Method for surface modification of ternary cathode material for lithium ion batteries by fluorine-based ionic liquid

A technology of lithium-ion batteries and ionic liquids, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of reducing the initial efficiency of materials, deteriorating specific capacity, and aggravating lithium-nickel mixing, so as to facilitate intercalation/extraction , avoid direct contact, reduce the effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

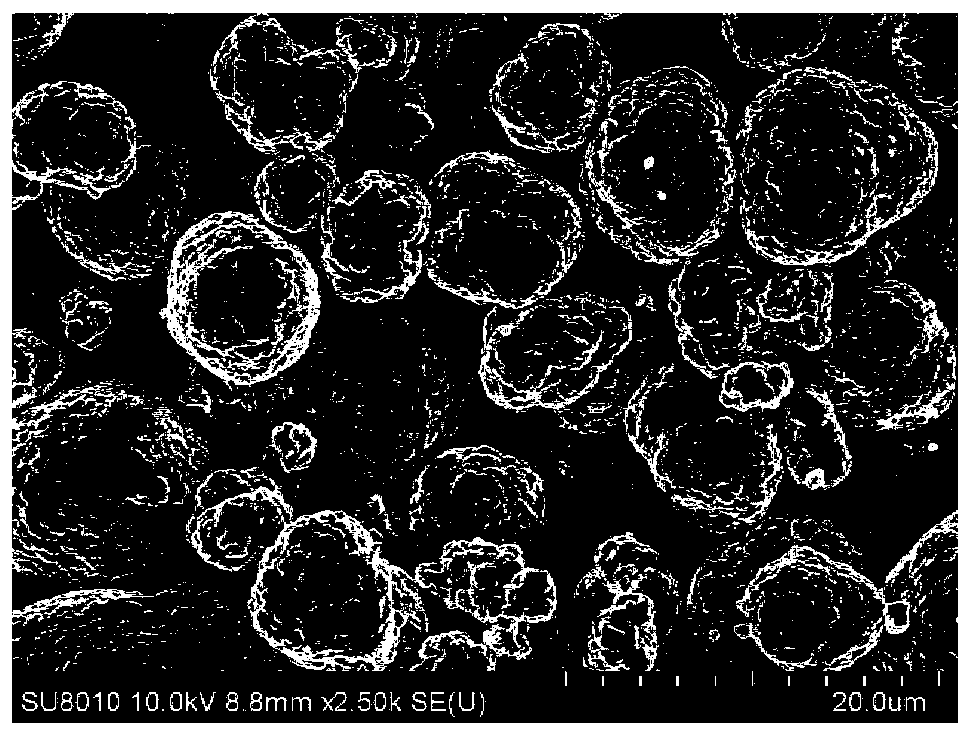

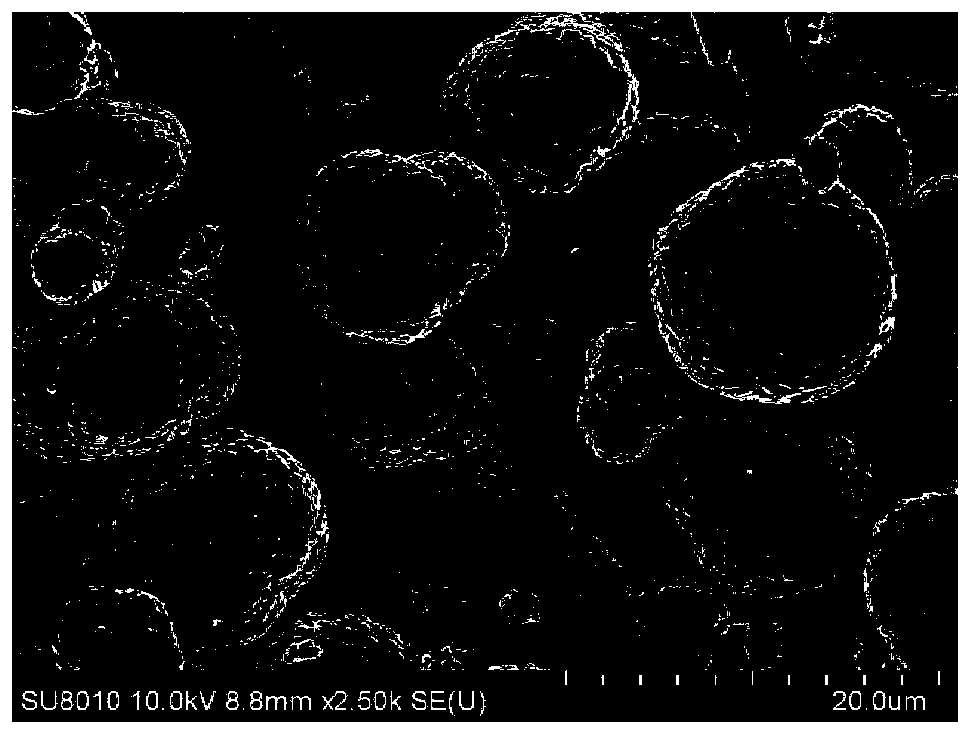

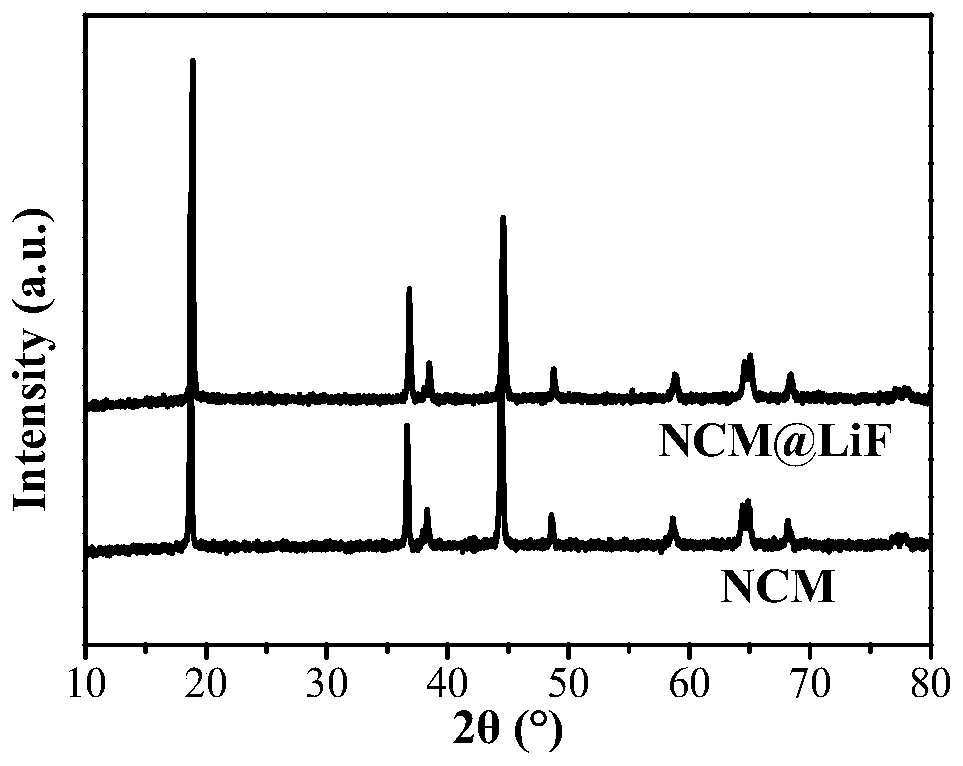

[0027] Weigh 1.0g LiNi 0.6 co 0.2 mn 0.2 o 2 Disperse the positive electrode material into 10g of fluorine-based ionic liquid 1-butyl-2,3-dimethylimidazolium tetrafluoroborate (alkylimidazolium tetrafluoroborate), and stir vigorously (500r / min) at room temperature 6h, then washed and filtered with absolute ethanol three times, dried at 60°C for 12h, and calcined at 300°C for 4h to obtain the fluorine-based ionic liquid surface-modified ternary cathode material of the present invention. After being modified by fluorine-based ionic liquids, its microscopic morphology is still maintained (see figure 1 and figure 2 ) and the crystal structure did not change (see image 3 ). The LiNi modified by fluorine-based ionic liquid 0.6 co 0.2 mn 0.2 o 2 The positive electrode material (NCM@LiF) was assembled into a battery. At 2.8-4.3V, 1C rate, its discharge specific capacity was 171.8mAh / g, and after 100 cycles, its discharge specific capacity was still 151.1mAh / g, showing excell...

Embodiment 2

[0029] Weigh 5.0g LiNi 0.8 co 0.1 mn 0.1 o 2 The positive electrode material is dispersed into 50g of fluorine-based ionic liquid 1-butyl-2,3-dimethylimidazolium tetrafluoroborate (alkylimidazolium tetrafluoroborate), and the sealing force is strong (800r / min) at 50°C Stir for 8 hours, wash and filter with absolute ethanol and acetone three times, dry at 60° C. for 12 hours, and calcined at 120° C. for 6 hours to obtain the fluorine-based ionic liquid surface-modified ternary cathode material of the present invention. After being modified by the fluorine-based ionic liquid, its microscopic morphology is still maintained and the crystal structure does not change (relevant morphology and crystal structure can refer to the corresponding drawings in Example 1, see figure 1 , figure 2 and image 3 ). The LiNi modified by fluorine-based ionic liquid 0.8 co 0.1 mn 0.1 o 2 The positive electrode material (NCM@LiF) was assembled into a battery, and at 2.8-4.3V, 0.1C rate, it...

Embodiment 3

[0031] Weigh 1.0g LiNi 0.3 co 0.2 mn 0.5 o 2 The material was dispersed into 5 g of ionic liquid N-alkylpyridine tetrafluoroborate, sealed and vigorously stirred (280 r / min) at room temperature for 12 h, then washed and filtered with absolute ethanol three times, and dried at 80° C. for 12 h. After calcining at 250° C. for 15 hours, the fluorine-based ionic liquid surface-modified ternary cathode material of the present invention is obtained. After being modified by the fluorine-based ionic liquid, its microscopic morphology is still maintained and the crystal structure does not change (relevant morphology and crystal structure can refer to the corresponding drawings in Example 1, see figure 1 , figure 2 and image 3 ). The LiNi modified by fluorine-based ionic liquid 0.3 co 0.2 mn 0.5 o 2 The positive electrode material is assembled into a battery. At 2.8-4.3V, 2C rate, its discharge specific capacity is 158.7mAh / g, and after 100 cycles, its discharge specific capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com