Turning plate structure of spray room

A technology of flipping and spraying booths, which is applied in the fields of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient operation, time-consuming and laborious, reducing work efficiency, etc., to achieve easy and simple operation and improve color changing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it should be noted that the description of the following embodiments is schematic and does not constitute a specific limitation to the present invention.

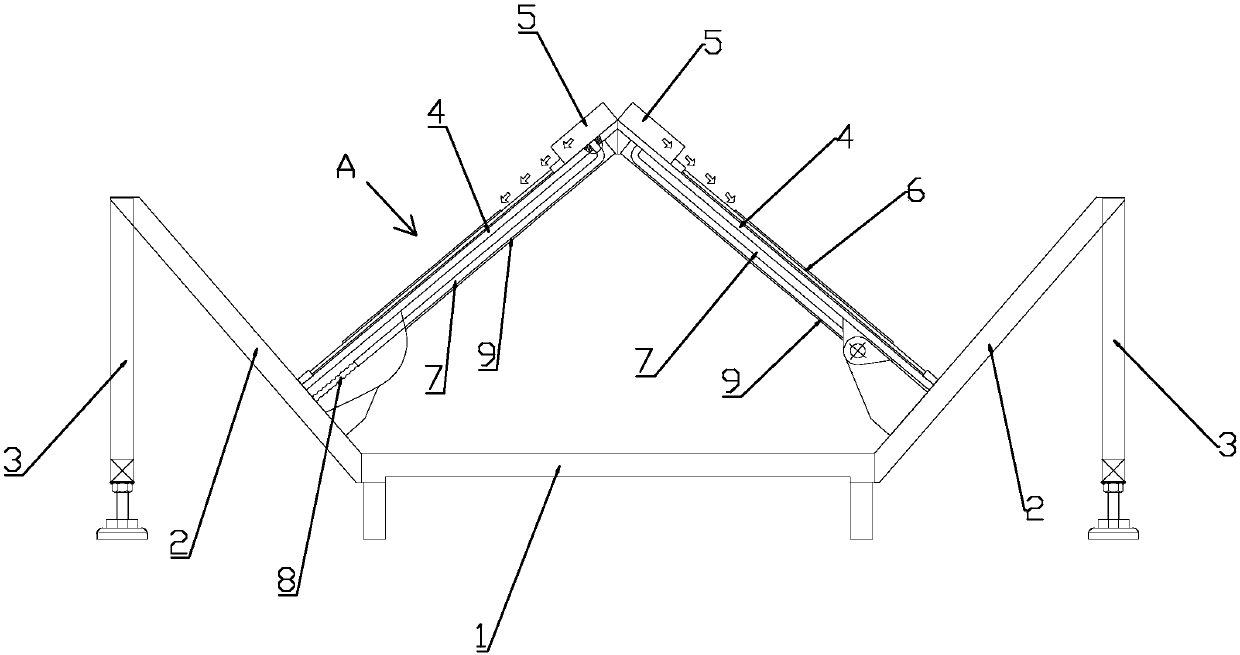

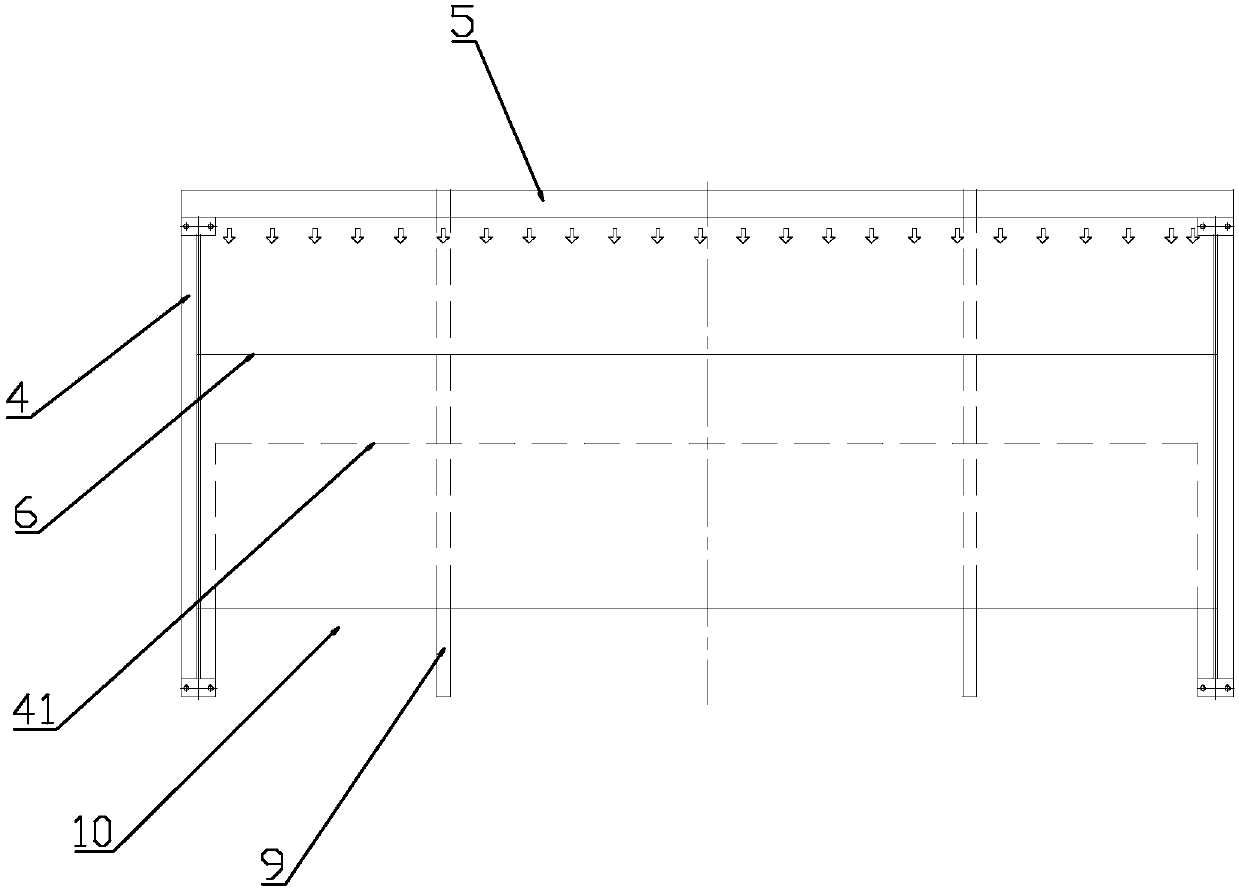

[0017] refer to figure 1 and figure 2 , a spray booth flap structure of the present invention, comprising: a base plate 1, two bottom side plates 2 connected to the two ends of the base plate 1 to form an outward opening, the bottom side plate 2 is provided with a Support the fixed support base 3, the inner side of the two bottom side panels 2 is hinged with a flap 4, and the other ends of the two flaps 4 abut against each other, the bottom panel 1, the two bottom side panels 2 and the two flaps 4 The air knife 5 is arranged at the end of the turning plate 4 away from the bottom side plate 2, and the air outlet direction of the air knife 5 is obliquely blowing downward to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com