Battery temperature adjustment device and temperature adjustment method, and temperature adjustment battery

A temperature control device and battery technology, which is applied in the field of temperature control systems, can solve problems such as easy explosion, high energy consumption, and low heat dissipation rate of batteries, and achieve the effects of prolonging service life, saving energy, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

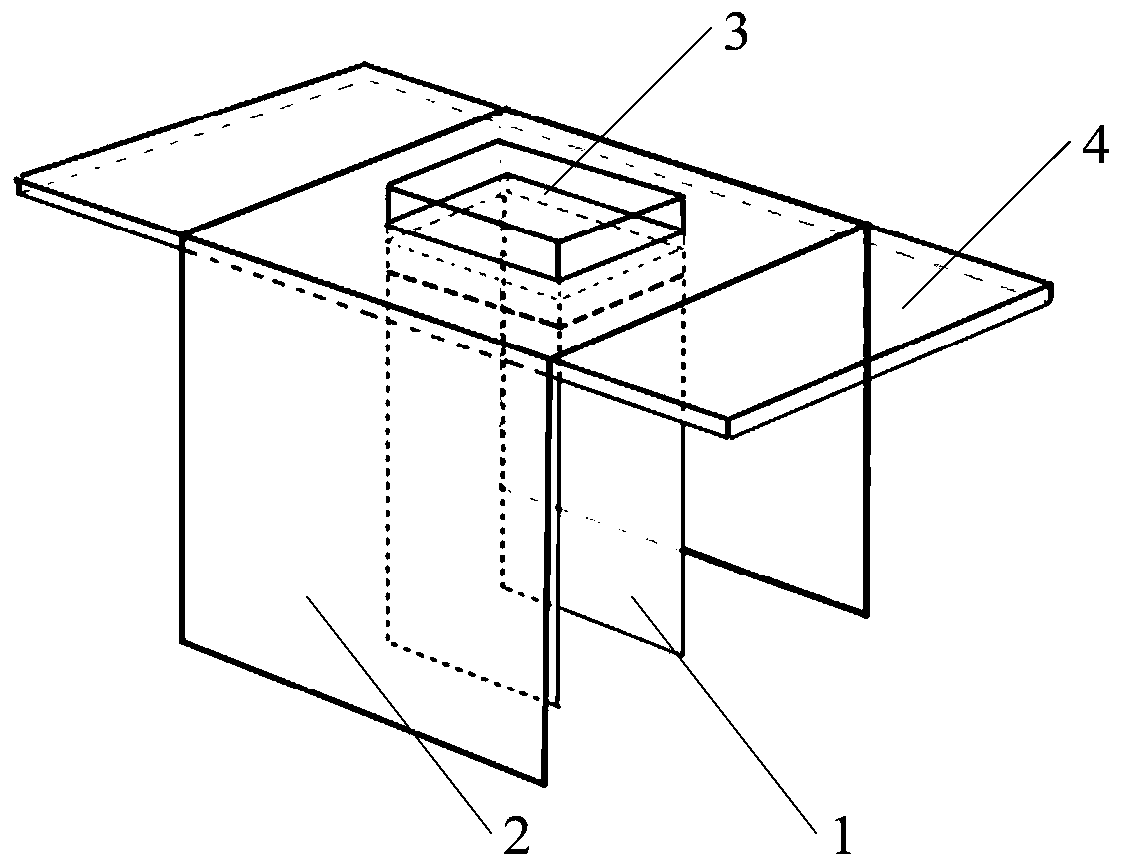

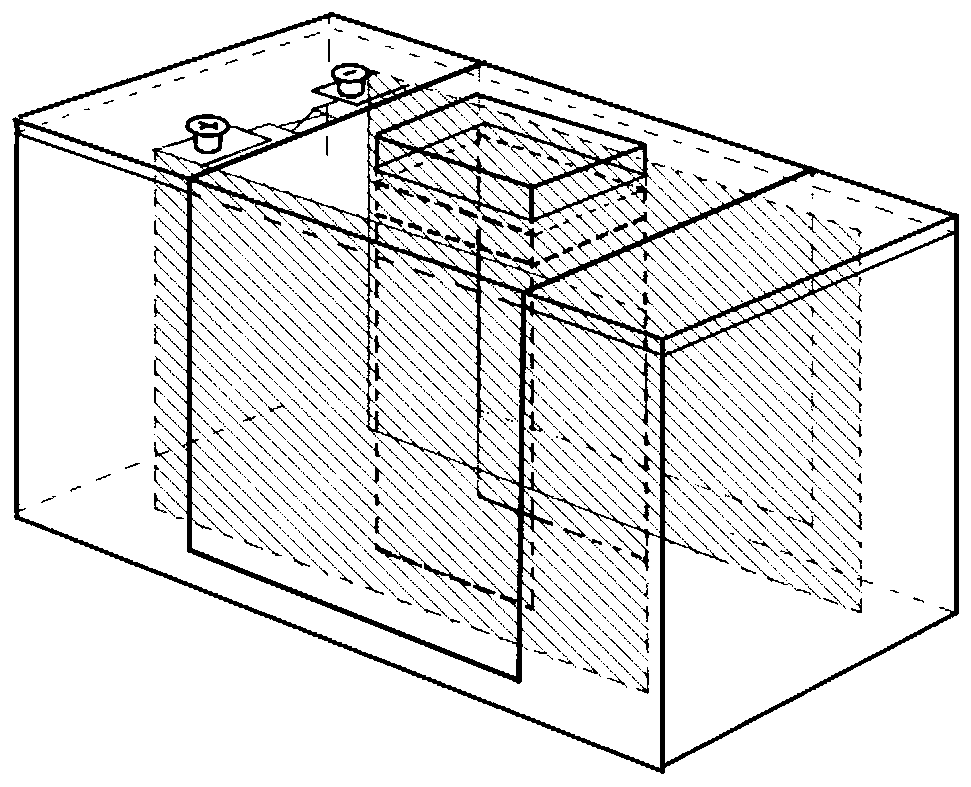

[0036] This embodiment provides a battery temperature regulating device, such as figure 2 As shown, it includes a bidirectional switch, an inner heat exchange plate 1, an outer heat exchange plate 2, and a semiconductor element 3 with a heating mode, a cooling mode, and an off mode. The outer heat exchange plate 2 is in contact with the outer surface of the battery, and the inner heat exchange plate 1 Located inside the battery, both the outer heat exchange plate 2 and the inner heat exchange plate 1 are in contact with the semiconductor element 3; the bidirectional switch is used to control the semiconductor element 3 in heating mode, cooling mode or off mode.

[0037] When the battery temperature is too high (the battery temperature is above 45°C), the bidirectional switch switches the semiconductor element 3 to cooling mode to cool down the battery; when the battery temperature is too low (the battery temperature is below 5°C), the bidirectional switch switches the semicond...

Embodiment 2

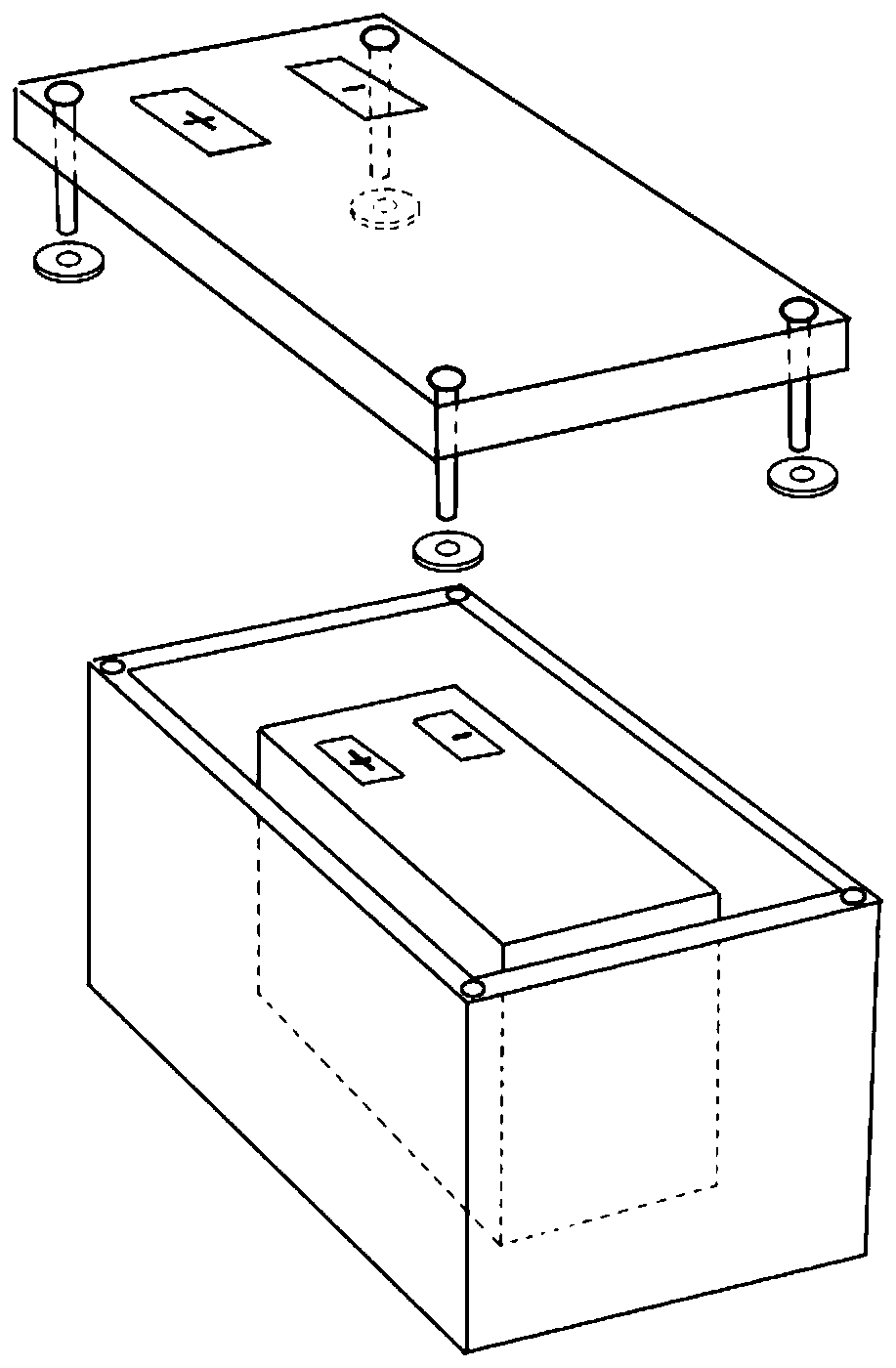

[0068] This embodiment provides an automatic temperature-regulating battery, such as image 3 As shown, the battery temperature regulating device in the first embodiment is included.

[0069] Compared with the prior art, the beneficial effects of the automatic temperature-regulating battery provided in this embodiment are basically the same as those of the battery temperature-regulating device in Embodiment 1, and will not be repeated here.

Embodiment 3

[0071] This embodiment provides a battery temperature regulation method, such as Figure 4 As shown, it includes the following steps: the bidirectional switch controls the semiconductor element to be in cooling mode or heating mode, the semiconductor element exchanges heat with the inside of the battery through the inner heat exchange plate, and exchanges heat with the outer surface of the battery through the outer heat exchange plate, and the battery For tempering.

[0072] Compared with the prior art, the beneficial effects of the battery temperature regulation method provided in this embodiment are basically the same as those of the battery temperature regulation device in Embodiment 1, and will not be repeated here.

[0073] Specifically, when the battery temperature adjustment device includes a controller, an internal temperature sensor, an explosion-proof box and an acceleration sensor, the above battery temperature adjustment method includes the following steps:

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com