Intelligent goods sorting system and goods sorting method

An intelligent and commodity technology, applied in the field of warehousing and picking, can solve the problems of cumbersome picking and inspection, low work efficiency, slow picking speed, etc., and achieve the effect of avoiding wrong delivery of goods, improving work efficiency, and scientific and reasonable layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

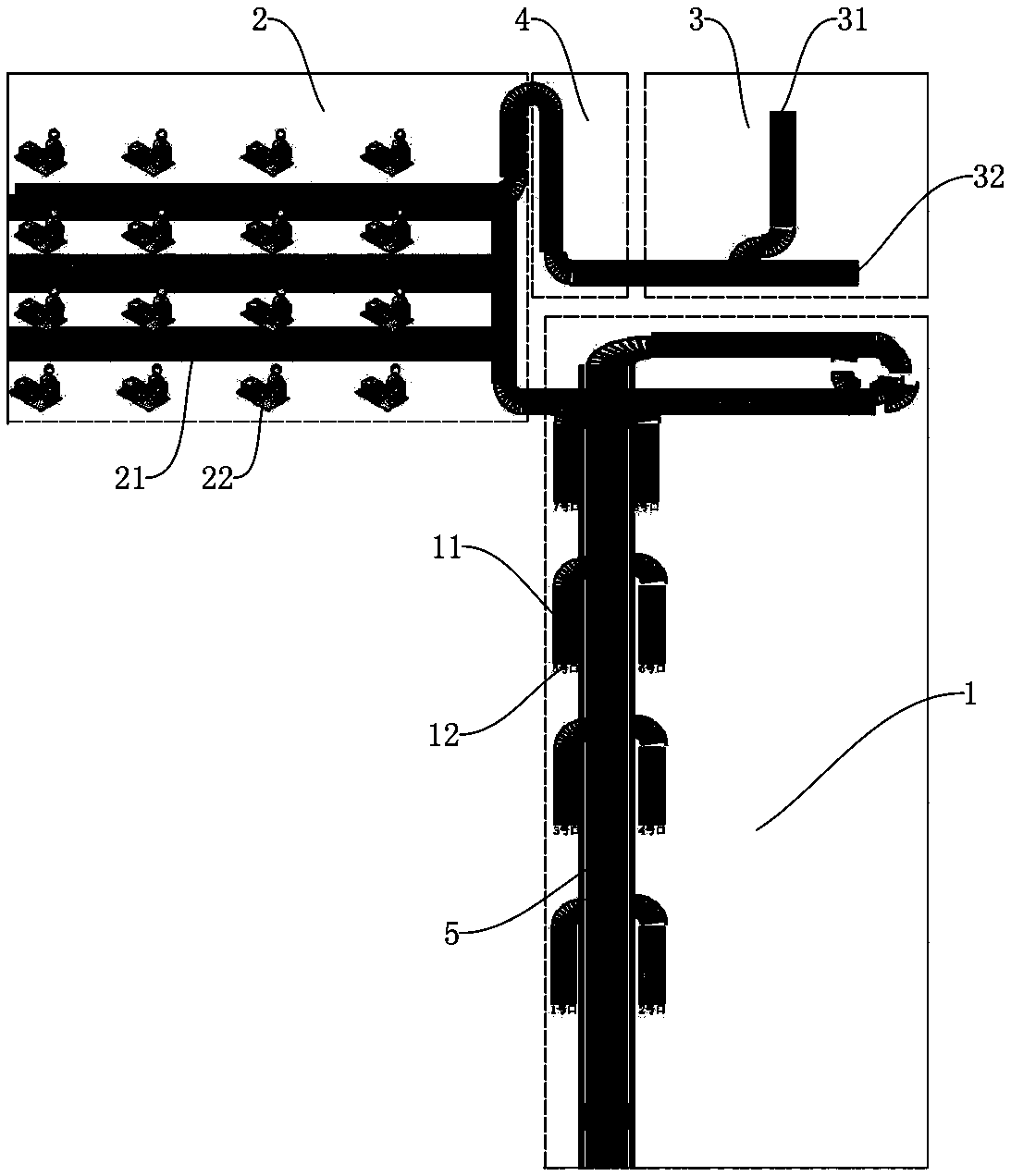

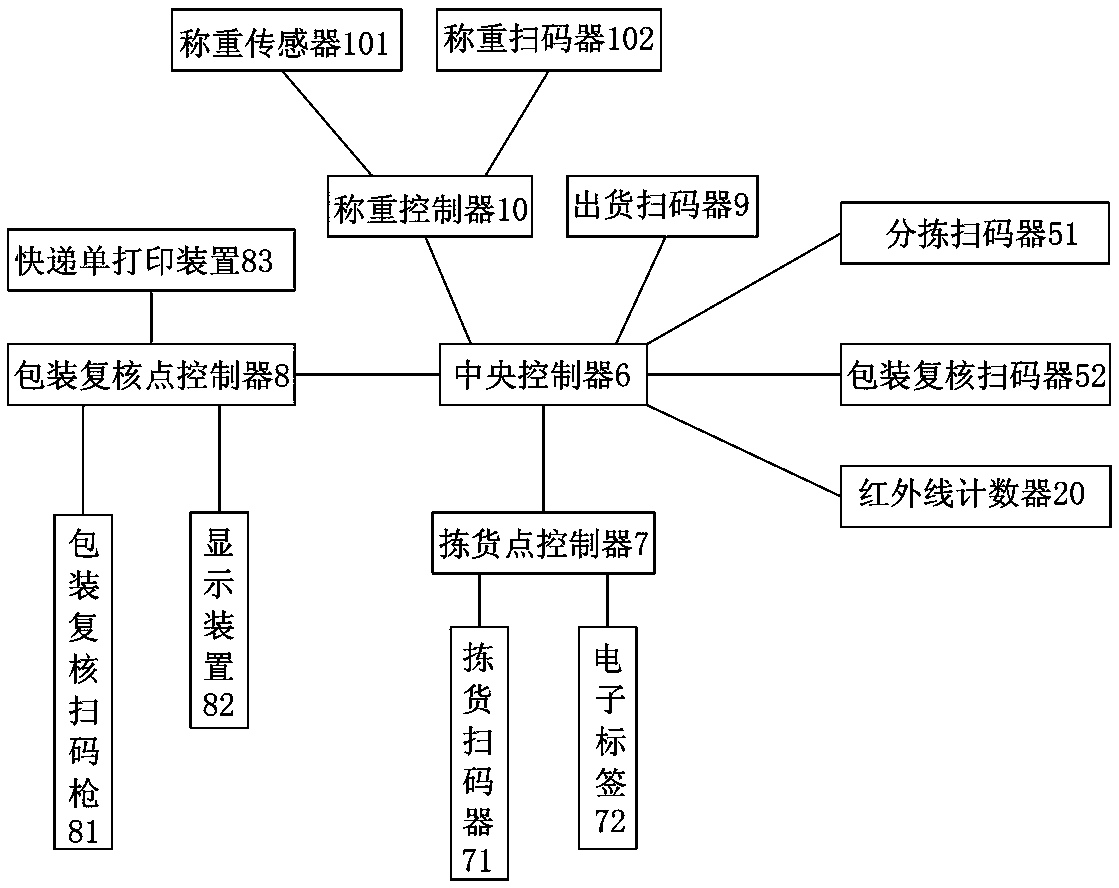

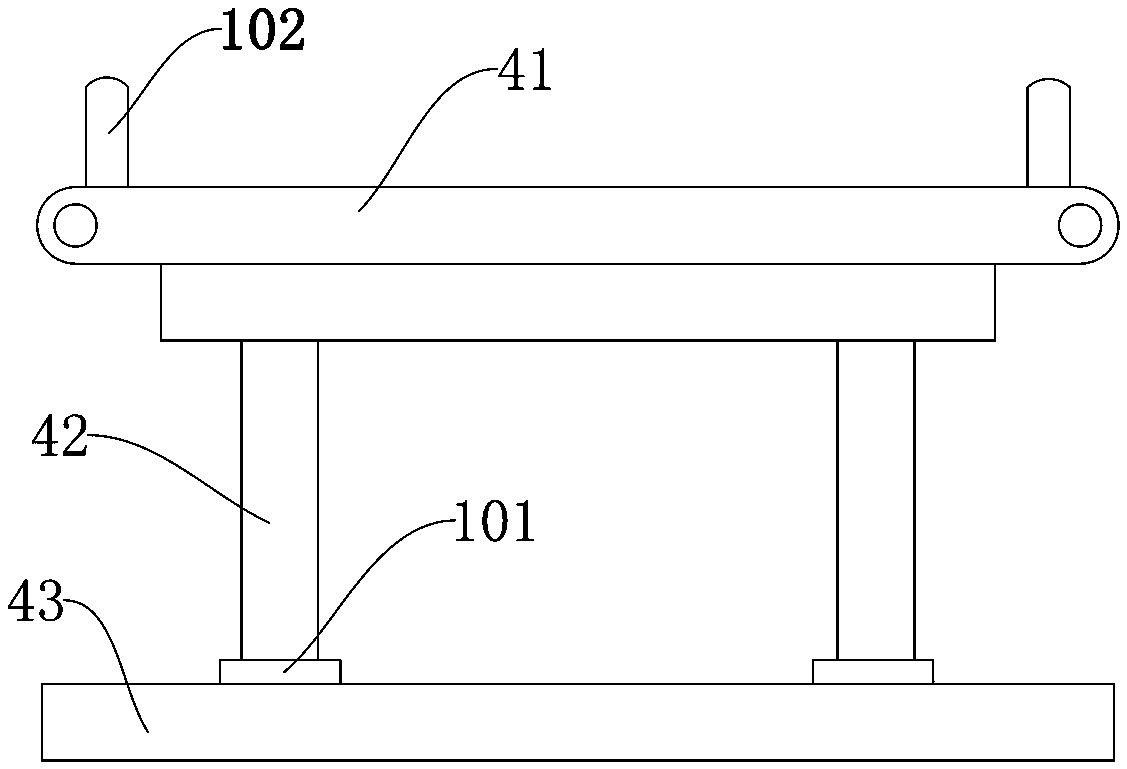

[0033] Such as figure 1 As shown, an intelligent picking system in this embodiment has a main conveyor belt 5 connected by multiple conveyor belts, and is equipped with a number of turnover boxes that can be rotated on the conveyor belt, and code areas are provided around the turnover box casing. The starting end of the main conveyor belt 5 is provided with an associated code scanner capable of communicating with the central controller 6. Along the conveying direction of the main conveyor belt 5, there are picking area 1, packaging review area 2, weighing verification area 4, and shipping area 3. .

[0034] In this embodiment, several picking points 11 are arranged in the picking area 1 , and a picking conveyor belt 12 extending from the main conveyor belt 5 to each picking point 11 is provided. Each picking point 11 is provided with a review scanning code gun 71 and a number of shelves, and electronic labels 72 are provided on the shelves corresponding to each type of goods,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com