Crawler belt-driving painting device

A track-driven, track-based technology, applied in the field of track-driven painting devices, can solve problems affecting product quality, increasing costs, etc., and achieve the effect of solving unevenness in all directions and uniform paint thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

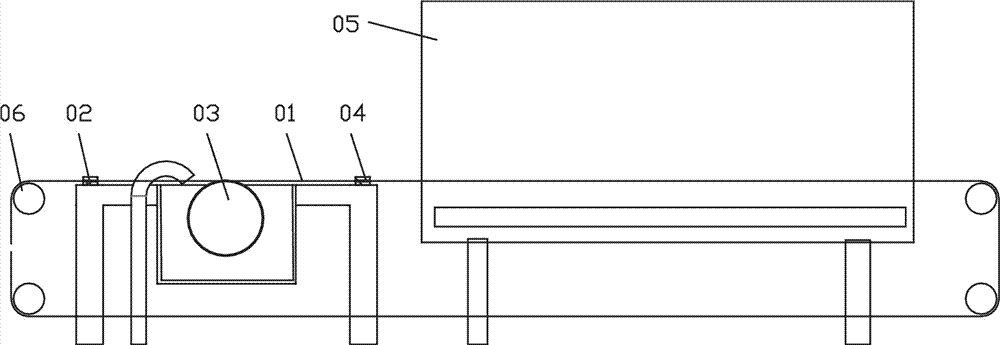

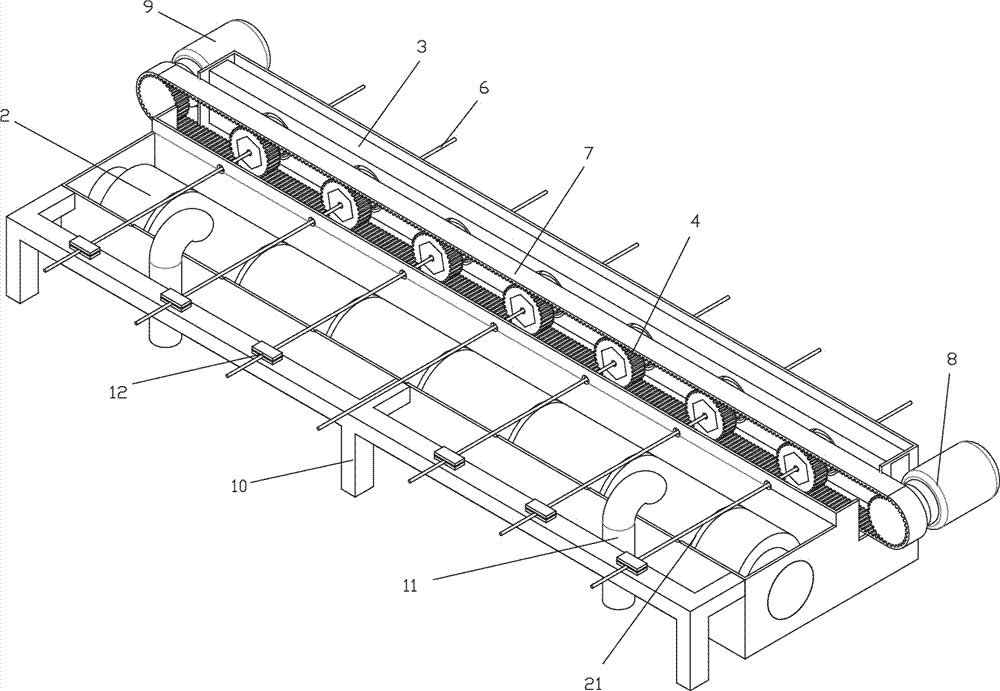

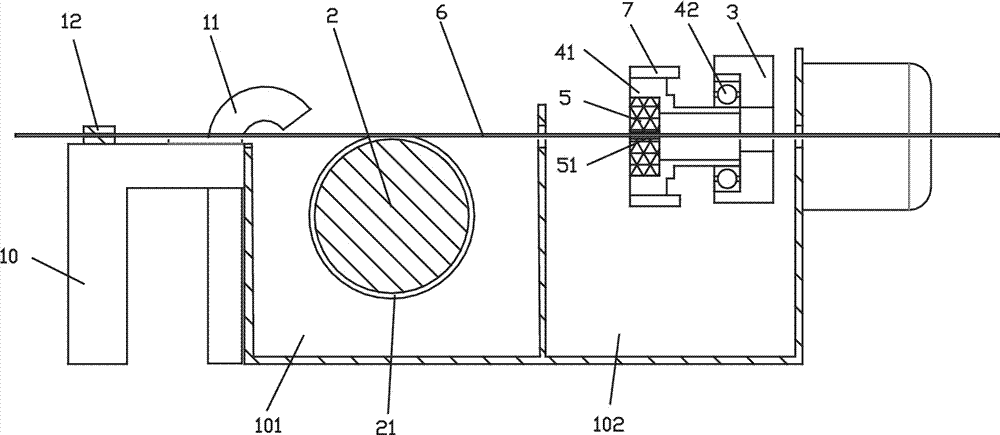

[0018] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments: Figure 1-5 As shown, the labels are as follows: paint tank 1, paint tank 101, empty tank 102, tooling gap 103, threading hole 104, paint roller 2, oil collecting ring groove 21, roller rack 3, step hole 31, roller assembly 4, Roller 41, bearing 42, spoke part 43, axle part 44, straight rack 45, nano felt cavity 46, felt block 5, wipe hole 51, enameled wire 6, crawler belt 7, vertical rack 71, main motor 8, standby motor 9 , Support 10, paint supply pipe 11, felt board assembly 12.

[0019] A crawler-driven painting device includes a painting tank 1 and a painting tank is divided into a paint tank 101 and an empty tank 102. The boundary of the empty tank is higher than the paint tank. The left and right borders are provided with threading holes 104 and the sides of the paint tank A bracket 10 and two paint supply pipes 11 are provided, and a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com