Enameled wire varnishing device

A technology of enameled wire and lacquer tank, which is applied in the direction of electrical components, circuits, conductor/cable insulation, etc., can solve the problems of affecting product quality and increasing costs, and achieve the effect of solving unevenness in all directions and uniform paint thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

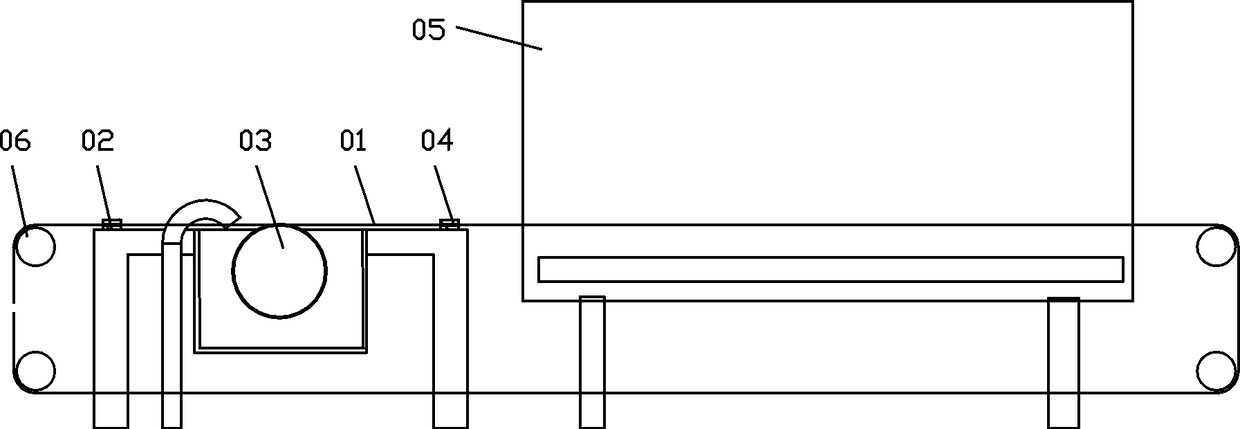

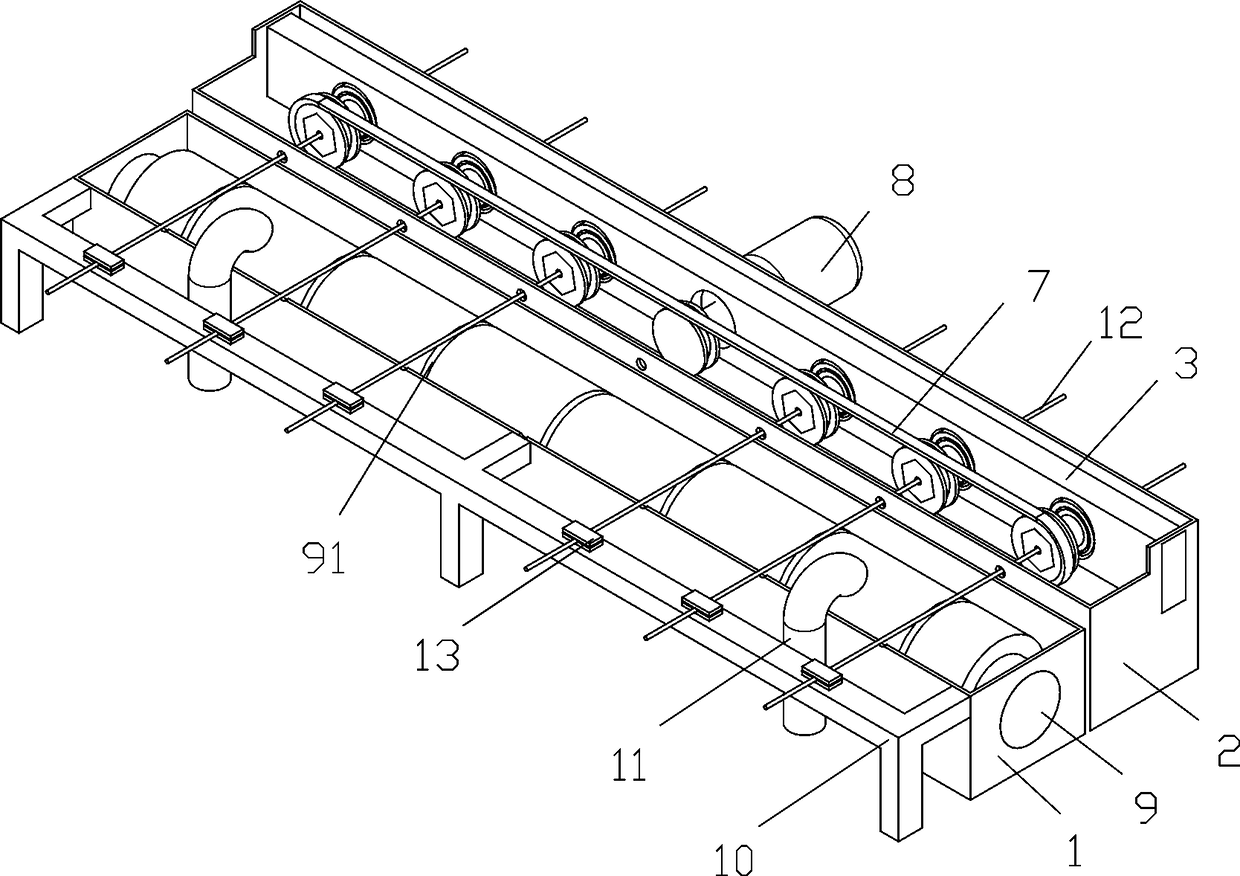

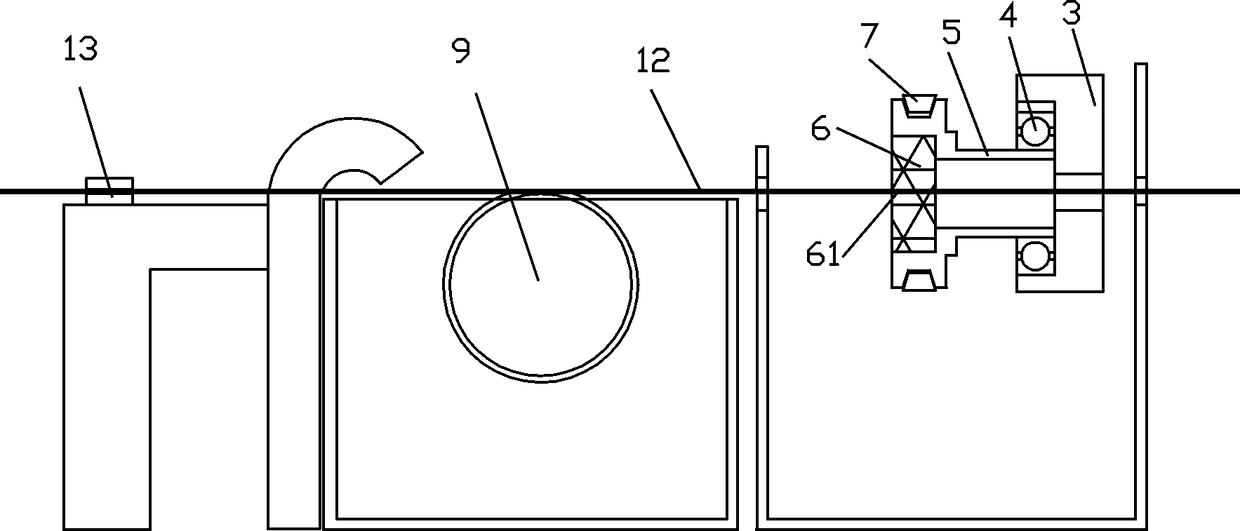

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments: Figure 1-5 shown, marked as follows: paint tank 1, scraping tank 2, runner frame 3, bearing hole 31, motor hole 32, bearing 4, runner 5, nano felt hole 51, trapezoidal groove 52, felt block 6, scraper Paint hole 61 , V-belt 7 , motor 8 , paint roller 9 , paint collecting ring groove 91 , felt support 10 , paint supply pipe 11 , enameled wire 12 , felt plate assembly 13 .

[0019] An enameled wire-painting device comprises a paint-coating groove 1 and a paint-scraping groove 2 arranged side by side, a runner frame 3 is set up in the paint-scraping groove, a plurality of bearing holes 31 are arranged on the runner frame, and bearings 4 are installed in the bearing holes. , the front head of the bearing is installed with a runner 5, the center of the runner runs through, and a nano-felt hole 51 is formed concavely toward the front. A felt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com