Speed reducer structure of lifting type platform lifting system

A reduction device and platform lifting technology, applied in the field of lifting systems, can solve the problems of lack of experience in the design and manufacture of heavy-duty and large-speed ratio reduction mechanisms, and difficulty in design and manufacture, and achieve the effects of light weight, weight reduction, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

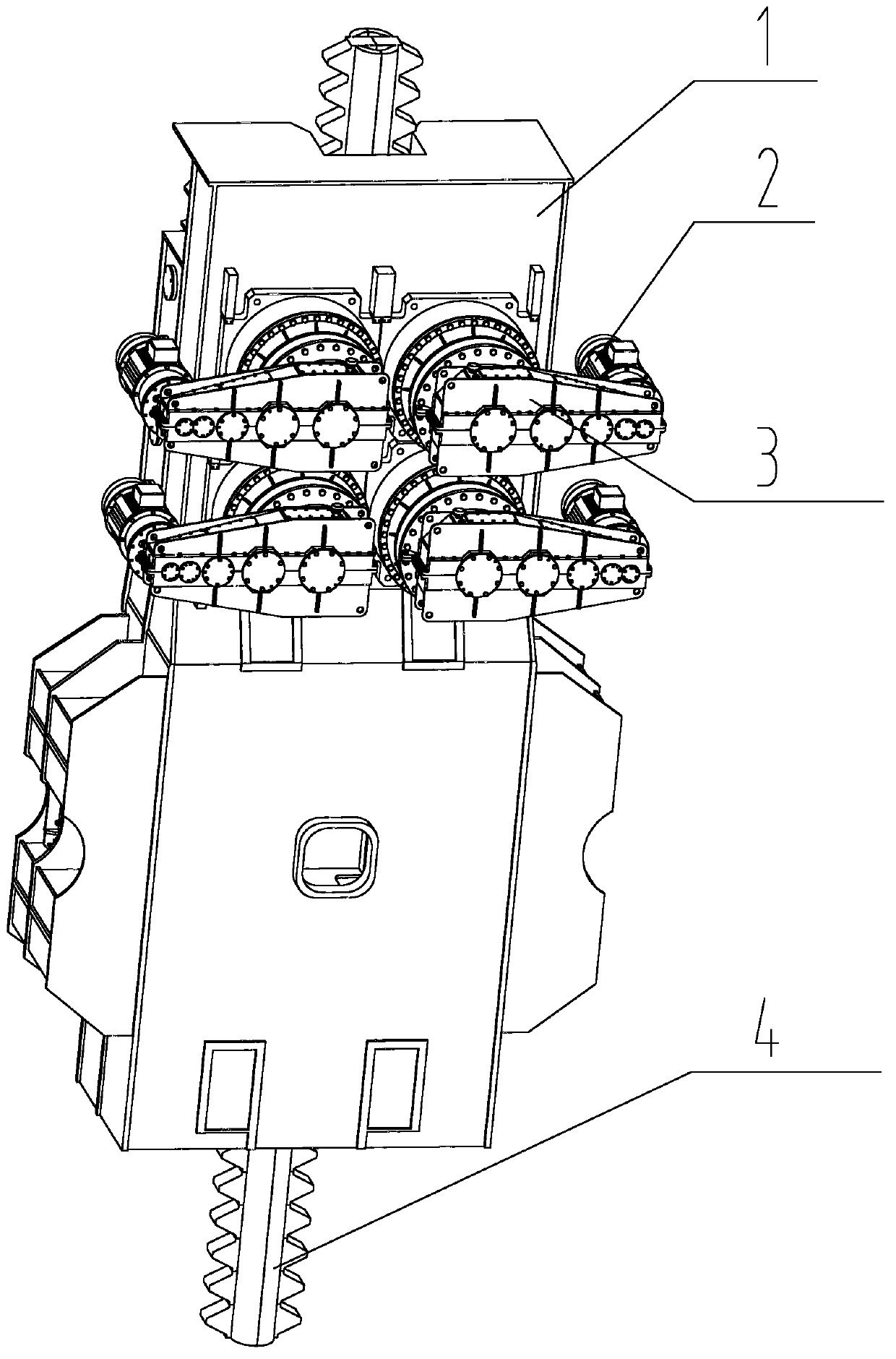

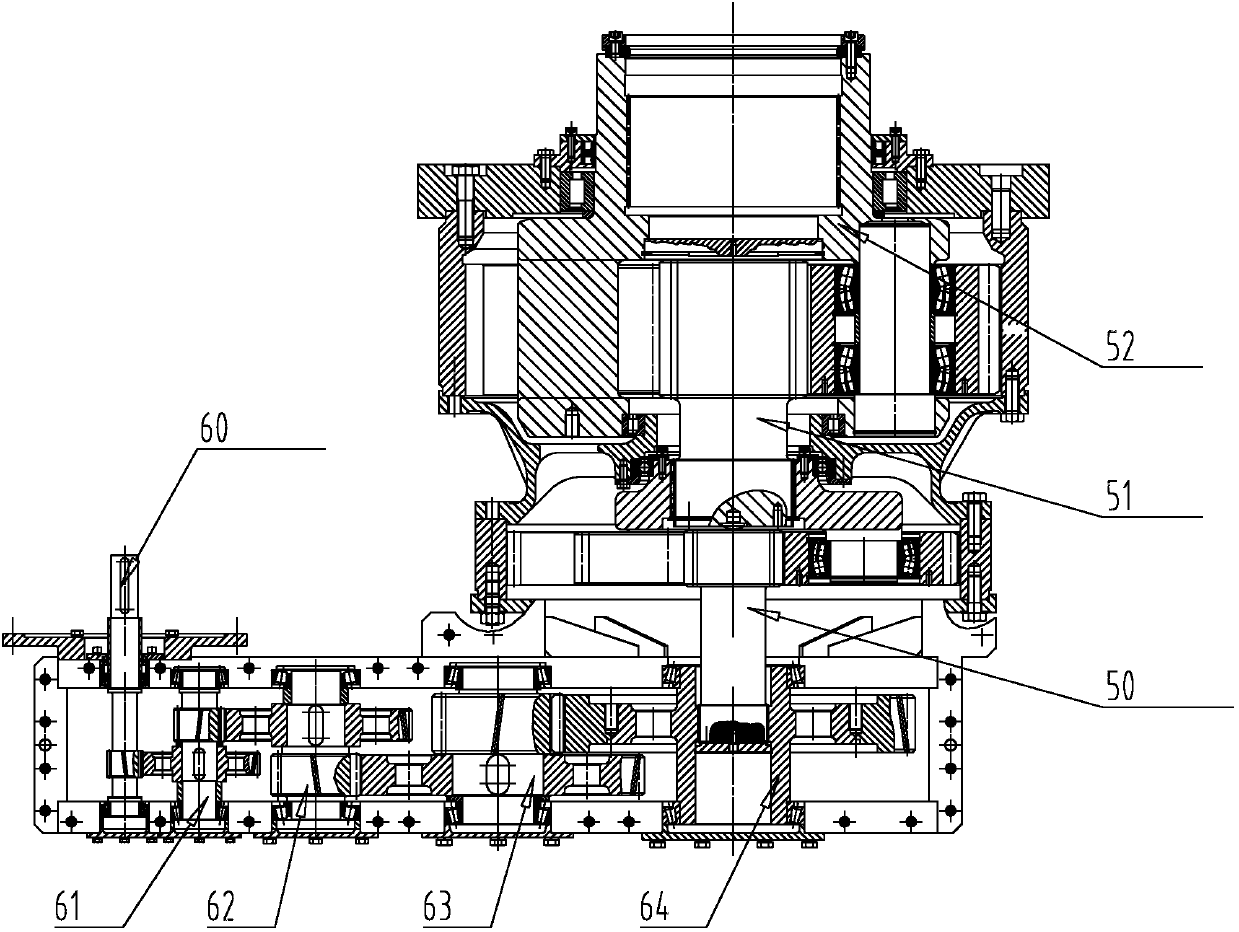

[0017] combine figure 1 with figure 2 , the present invention includes a pile box 1 and a speed reduction device 3, the speed reduction device 3 includes a helical gear reducer and a planetary gear reducer, the motor 2 is connected with the input shaft 60 of the helical gear reducer, and through a first-stage helical gear reduction 61, a second-stage helical gear The deceleration 62, three-stage helical reduction 63 and four-stage helical reduction 64 output the torque to the input shaft 50 of the planetary gear reducer, and the planetary gear reducer passes through the first-stage planetary reduction 51 and the second-stage planetary reduction 52 to transmit the torque through the lifting gear Transport to the leg rack 4, the leg rack 4 is connected to the leg, and the lifting of the leg drives the platform up and down. The lifting gear and the leg rack 4 are arranged in the pile box 1 . The whole composed of the helical gear reducer, the planetary gear reducer and the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com