Multifunctional end beam mechanical arm welding clamp

A welding fixture and manipulator technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the utilization rate of fixtures cannot be guaranteed, the manufacturing cost of locomotives cannot be effectively controlled, and the investment of special fixtures is large. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

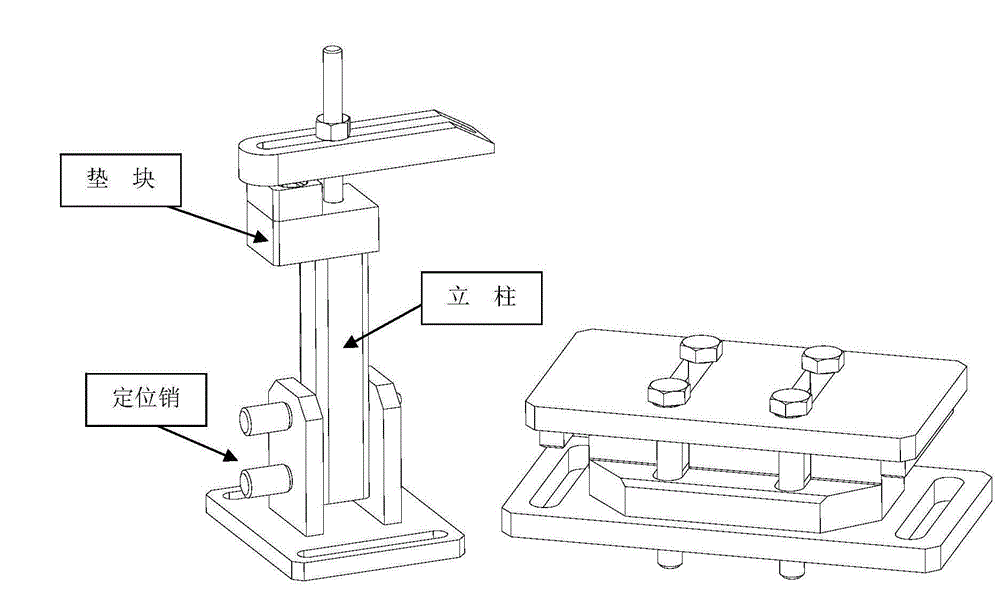

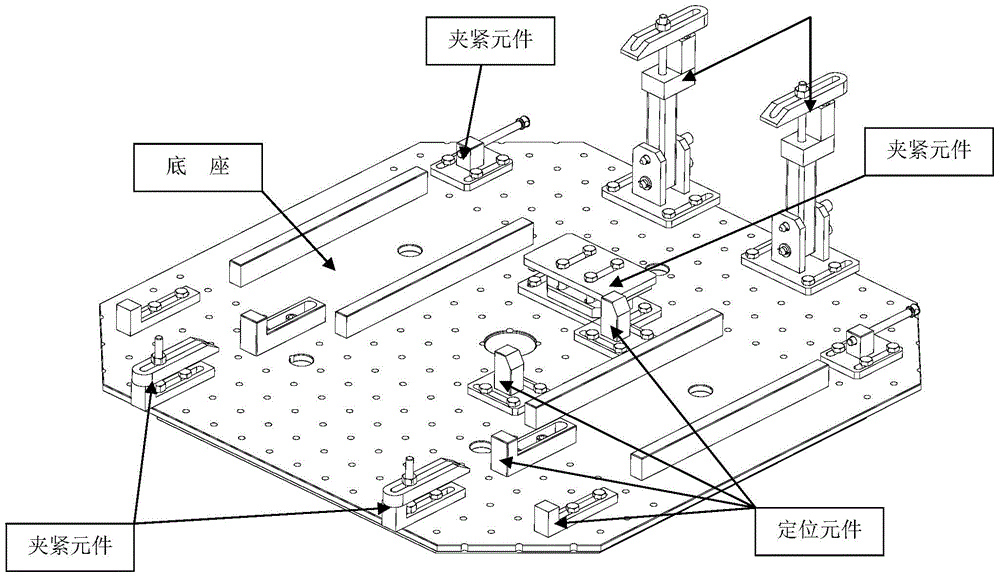

[0017] like figure 1 As shown, the device mainly includes three units: base, positioning and clamping. There are threaded positioning holes on the base cover of the base part, which is convenient for positioning and replacement of the position of clamping components, and meets the position requirements of different workpieces for positioning and clamping components; the positioning part ensures the accurate positioning of the workpiece when it is clamped; the clamping part After the workpiece is positioned, the workpiece is clamped to prevent the workpiece from loosening and changing its position.

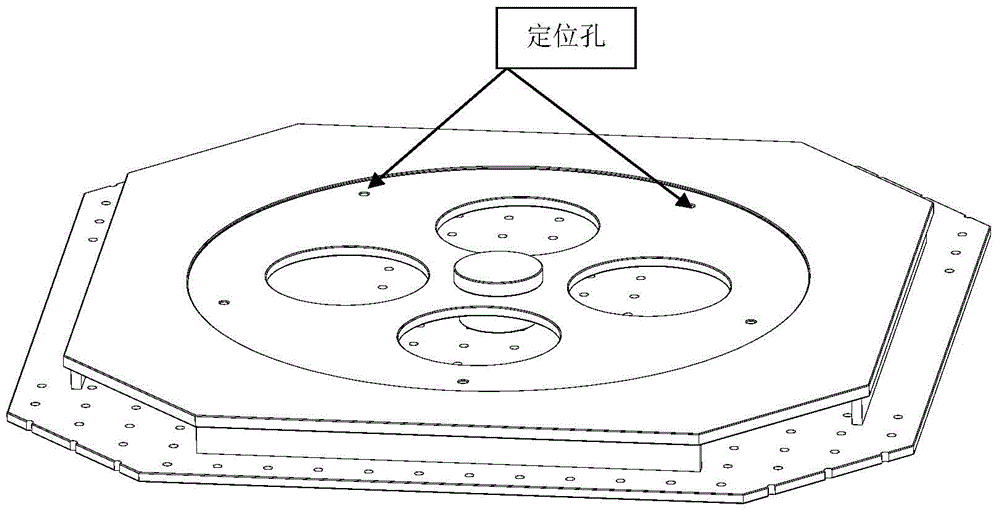

[0018] like figure 2 As shown in the figure, there are five positioning holes on the bottom plane of the base. Using these positioning holes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com