Tightness detection method for 90 degree fillet weld at CM node of LNG ship

The technology of an LNG ship and a detection method is applied in the field of vacuum detection devices, which can solve the problems of inability to detect the tightness of 90° welds, and achieve the effects of improving shipbuilding efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

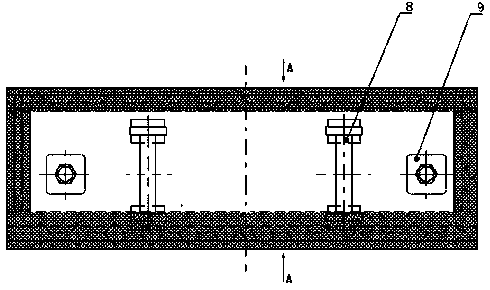

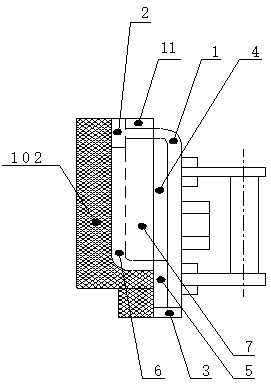

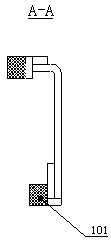

[0021] The vacuum device for detecting the tightness of the 90° fillet weld at the CM node in the LNG ship construction of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments, in order to understand its structure type and usage more clearly. , but it cannot be used to limit the protection scope of the present invention.

[0022] The invention is a tightness detection method for 90° fillet welds at CM nodes of LNG ships, and the method is developed based on a special equipment. The 90° angle at the CM node of the LNG ship is the angle between the platform plate and the longitudinal wall plate. The longitudinal wall plate stands on the platform plate for welding connection, and a weld seam is formed at the position of the included angle. The 90° fillet weld The seam is 30mm away from the end edge of the platform plate. This structure determines that the existing large-scale tightness testing equipment cann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com