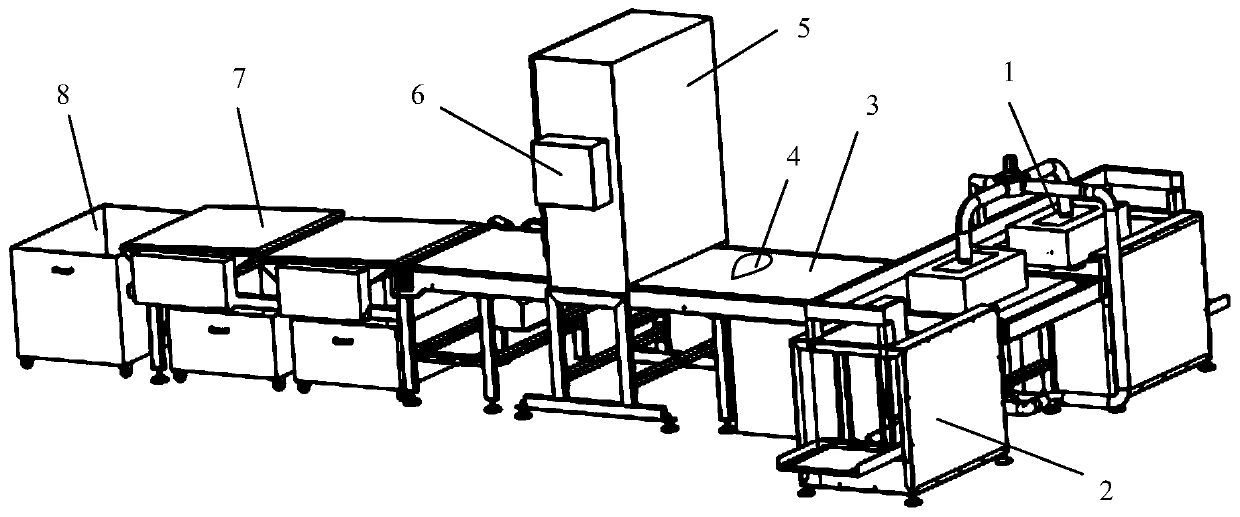

A detection and classification device and detection method suitable for fresh tobacco leaves

A grading device and fresh tobacco leaf technology, applied in the field of detection and grading devices for fresh tobacco leaves, can solve the problems of difficulty in realizing fully automatic operation, unsuitable methods and device structures, etc., and achieve convenience for subsequent use, simple manual operation, and improved detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

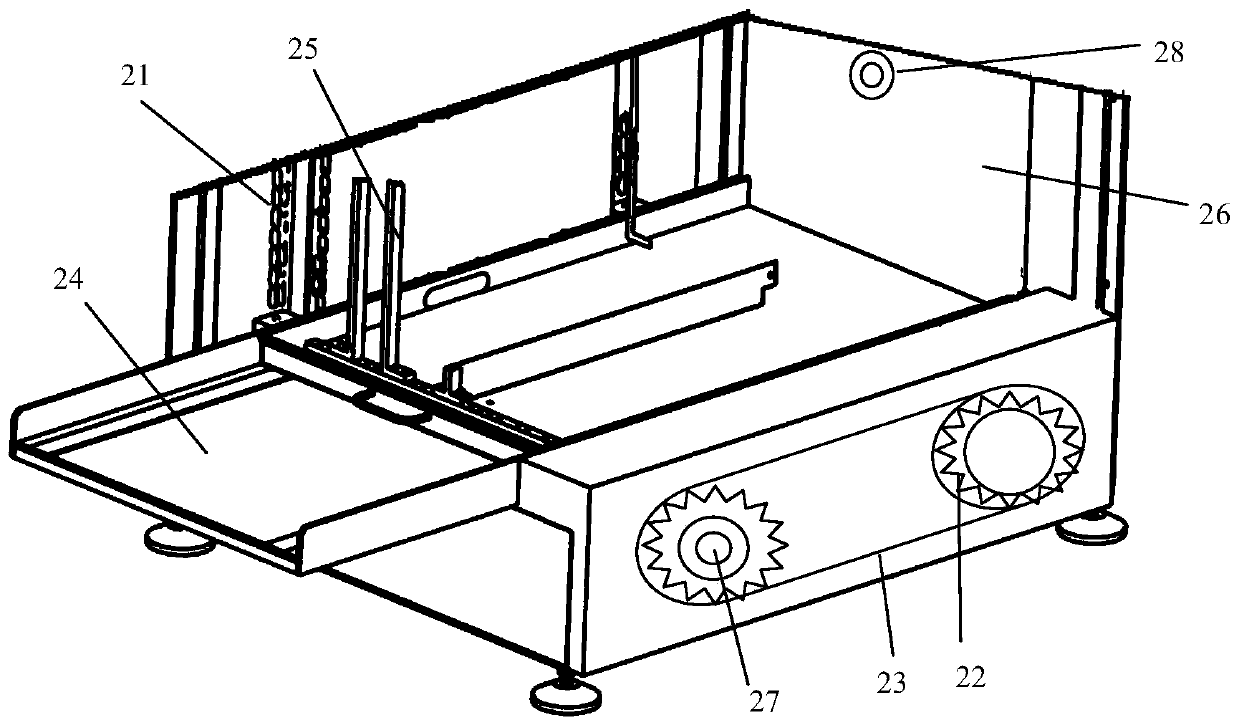

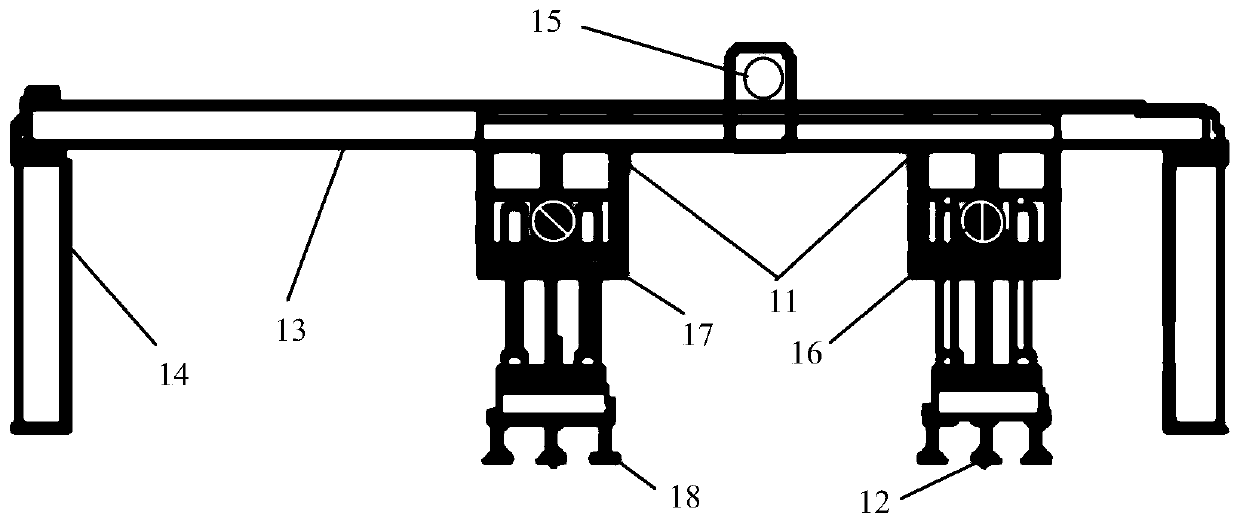

Method used

Image

Examples

example

[0039] Three types of tobacco leaves with different colors are manually classified, each of which has more than 8 tobacco leaves. In this experiment, 15 pieces are selected for each of the various samples. The detection and classification software of the device selects the sample learning and folds them in three Plant tobacco to learn. After learning through the sample, the tobacco leaf is then tested on a large sample. The first type of test was uniformly divided into the first collection box, the second type was uniformly divided into the second collection box, and the third type was uniformly divided into the third collection box. The experimental results show that the mixed tobacco leaves of large samples can be separated to form three types of tobacco leaves with the same color as the classified samples. The sorting results show that the color effects of the sorted tobacco leaves between different categories are obvious, and the colors between the same categories are simi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com