Optical lens

An optical lens and lens technology, applied in the field of optical lenses, can solve the problems of inability to meet the camera equipment, complex lens structure, poor optical performance, etc., and achieve the effects of good cold processing process performance, low cost, and high mass production yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Table I

[0073]

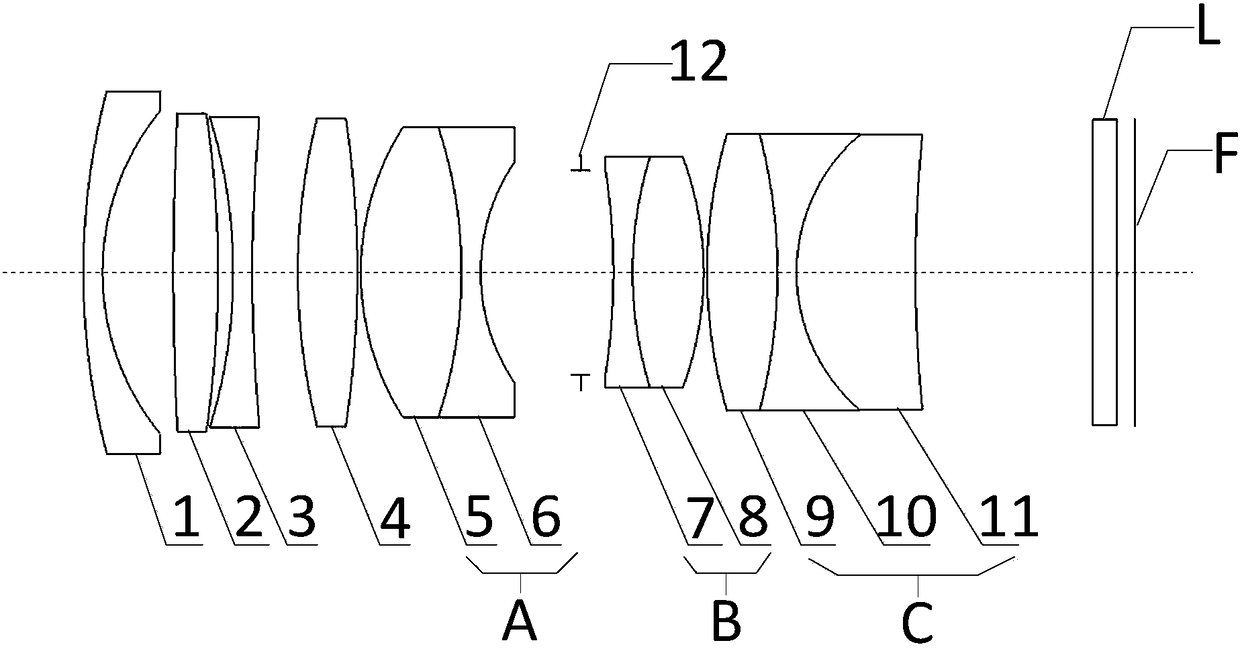

[0074] Among them, the effective focal length of the optical system provided in Table 1 is 11.216mm, the clear aperture is F / 1.65, and the total length of the optical system is 30.3mm. In Table 1, mirror numbers 1 and 2 represent the two mirror surfaces of lens 1 along the incident direction of light, mirror numbers 3 and 4 represent the two mirror surfaces of lens 2 along the incident direction of light, and mirror numbers 5 and 6 represent lens 3 The two mirrors along the incident direction of the light, the mirror numbers 7 and 8 represent the two mirrors of the lens 4 along the incident direction of the light, the mirror number 9 represents the mirror surface of the lens 5 facing the object side, and the mirror number 10 represents the distance between the lens 5 and the lens 6 The cemented surface, mirror number 11 represents the mirror surface of lens 6 facing the image side, mirror number 12 represents the mirror surface of lens 7 facing the...

Embodiment 2

[0086] Table II

[0087]

[0088] Among them, the effective focal length of the optical system provided in Table 1 is 11.245mm, the clear aperture is F / 1.65, and the total length of the optical system is 30.25mm. In Table 2, mirror numbers 1 and 2 represent the two mirror surfaces of lens 1 along the incident direction of light, mirror numbers 3 and 4 represent the two mirror surfaces of lens 2 along the incident direction of light, and mirror numbers 5 and 6 represent lens 3 The two mirror surfaces along the incident direction of the light, the mirror serial numbers 7 and 8 represent the two mirror surfaces of the lens 4 along the incident direction of the light, the mirror serial number 9 represents the mirror surface of the lens 5 towards the object side, and the mirror serial number 10 represents the mirror surface of the lens 5 and the lens 6 The glued surface, mirror number 11 represents the mirror surface of lens 6 facing the image side, mirror number 12 represents t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com