Steel bushing inlay casting method for motor casing front and rear end covers and front and rear end covers

A technology of front and rear ends and motor shells, which is applied in the field of motor shell end cover preparation, can solve the problems of increasing bearing position hardness and bearing position deformation, and achieves the effects of increasing strength, increasing hardness and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

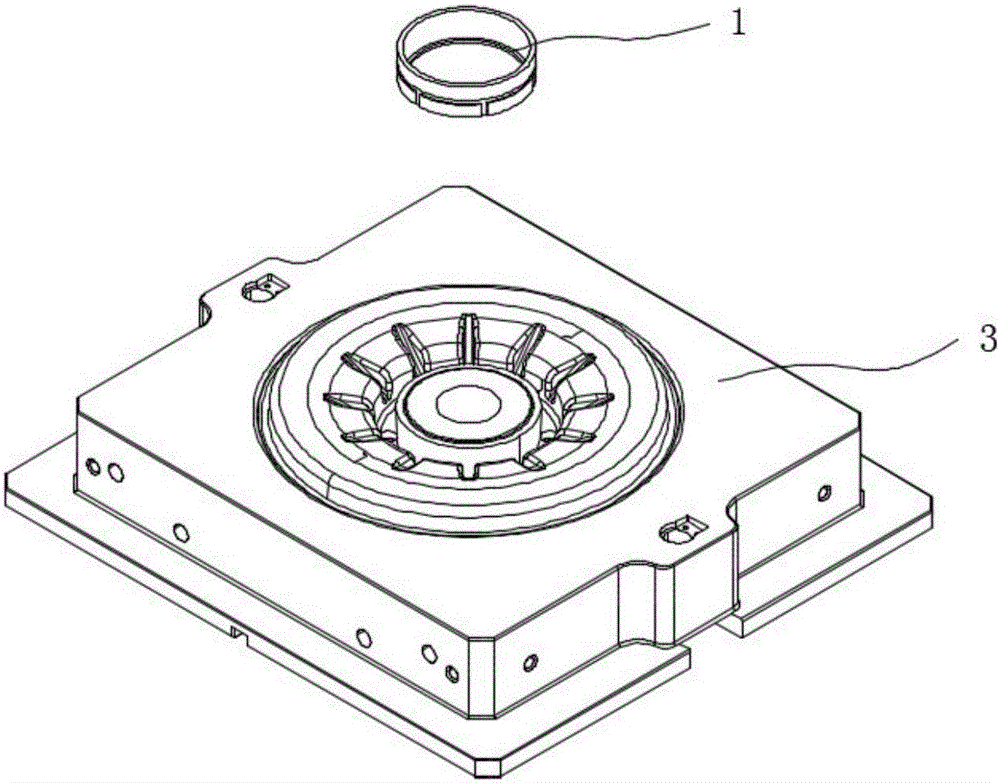

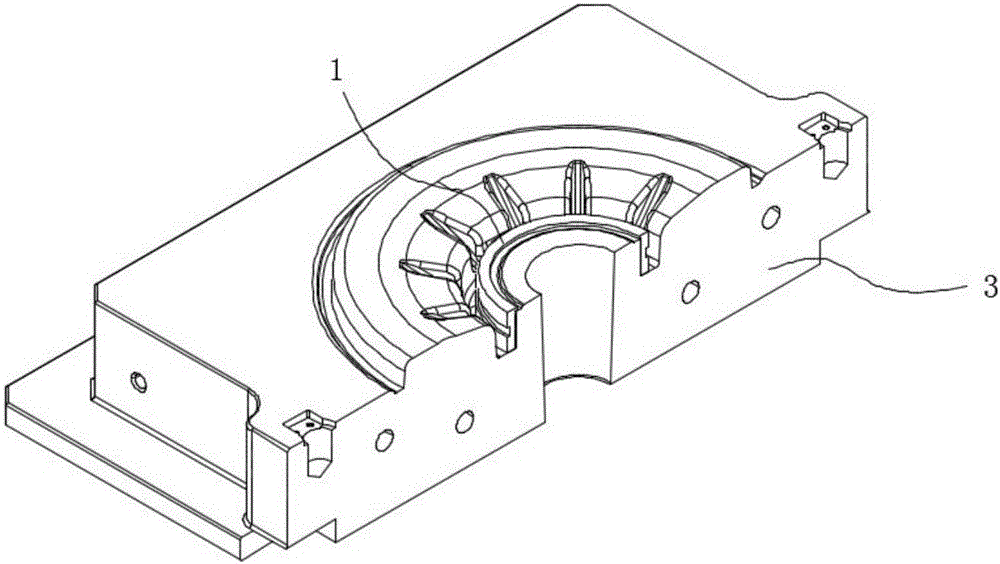

[0029] Examples, see Figure 1~4 , the method for casting the front and rear end covers of the motor casing with steel sleeves provided in this embodiment includes the following steps:

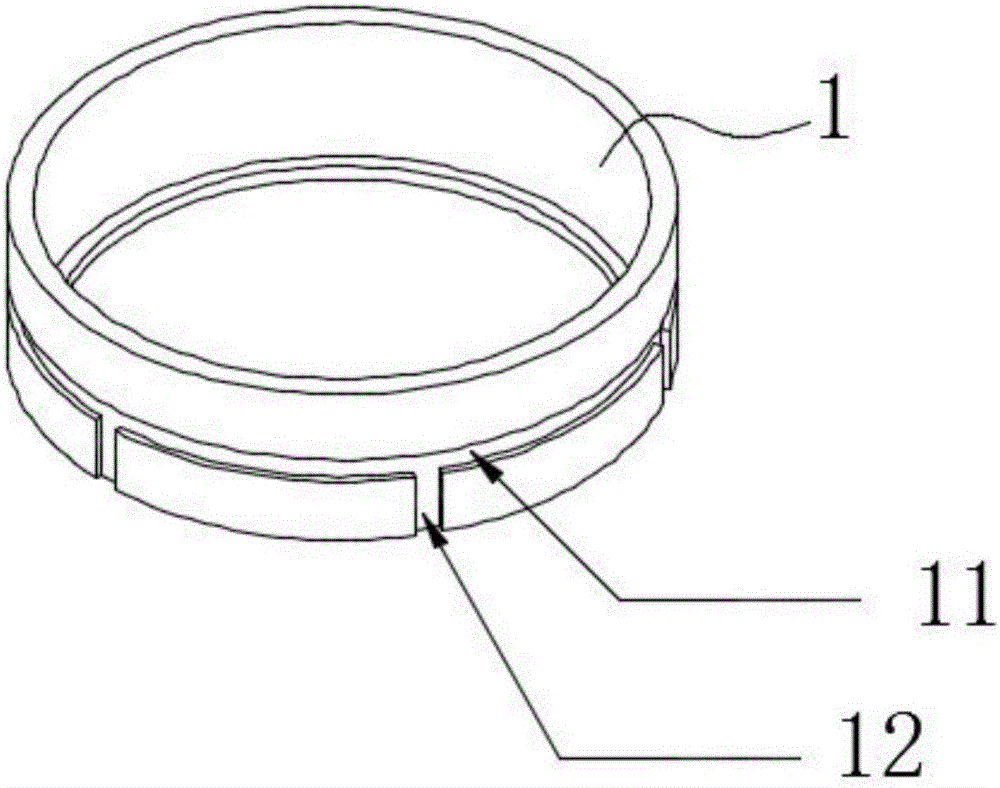

[0030] (1) Steel sleeve 1 is prepared, and steel sleeve 1 is provided with anti-off groove 11 and anti-skid groove;

[0031] (2) Plasma heating equipment is installed, and the steel sleeve 1 is heated at an ultra-high temperature through the electromagnetic induction coupled plasma of the plasma heating equipment, and the steel sleeve 1 is heated by high-frequency plasma for 8 to 12 seconds, and the temperature of the steel sleeve 1 reaches above 400°C ;Set the high-frequency plasma generating equipment, which is composed of two coaxial quartz tubes, and the outer tube is covered with a spiral tube wound by a thin copper tube, through which a high-frequency current is passed to generate a high-frequency alternating magnetic field in the spiral tube , the change of magnetic flux induces an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com