Vertical cavity surface emitting laser and method for fabricating the same

A vertical cavity surface emission and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as poor laser stability and yield, and achieve easy-to-achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

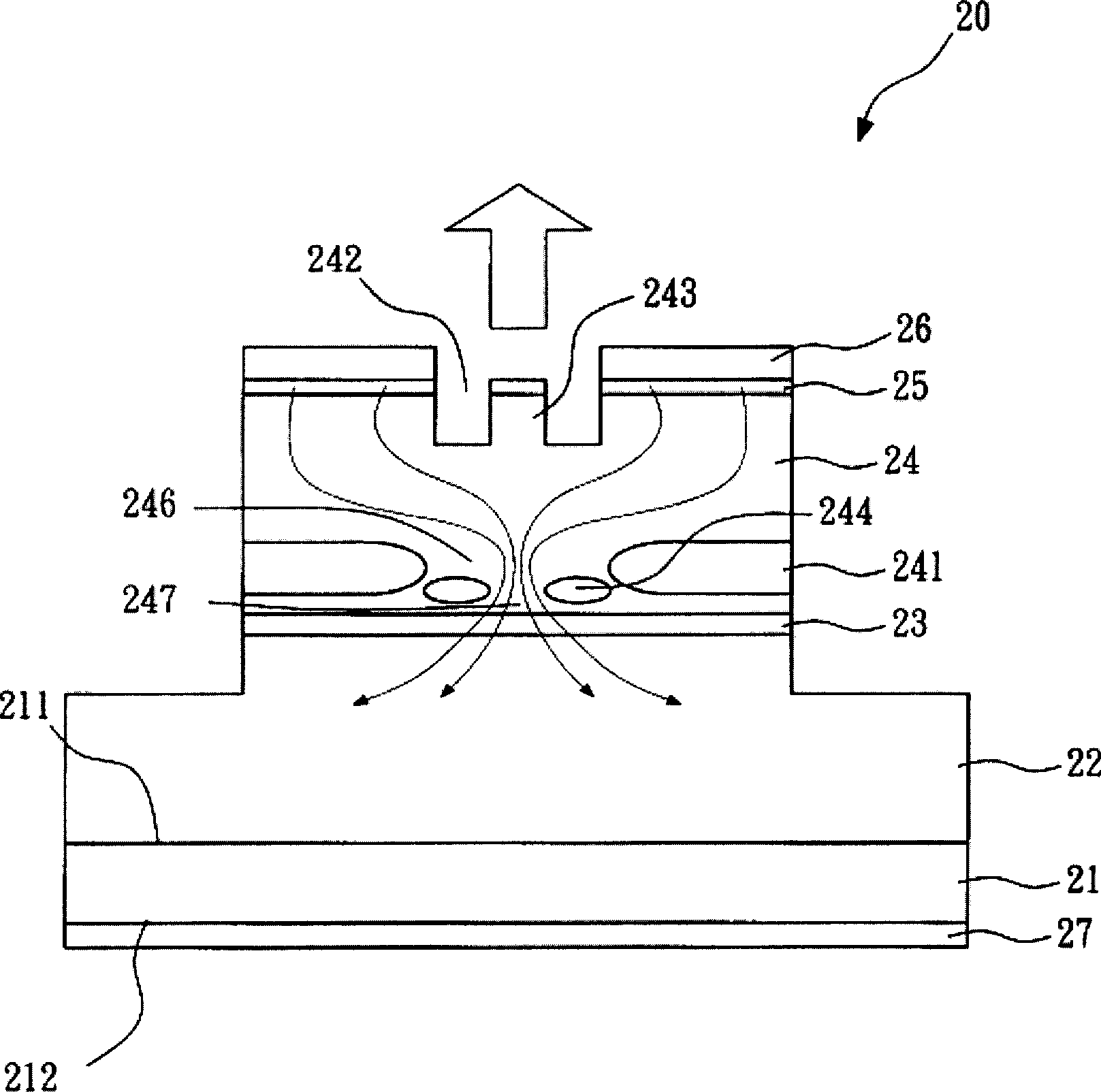

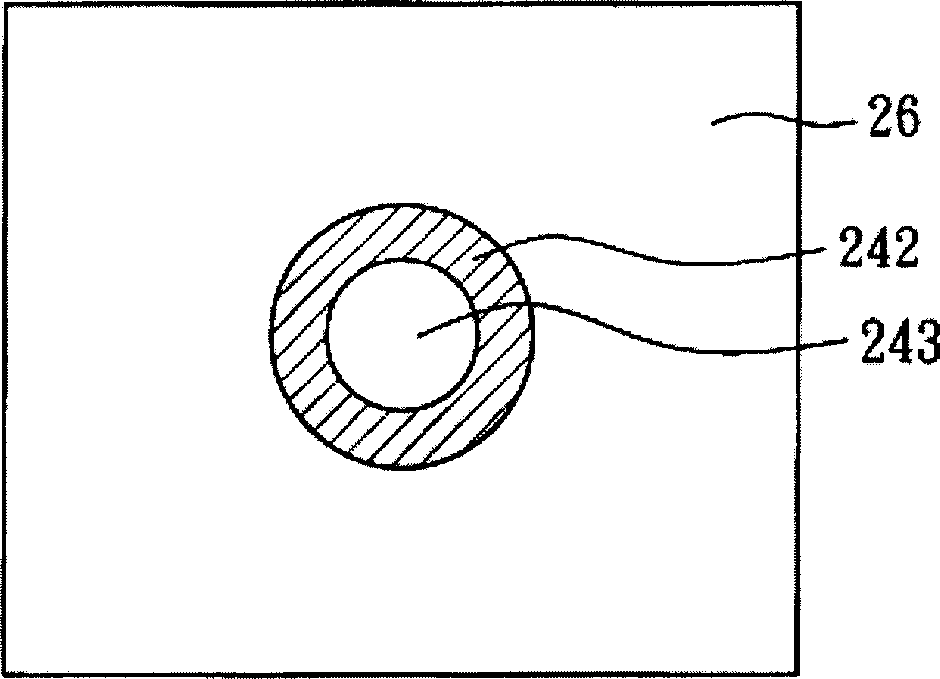

[0012] see figure 2 According to the present invention, the VCSEL 20 includes: a substrate 21, a first reflector 22, an active layer 23, a second reflector 24, a first electrode layer 26 and a second electrode layer 27 . Substrate 21 can be a n + Type GaAs or InP substrate. The substrate 21 has a first surface 211 and a second surface 212 . The first reflector 22 is formed on the first surface 211 of the substrate 21 . The first reflector 22 is a distributed Bragg reflector (DBR) having many pairs of planes. Each pair of layers is formed as graded silicon-doped n + Type Al x Ga (1-x) As / AlAs structure, where x varies from 0.12 to 1, and 1-x varies from 0.88 to 0.

[0013] The active layer 23 is formed on the first reflector 22 . The active layer 23 includes a plurality of undoped GaAs and Al y Quantum wells of GaAs, where y varies from 0.3 to 0.6. The second reflector 24 is formed on the active layer 23 . The second reflector 24 is a distributed Bragg reflector (D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com