Rotary friction coordination module for driving part of cam splitter

A technology of driving components and rotating friction, which is applied to transmission parts, mechanical equipment, belts/chains/gears, etc., and can solve problems such as poor running effect, impact, abnormal friction and rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

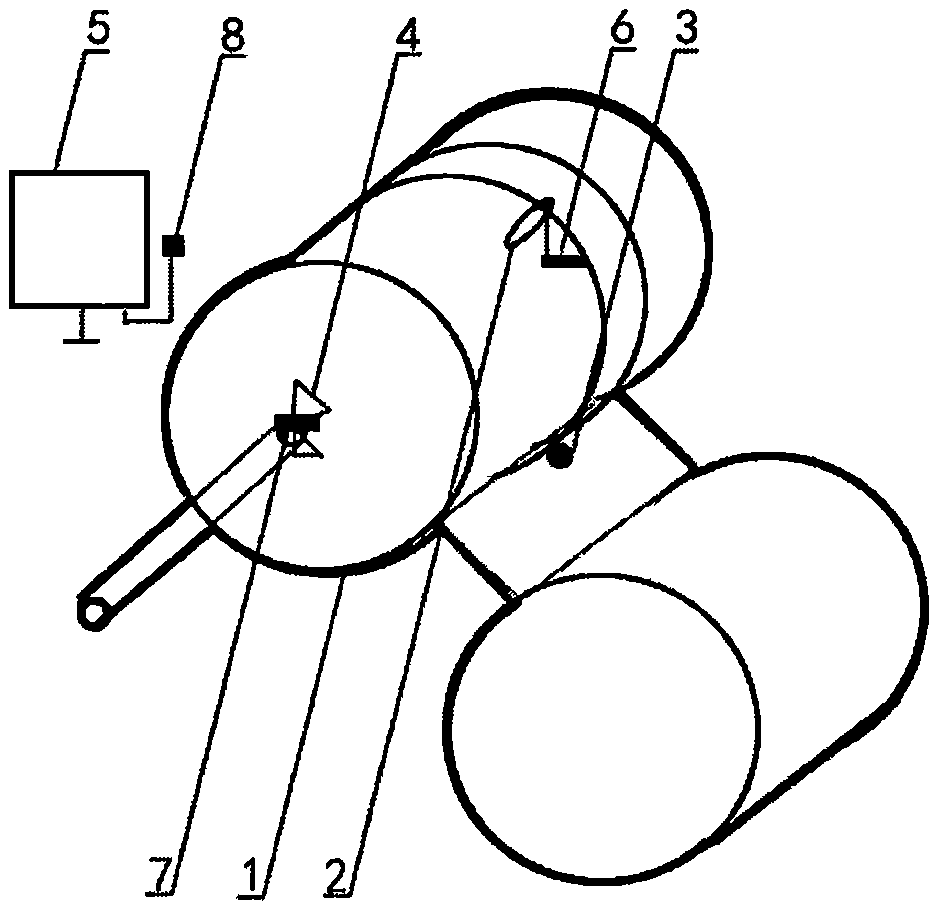

[0012] Embodiment: as shown in the accompanying drawing. The rotary friction coordination module of the driving part of the cam splitter includes a body (1), on which a slip sensing module (2), a gap sensing module (3), a rotation sensing module (4), and a management module (5 ), during operation, the slip sensing module (2) is set on the gear part to sense its slippage, the gap sensing module (3) senses the gap value of the gear part, the rotation sensing module (4) is set on the force shaft, and the management module (5) Process comprehensive information.

[0013] The driving part of the cam splitter rotates the friction coordination module, and the fastening friction module (6) is arranged on the slip sensing module (2) to increase the friction of the gear parts and fasten its position.

[0014] The driving part of the cam splitter rotates the friction coordination module, and the pressure sensing module (7) is arranged on the rotation sensing module (4) to sense the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com