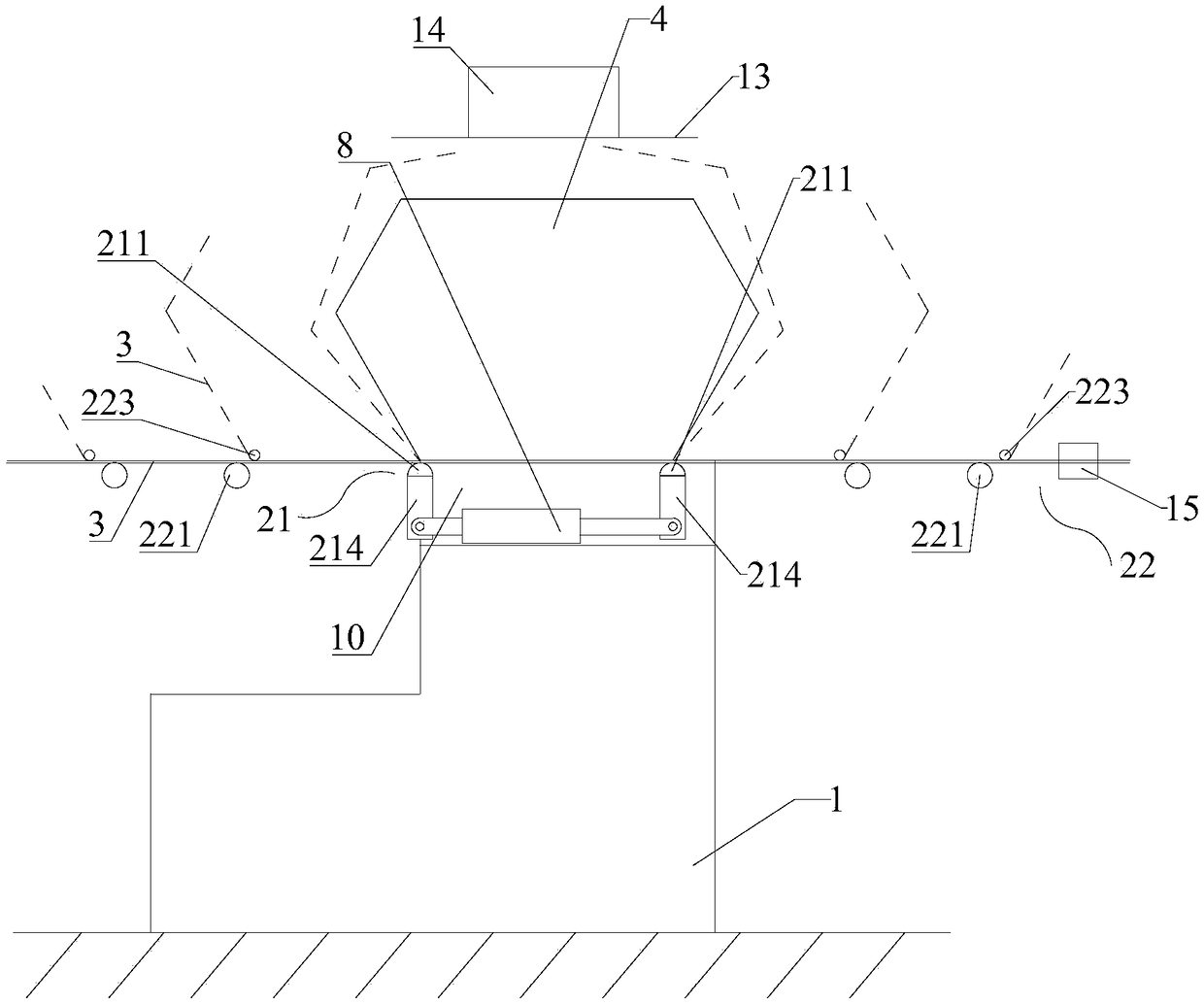

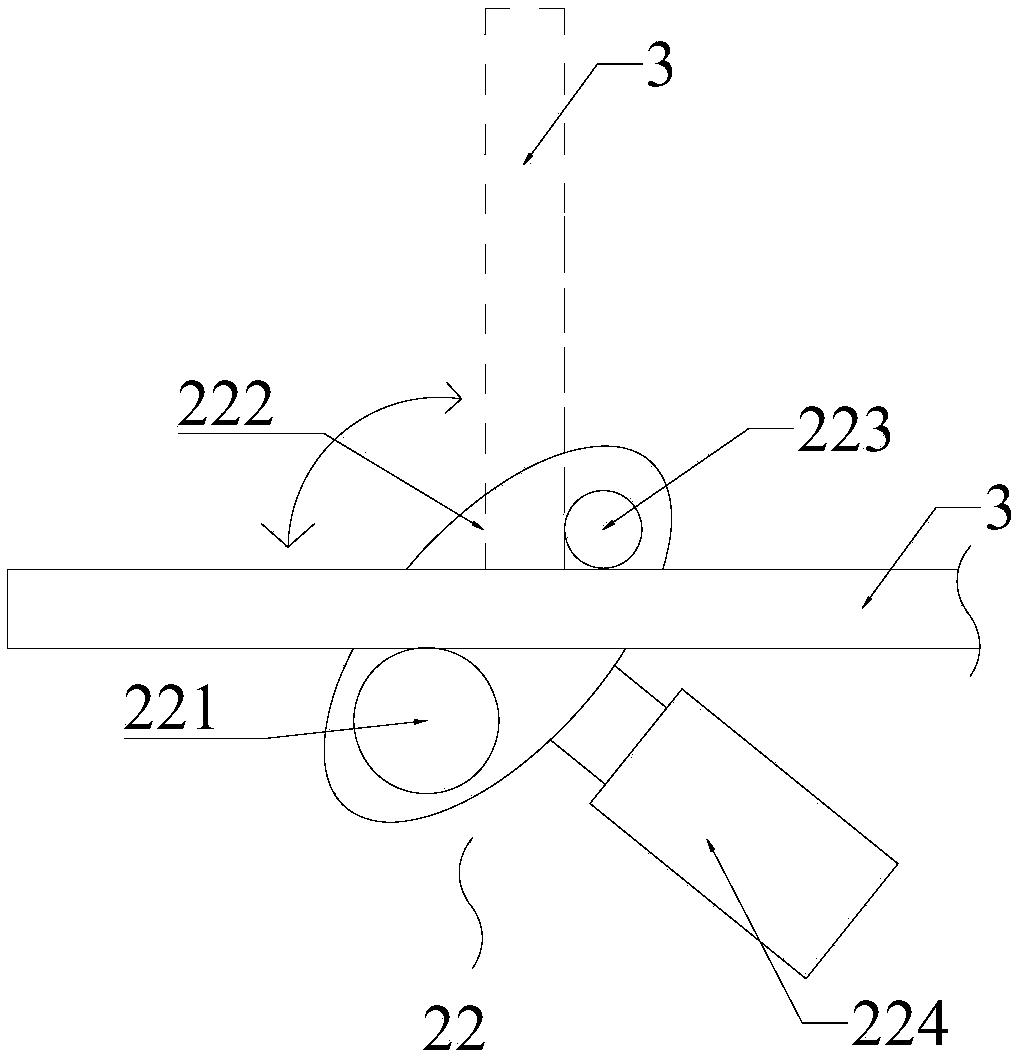

Automatic steel belt automatic bundle strapping machine

The invention provides an automatic steel belt automatic bundle strapping machine, and belongs to the field of steel bundling. The machine comprises an objective table used for placing objects to be bundled, and further comprises forming mechanisms, the two forming mechanisms are symmetrically arranged on the two sides of the objective table, each forming mechanism comprises a first bending deviceand at least one second bending device, the first bending device is arranged between the objective table and the second bending device, the first bending device for pressing and covering a packagingbelt on the objects to be bundled is arranged on the outer side of the objective table, at least one second bending device is arranged on the outer side of the first bending device, the second bendingdevice and the first bending device are distributed along a first path, the second bending device is used for bending the side of the packaging belt according to the stacking shape of the objects tobe bundled, and the first bending device and the second bending device are close to or away from the objective table along the first path. The automatic steel belt automatic bundle strapping machine solves the problem that in the prior art, a thick steel belt bundle strapping machine only can carry out bundling according to the single stacking-shaped objects to be bundled.

Owner:石家庄市梓起机电设备科技有限公司

Variable-pitch locking dog of mechanical digital lock

InactiveCN102182346ASimple structureWide range of placesPuzzle locksPermutation locksPitch controlCanis lupus familiaris

The invention relates to a mechanism digital lock. A variable-pitch locking dog of a mechanical digital lock consists of a main locking dog and an auxiliary locking dog, wherein the main locking dog is a lock clamping end, the main locking dog and the auxiliary locking dog are connected in a sliding way by a sliding rail and a track slot, the lock clamping end is provided with a return spring hole parallel to the sliding rail, two side surfaces of the return spring hole are provided with lock clamping plate driving pins, the auxiliary locking dog is provided with a spring stabilizing penetrating pin corresponding to the return spring hole of the main locking dog, a spring is arranged on the spring stabilizing penetrating pin and is assembled with the return spring hole, and the main locking dog and the auxiliary locking dog are provided with relative travel limiting devices. The variable-pitch locking dog has a simple structure, and adopts a two-body structure; the main locking dog and the auxiliary locking dog are sheathed together coaxially in a sliding way, and can slide relatively to realize a variable-pitch integral structure; and variable-pitch control on the main locking dog and the auxiliary locking dog can be conducted freely by a handle indoors and outdoors, therefore, the mechanical digital lock can be freely controlled to be opened and closed from the inner side and the outer side, and can be used on a door body such as an antitheft door and the like.

Owner:大连鼎信机电技术有限公司

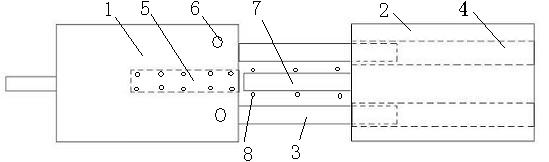

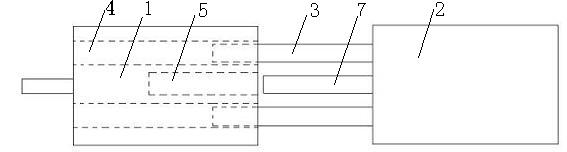

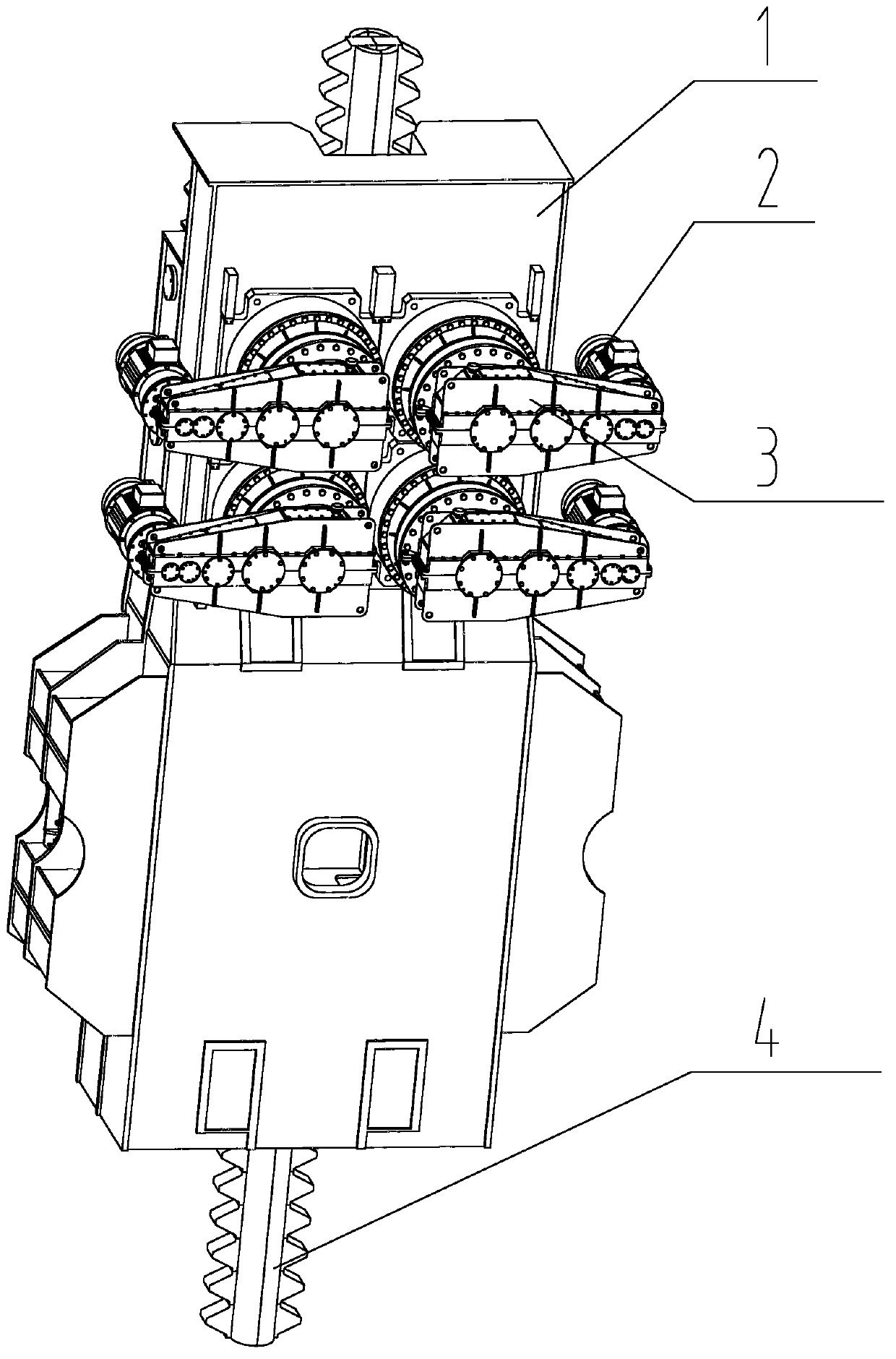

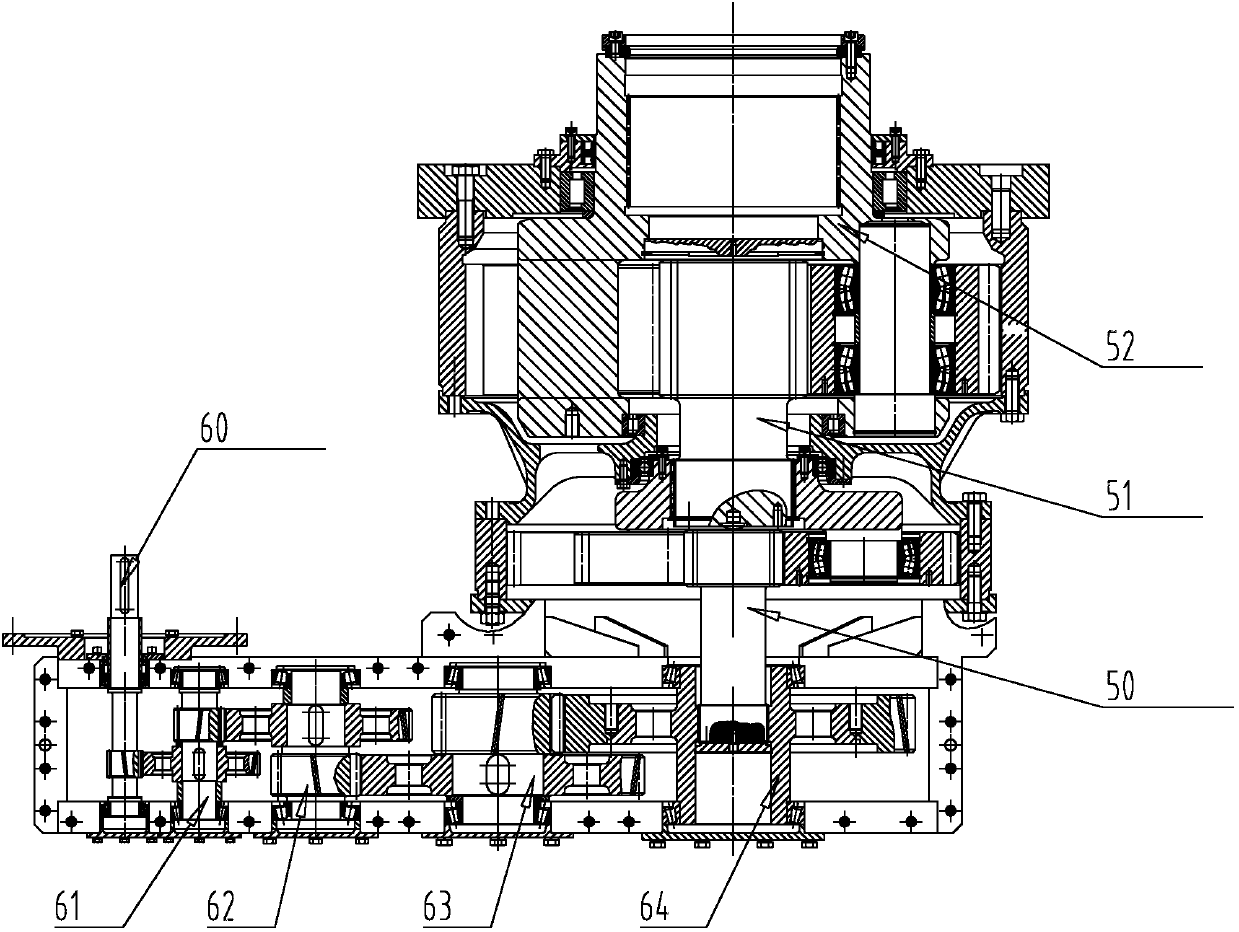

Speed reducer structure of lifting type platform lifting system

InactiveCN103343800AReasonable structureCompact structureArtificial islandsToothed gearingsGear wheelElectric machinery

The invention discloses a speed reducer structure of a lifting type platform lifting system. The speed reducer structure of the lifting type platform lifting system comprises a pile box and a speed reducer. The speed reducer comprises a helical gear speed reducer body and a planet gear speed reducer body. The input shaft of the helical gear speed reducer body is connected with a motor, the output shaft of the helical gear speed reducer body is connected with the planet gear speed reducer body, and a whole formed by the motor, the helical gear speed reducer body and the planet gear speed reducer body is arranged on the side face of the pile box in a U-shaped mode. The speed reducer is reasonable and compact in structure, light in weight, stable in operation, and capable of effectively utilizing space of the pile box, reducing the weight of a platform, and meeting the using requirement of the lifting system.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

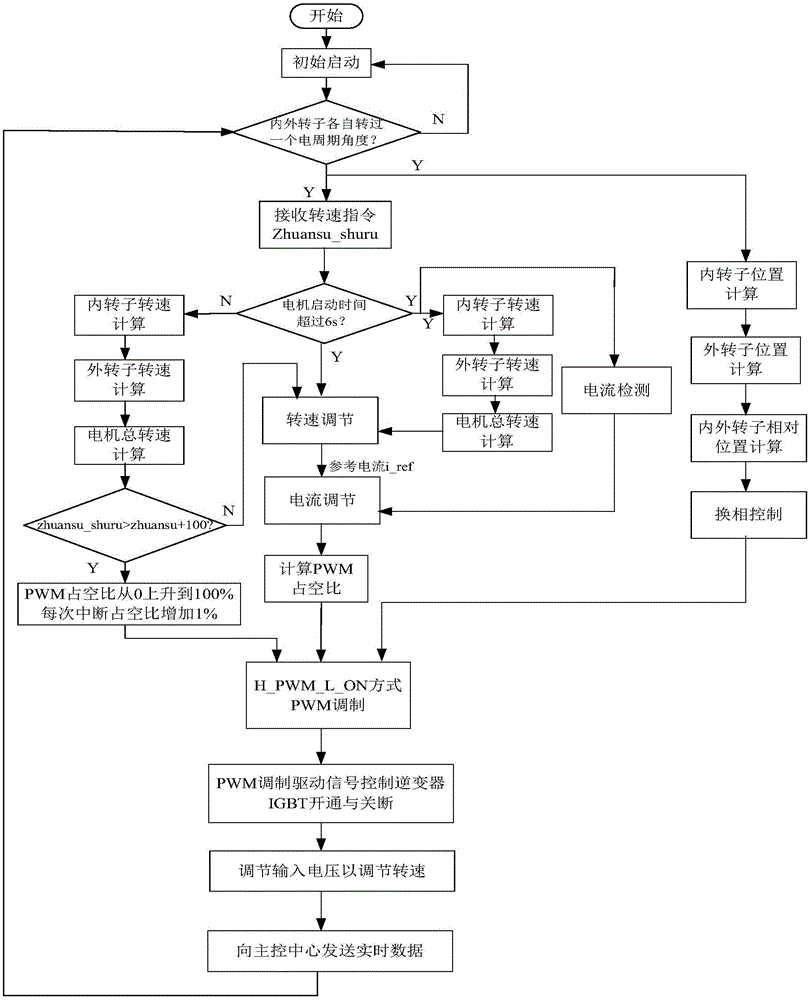

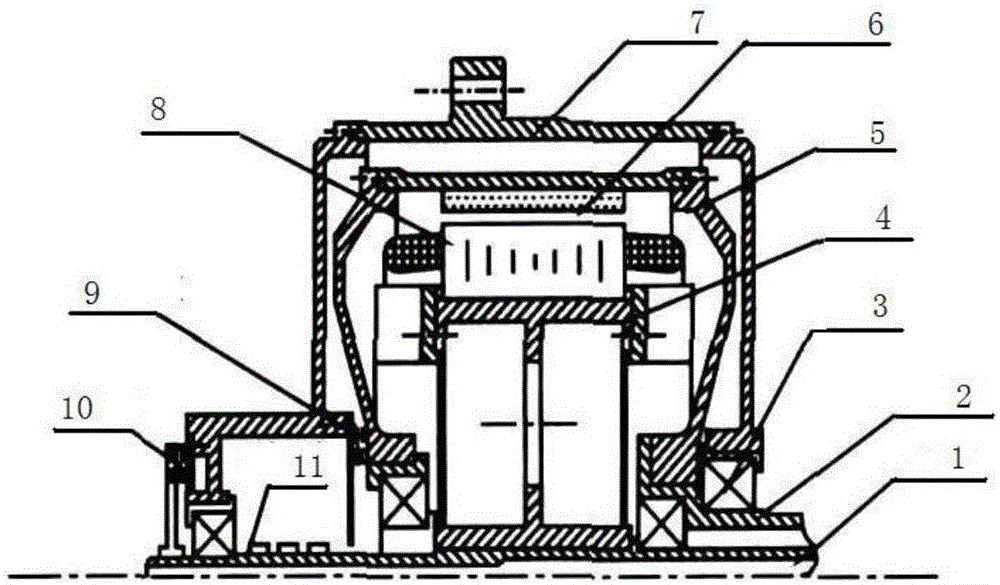

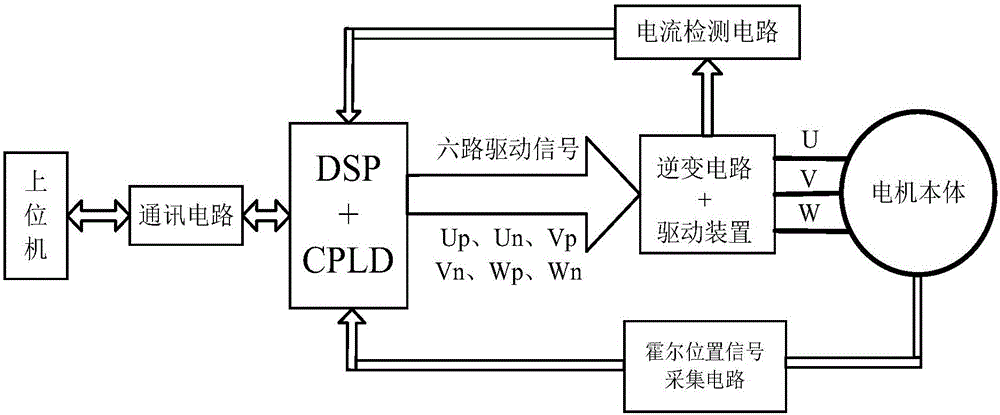

Method for adjusting speed of high-power biaxial contra-rotating brushless direct-current motor for underwater vehicles

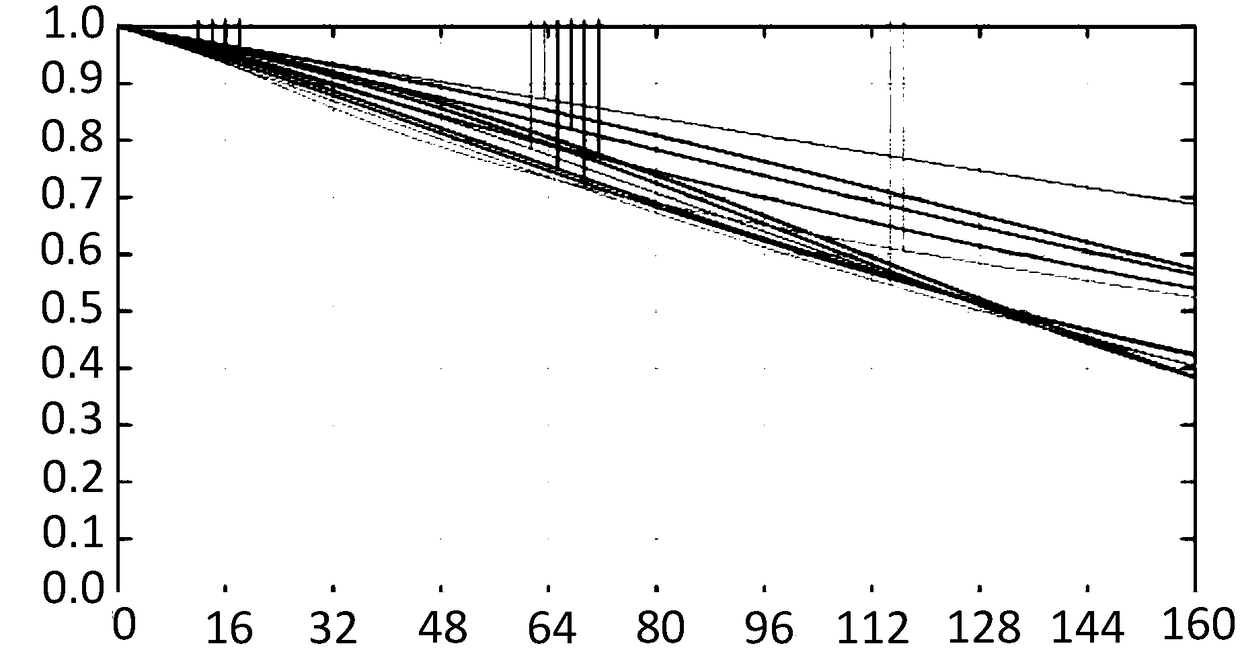

ActiveCN105007010AFulfill usage requirementsMeet the use requirementsSingle motor speed/torque controlElectronic commutatorsCurrent meterElectricity

The invention relates to a method for adjusting the speed of a high-power biaxial contra-rotating brushless direct-current motor for underwater vehicles. After inner and outer rotors rotate an angle of one power cycle, if the starting time of a motor is within 6s, the PWM duty cycle is raised by 1% for each interruption through system cycle interruption; if the difference between the total speed of the motor and the speed set by a main control center of an underwater vehicle is within 100 r / min, the speed is adjusted, or the PWM duty cycle is raised from 0 to 100% in 6s; when the starting time of the motor is beyond 6s, reference current is generated through speed adjustment, motor current detected by a system is received and adjusted, and the PWM duty cycle is calculated; and after inner and outer rotor position detection and phase commutation control, six driving signals and PWM waves meeting the duty cycle requirement of the process are output to perform PWM modulation. The method of the invention has the advantages of wide speed adjustment range, good speed adjustment performance, fast response, high stability, and the like. Test shows that the method satisfies the actual use requirement of underwater vehicles.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

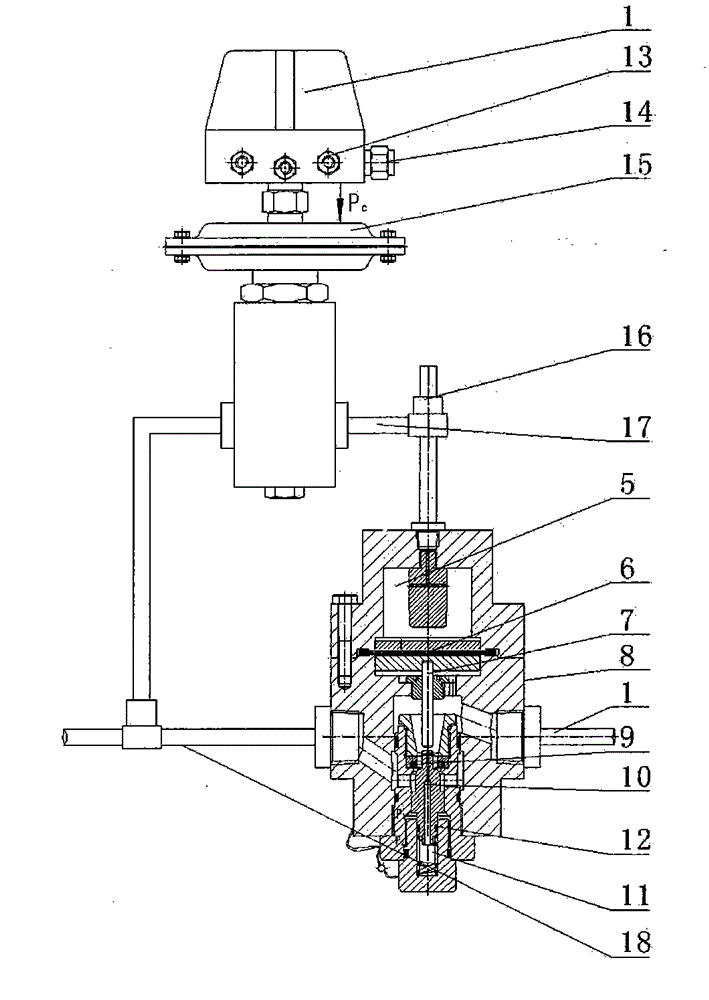

Electronic control pilot-operated type high-precision large-flow regulating valve

InactiveCN105889589AIncrease outlet pressureRealize long-distance precise controlEqualizing valvesSafety valvesClosed loop feedbackThe Internet

The invention discloses an electronic control pilot-operated type high-precision large-flow regulating valve. The electronic control pilot-operated type high-precision large-flow regulating valve comprises a first connection pipe which is connected with a high-voltage large-flow valve. The high-voltage large-flow valve comprises a shell, wherein the first connection pipe is connected with one side of the shell, a valve seat is arranged on the lower portion inside the shell, and a valve rod is installed in the valve seat. An electronic pressure controller can select and regulate a fixed point signal source, wherein the current of an external analog signal ranges from 4 mA to 20 mA or the voltage of the external analog signal ranges from 1 VDC to 5 VDC, and feedback and error signals are limited in a programmable mode. The electronic control pilot-operated type high-precision large-flow regulating valve provides closed-loop feedback control for a system, has the supernormal accuracy and response time, and can be connected with a computer to conduct internet control.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

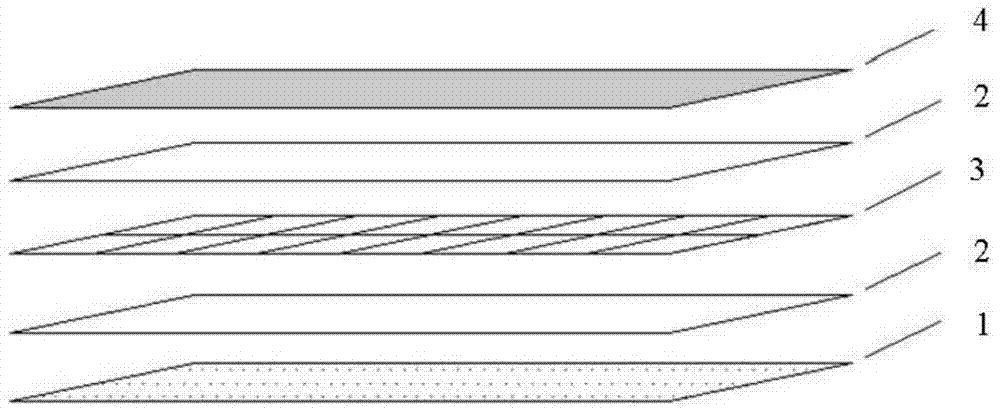

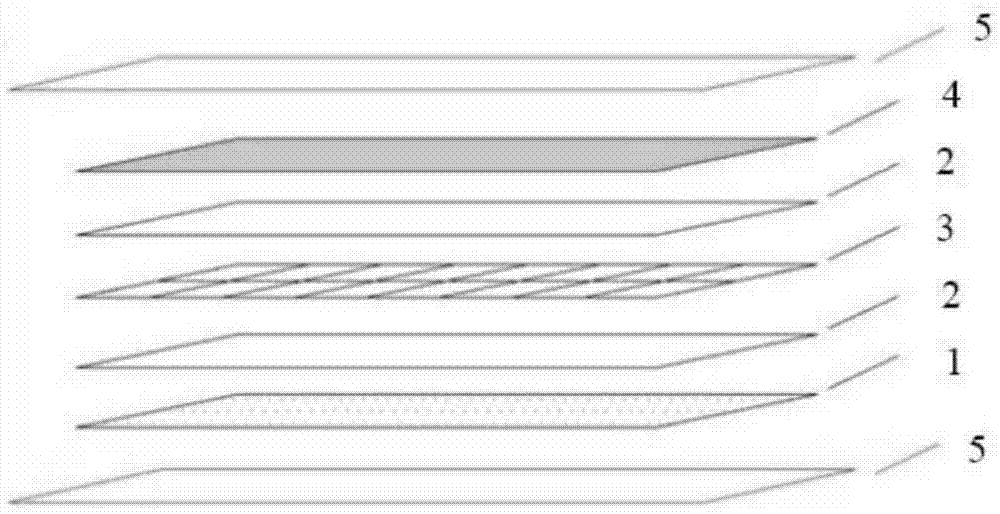

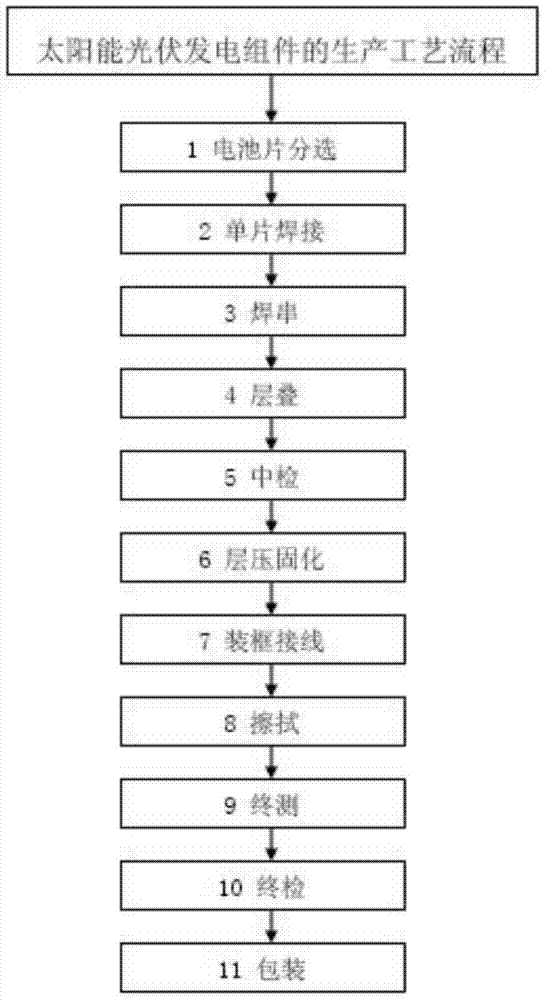

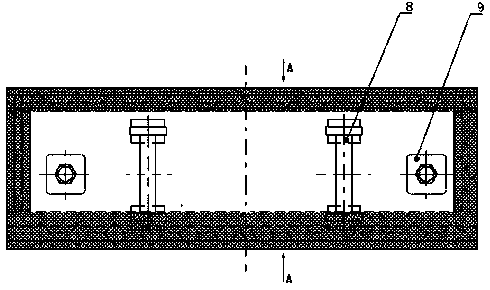

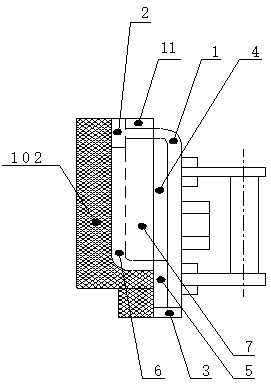

Light solar photovoltaic power generation component and stacking method in production technology thereof

InactiveCN103887356AHigh mechanical strengthReduce weightFinal product manufacturePhotovoltaic energy generationString groupEngineering

Disclosed are a light solar photovoltaic power generation component and a stacking method in the production technology of the component. A component body sequentially comprises tempered glass layers, a thermoplastic resin layer (EVA), a solar cell string group piece, a thermoplastic resin layer (EVA) and a back plate layer from bottom to top, preferably, reinforcing ribs are bonded on the back face of the component body, screw holes are formed in the component body, and the photovoltaic component is in threaded connection with a bearing carrier. The stacking method in the production technology comprises the steps that the upper face and the lower face of the component body are respectively and additionally provided with the tempered glass layer with the thickness of 4 mm, the two short edges of the component body are respectively and manually held, the component body rotates by 180 degrees and is exchanged up and down, the two tempered glass layers with the thickness of 4 mm are removed, and the next working procedure is executed. According to the method, the problems that in the production process, the component in the stacking step is not easy to move, and the tempered glass is easily smashed are solved, and therefore the light solar photovoltaic power generation component which has the qualified quality and is light and high in power generation efficiency is obtained.

Owner:JIANGSU ST SOLAR

Tightness detection method for 90 degree fillet weld at CM node of LNG ship

InactiveCN109297644AFulfill usage requirementsImprove shipbuilding efficiencyDetection of fluid at leakage pointFillet weldEngineering

The invention relates to a tightness detection method for a 90 degree fillet weld at a CM node of a LNG ship, which carries out a tightness detection through the special detection device. A vacuum device structure comprises a panel, sealing plates, surrounding plates, rubber sponges and joints. The method comprises the steps of: during the tightness inspection, spraying soap liquid to a 45 degreefillet weld at the CM node after the vacuum device is prepared, covering the fillet weld with the vacuum device, finely adjusting through position of the vacuum device, and compressing the rubber sponges to form sealing space; adjusting a ventilation valve, and when the pressure gauge reaches a specified pressure value, detecting whether bubbles bubble up on the fillet weld through, and achievingtightness detection of the fillet weld; closing the ventilation valve after detection is completed; if a defect on the fillet weld is detected, repeating the three steps after repairing; if the filletweld is intact, the detection is complete. The method and the vacuum device of the invention can overcome a difficulty that conventional vacuum cover cannot detect, and improves construction efficiency of the LNG ship cargo tank.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

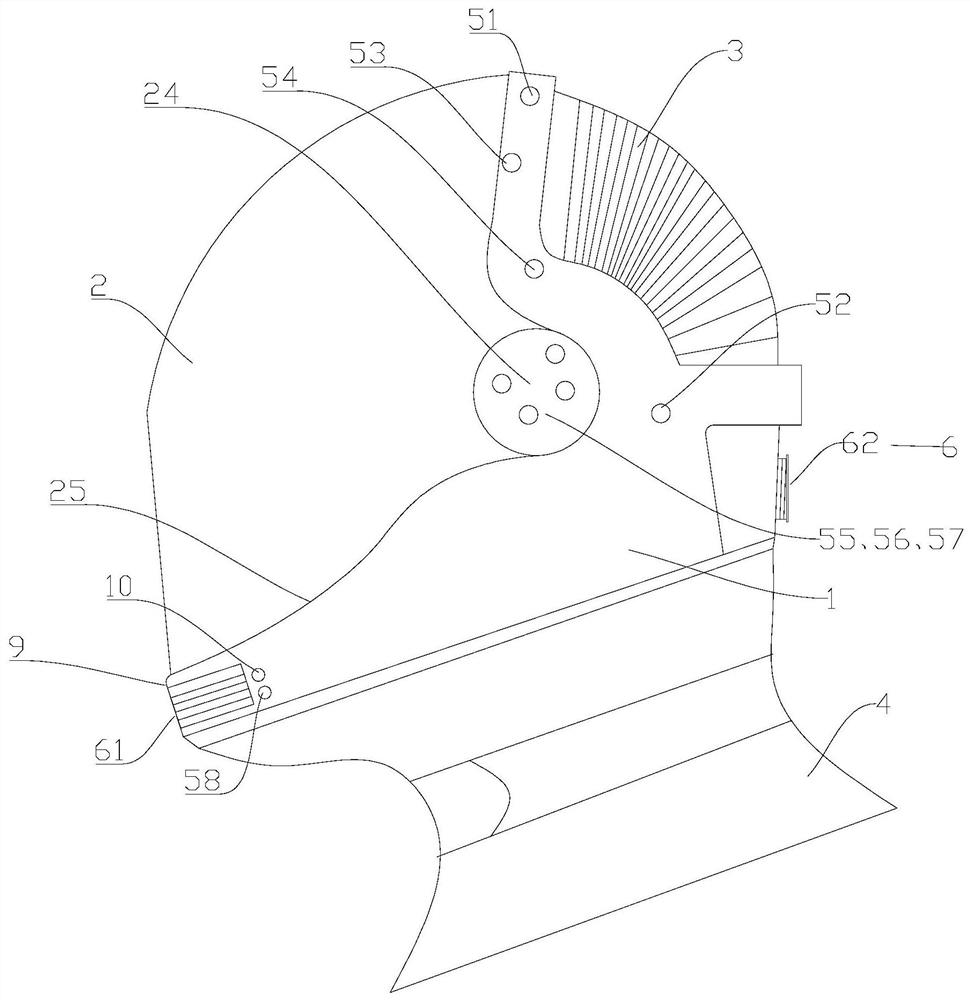

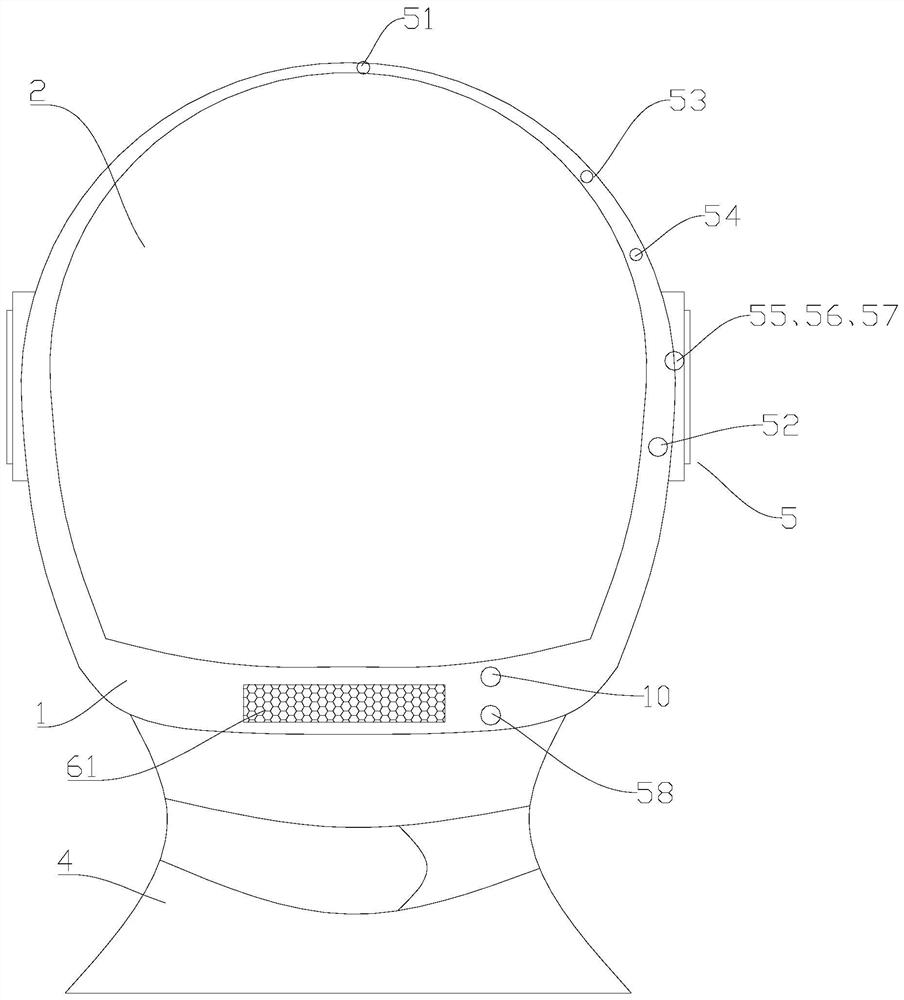

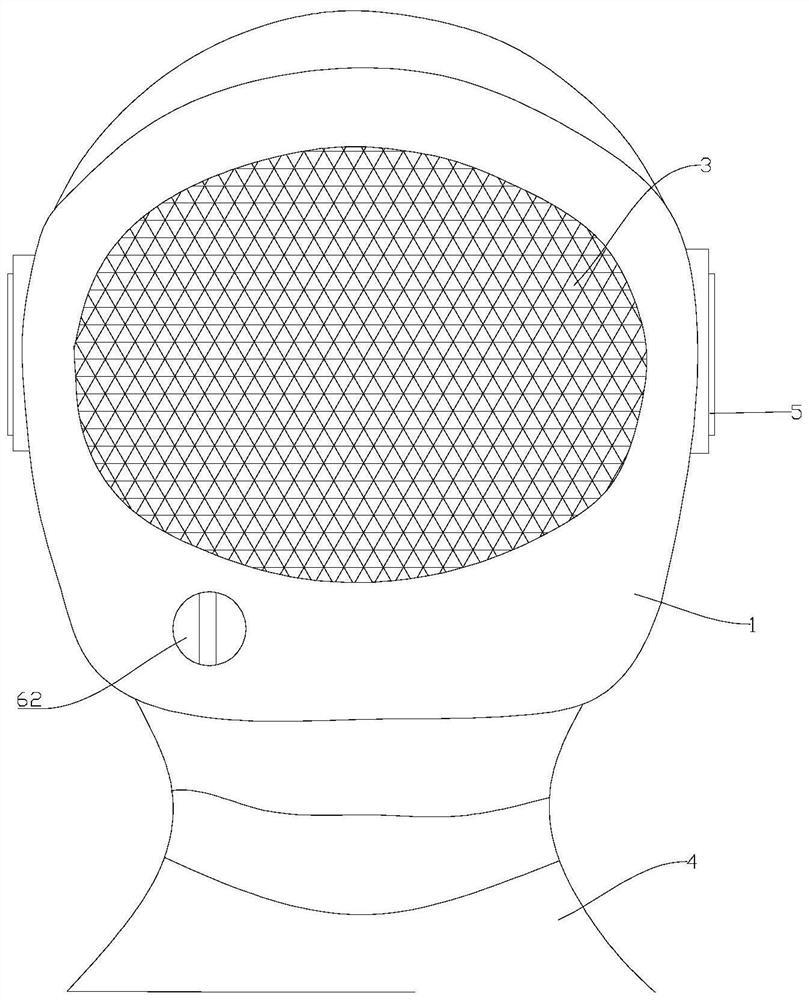

Novel anti-virus intelligent helmet

PendingCN111713795AStop transmissionMeet collectionHelmetsHelmet coversPhysical medicine and rehabilitationAir filter

The invention provides a novel anti-virus intelligent helmet, relates to the technical field of sanitation and health, and solves the technical problems of poor air permeability, poor leakproofness and poor comfort of an anti-virus medical mask. The helmet comprises a full-helmet type helmet body, a transparent mask, an air filtering assembly, a neck sealing assembly, an intelligent electronic assembly and a reserved external interface, the transparent mask is arranged on the front side of the helmet body in an openable manner; the air filtering assembly is arranged on the rear side of the helmet body; the neck sealing assembly is arranged at the lower part of the helmet body; the intelligent electronic assembly is arranged on the helmet body; the reserved external interface is arranged onthe front side and / or the rear side of the helmet body; after the helmet body is worn, the top and / or the side portion of the inner cavity of the helmet body are / is provided with a channel for air circulation so that air in the helmet can flow front and back. Spreading of air droplets of viruses can be effectively blocked, the same protection effect of the medical mask is achieved, a wearer cannot breathe difficultly, and the medical mask is comfortable to wear.

Owner:北京英华高科技环保有限公司

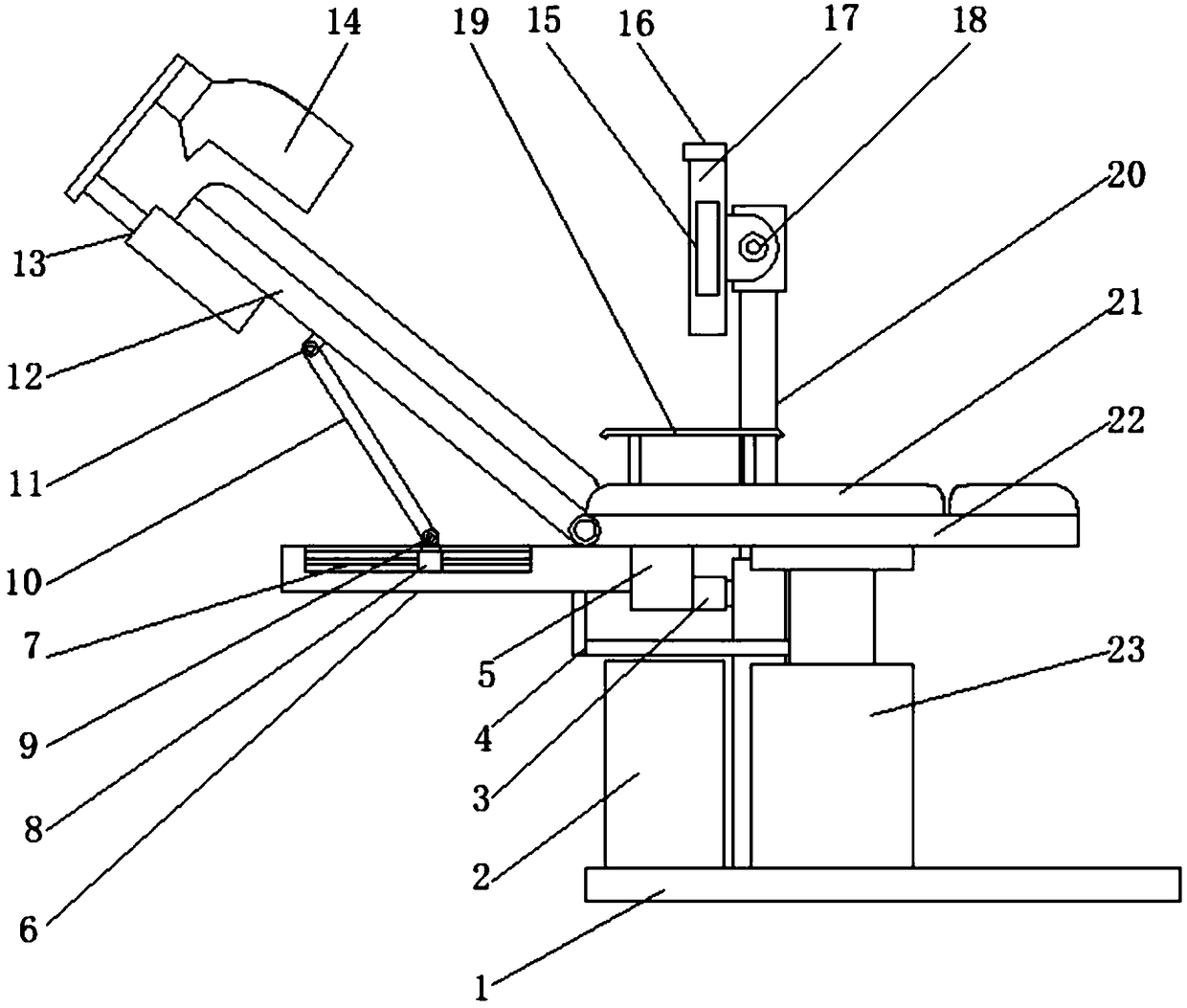

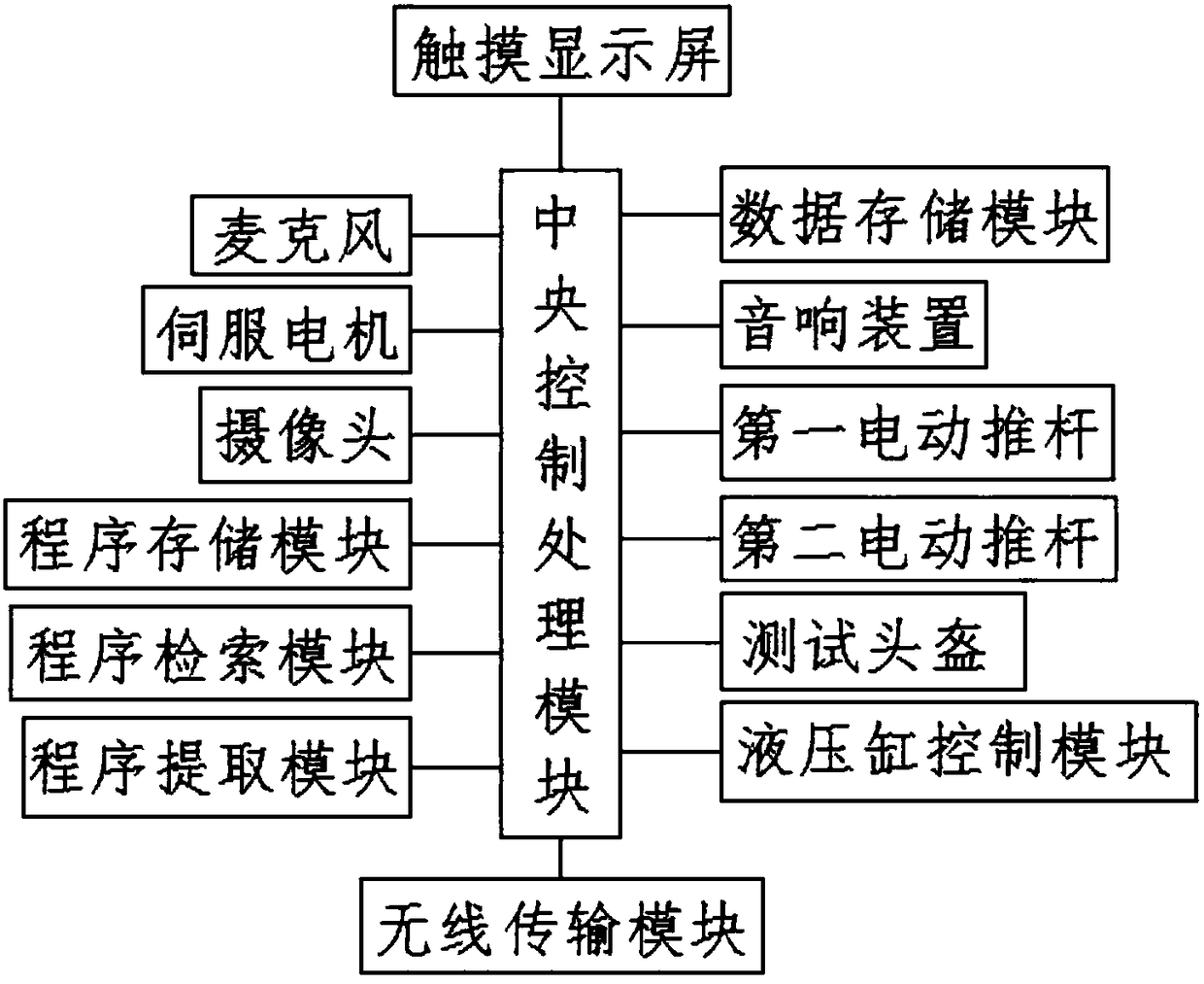

Tester for psychology department

InactiveCN108553113AEasy accessFulfill usage requirementsSensorsPsychotechnic devicesHydraulic cylinderTester device

The invention discloses a tester for the psychology department. The tester comprises a base, a lifting hydraulic cylinder device is arranged on the base, a seat is mounted at the movable end of the upper end of the lifting hydraulic cylinder device, a back plate is hinged to the rear end of the seat, a sliding base is mounted below the back plate, and a threaded rod is mounted in the sliding base;a first hinge frame is mounted at the upper end of a threaded sliding block and hinged to one end of a hinge supporting rod, and a second hinge frame is hinged to the other end of the supporting rodand fixedly connected to the back face of the back plate; a first electric push rod is mounted on the back face of the left end of the back plate, the upper end of the first electric push rod is connected with a test helmet, a second electric push rod is mounted on one side of the base, the upper end of the second electric push rod is connected with a turntable device, the turntable device is provided with a touch display screen, and a control box is installed on the base. The tester is stable in structure and operation and convenient to use, adjust and control, convenience is provided for a patient to stay in a test state, the test effect is good, and different test functions can be achieved.

Owner:王立钢

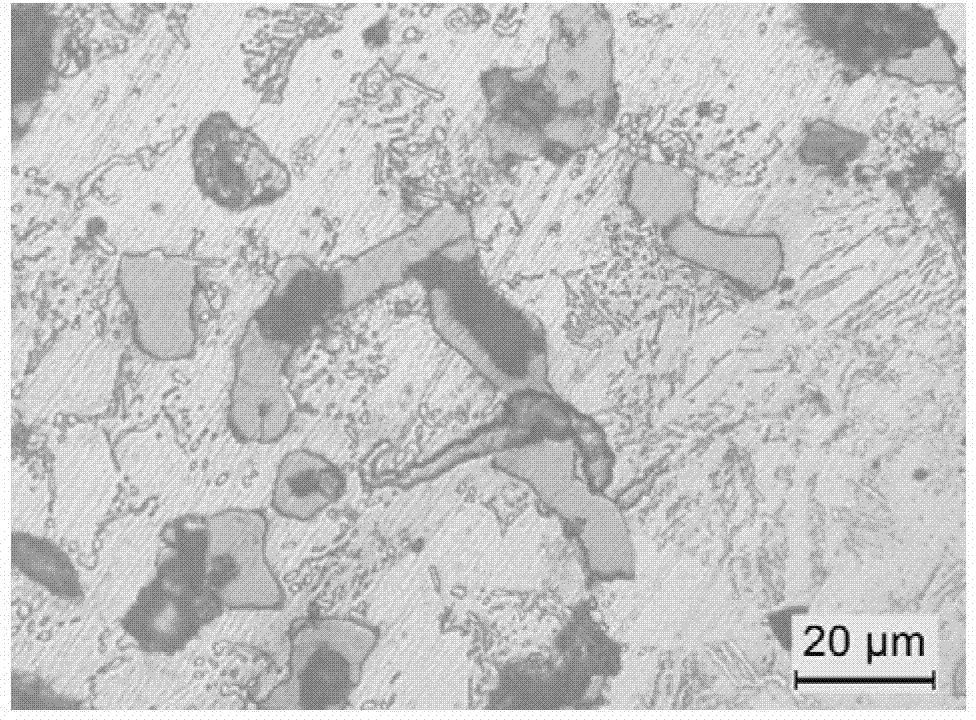

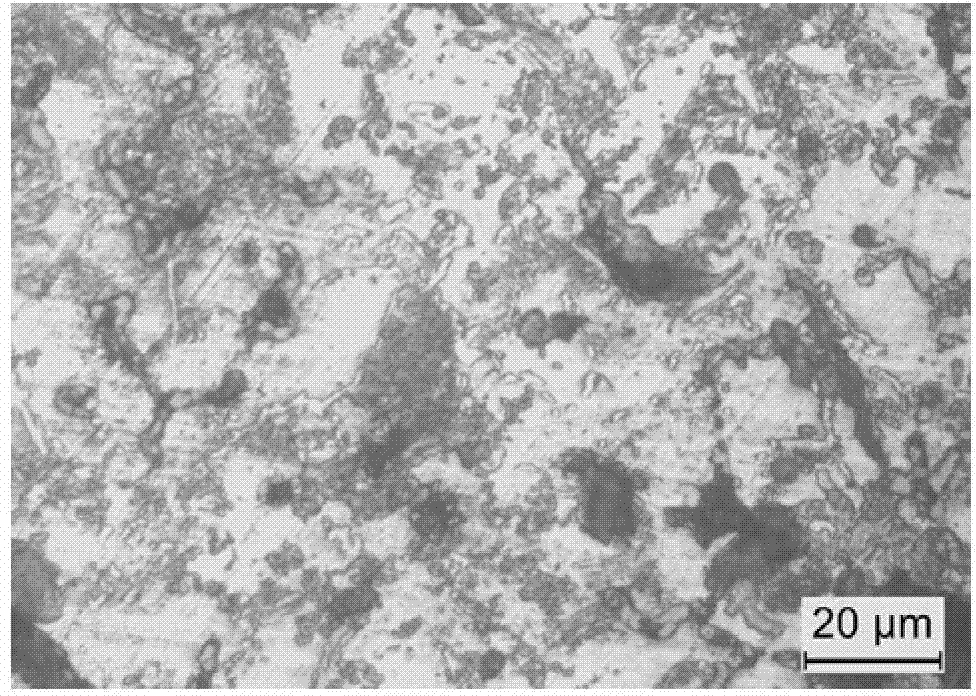

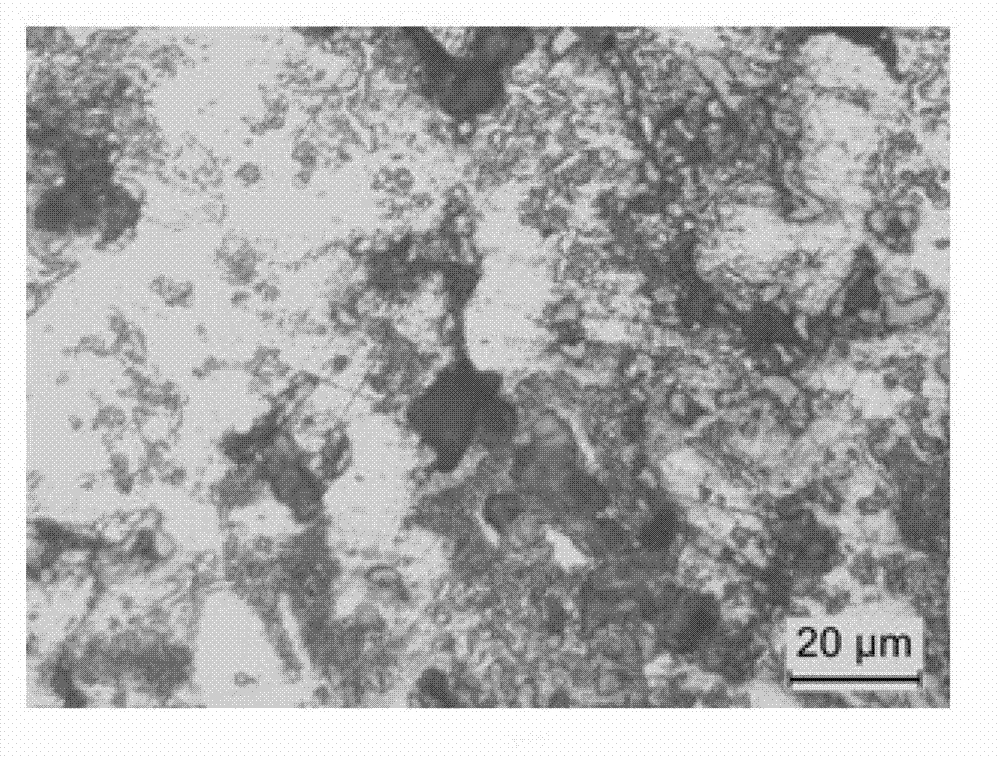

Powder metallurgy iron-based material suitable for high speed boring and preparation method

ActiveCN102925807AReduce wearExcellent high-speed cutting performanceTurning toolsPowder metallurgyManganese sulfide

The invention discloses a powder metallurgy iron-based material suitable for high speed boring and a preparation method. The powder metallurgy iron-based material comprises the following raw materials in percentage by weight: 1-2% of copper, 1-2% of manganese sulfide, 0.5-1% of molybdenum disulfide, 0.3% of calcium fluoride, 0.3% of magnesium fluoride, 0.6-0.8% of graphite, and the balance of iron, wherein the iron, the copper and the graphite are added in the form of elemental powder, while the manganese sulfide, the molybdenum disulfide, the calcium fluoride and the magnesium fluoride are added in the form of compounds. The preparation method comprises the following three steps of mixing, molding and sintering heat treatment. According to the invention, the preparation method is simple and feasible, the prepared powder metallurgy iron-based material has good high-speed fine machining properties and mechanical properties and can meet requirements of an existing high-speed boring machine tool on the machining surface quality and the use of a cutter, and the use requirements of related household appliances on sliding bearing part products. Due to the application of the invention, the purpose of replacing grinding with boring can be realized, the production cost can be reduced significantly, and the machining surface quality can be improved. The invention is suitable for industrial popularization and application.

Owner:湖南屹林材料技术有限公司

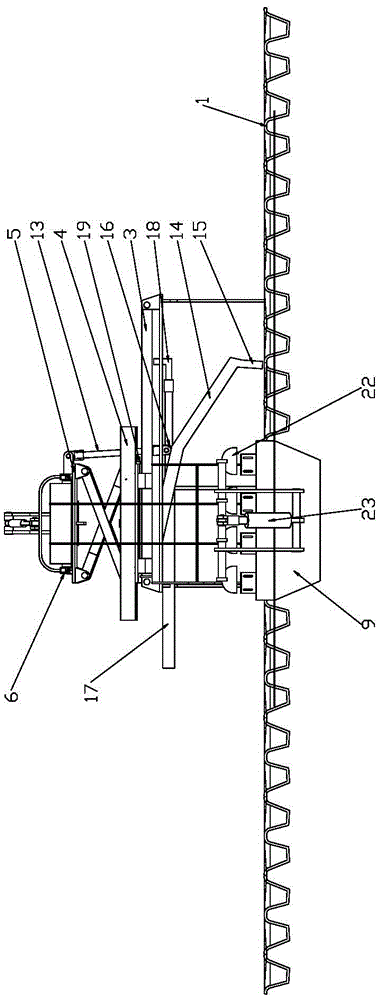

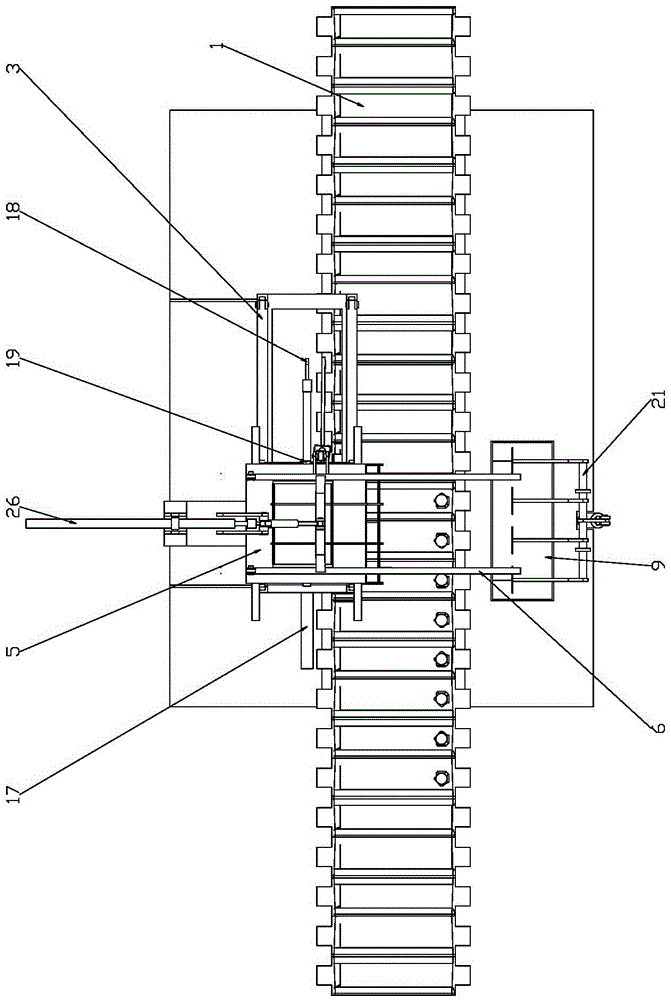

Slag removing mechanism of electrolytic aluminum liquid slag removing machine

ActiveCN105728706AFulfill usage requirementsRealize slag removalCasting cleaning apparatusReciprocating motionLiquid slag

The invention discloses a slag removing mechanism of an electrolytic aluminum liquid slag removing machine. The slag removing mechanism comprises a mounting rack arranged on one side of a cast mold chain, wherein a guide rail parallel to the moving direction of the cast mold chain is arranged on the mounting rack; a sliding plate is arranged on the guide rail through sliding matching; a lifting plate is arranged above the sliding plate; a lifting mechanism used for driving the lifting plate to perform rising and falling motions is arranged between the lifting plate and the sliding plate; a synchronous mechanism used for driving the lifting plate to perform synchronous movement with the cast mold chain when the lifting plate is in a low position, and a resetting mechanism used for driving the lifting plate to rest when the lifting plate is in a high position are arranged on the sliding plate; a slide rail vertical to the moving direction of the cast mold chain is arranged on the lifting plate; a slag shoveling device is arranged on the slide rail through sliding matching; the slag shoveling device comprises a slag shoveling plate which stretches into a cast mold of the cast mold chain to perform slag removing operation when the lifting plate is in a low position; and a slag shoveling driving mechanism used for driving the slag shoveling device to perform reciprocating motion along the slide rail is arranged on the lifting plate.

Owner:CHONGQING QINENG ELECTRICITY & ALUMINUM

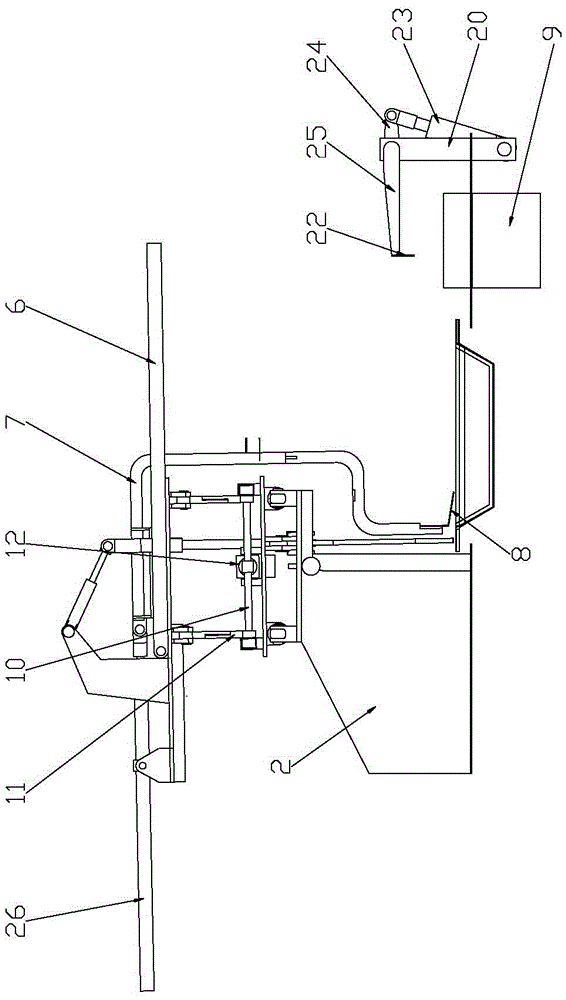

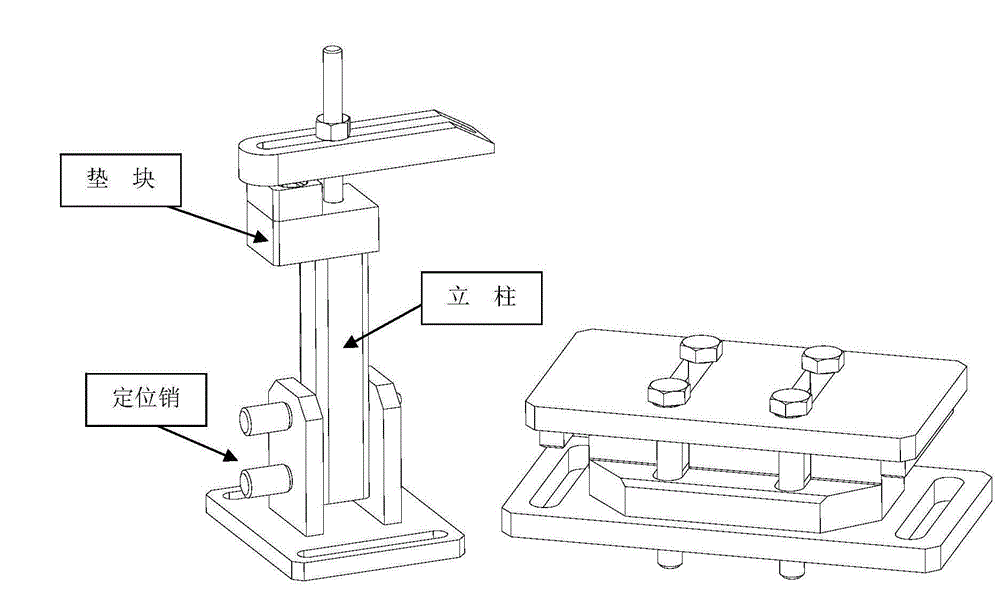

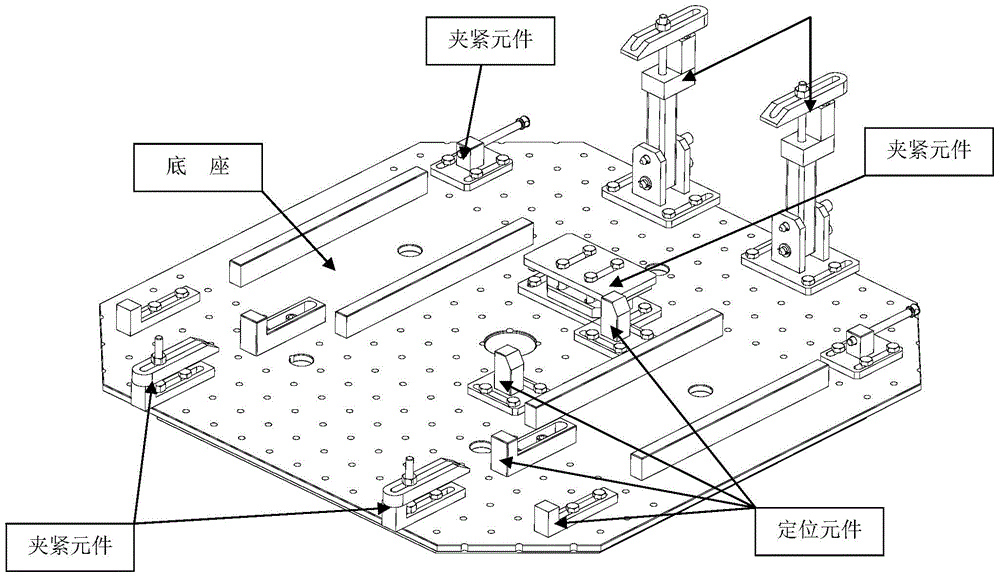

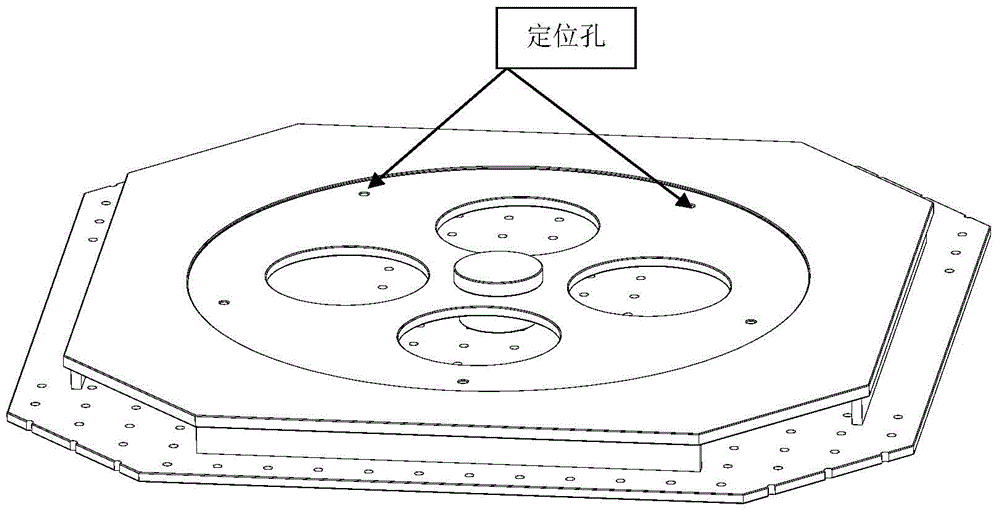

Multifunctional end beam mechanical arm welding clamp

InactiveCN104588944AFulfill usage requirementsWelding/cutting auxillary devicesAuxillary welding devicesManipulatorBiomedical engineering

The invention relates to a multifunctional end beam mechanical arm welding clamp. The multifunctional end beam mechanical arm welding clamp is matched with universalized and standardized clamp fixtures, the clamping fixtures are rapidly replaced according to different use objects, and the rapid positioning effect and the rapid clamping effect on workpieces are achieved. The multifunctional end beam mechanical arm welding clamp is beneficial for improving the clamp use efficiency and meets the use requirements of multiple products. Based on the multifunctional end beam mechanical arm welding clamp, the design thought of the multifunctional end beam mechanical arm welding clamp can be widely applied to the machinery industry, the idea of the multifunctional end beam mechanical arm welding clamp can be widely applied to designing weld part clamps of similar structures, and as the use requirements of multiple products are met by using one clamp, the multifunctional end beam mechanical arm welding clamp has the advantages of being high in adaptability, high in use efficiency, low in composite cost ad the like. The concept of the multifunctional end beam mechanical arm welding clamp is drawn from practical work, a device, a thought and a method are provided, and the multifunctional end beam mechanical arm welding clamp has the advantages of being simple, high in practicability and the like.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

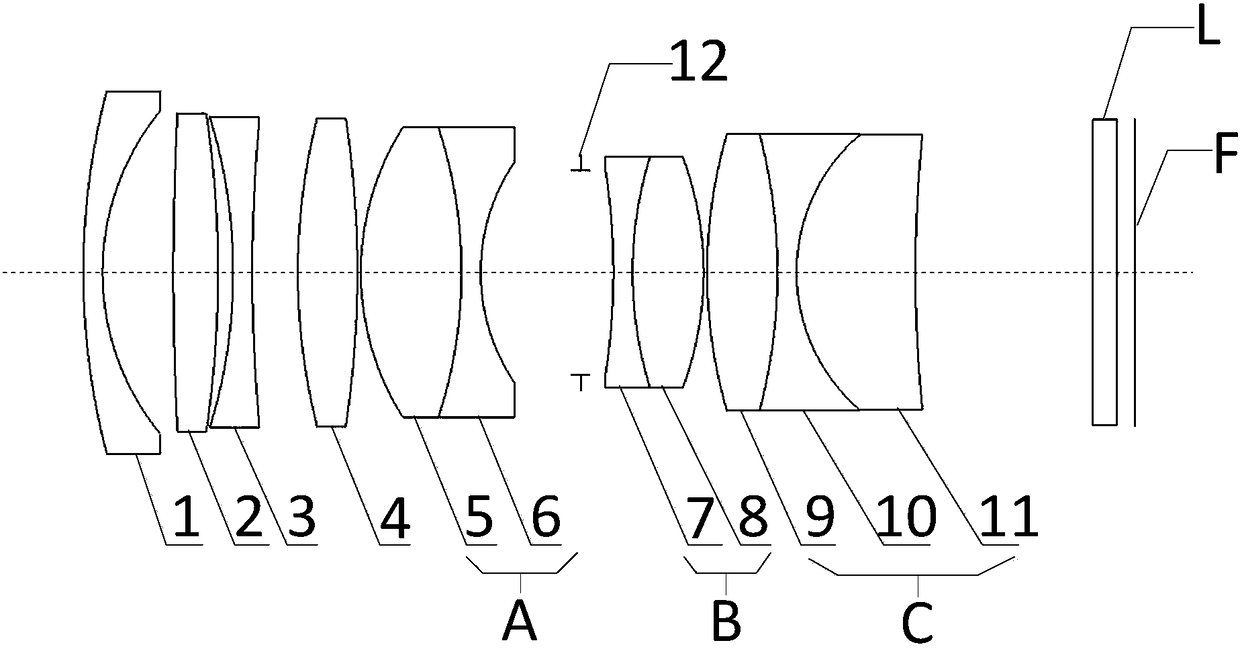

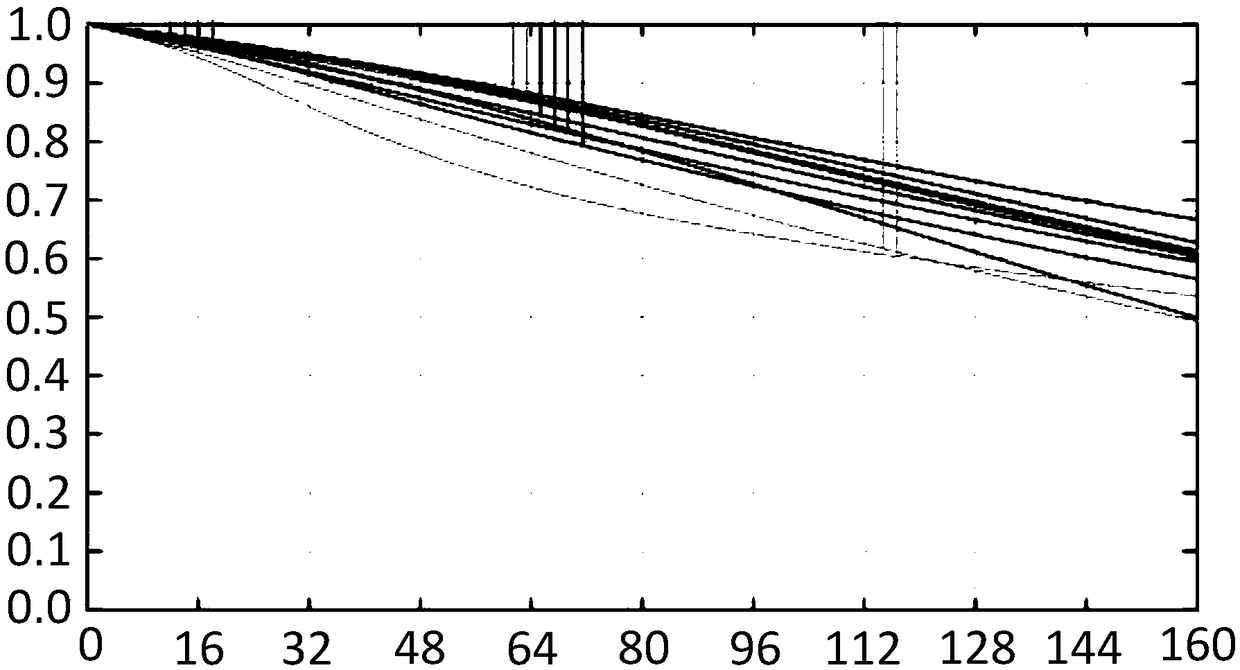

Optical lens

The invention discloses an optical lens. The optical lens is distributed by adopting reasonable focal power and has a specific structure shape; the ten million level pixel grade resolution can be reached under a relatively compact framework. Besides, for the framework is simple, the optical lens of the embodiment has low cost. By adopting the structure shape of the optical lens system provided bythe invention, abbe coefficients and other parameters of an optical glass material are well matched with the imaging condition, thus the spherical aberration, coma, astigmatism, field curvature, chromatic difference of magnification, and chromatism of position of the lens system are well corrected; the uniform imaging of the whole pixel face is guaranteed while the dual-purpose function in daytimeand nighttime is also realized; the optical lens meets the using requirement of a 4K camera and is compact structure and small in outside dimension; besides, all optical lenses adopt spherical surface design, the cold processing technical performance of the lens is good; the glass material and the finished product lens are low in cost, massive in output, and high in yield; the optical lens can bewidely applied to the security defense monitoring field.

Owner:ZHEJIANG DAHUA TECH CO LTD

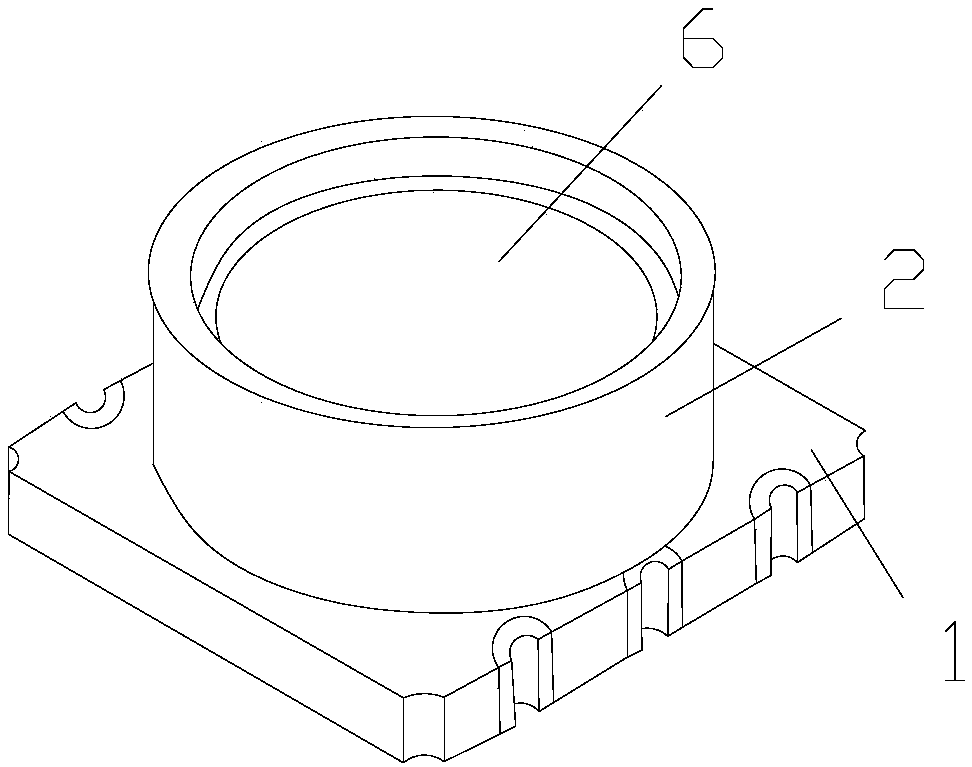

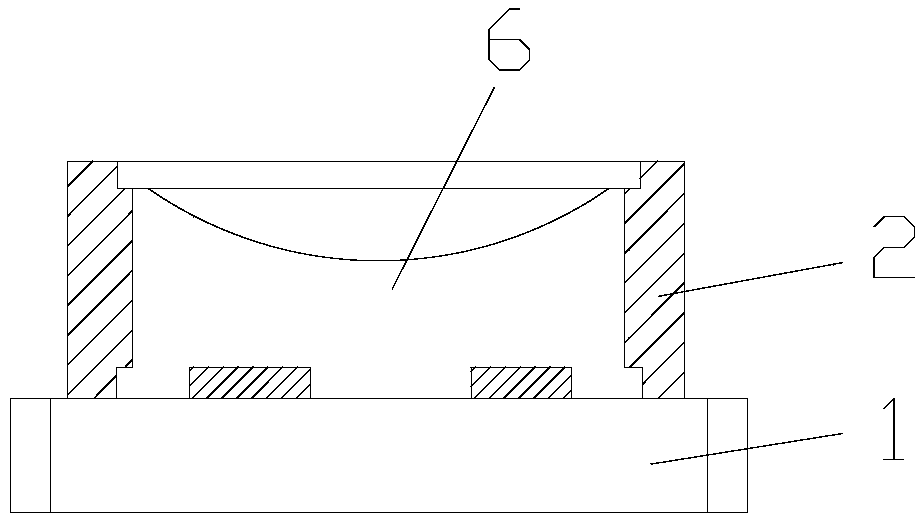

Corrosion-resistant gas meter temperature and pressure compensation integrated sensor and manufacturing method thereof

PendingCN108871483AAchieve calibrationAchieve temperatureVolume meteringElectrical resistance and conductancePlatinum resistance

The invention relates to a corrosion-resistant gas meter temperature and pressure compensation integrated sensor and a manufacturing method thereof, wherein the sensor adopts a small integrated SMD structure, and comprises a frame, a cylindrical shell, a signal conditioning chip, a pressure sensor and a platinum resistance temperature sensor. The cylindrical shell is arranged on the frame, the signal conditioning chip, the pressure sensor and the platinum resistance temperature sensor are bonded on the frame and are encapsulated in the cylindrical shell by a potting glue; the signal conditioning chip, the pressure sensor and the platinum resistance temperature sensor are electrically connected through alignment bonding wire; and the potting glue is a fluorine-containing gel. After the calibration compensation of the corrosion-resistant gas meter temperature and pressure compensation integrated sensor is finished, a digital pressure signal output and a platinum resistance signal temperature output are provided, thereby satisfying the requirements of the 'Gas Meter Verification Regulations' on the use of gas meter temperature and pressure compensation, solving users' demand for miniaturized products and reserves more space for users to innovate and upgrade.

Owner:深圳电通纬创微电子股份有限公司

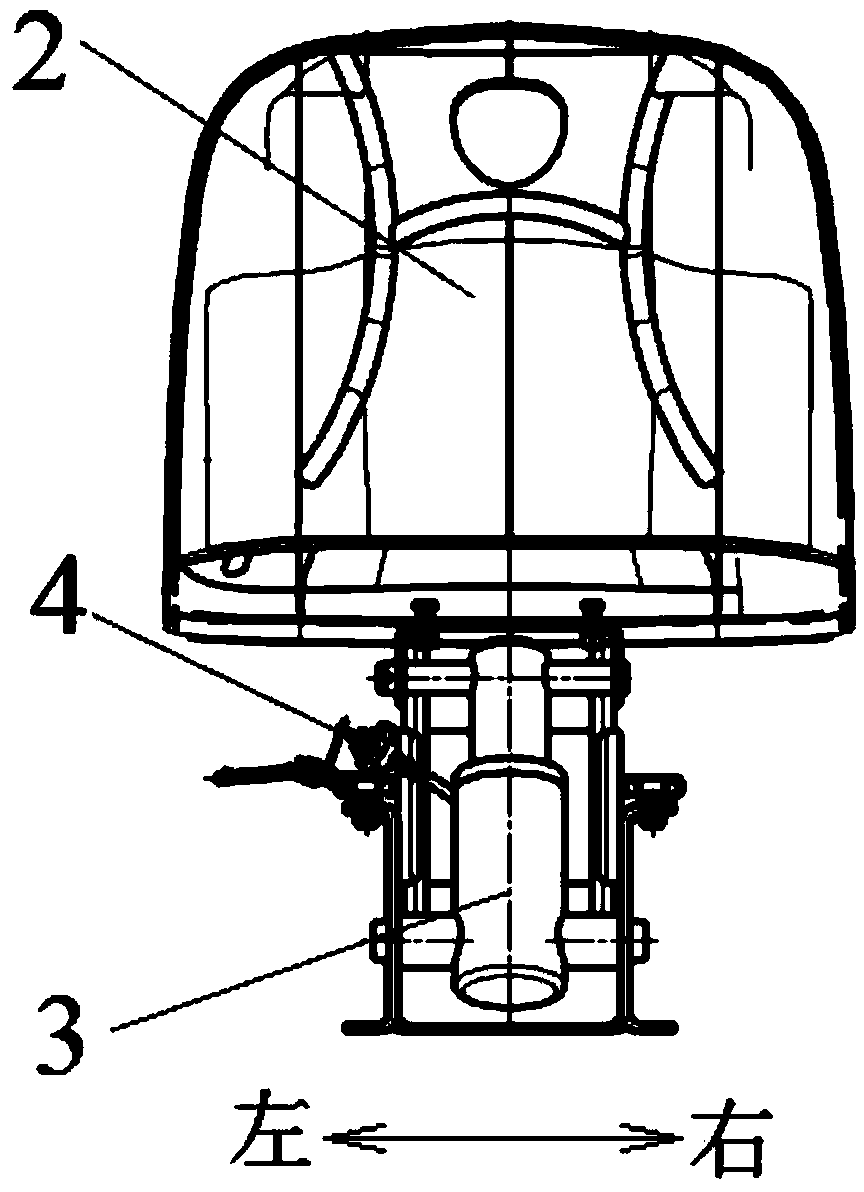

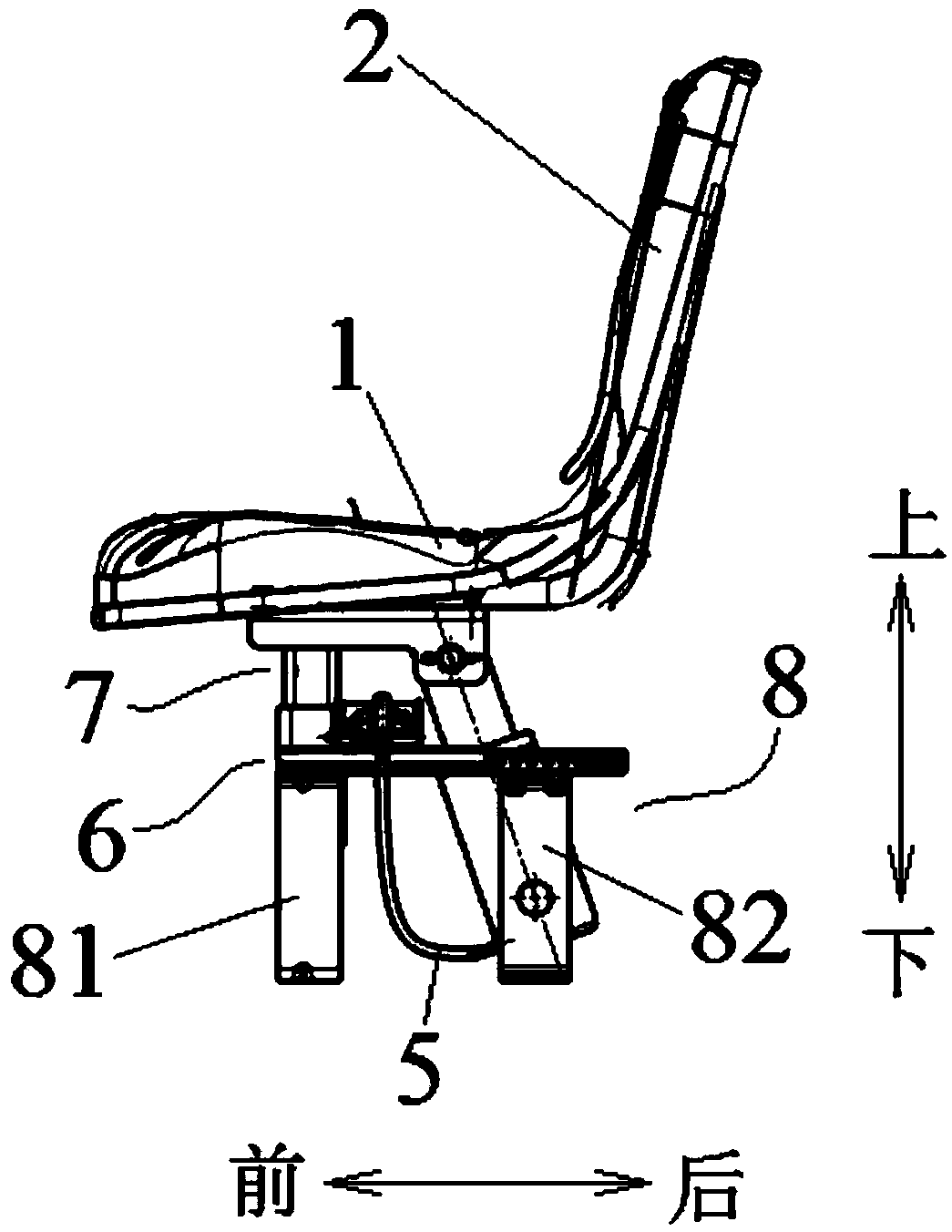

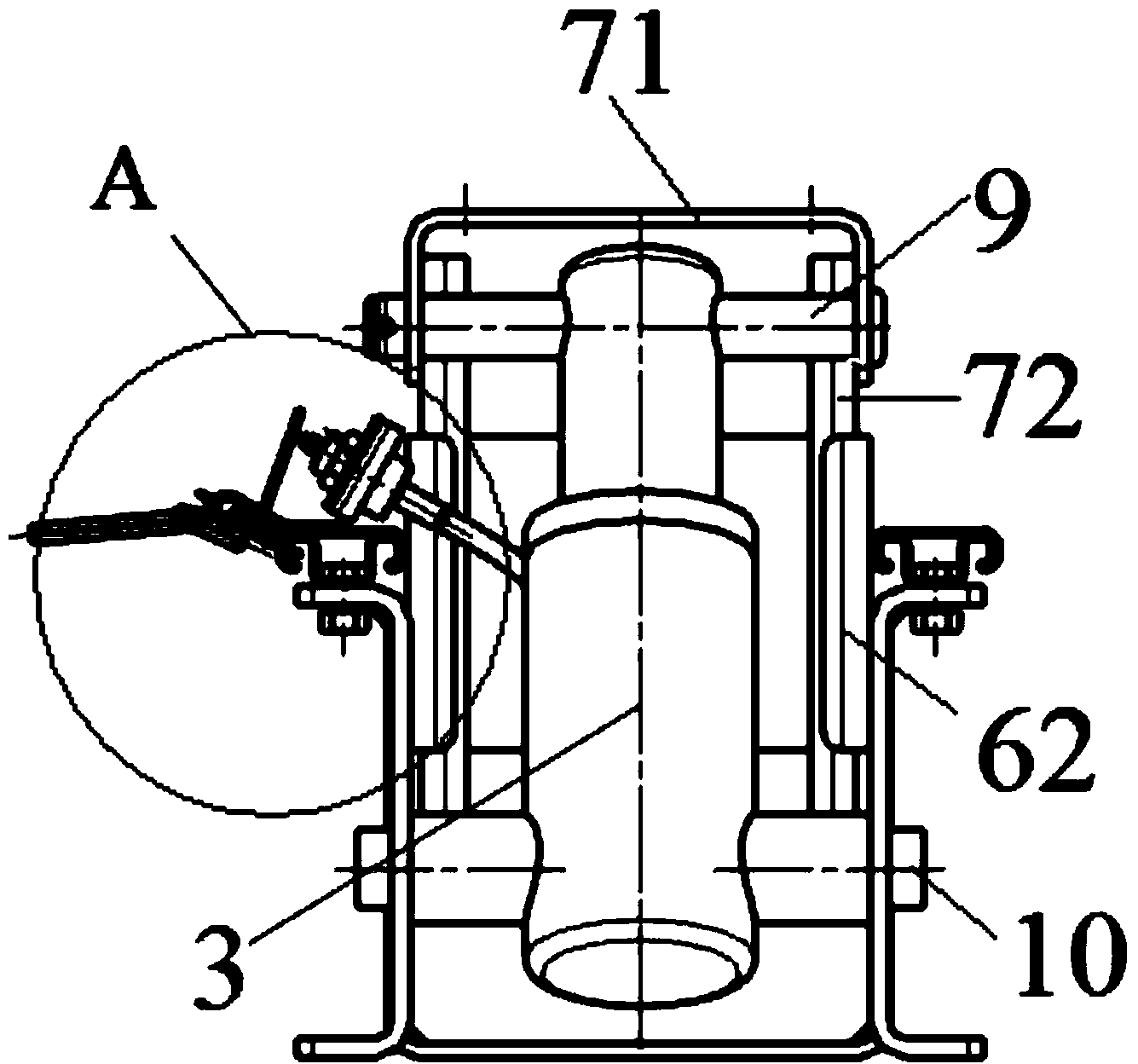

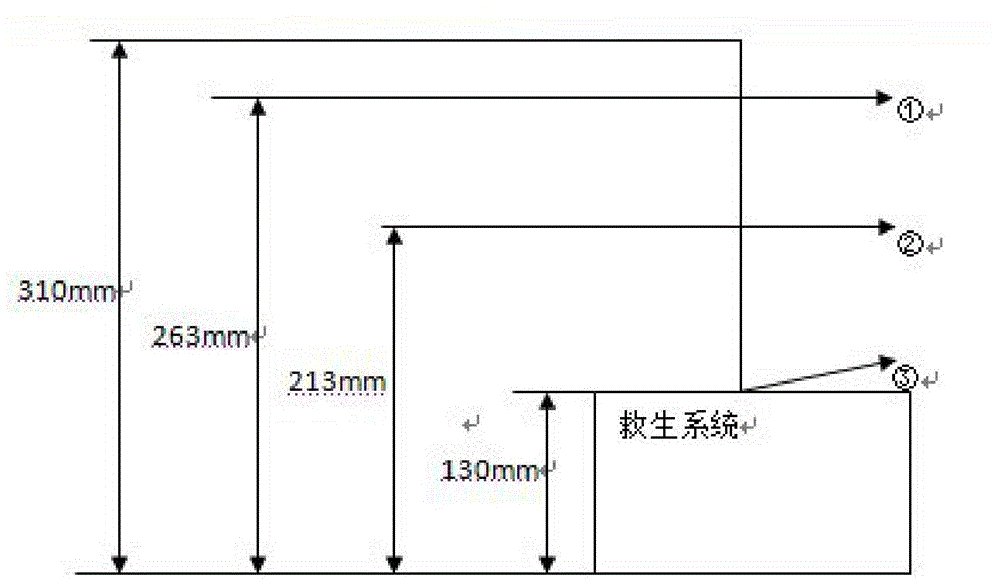

Seat and agricultural machinery with same

ActiveCN103909840AExtended position adjustment rangeWith shock absorption functionMovable seatsSeat suspension devicesDamping functionEngineering

The invention discloses a seat and agricultural machinery with the same. The seat comprises a seat main body and a positioning adjusting device, wherein the position adjusting device comprises a supporting base, a horizontal sliding rack and a vertical sliding rack, wherein the horizontal sliding rack is slidably connected with the base and slides along the horizontal direction; the vertical sliding rack is slidably connected with the horizontal sliding rack and slides along the vertical direction; the vertical sliding rack is connected with the seat main body; and an elastic supporting mechanism is also arranged between the vertical sliding rack and the base. The position adjusting range of the seat can be expanded by using the position adjusting device which can adjust the position of the seat in the horizontal direction and the vertical direction, so that using demands of drivers with different heights and different driving habits can be met; the seat is not required to be manually dragged in a position adjusting process by using the elastic supporting mechanism; the seat can be automatically adjusted; and moreover, the elastic supporting mechanism has an elastic buffering performance, so that the seat has a damping function, and the driving comfort level is improved.

Owner:ZOOMLION HEAVY MASCH CO LTD

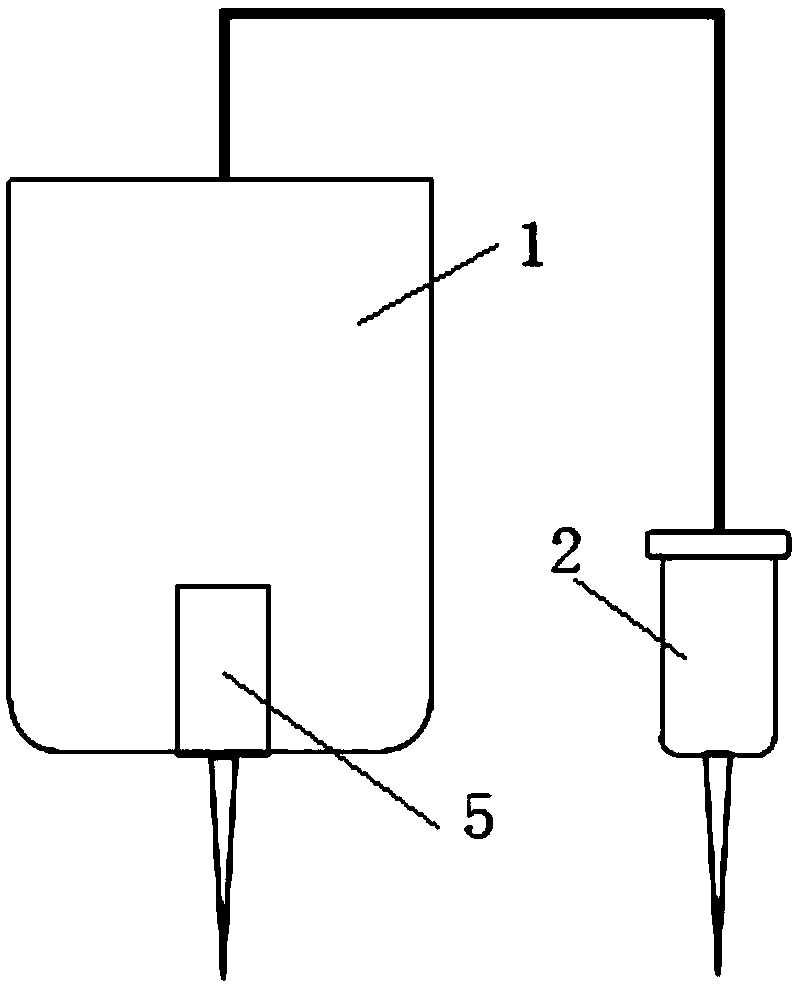

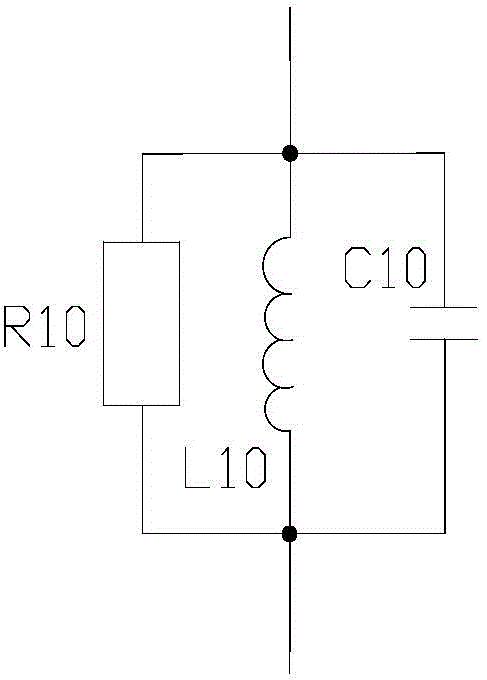

Small-size lifesaving antenna

InactiveCN104538748AReduce the impact of wavesSmall sizeRadiating elements structural formsAntenna equipments with additional functionsLoad circuitCapacitance

The invention relates to a small-size lifesaving antenna which comprises a loaded circuit. The loaded circuit is composed of at least three loaded circuit bodies which are connected through circuit metal connecting conductors. The three loaded circuit bodies are connected with one another through the at least three metal connecting conductors of different lengths. One loaded circuit body comprises a first PCB, a resistor R10, an inductor L10 and a capacitor C10, wherein the resistor R10, the inductor L10 and the capacitor C10 are welded to the first PCB. Another loaded circuit body comprises a second PCB, a resistor R20, an inductor L20 and a capacitor C20, wherein the resistor R20, the inductor L20 and the capacitor C20 are welded to the second PCB. The rest loaded circuit body comprises a third PCB, an inductor L31, an inductor L32, an inductor L33, a resistor R31, a resistor R32, a resistor R33, a capacitor C31, a capacitor C32, a capacitor C33 and a transmission line transformer T, wherein the inductor L31, the inductor L32, the inductor L33, the resistor R31, the resistor R32, the resistor R33, the capacitor C31, the capacitor C32, the capacitor C33 and the transmission line transformer T are welded to the third PCB. The small-size lifesaving antenna is simple and reasonable in structural design, small in size, capable of being arranged in the system, convenient to use, capable of effectively lowering the wave influence of a wind turbine, and capable of meeting the using demands for the small antenna, wide bands and large gains by loading.

Owner:陕西烽火诺信科技有限公司

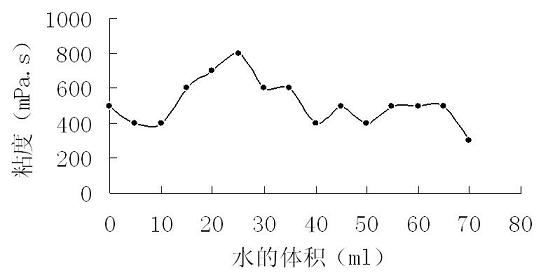

Synthesis of modified aqueous epoxy resin and method for preparing antiseptic rusty paint

ActiveCN101775108BGood water dispersibilityGood storage stabilityAnti-corrosive paintsEpoxyDistilled water

The invention discloses synthesis of modified aqueous epoxy resin and a method for preparing antiseptic rusty paint, relating to synthesis of epoxy resin and a method for preparing paint. The invention solves the problems of the traditional aqueous epoxy resin antiseptic paint that storing stability of base material resin and water resistance and corrosion resistance of an aqueous epoxy resin antiseptic paint coating film can not be met simultaneously. the synthesis method of modified aqueous epoxy resin comprises the steps of: mixing Span 60 with Tween 20, adding E-51; heating and stirring, and dropwise adding distilled water till the system viscosity is suddenly reduced; and finally dropwise adding an initiating agent and a monomer to carry out heating reaction. The method for preparingantiseptic rusty paint comprises the steps of: mixing the modified aqueous epoxy resin, a corrosion inhibitor and a rust preventing agent, stirring and grinding; adding a defoaming agent, a curing agent and deionized water; and stirring the mixture to obtain the modified aqueous epoxy resin antiseptic rusty paint. The invention simultaneously meets the storing stability of the base material resin of the aqueous epoxy resin antiseptic paint and the water resistance and the corrosion resistance of the aqueous epoxy resin antiseptic paint coating film.

Owner:HARBIN INST OF TECH

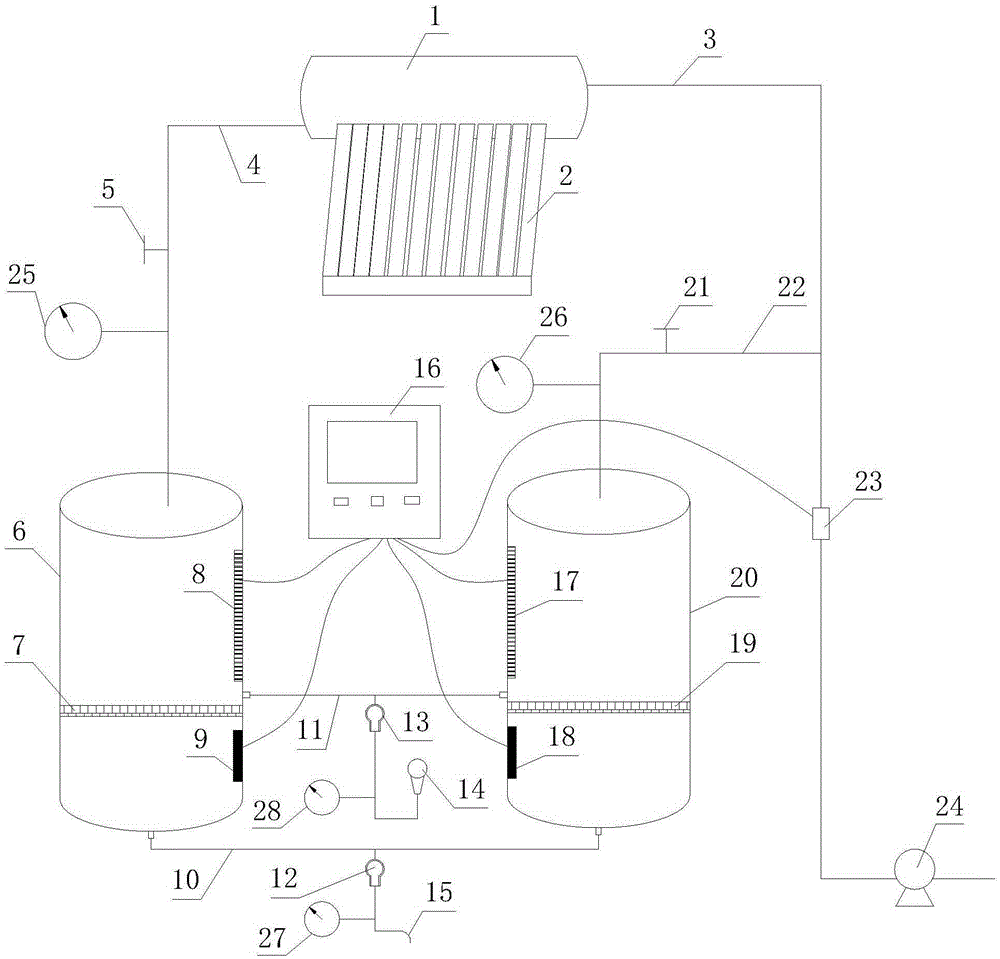

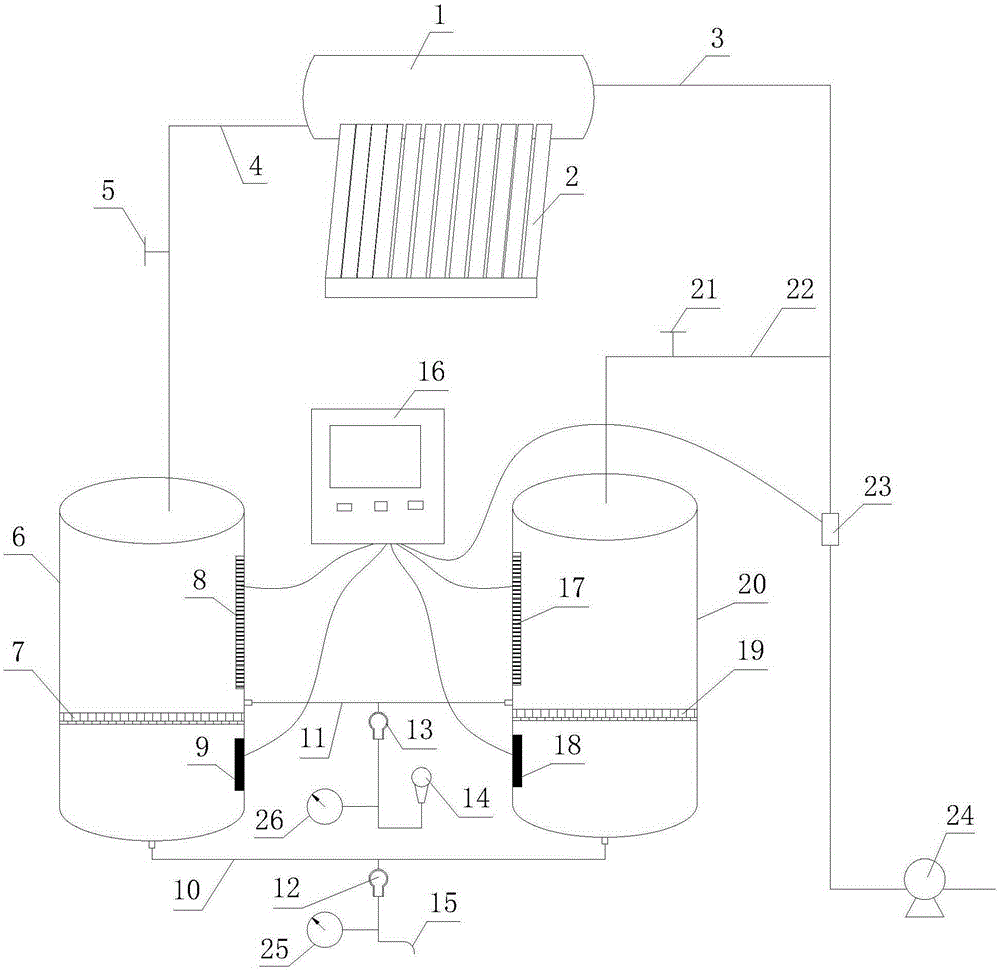

Intelligent cold water and hot water supply system

InactiveCN105240920AMeet supply demandMeet drinking waterLighting and heating apparatusSpace heating and ventilation detailsWater filterWater storage tank

The invention discloses an intelligent cold water and hot water supply system. The intelligent cold water and hot water supply system comprises a solar water heater, a hot water storage tank, a cold water storage tank and a controller. The solar water heater is composed of a water tank and solar collector pipes mounted on the water tank. An inlet of the water tank is communicated with a cold water pipe A. An outlet of the water tank is communicated with the hot water storage tank through a hot water pipe. A cold water pipe B is arranged on the cold water pipe A and communicated with the cold water storage tank. A hot water filtering device is arranged on the lower portion of the interior of the hot water storage tank. A cold water filtering device is arranged on the lower portion of the interior of the cold water storage tank. A hot water level detector is arranged on the upper portion of the hot water storage tank, and a cold water level detector is arranged on the upper portion of the cold water storage tank. A hot water quality detector is arranged on the lower portion of the hot water storage tank, and a cold water quality detector is arranged on the lower portion of the cold water storage tank. The hot water level detector, the hot water quality detector, the cold water level detector and the cold water quality detector are connected with the controller through wires. By adopting the intelligent cold water and hot water supply system, the water levels and water quality information are controlled and displayed through the controller, and intelligent water supply is realized.

Owner:广西大美节能设备有限公司

Integrated cold water and hot water storage device

InactiveCN105241076AMeet supply demandMeet drinking waterSolar heat devicesSolar thermal energy generationWater storage tankWater filter

The invention discloses an integrated cold water and hot water storage device. The integrated cold water and hot water storage device comprises a solar water heater, a hot water storage tank and a cold water storage tank. The solar water heater is composed of a water tank and solar collector tubes mounted on the water tank. An inlet of the water tank is communicated with a cold water pipe A. An outlet of the water tank is communicated with the hot water storage tank through a hot water pipe. A cold water pipe B is further arranged on the cold water pipe A and communicated with the cold water storage tank. A hot water filtering device is arranged in the lower portion of the hot water storage tank. A cold water filtering device is arranged in the lower portion of the cold water storage tank. The part, above the hot water filtering device, of the hot water storage tank is communicated with the part, above the cold water filtering device, of the cold water storage tank through a communicating pipe B. The bottom of the hot water storage tank and the bottom of the cold water storage tank are communicated through a communicating pipe A. A thermometer A is connected with a water mixing valve A in series, and a thermometer B is connected with a water mixing valve B in series. By adopting the integrated cold water and hot water storage device, the requirement for hot water supply or cold water supply can be met, and meanwhile the requirements for drinking water and clean water can be met.

Owner:广西大美节能设备有限公司

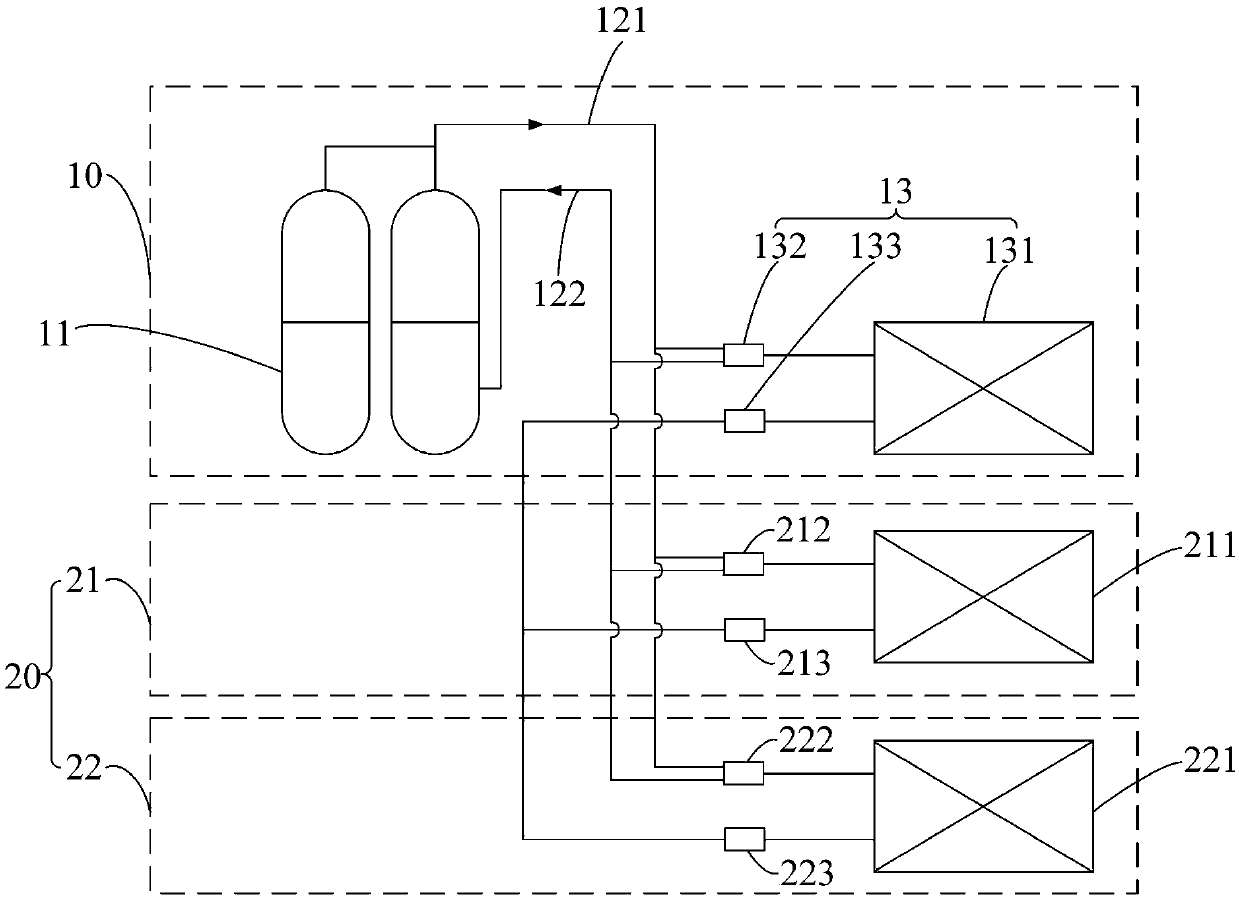

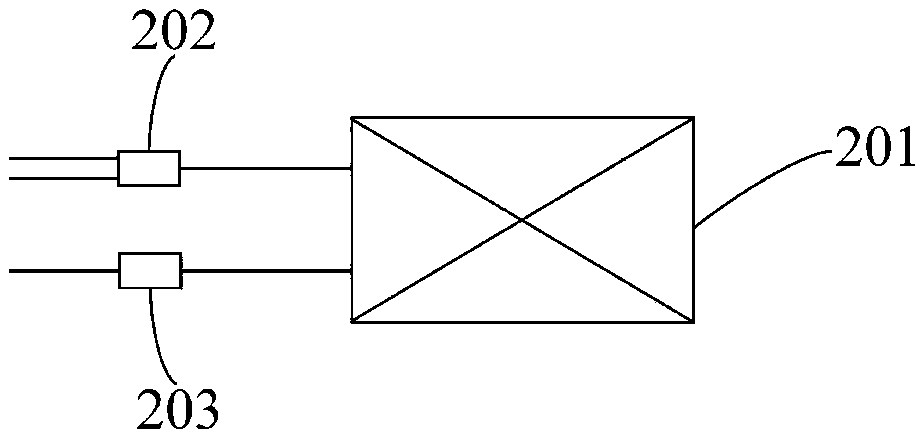

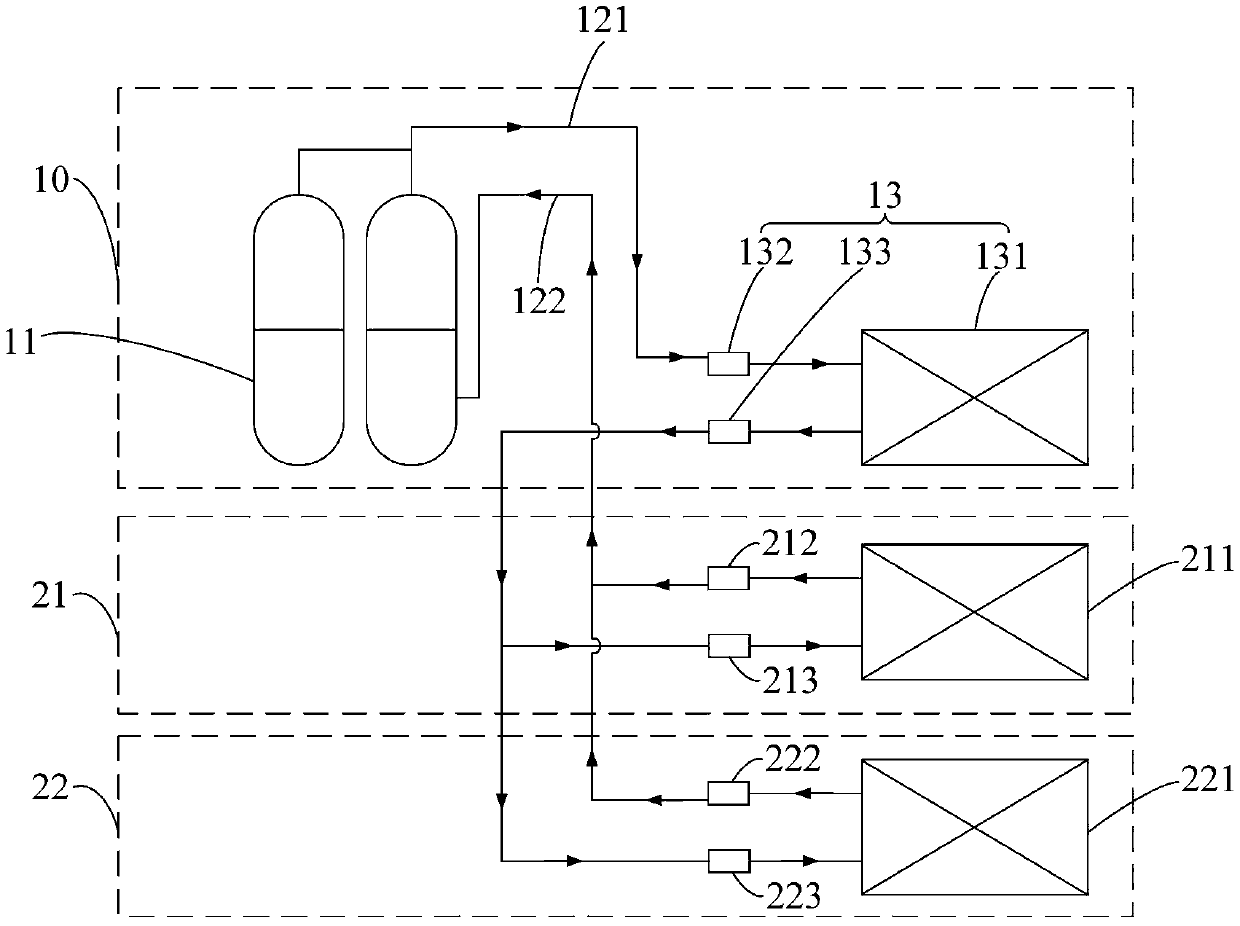

Multivariate heat recovery air conditioner system

PendingCN109654612AReduce energy consumptionEnergy savingEnergy recovery in ventilation and heatingMechanical apparatusProcess engineeringHigh pressure

The invention relates to the technical field of energy utilization and provides a multivariate heat recovery air conditioner system. The multivariate heat recovery air conditioner system comprises anoutdoor device and an indoor device. The outdoor device comprises a compressor and an outdoor unit arranged outdoors. The compressor is used for converting coolants from the low-pressure gas state into the high-pressure gas state. The indoor device comprises at least two indoor units arranged in different rooms indoors. The indoor units can be used for cooling or heating. The indoor units are mutually connected. The indoor units are connected with the compressor and the outdoor unit. After being output from the compressor, the coolants pass through the outdoor unit and the indoor units and then return to the compressor. The multivariate heat recovery air conditioner system can make full use of heat energy and cold energy in the different rooms where the indoor units are located, and the energy consumption is effectively reduced. There is no need to adopt a cooling water pump, a chilled water pump and a cooling tower, energy consumption is reduced, the system maintenance cost is reduced, and the multivariate heat recovery air conditioner system is more flexible in installation.

Owner:XINAO SHUNENG TECH CO LTD

Casting processing process of car air cylinder sleeve

InactiveCN108796369AImprove wear resistanceFulfill usage requirementsFoundry mouldsMetallic material coating processesTO-18Alloy

The invention discloses a casting processing process of a car air cylinder sleeve. The air cylinder sleeve is composed of, by mass percent, 23 to 25% of Si, 14 to 18% of Al, 4.55 to 5.75% of Cu, 0.47to 0.63% of Mg, 0.45 to 0.72% of Mn, 0.65 to 1.35% of Zn, 1.35 to 1.85% of Ni, 0.25 to 0.37% of P and the balance Fe. According to selection and a preparing process of the air cylinder sleeve, an engine cylinder sleeve made of a hypereutectic alloy can be obtained, the air cylinder sleeve has the good wear resistance, meanwhile, the rigidity and the strength can meet the use needs to the air cylinder sleeve to a certain degree, hardness and tensile strength of the air cylinder sleeve can meet the use needs of the engine cylinder sleeve, and the process is simple, effect and easy to implement.

Owner:ZYNP GRP ANHUI CO LTD

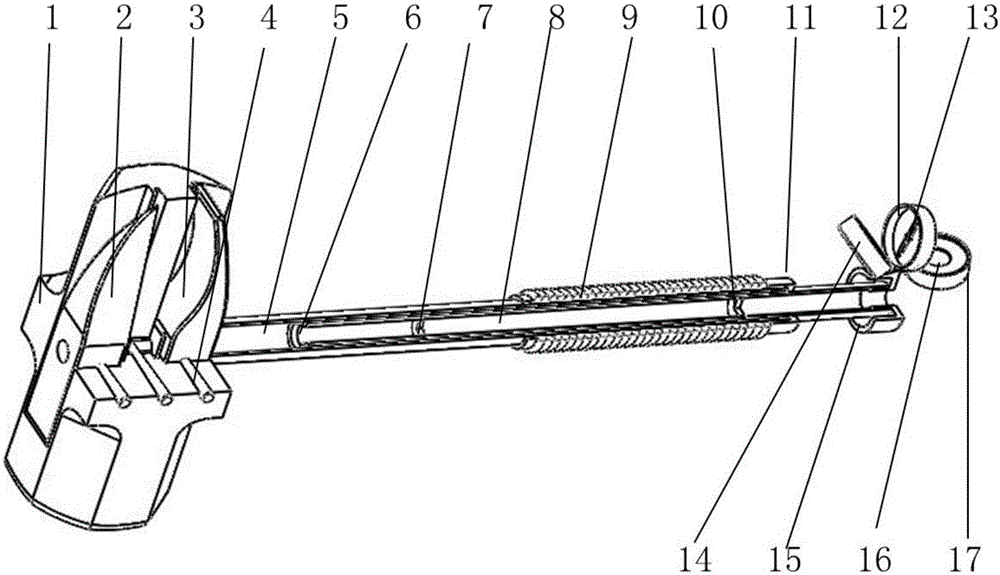

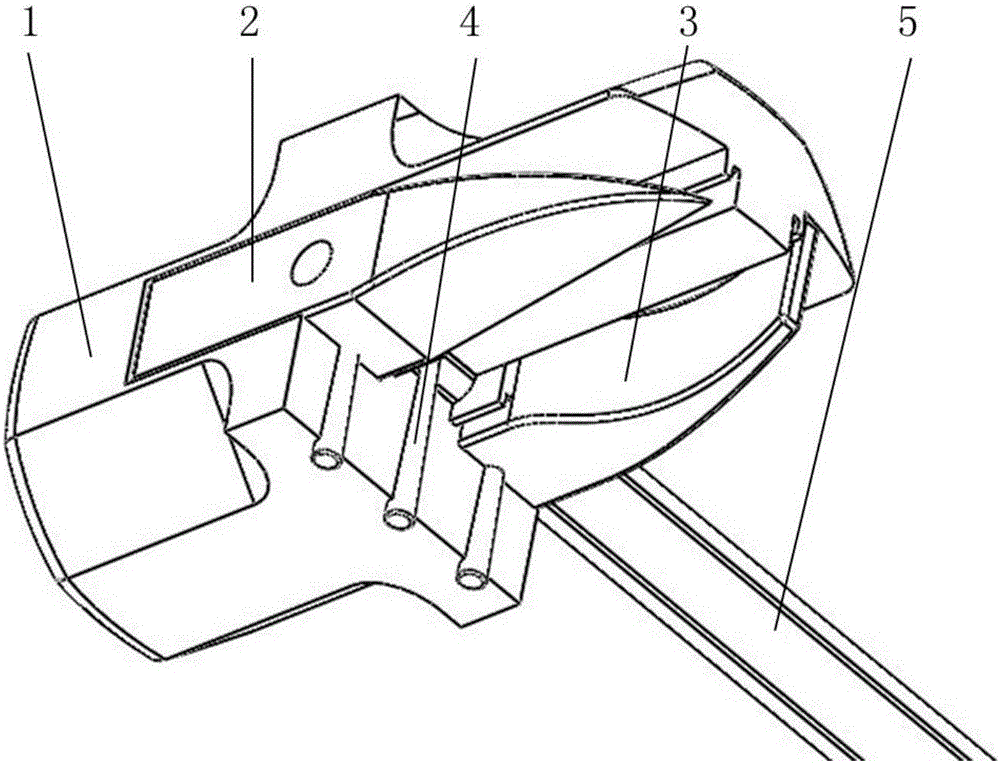

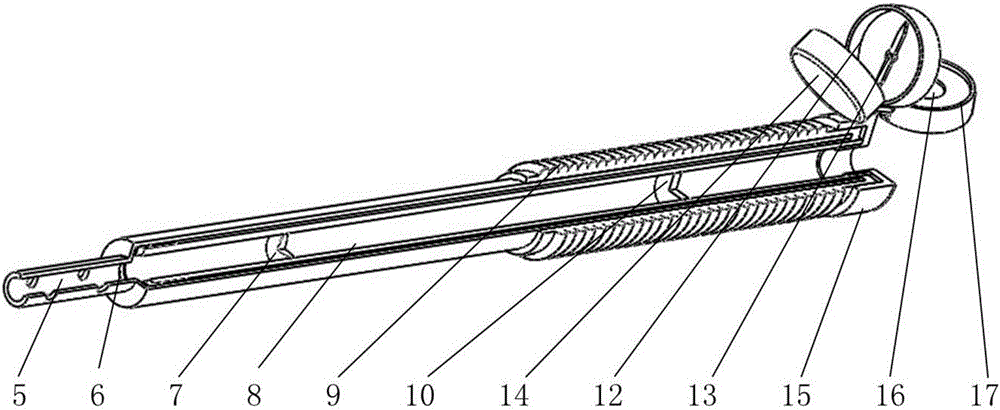

Quick-release multi-functional geological hammer

InactiveCN105710844AQuick mergeMeet the use requirementsPortable percussive toolsHand hammersEyepieceEngineering

The invention relates to a geological hammer, in particular to a quick-release multi-functional geological hammer which comprises an octagonal hammer head, a hard rock hammer head, a soft rock hammer head, main taper pins, a main hammer handle, an extended hammer handle inner connector, a built-in objective lens, an extended hammer handle, a non-slip shock-mitigating rubber sleeve, a built-in prism, a main hammer handle connector, a compass bottom cover, a compass, a bottom cover, a bottom cover base, an eyepiece, an eyepiece bottom cover and an auxiliary taper pin, wherein the octagonal hammer head is mounted at the upper part of the main hammer handle through a hammer handle mounting hole; and the hard rock hammer head and the soft rock hammer head are mounted on the octagonal hammer head through the hammer handle mounting hole or mounted at the upper part of the main hammer handle through the hammer handle mounting hole. Compared with a conventional geological hammer, the quick-release multi-functional geological hammer provided by the invention is solid and durable, and can be disassembled and assembled quickly; the quick-release multi-functional geological hammer can be combined and compressed, so as to save the transportation and storage space; the hammer handle of the quick-release multi-functional geological hammer is telescopic for assembly and can be assembled into a simple cane, so as to realize simple length measurement; and the quick-release multi-functional geological hammer has the functions of the compass and a telescope, and the objective lens is flexible to use, so that quick-release multi-functional geological hammer can serve as an emergency ignition source.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

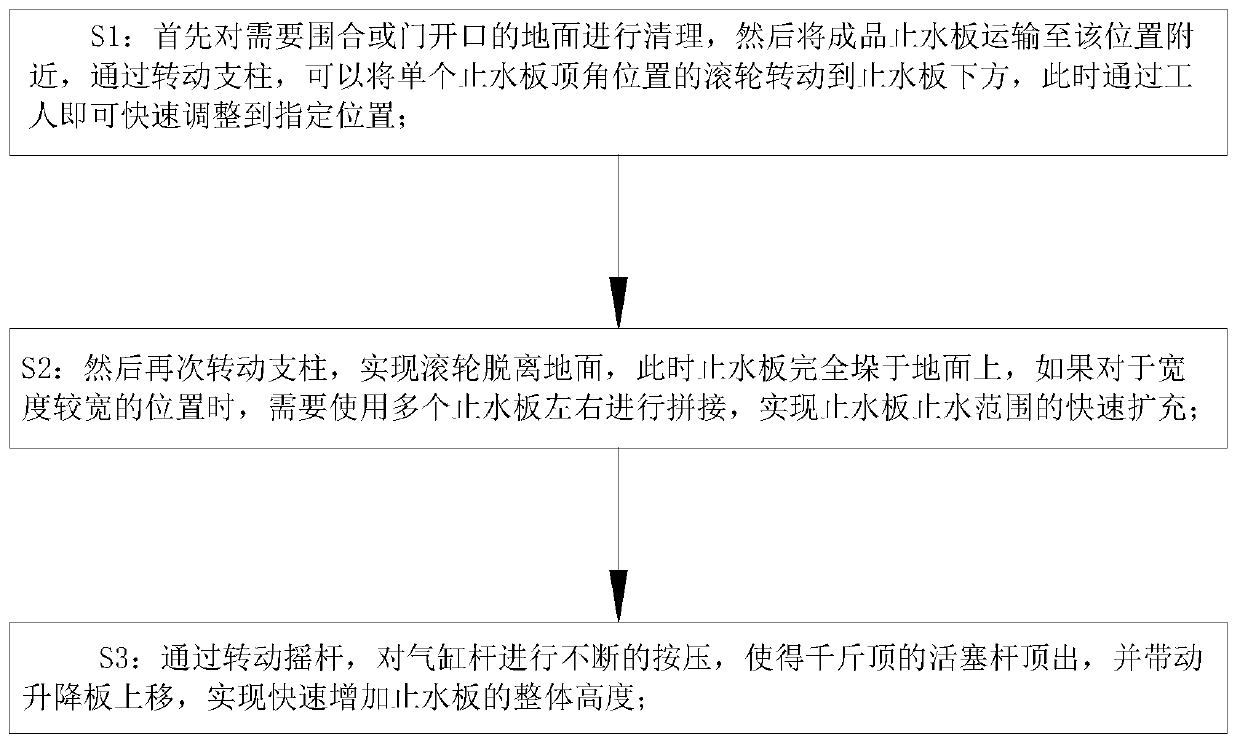

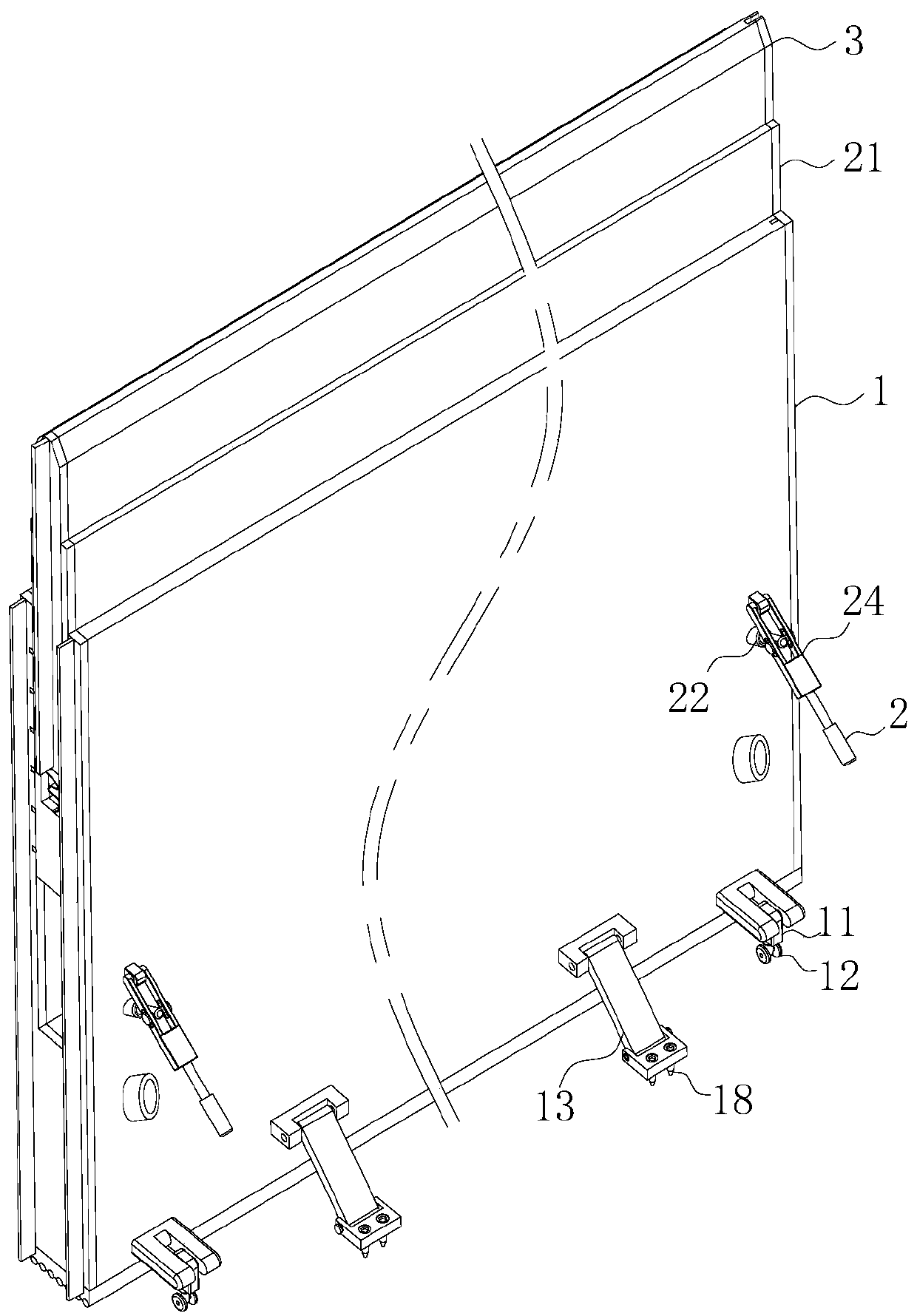

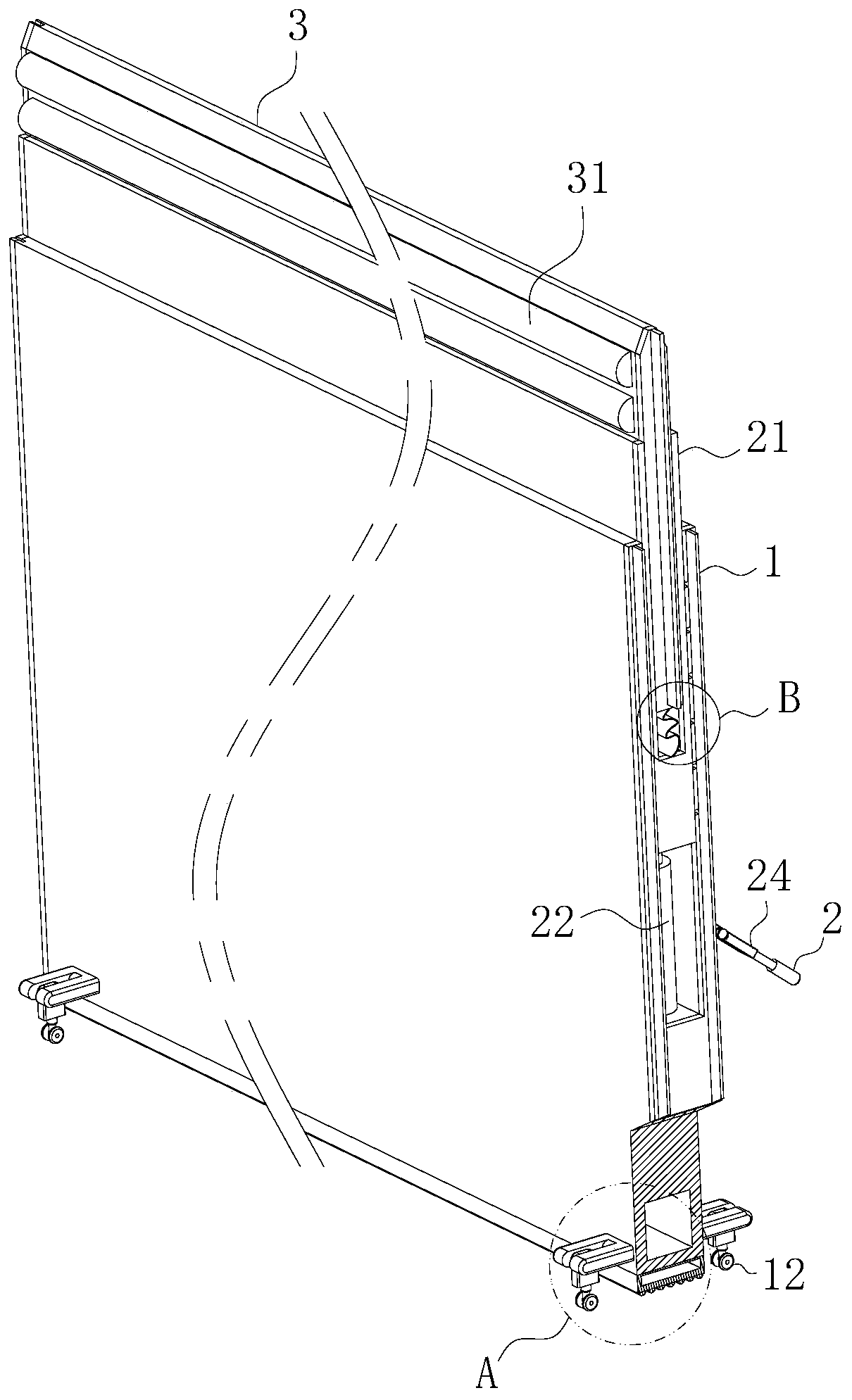

Construction method of vertical water stop structure of hydraulic engineering

The invention belongs to the technical field of vertical water stop, and particularly relates to a construction method of a vertical water stop structure of hydraulic engineering. Water stop plates adopted in the method comprise substrates, rocking bars and light baffles. First sliding grooves are formed in the upper surfaces of the substrates. Lifting plates are in sliding connection in the firstsliding grooves. Jacks are fixedly connected between the lower surfaces of the lifting plates and the groove bottoms of the first sliding grooves. The surfaces of the substrates are fixedly connectedwith fixed blocks. The positions, under the fixed blocks, of the substrates are fixedly connected with air cylinder bars. Connecting bars are connected between the air cylinder bars and the fixed blocks. The rocking bas are fixedly connected to the surfaces of the connecting bars. Second sliding grooves are formed in the upper surfaces of the lifting plates. The light baffles are in sliding connection in the second sliding grooves. By means of the construction method, the height of the water stop plates can be rapidly adjusted effectively, the requirements of water stop of different grades offlood disasters are greatly met, integrality is high, transporting and adjusting are convenient, and the process that professionals carry out professional splicing operation is not needed.

Owner:安徽派农生态农业有限公司

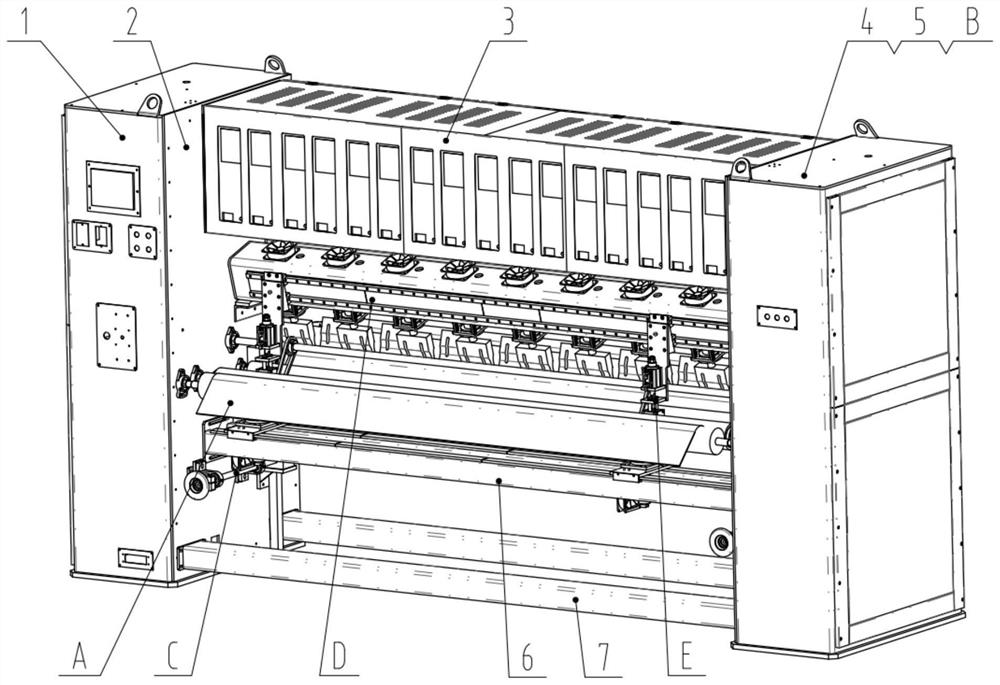

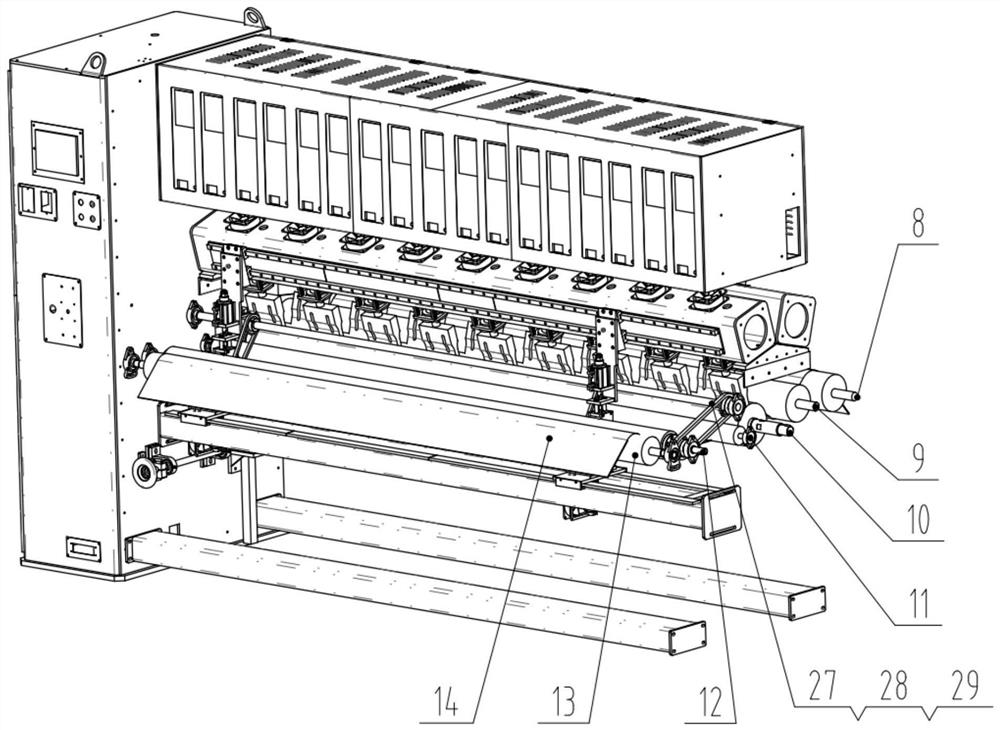

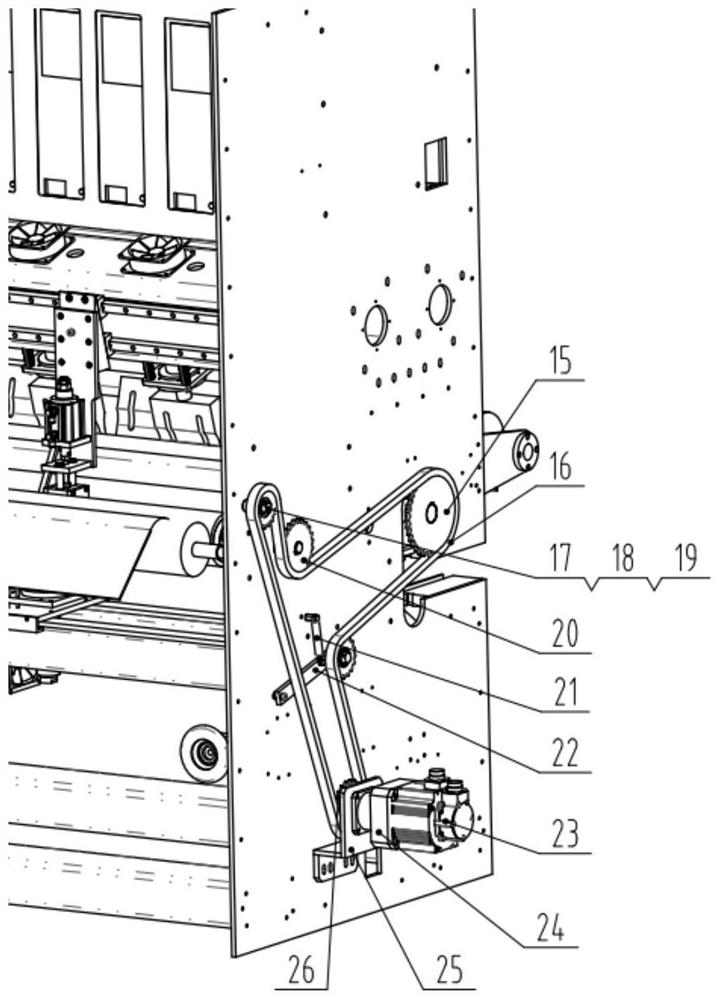

Ultrasonic quilting machine

PendingCN114603866AAchieve widthFulfill usage requirementsPattern makingSevering textilesUltrasonic weldingEngineering

The invention discloses an ultrasonic quilting main machine which comprises a left side box body, a left side plate, a generator support, a right side plate, a right side box body, an edge cutting ultrasonic fixed sliding rail, a fixed lower beam, a cloth trend, a transmission part, a flower roller adjusting part, an ultrasonic part, an edge cutting part and a centrifugal fan. Cloth penetrates in from the upper portion of the first scutching roller from the rear portion from bottom to top, passes through the lower portion of the second scutching roller, the upper portion of the ultrasonic embossing roller, the lower portion of the cloth passing roller, the position between the edge cutting embossing wheel and the second ultrasonic welding head and the position below the first cloth outlet rubber coating roller, and finally penetrates out from the position between the first cloth outlet rubber coating roller and the second cloth outlet rubber coating roller. According to the invention, the use requirement of customers on the edge-cutting welding spots of the cloth finished products is met, and the widths of different cloth finished products are realized by adjusting the position of the edge-cutting part on the guide rail sliding block and the position of the ultrasonic mounting plate II on the edge-cutting ultrasonic fixed sliding rail; and the replacement of the ultrasonic embossing roller is realized by virtue of an auxiliary part, namely the embossing roller replacement support, so that the requirements of different patterns are met.

Owner:上工富怡智能制造(天津)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com