Powder metallurgy iron-based material suitable for high speed boring and preparation method

A technology of powder metallurgy and iron-based materials, which is applied in the field of powder metallurgy iron-based materials and its preparation, can solve the problems of accelerated wear, poor machinability, prone to chipping, etc., and achieve extended service life, low manufacturing cost, stable and reliable high-speed Effect of Boring Machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

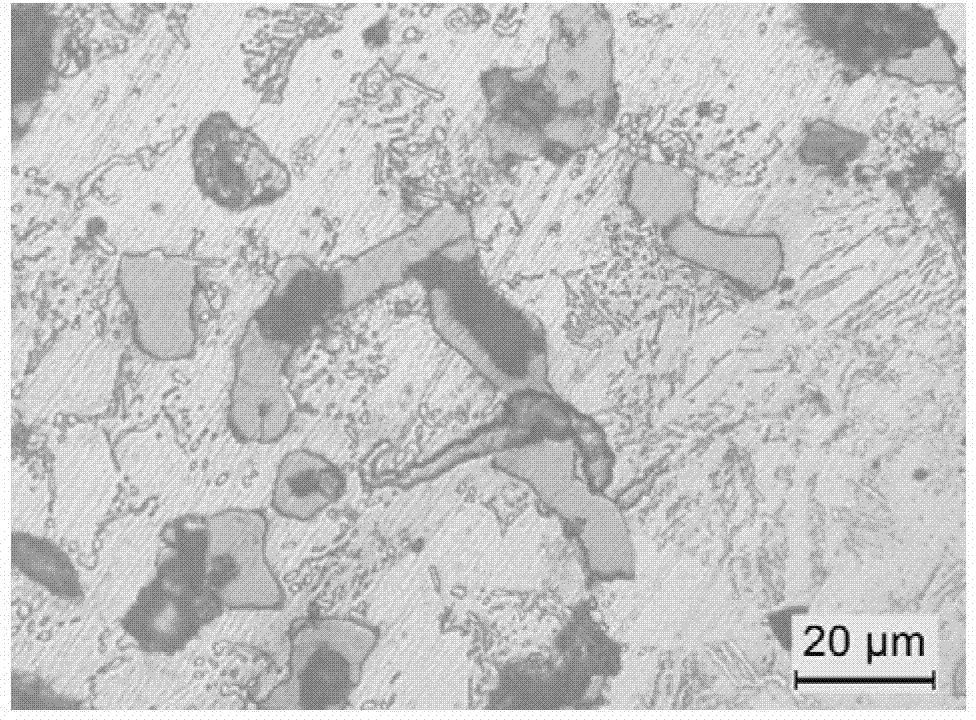

Embodiment 1

[0034] Prepare a powder metallurgy iron-based material suitable for high-speed boring processing, including: iron 96wt%, copper 1wt%, manganese sulfide 1wt%, molybdenum disulfide 0.8wt%, calcium fluoride 0.3wt%, magnesium fluoride 0.3wt% %, graphite 0.6wt%. Its preparation process includes the following steps: put the weighed materials into a V-type mixer for 60 minutes; press the blank in a steel mold with a pressing pressure of 500 MPa and a holding time of 3 seconds; , the heating rate is 8-10°C per minute, and the pressed blank is evenly heated from room temperature to 1050°C for 1 hour, then kept at 800-900°C for 1 hour, and then uniformly cooled to below 200°C to obtain sintered powder metallurgy iron base Material.

[0035] Properties of the sintered powder metallurgy iron-based material prepared in this example: density 6.90g / cm 3 , hardness 70-90HB, tensile strength 280-320MPa; high-speed boring processing performance is good, when using cubic boron nitride cutter g...

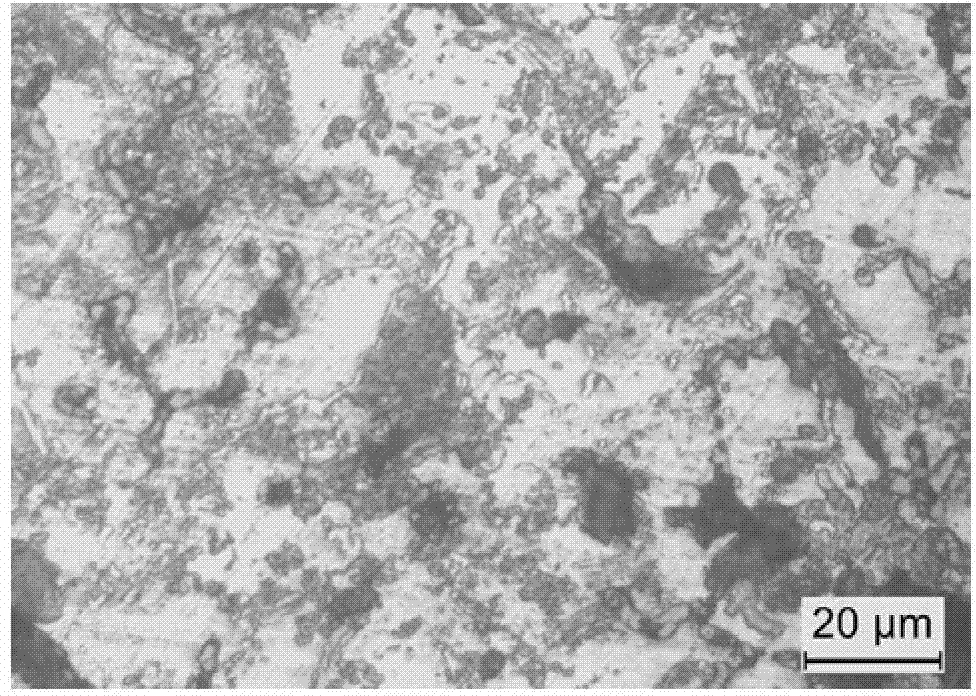

Embodiment 2

[0037] Prepare a powder metallurgy iron-based material suitable for high-speed boring processing, including: iron 95wt%, copper 2wt%, manganese sulfide 1wt%, molybdenum disulfide 0.8wt%, calcium fluoride 0.3wt%, magnesium fluoride 0.3wt% %, graphite 0.6wt%. The preparation process includes the following steps: put the weighed materials into a V-shaped mixer for 60 minutes; press the blank in a steel mold with a pressing pressure of 600 MPa and a holding time of 3 seconds; , the heating rate is 8-10°C per minute, and the pressed blank is evenly heated from room temperature to 1100°C for 1 hour, then kept at 800-900°C for 1 hour, and then uniformly cooled to below 200°C to obtain sintered powder metallurgy iron base Material.

[0038] Properties of the sintered powder metallurgy iron-based material prepared in this example: density 6.95g / cm 3 , hardness 80-100HB, tensile strength 320-380MPa; high-speed boring processing performance is good, when using cubic boron nitride cutte...

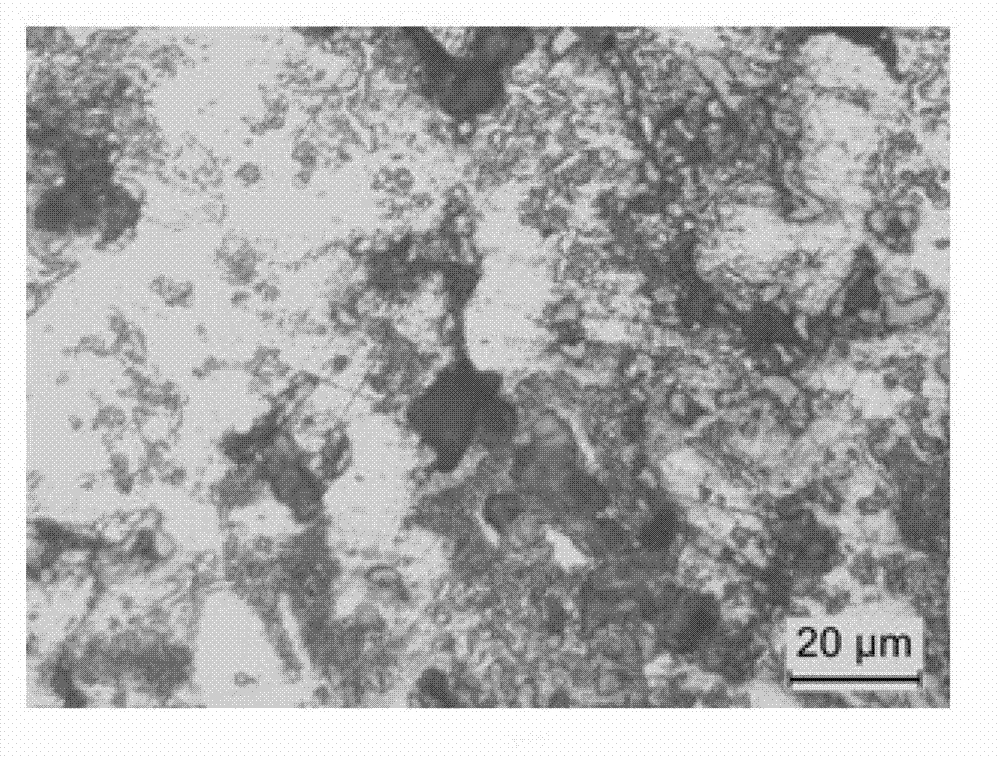

Embodiment 3

[0040] Prepare a powder metallurgy iron-based material suitable for high-speed boring processing, including: iron 94wt%, copper 2wt%, manganese sulfide 2wt%, molybdenum disulfide 0.6wt%, calcium fluoride 0.3wt%, magnesium fluoride 0.3wt% %, graphite 0.8wt%. The preparation process includes the following steps: put the weighed materials into a V-shaped mixer for 90 minutes; press the blank in a steel mold with a pressing pressure of 700 MPa and a holding time of 3 seconds; , the heating rate is 8-10°C per minute, and the pressed blank is evenly heated from room temperature to 1050°C for 1 hour, then kept at 800-900°C for 1 hour, and then uniformly cooled to below 200°C to obtain sintered powder metallurgy iron base Material.

[0041] Properties of the sintered powder metallurgy iron-based material prepared in this example: density 6.85g / cm 3, hardness 70-90HB, tensile strength 270-310MPa; high-speed boring processing performance is good, when using cubic boron nitride cutter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com