Construction method of vertical water stop structure of hydraulic engineering

A vertical water stop and construction method technology, applied in water conservancy projects, sea area projects, dams, etc., can solve the problems of water stop plate height adjustment, heavy workload, sealing bottom, etc., to increase the overall height and meet the water retaining requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

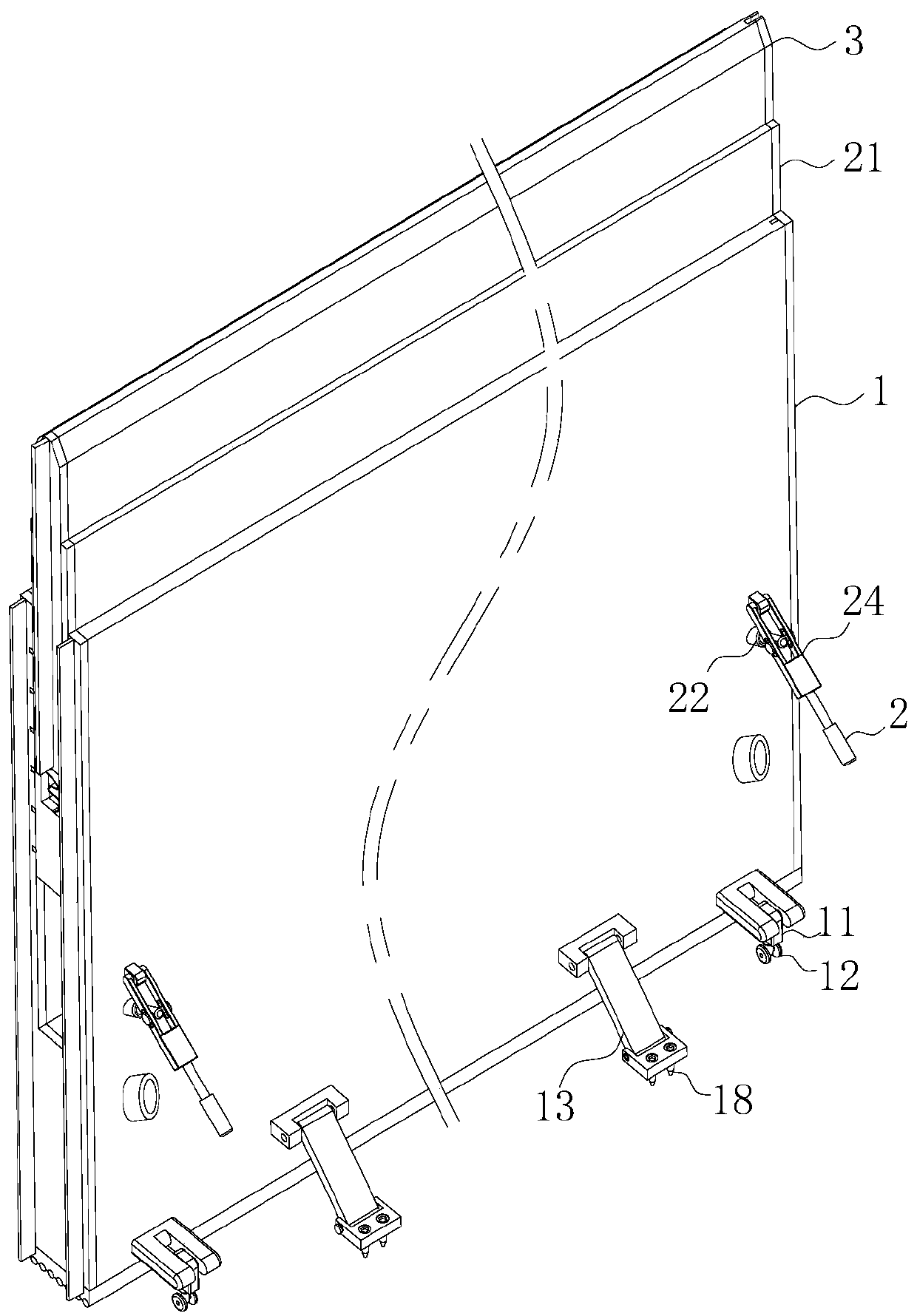

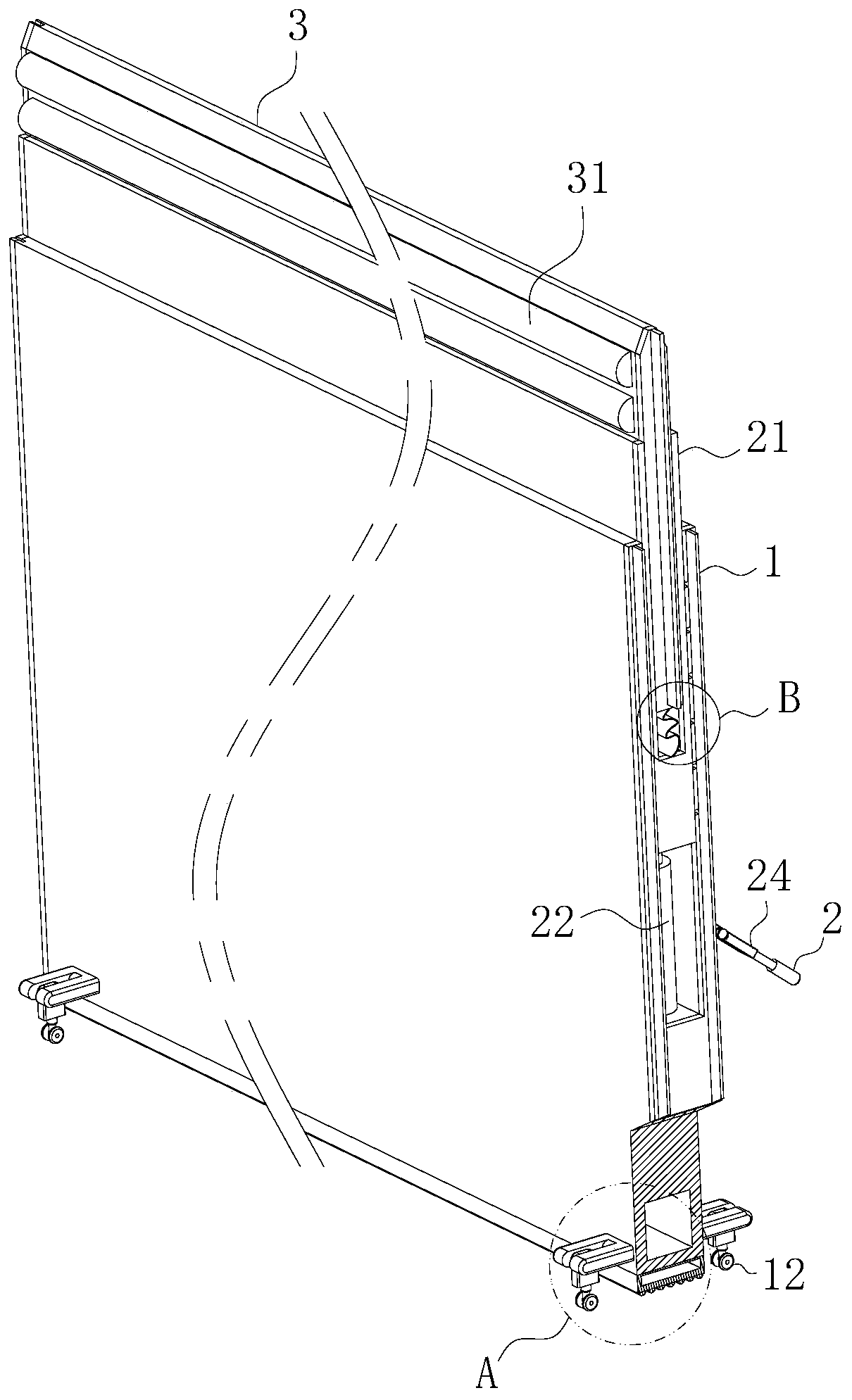

[0033] As an embodiment of the present invention, the upper surface of the lifting plate 21 is provided with a second chute; the inside of the second chute is slidingly connected with a light baffle 3 up and down; One side is fixedly connected with a strip-shaped floating column 31; the inside of the floating column 31 is provided with a cavity, and the inside of the cavity is filled with light gas; during operation, when the flood rises rapidly, due to the lifting plate 21 The height needs to be adjusted by the operator. When the operator is doing other work, he has not observed the change of the flood water level in time, so it is easy for the flood to overflow the water stop plate and the problem of backflow, and once this problem occurs At this time, it is more difficult to carry out remediation, and it is difficult to perform effective operation in the case of a large amount of water flow to realize the height adjustment of the lifting plate 21. Therefore, by setting the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com