A Coiled Tubing Safety Mechanism

A safety mechanism and tubing technology, which is applied to drill pipes, casings, drill pipes, etc., can solve the problems that cannot be fully guaranteed, easily lead to dangerous accidents, and no tubing safety mechanism is found, so as to prevent the tubing string from falling into the well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

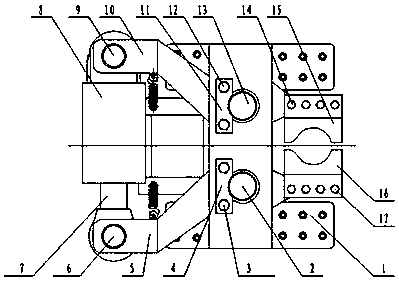

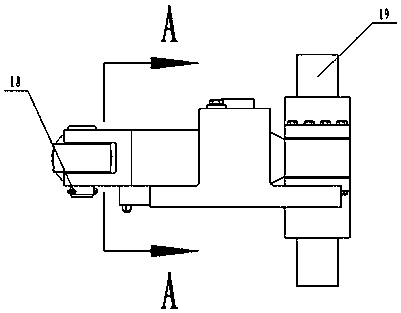

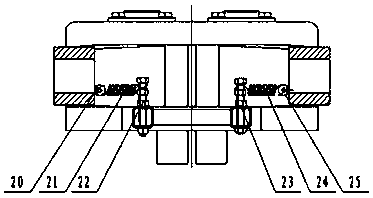

[0022] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0023] according to Figure 1-3 , a coiled tubing safety mechanism, mainly consists of a support seat 1, a right pin shaft 2, a right pin shaft baffle bolt 3, a right pin shaft baffle plate 4, a right arm 5, a right connecting shaft 6, a cylinder piston rod 7, and a cylinder cylinder Body 8, left connecting shaft 9, left arm 10, left pin baffle 11, left pin baffle bolt 12, left pin 13, left slip bolt 14, left slip 15, right slip 16, right Slip bolt 17, split pin 18, coiled tubing 19; left lifting screw 20, left spring 21, left spring bolt 22, right spring bolt 23, right spring 24, right lifting screw 25.

[0024] The right pin shaft 2 passes through the reserved hole on the support base 1 and the reserved hole on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com