Patents

Literature

35results about How to "Solve the problem of unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

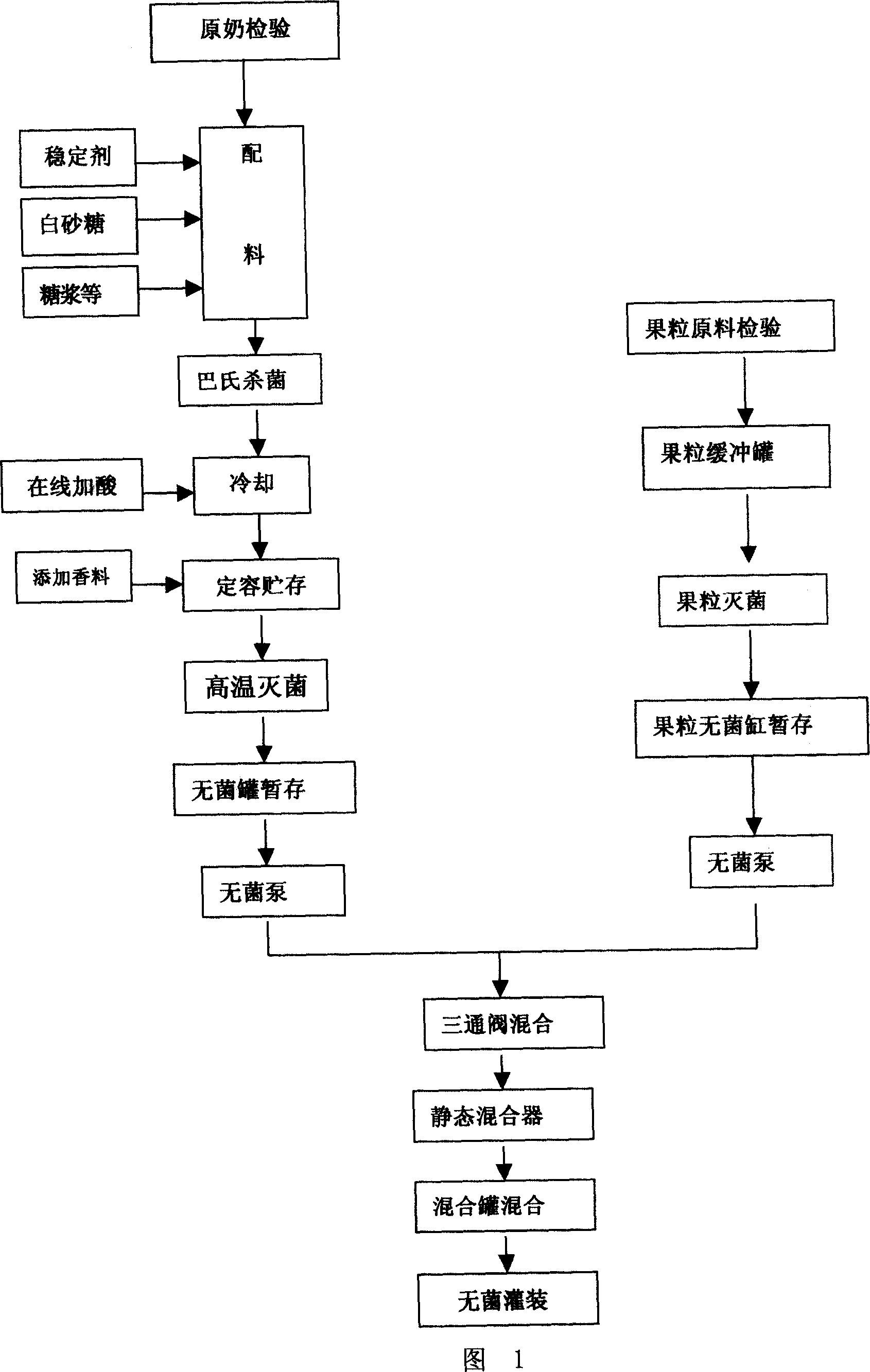

Method for producing lactic acid drink containing flesh grains

ActiveCN101040634ASolve incomplete sterilizationProtect fruit typeMilk preparationMilk preservationCow milkChemistry

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

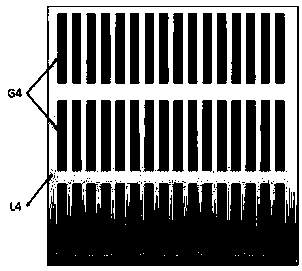

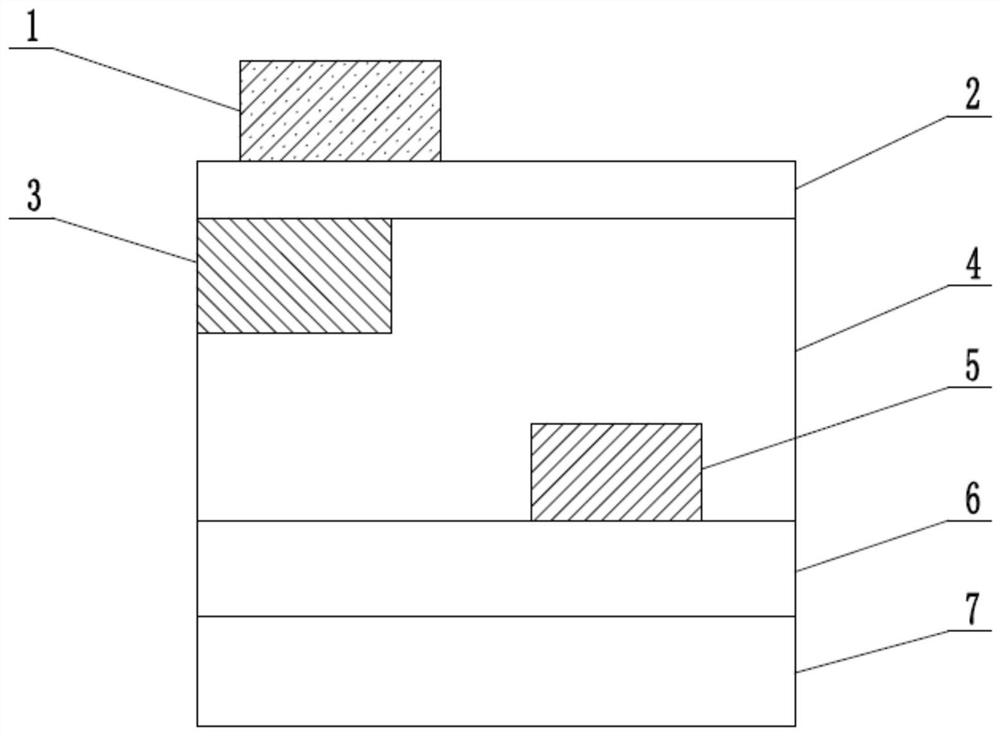

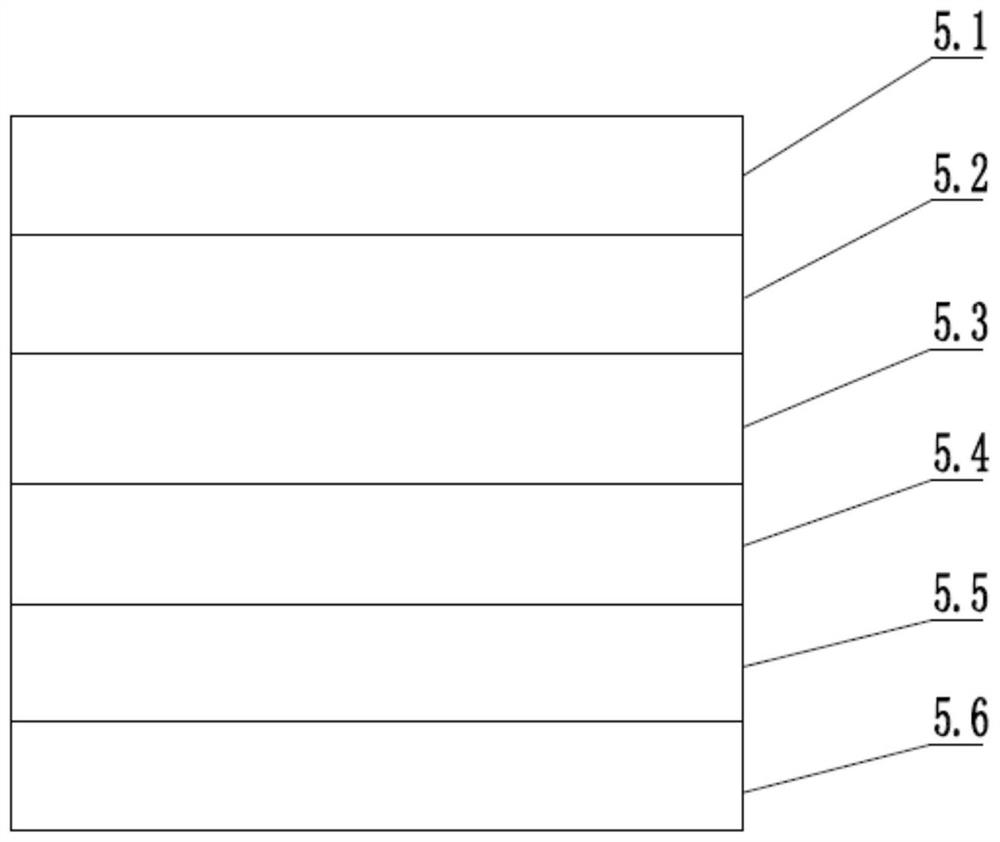

A preparation method of GaN-based horizontal nano cylindrical shell-core structure array LED

InactiveCN109037401AUniform device aspect ratioEasy to prepareSolid-state devicesNanotechnologyMultiple quantumPhotolithography

The invention discloses a preparation method of a GaN-based horizontal nano cylindrical shell-core structure array LED. The prepared LED structural unit comprises the following steps: an undoped and doped GaN thin film substrate is epitaxially grown on a sapphire; a GaN thin film substrate is epitaxially doped with a GaN thin film; SiO2 Mask Layer of Grating Array Pattern Prepared by Nano-imprintPrinting; GaN-based multiple quantum well shell-core horizontal nano-column array grown by MOCVD with InGaN / GaN active layer and p-type GaN shell; Transparent dielectric filling layer between nano-column arrays; Etched mesas and electrodes. The invention has the following advantages: using nano-imprinting can overcome the diffraction limit of the traditional photolithography technology to preparea window area below 100 nanometers; The size and position of nano-column array can be controlled precisely by grating array pattern mask and MOCVD secondary epitaxy. The number of nano-columns in thenano-column array LED can be flexibly changed according to the power demand. The structure prepared by the invention has potential application value in visible light communication, high-resolution intelligent display and photoelectric interconnection.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

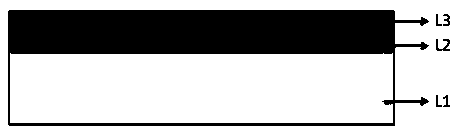

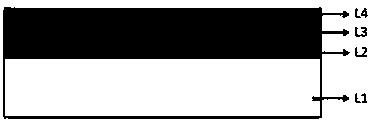

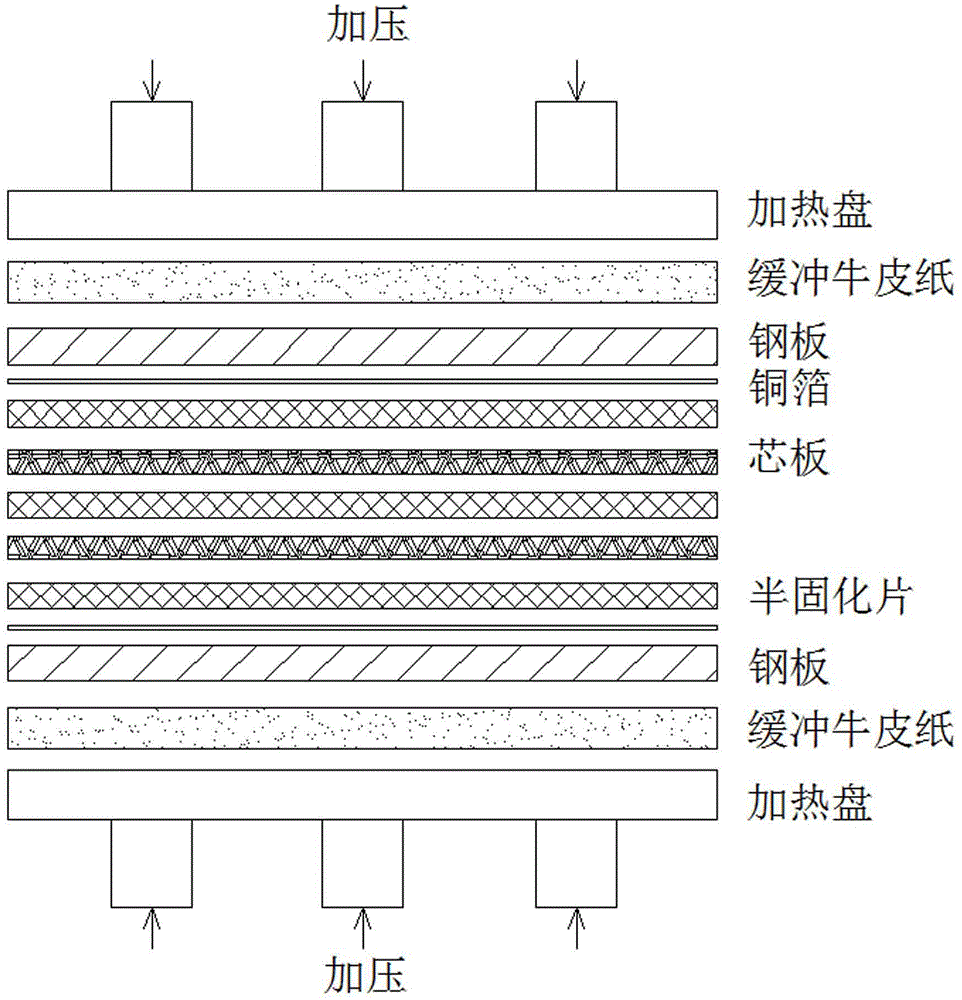

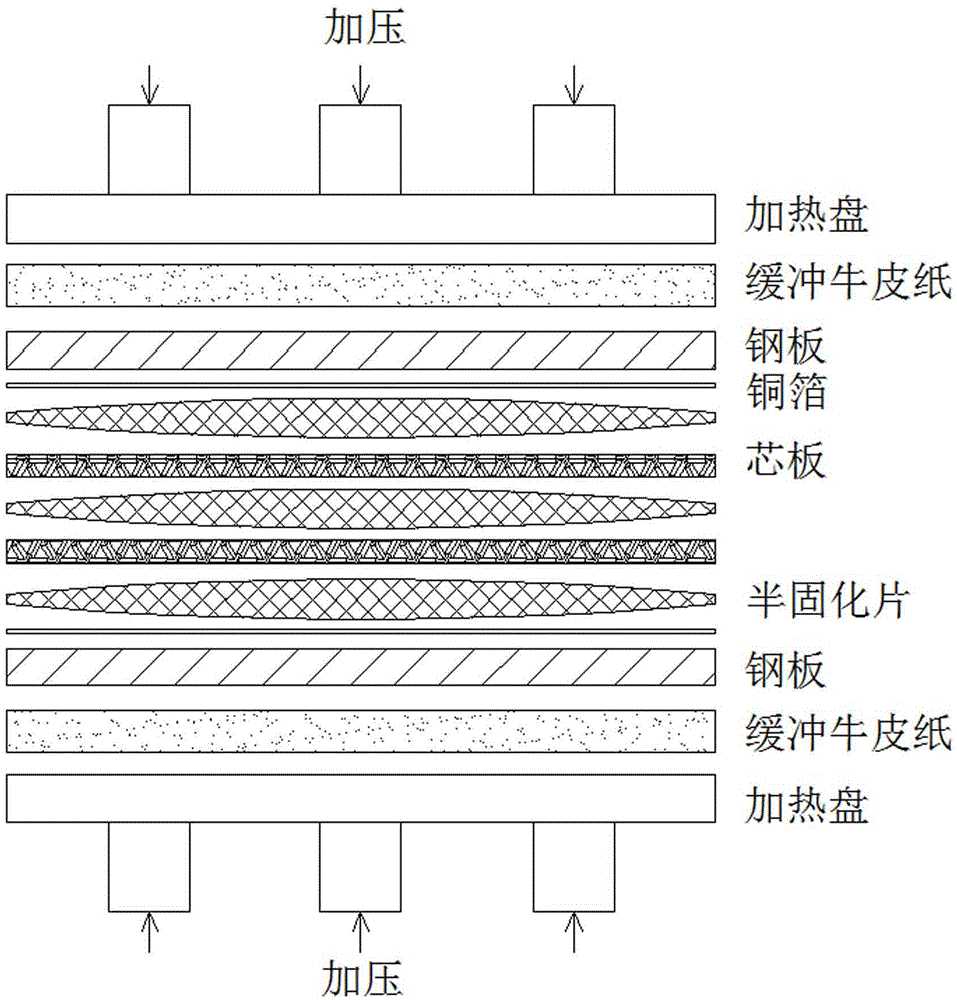

High speed PCB laminating method

InactiveCN105142363AImprove manufacturabilityPracticalLaminationLamination apparatusAdhesiveCopper foil

The invention discloses a high speed PCB laminating method, which comprises following specific implementation processes that a stacked layer is laminated through upper and lower steel plates; the stacked layer comprises a copper foil layer and a plurality of core plate layers in order from top to bottom; prepregs are respectively set between the copper foil layer and the adjacent core plate layers, and between the adjacent core plate layers; and the two steel plates are thick in the middle and thin at two edges. By adopting the high speed PCB laminating method, the problem of uneven insulating layers during the PCB laminating process due to adhesive overflowing at the edges is solved effectively in comparison with the existing technology; the thickness evenness of the PCB insulating layers manufactured by the technical solution is within the range of plus or minus 5 %; and the problem of edge part layering due to the fact that resin in the prepregs flows out and causes the edges lack of adhesive doesn't exist, thus good manufacturability is provided for the high speed PCB; the practicality is strong; and the high speed PCB laminating method provided herein is easily popularized.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

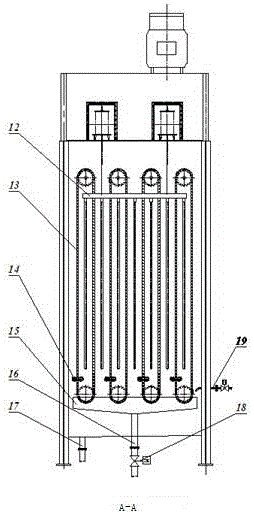

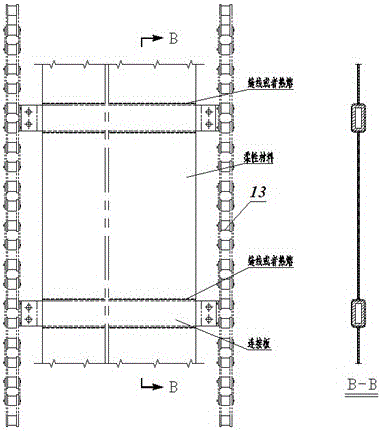

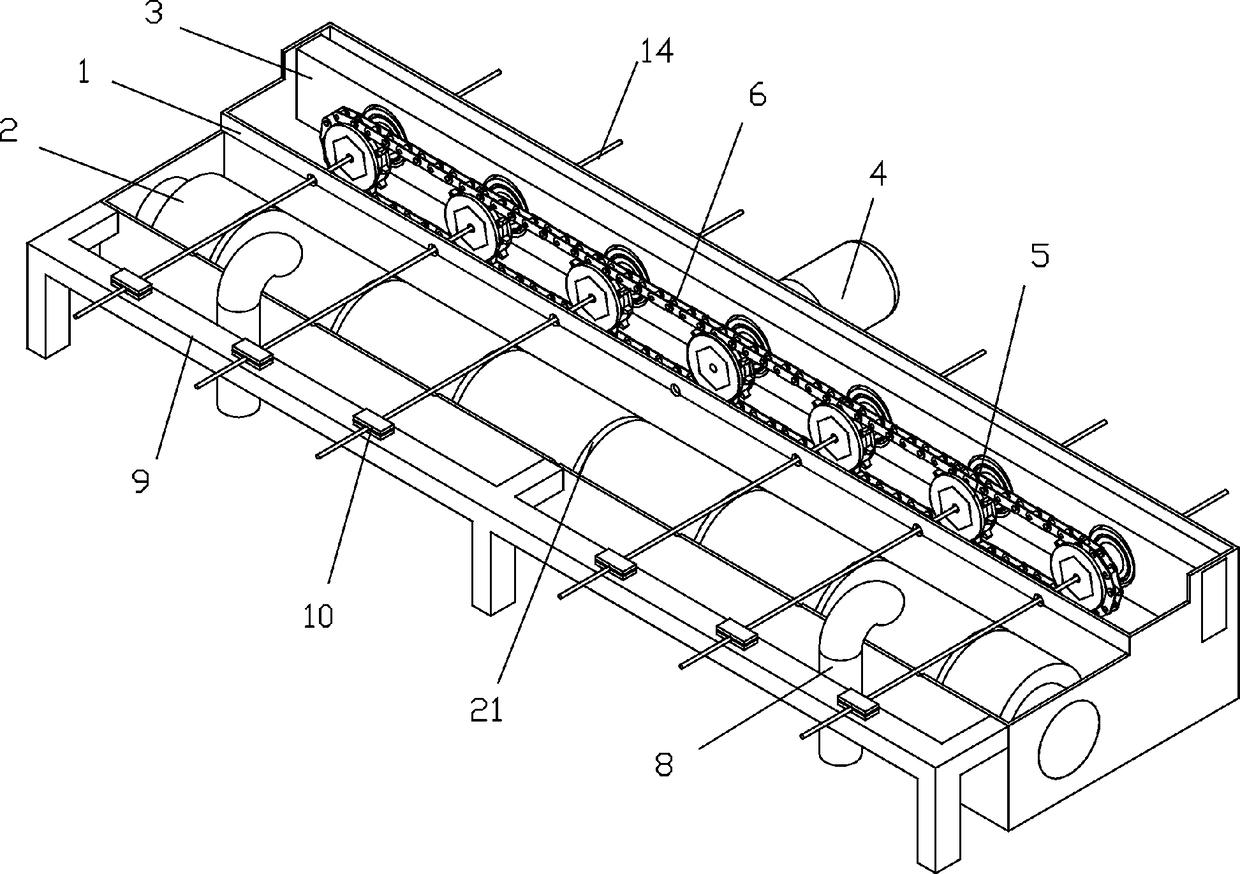

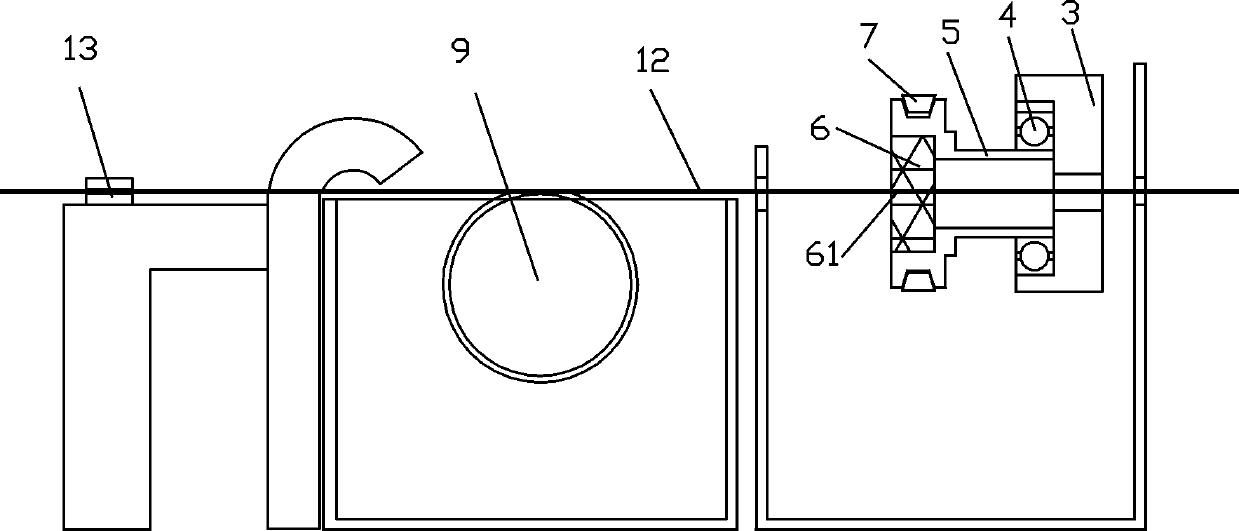

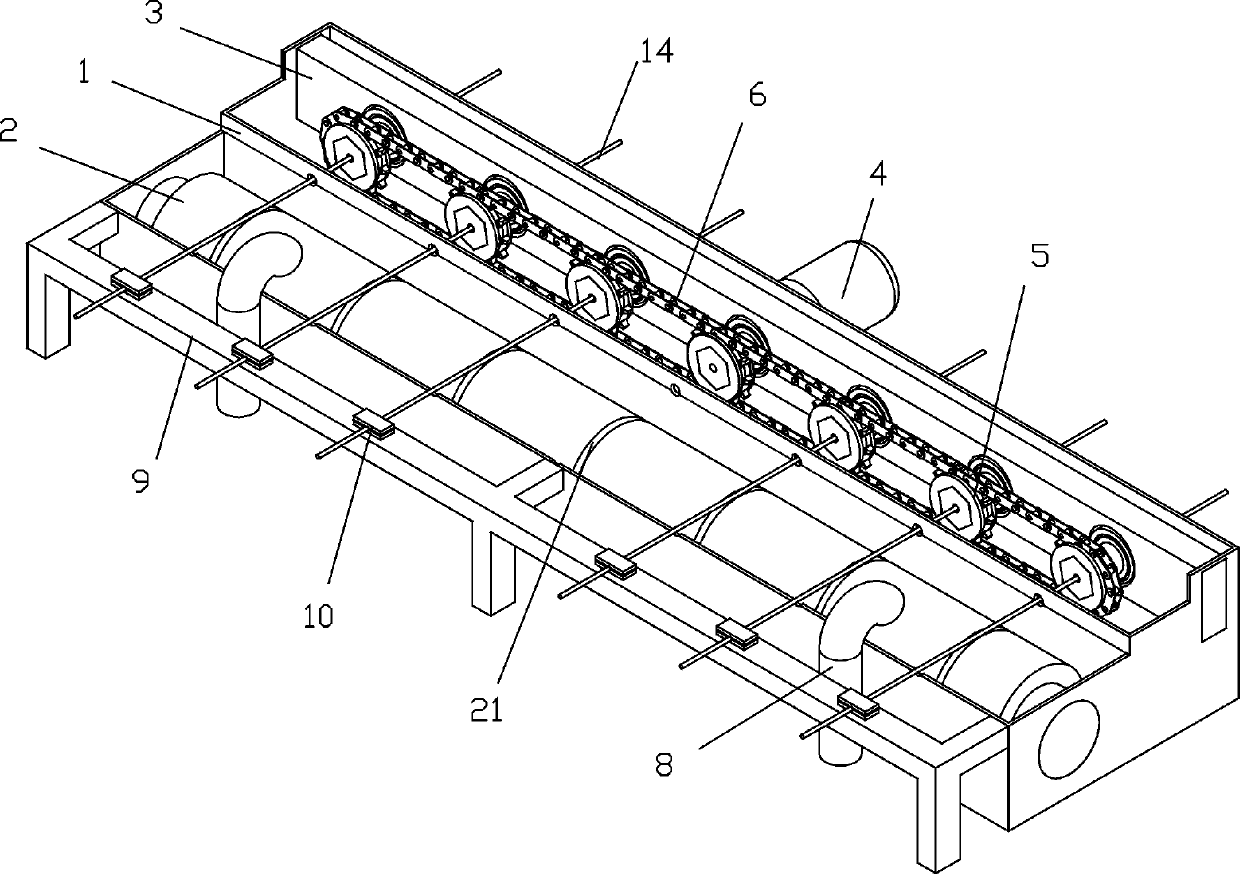

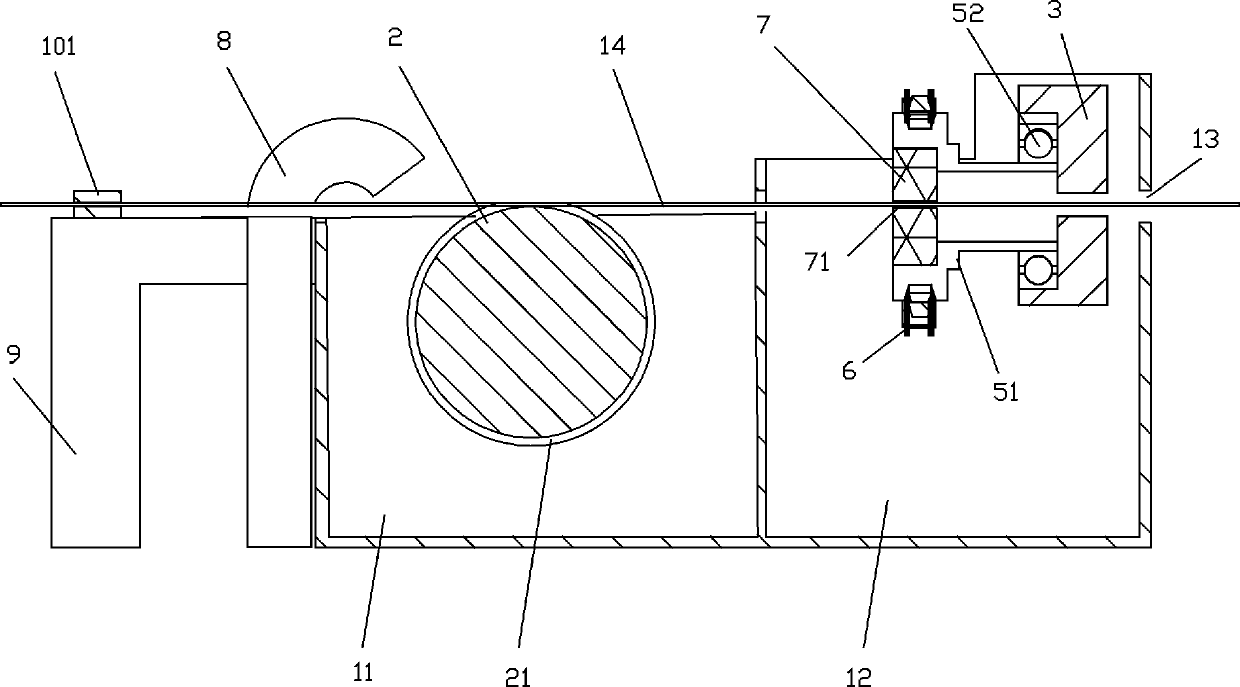

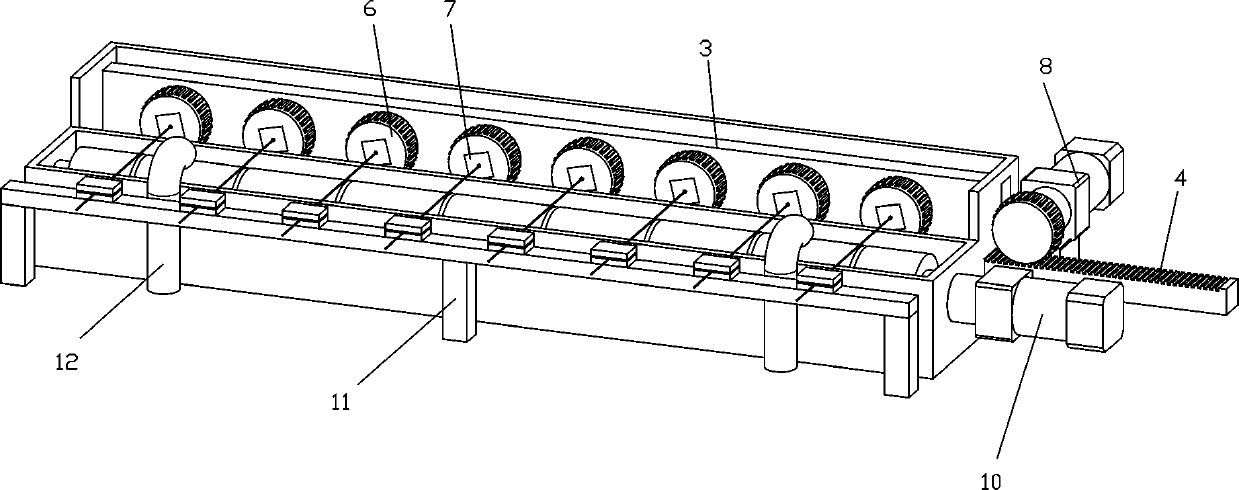

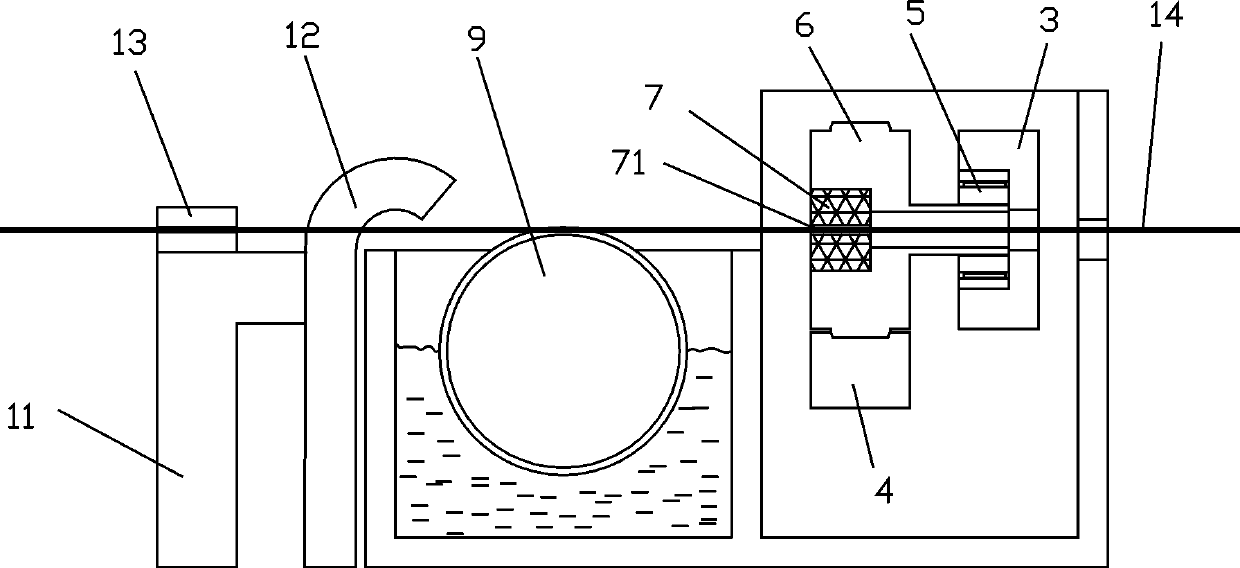

Wet type flexible movable pole plate electrostatic dust collector with rotating brushes

InactiveCN106140480AWith water absorptionSolve the problem of unevennessExternal electric electrostatic seperatorElectrode constructionsWater collectionMechanical engineering

The invention provides a wet type flexible movable pole plate electrostatic dust collector with rotating brushes. A dust collection pole plate of the electrostatic dust collector is made of flexible materials and is connected with a chain in a fastened manner through a connection plate fixed between the two layers of flexible materials. During normal operation, the chain is driven by a gear of a transmission device, and therefore the flexible pole plate is driven to rotate. A water collection tank is arranged at the bottom of the pole plate, the bottom of the pole plate is immersed in water in the water collection tank, the surface of the pole plate is unceasingly moistened in the rotation process, and the effect of dust removing and water covering is achieved; and meanwhile, the rotating brushes are arranged on the two sides of the pole plate so as to further remove pollutant on the surface of the pole plate. The wet type flexible movable pole plate electrostatic dust collector has the beneficial effects of being novel in structure, efficient, economical, practical, and the like.

Owner:ENELCO ENVIRONMENTAL TECH ANHUI

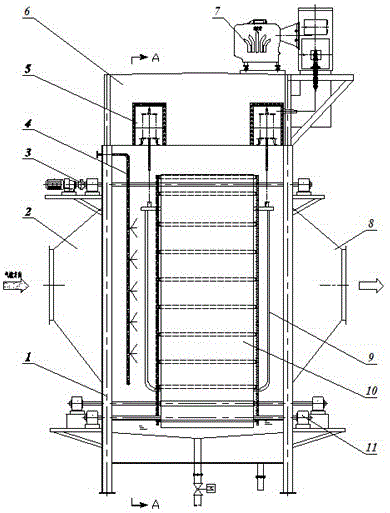

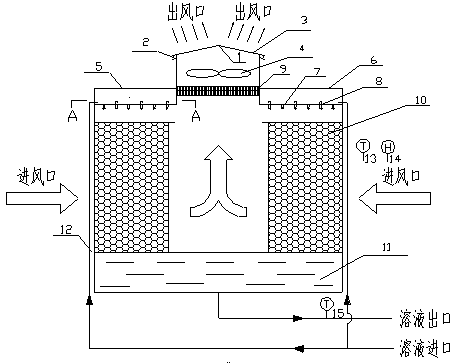

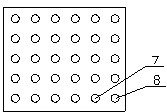

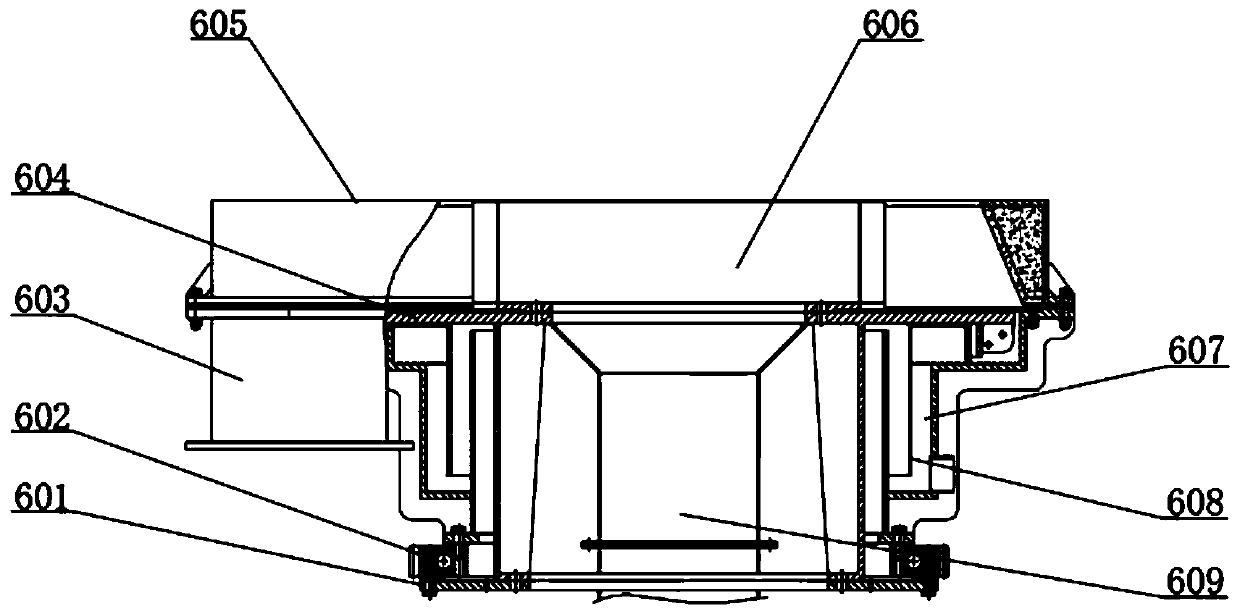

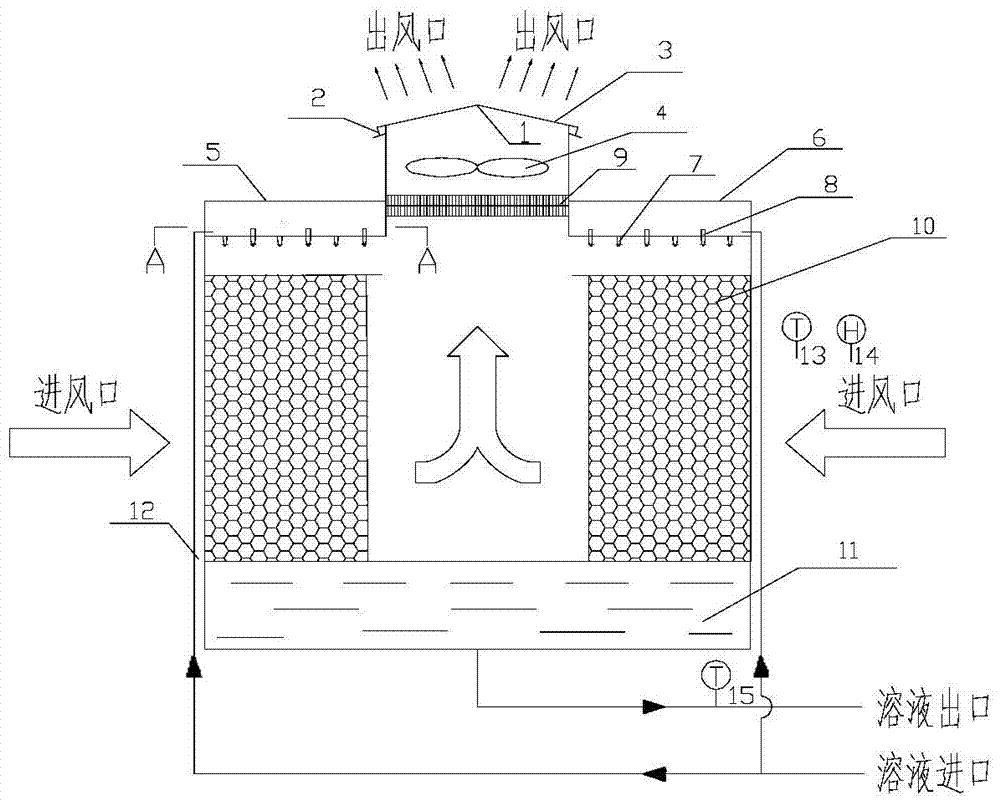

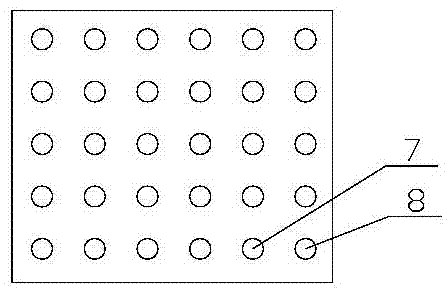

Multifunctional transverse flow type heat source tower device

ActiveCN103292401AGuaranteed uptimeAvoid enteringSpace heating and ventilation safety systemsLighting and heating apparatusThermodynamicsEngineering

The invention discloses a multifunctional transverse flow type heat source tower device which comprises a heat source tower body, an air flowing return circuit and a solution flowing return circuit, wherein the air flowing return circuit and the solution flowing return circuit are arranged in the heat source tower body. The air flowing return circuit comprises an air outlet which is formed in the top of the heat source tower body, air inlets which are formed in the two sides of the middle portion of the heat source tower body, fillings which are symmetrically arranged on the two sides of the inner portion of the heat source tower body and face towards the air inlets, liquor drifting resistant devices which are sequentially arranged below the air outlet from bottom to top, a speed changing draught fan and a self-open type rainproof device. The solution flowing return circuit comprises a liquor distributing system which is arranged above the fillings and placed inside the heat source tower body, fillings and a liquor collecting pool which is placed at the bottom of the heat source tower body, the liquor collecting pool is placed below the fillings, and a heat source tower solution outlet is formed in the bottom of the liquor collecting pool. The multifunctional transverse flow type heat source tower device can prevent rainwater from entering a heat source tower and diluting a solution, reduce solution mass loss caused by solution drifting, achieve the objective that a heat source tower can efficiently and stably operate.

Owner:SOUTHEAST UNIV

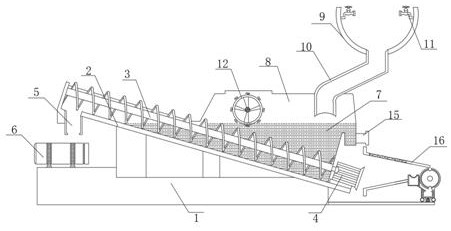

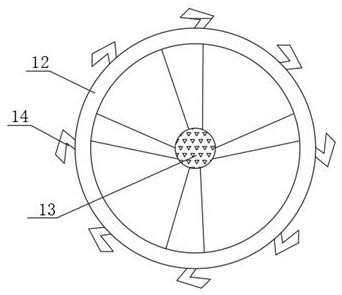

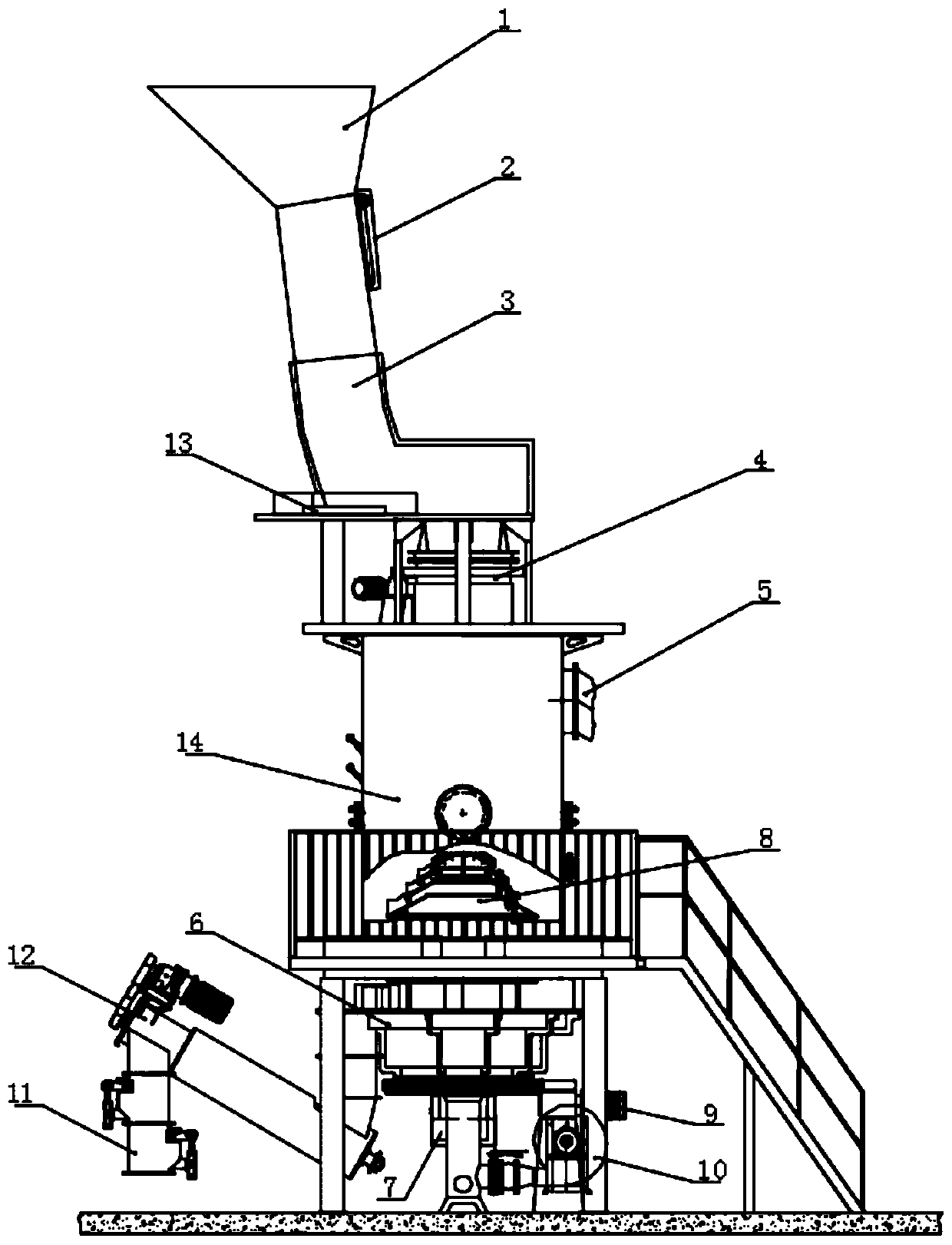

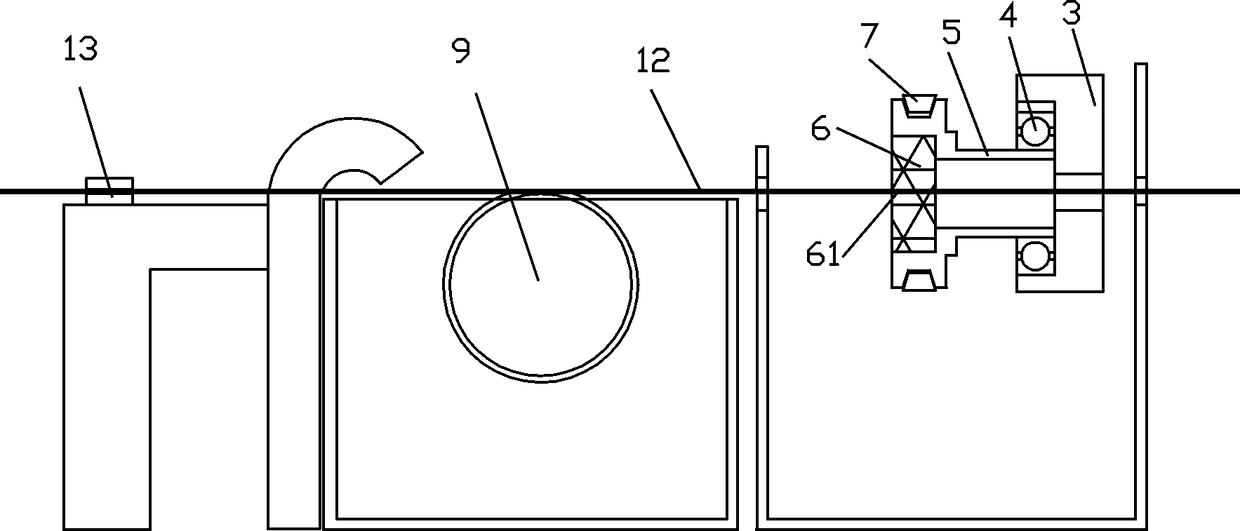

Casting waste sand treatment device

InactiveCN112157212AImprove sorting efficiencySolve the problem of unevennessMould handling/dressing devicesElectric machineryScrew conveyor

The invention discloses a casting waste sand treatment device. The casting waste sand treatment device comprises a main support; an auger frame is obliquely arranged at the upper end of the main support; a spiral conveyor is placed in the auger frame; a gear motor is mounted at one end part of the spiral conveyor; a first discharging port is formed in the end part, far away from the gear motor, ofthe spiral conveyor; a drying cylinder is arranged below the first discharging port; one half of the auger frame is located in a sand washing pool; a top cover is fixedly arranged above the sand washing pool; a feeding hopper is arranged obliquely above the top cover; the lower end of the feeding hopper communicates with a guide pipe and penetrates through the top cover downwards; and a faucet ismounted in the feeding hopper. According to the casting waste sand treatment device, by designing the sand washing pool, on the one hand, waste sand is washed, and on the other hand, sorting is completed; sand grains meeting the specification sink and are conveyed away by the conveyor, sand grains not meeting the specification float and are washed away along with water flow; and therefore, the casting waste sand treatment device is suitable for different working conditions, and better using prospects are brought.

Owner:含山县承力铸造厂

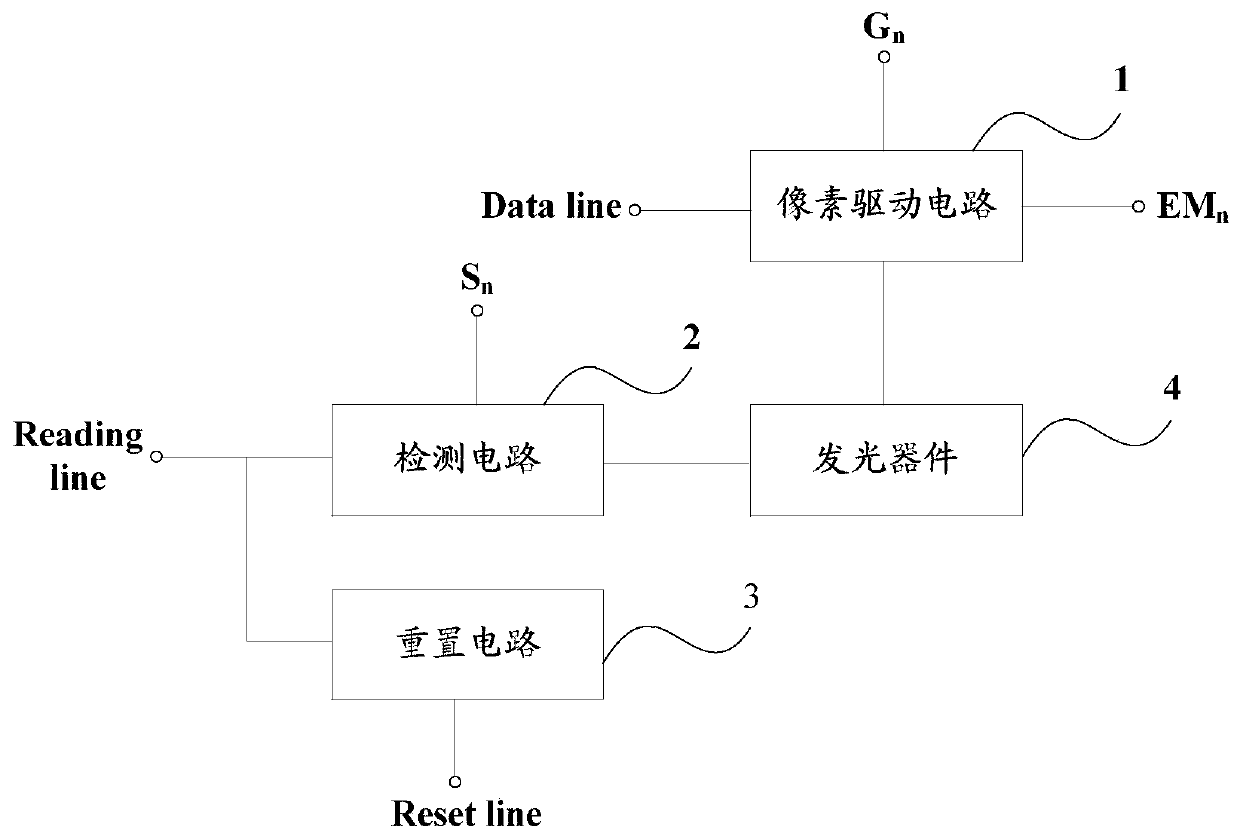

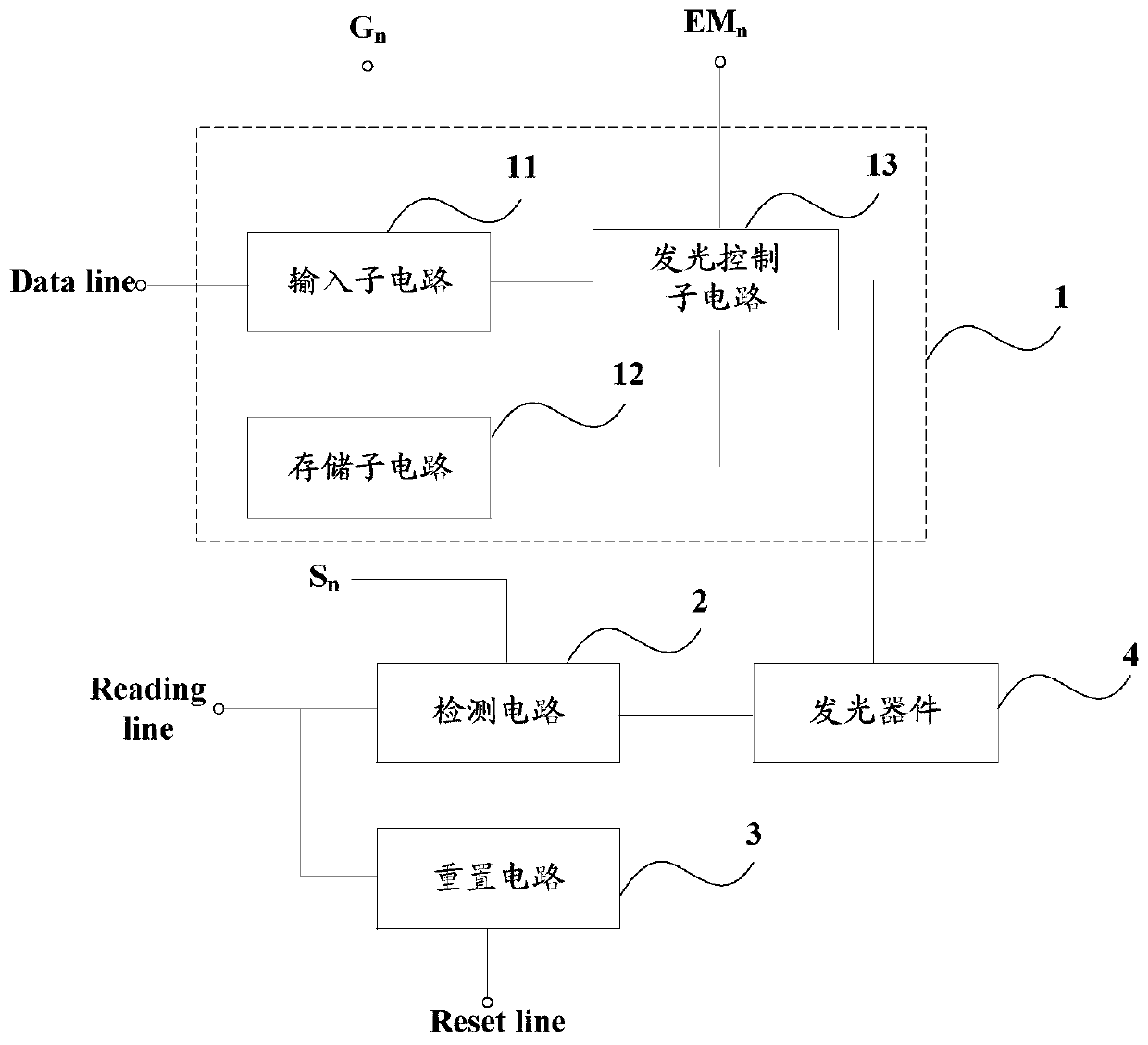

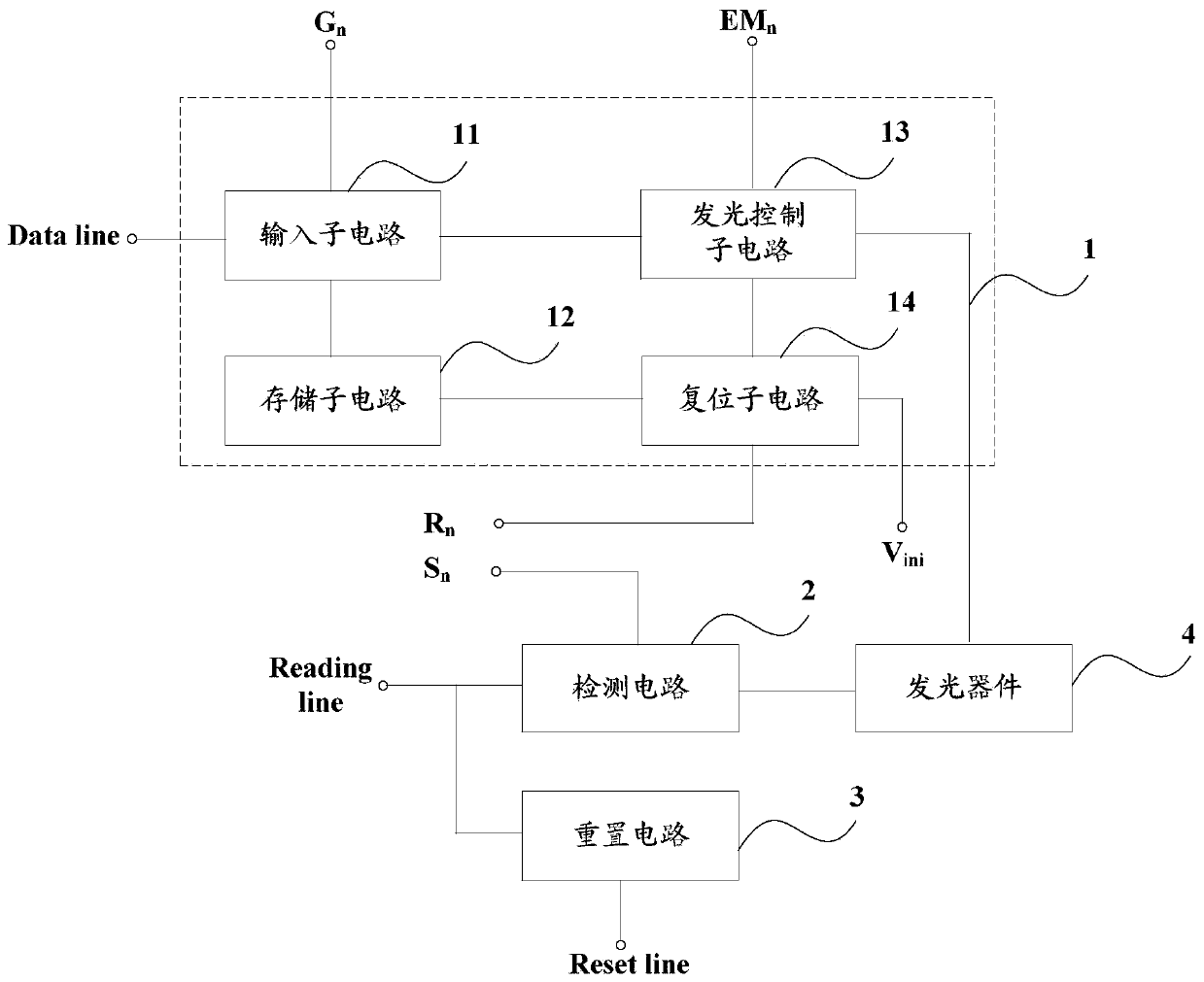

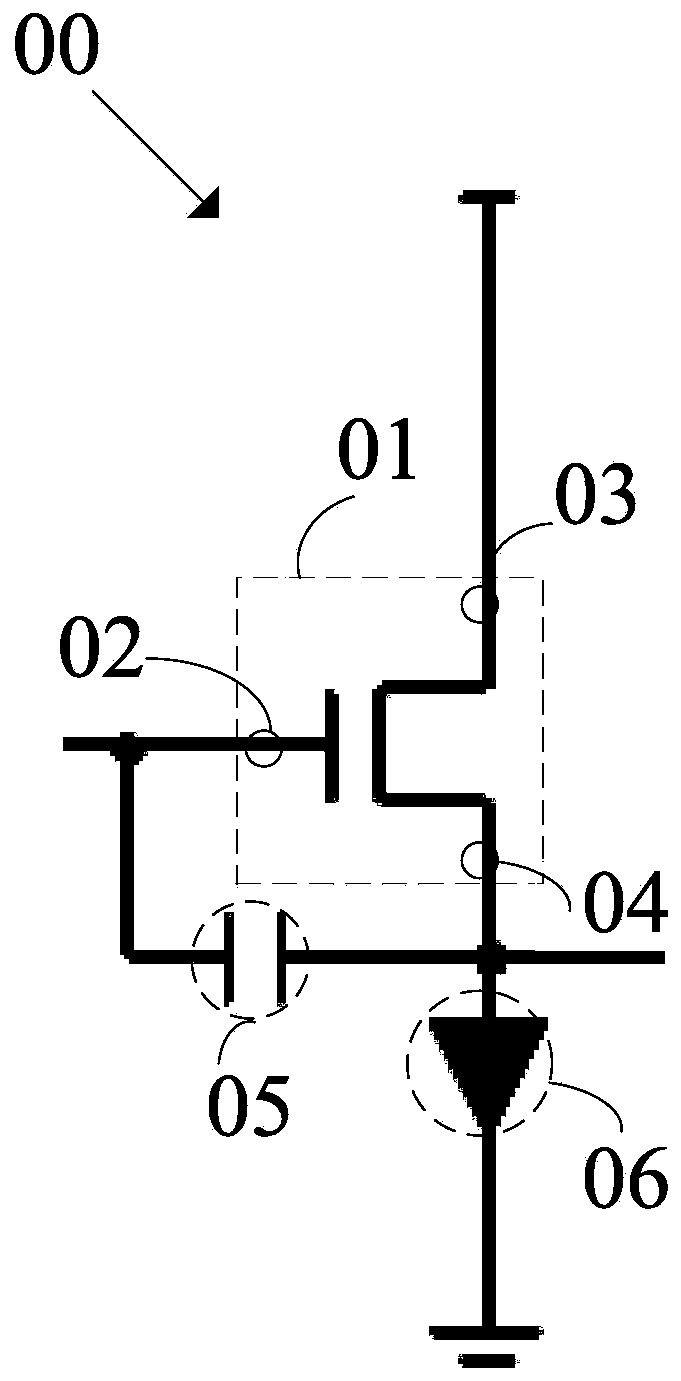

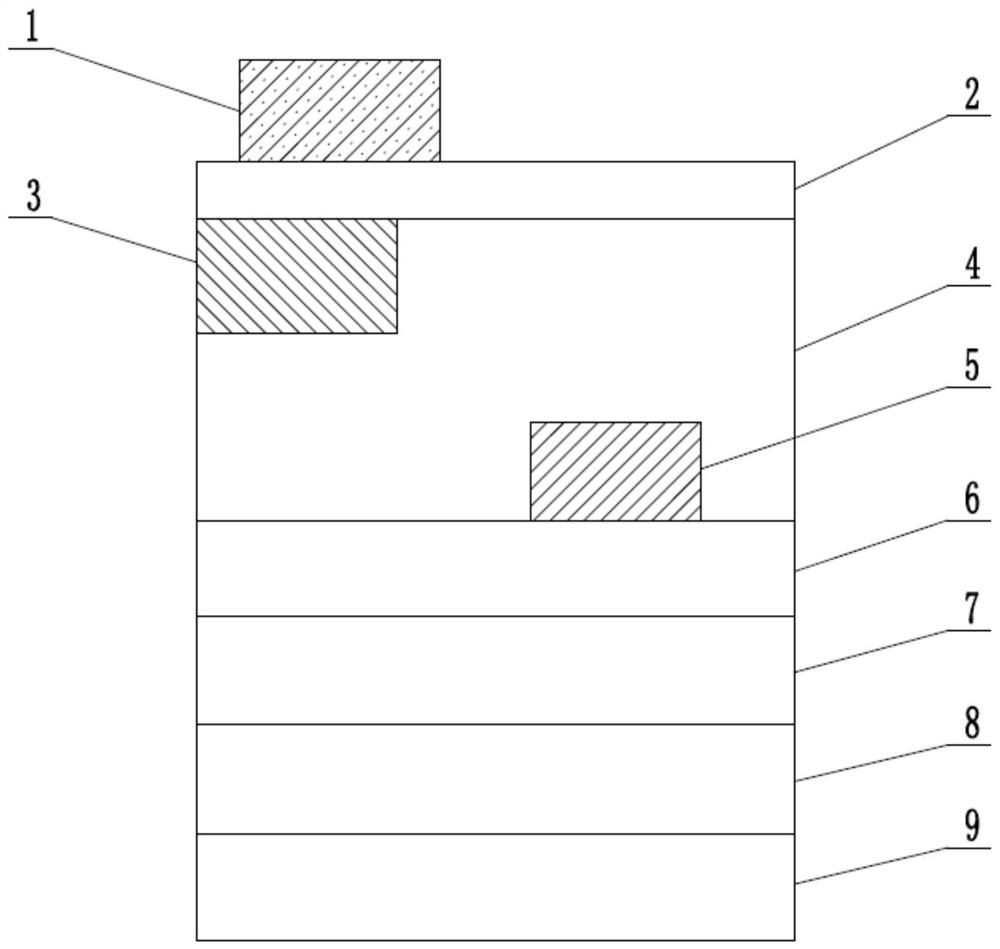

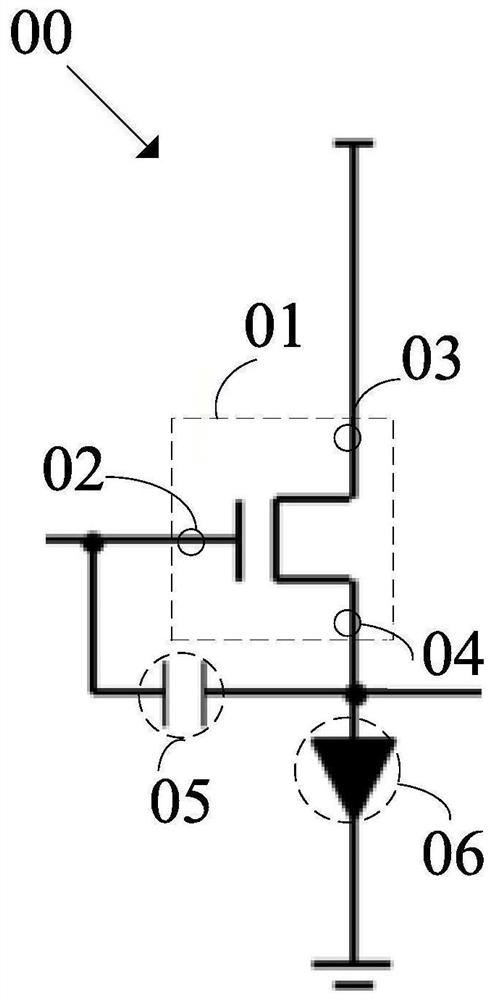

Pixel circuit, light-emitting device aging detection compensation method and display substrate

PendingCN111312129AGuaranteed reliabilityGuaranteed uniformityStatic indicating devicesHemt circuitsComputational physics

The embodiment of the invention provides a pixel circuit, a light-emitting device aging detection compensation method and a display substrate, and can solve the problem of non-uniform screen display pictures caused by aging of an OLED device. The pixel circuit includes a pixel driving circuit, a detection circuit, a reset circuit, and a light emitting device. The pixel driving circuit is connectedwith the grid line, the data line, the light-emitting signal line and the light-emitting device and is configured to drive the light-emitting device to emit light. The detection circuit is connectedwith the light-emitting device, the detection signal line and the reading signal line, and is configured to read the anode potential of the light-emitting device in a light-emitting state and transmitthe anode potential to the reading signal line. The reset circuit is connected with the reset signal line and the read signal line and resets the read signal line. The pixel circuit, the detection and compensation method for aging of the light-emitting device and the display substrate provided by the embodiment of the invention are used for carrying out aging information detection and aging compensation on the light-emitting device.

Owner:BOE TECH GRP CO LTD +1

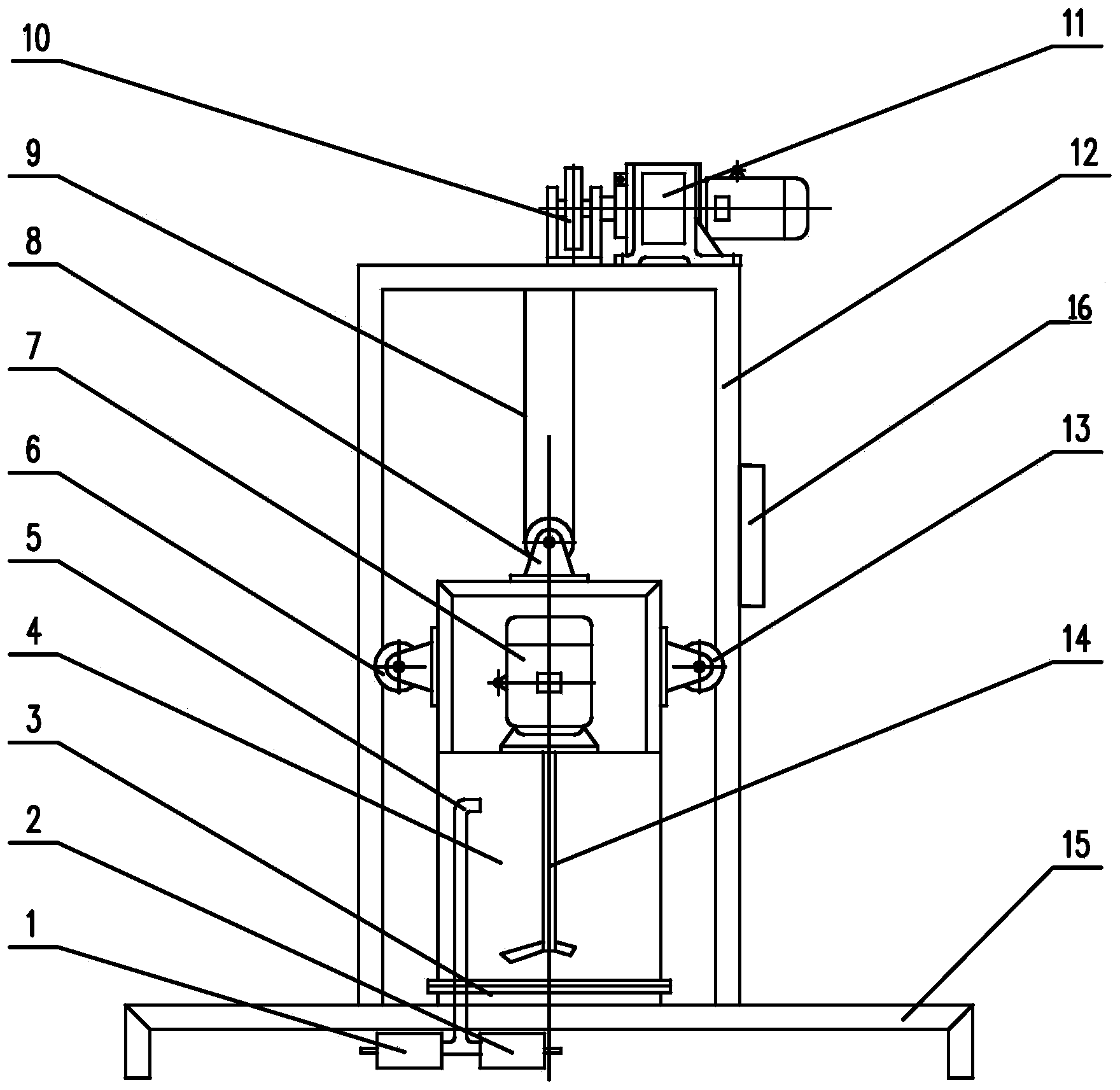

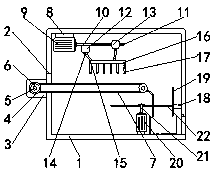

Vacuum stirrer

InactiveCN104369269AAddressing disorganizationExtended service lifeCement mixing apparatusElectric machineryGypsum

The invention discloses a vacuum stirrer and belongs to the technical field of domestic ceramic mechanical equipment. The vacuum stirrer comprises a machine base, an n-shaped bracket, a lower bell jar, an upper bell jar, a coiling wheel, a coiling wheel motor and an air pipe, wherein the n-shaped bracket and the lower bell jar are fixedly mounted on the machine base; sliding guide slots are formed in the inner sides of two stand columns of the n-shaped bracket; the coiling wheel is electrically connected with the coiling wheel motor and is arranged on the n-shaped bracket; the upper bell jar and the lower bell jar are covered by sealing adhesive tapes; a stirring motor is mounted inside the upper bell jar; guide wheels capable of moving up and down along the sliding guide slots are respectively arranged on the left side and the right side of the outer side of the upper bell jar; a pulley is also arranged at the top of the upper bell jar and is connected with the coiling wheel by virtue of a steel wire rope; the air pipe runs through the machine base and the lower bell jar and extends into the upper bell jar; the lower end of the air pipe is arranged under the machine base and is connected with a vacuum valve and an air valve by virtue of a three-way pipe. The vacuum stirrer is capable of stirring gypsum under the vacuum condition, fully removing bubbles in the process of stirring the gypsum and ensuring that the gypsum is uniformly stirred.

Owner:李金盛

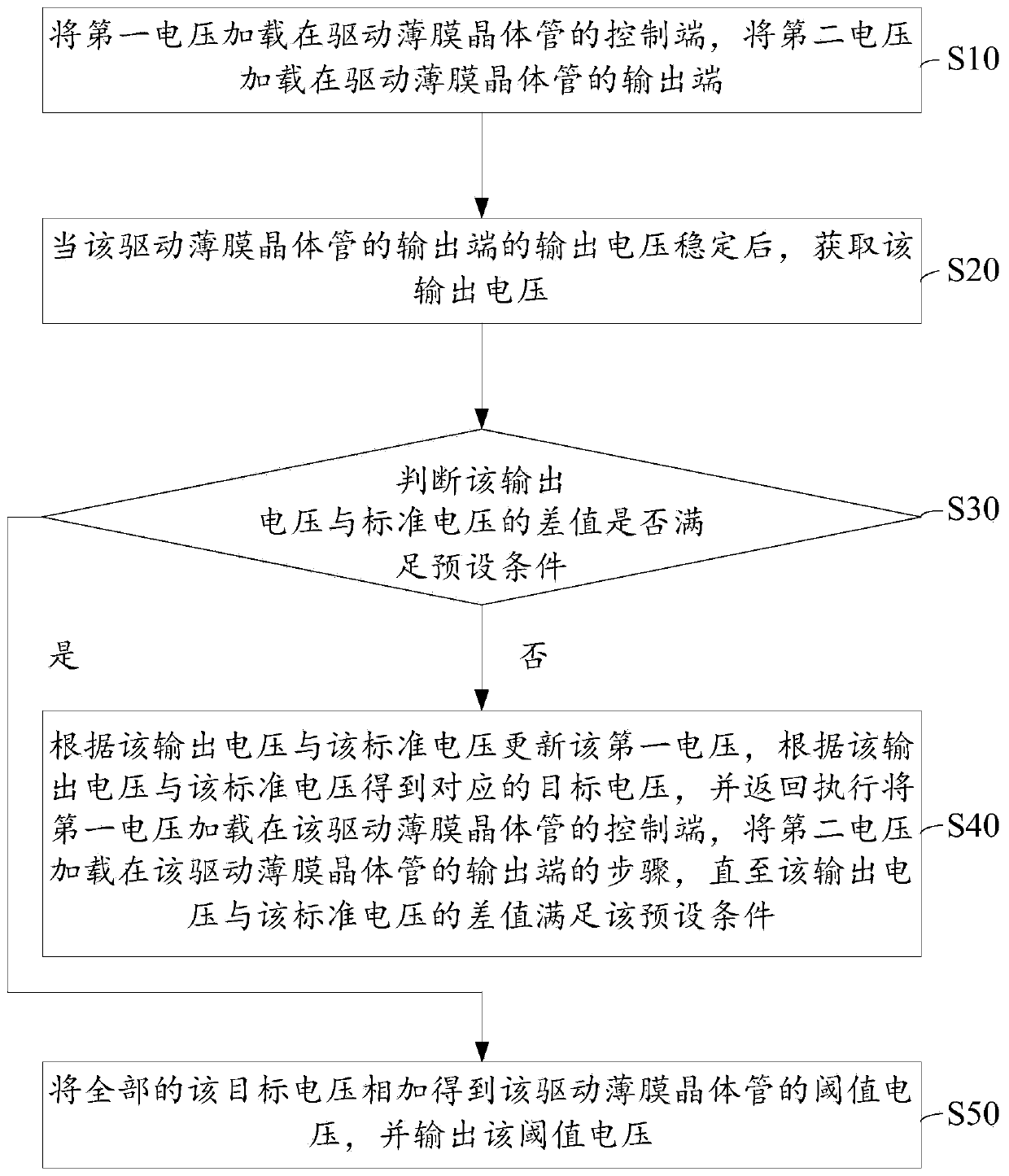

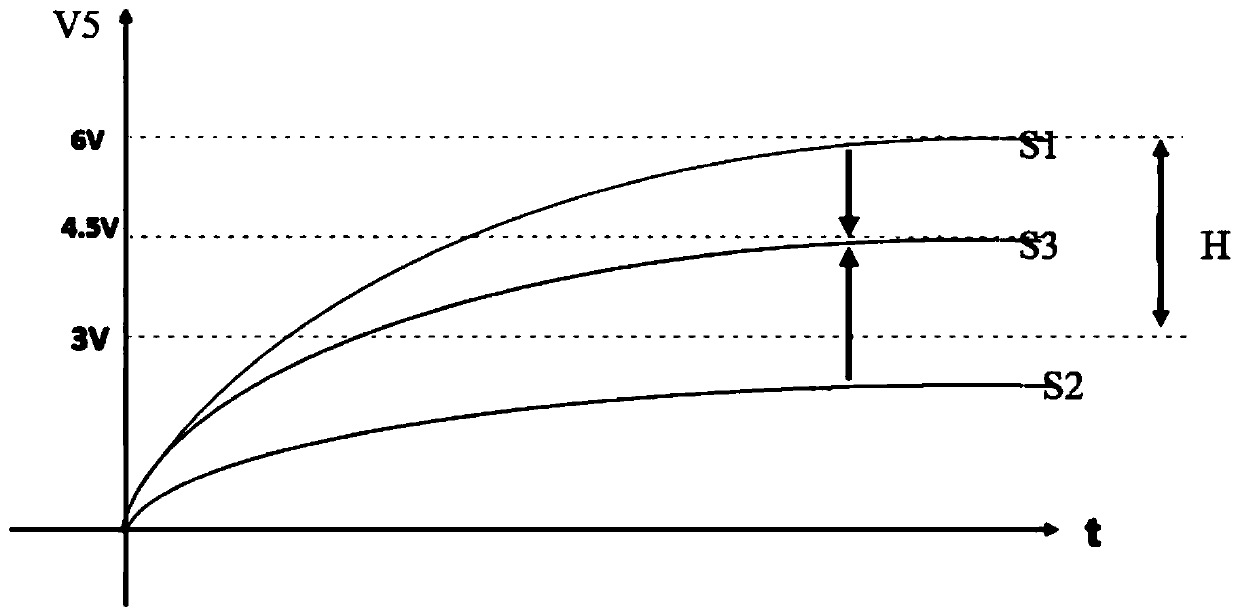

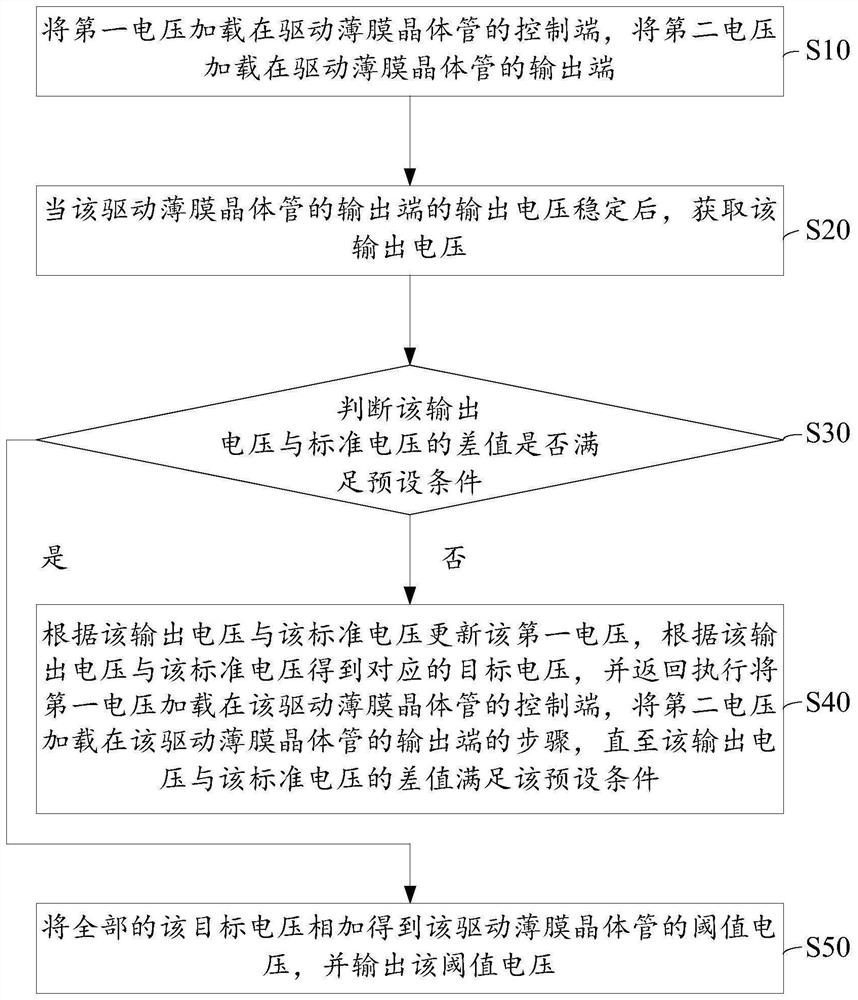

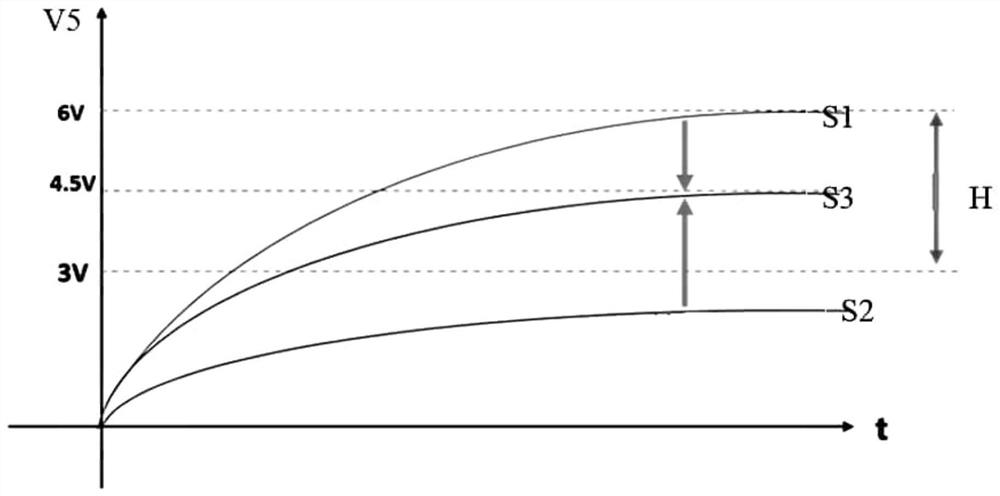

Voltage output method and device, controller and storage medium

ActiveCN111312167AImprove accuracySolve the problem of uneven display screenStatic indicating devicesDisplay deviceHemt circuits

The invention provides a voltage output method and device, a controller and a storage medium. The method is applied to a pixel circuit comprising a driving thin film transistor. The first voltage andthe second voltage are respectively loaded at the control end and the output end of the driving thin film transistor; obtaining the stabilized output voltage of the output end of the driving thin filmtransistor; judging whether the difference between the output voltage and the standard voltage meets a preset condition or not; when the preset condition is not met; updating the first voltage according to the output voltage and the standard voltage, obtaining a corresponding target voltage, returning to execute the step of loading the first voltage and the second voltage to the control end and the output end of the driving thin film transistor respectively until a preset condition is met, adding all the target voltages to obtain a threshold voltage of the driving thin film transistor, and outputting the threshold voltage; according to the scheme, the accuracy of threshold voltage detection of the driving thin film transistor can be improved, so that the problem of non-uniform display frames of the OLED display can be better solved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

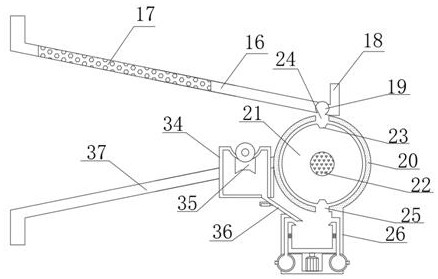

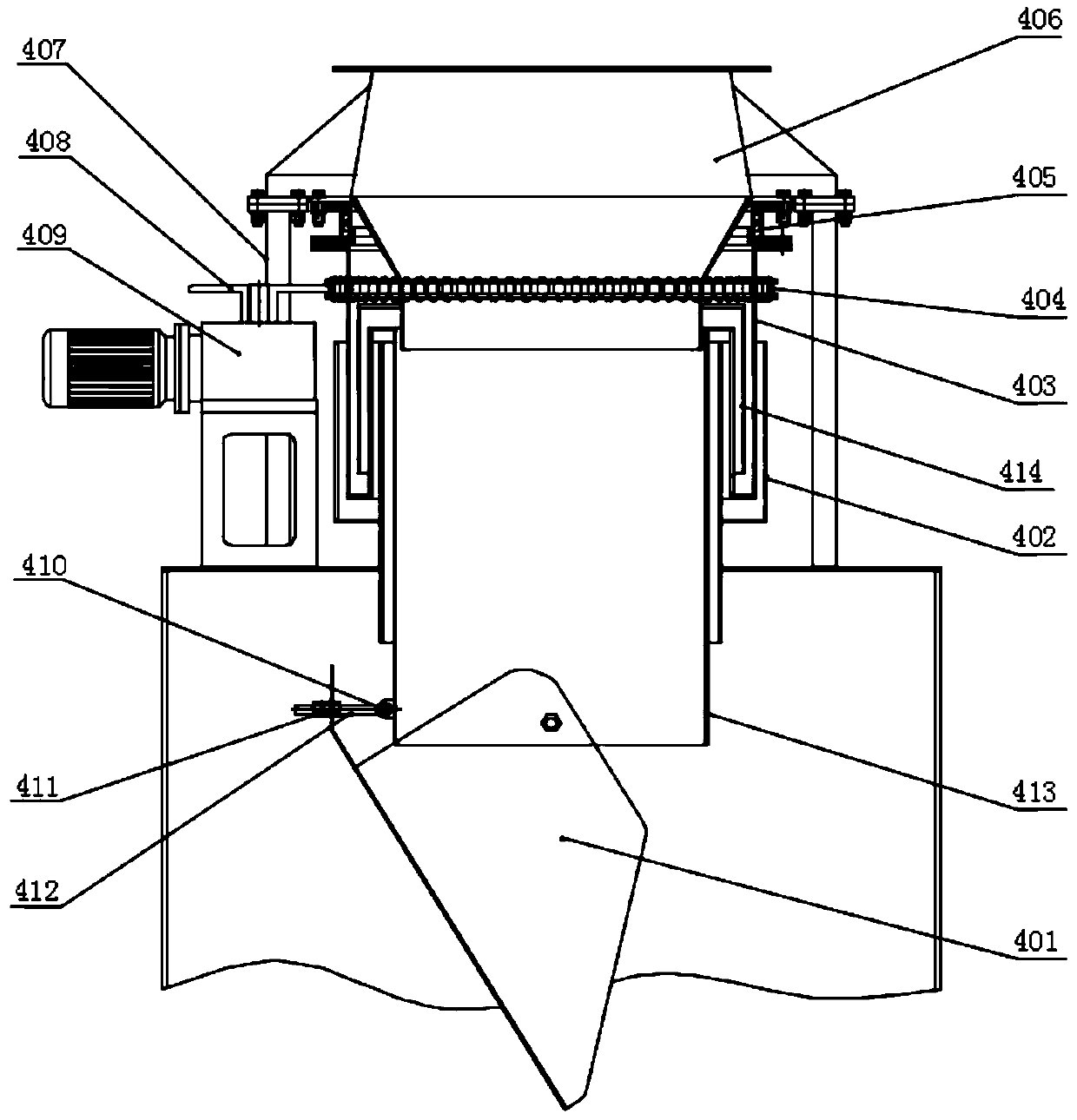

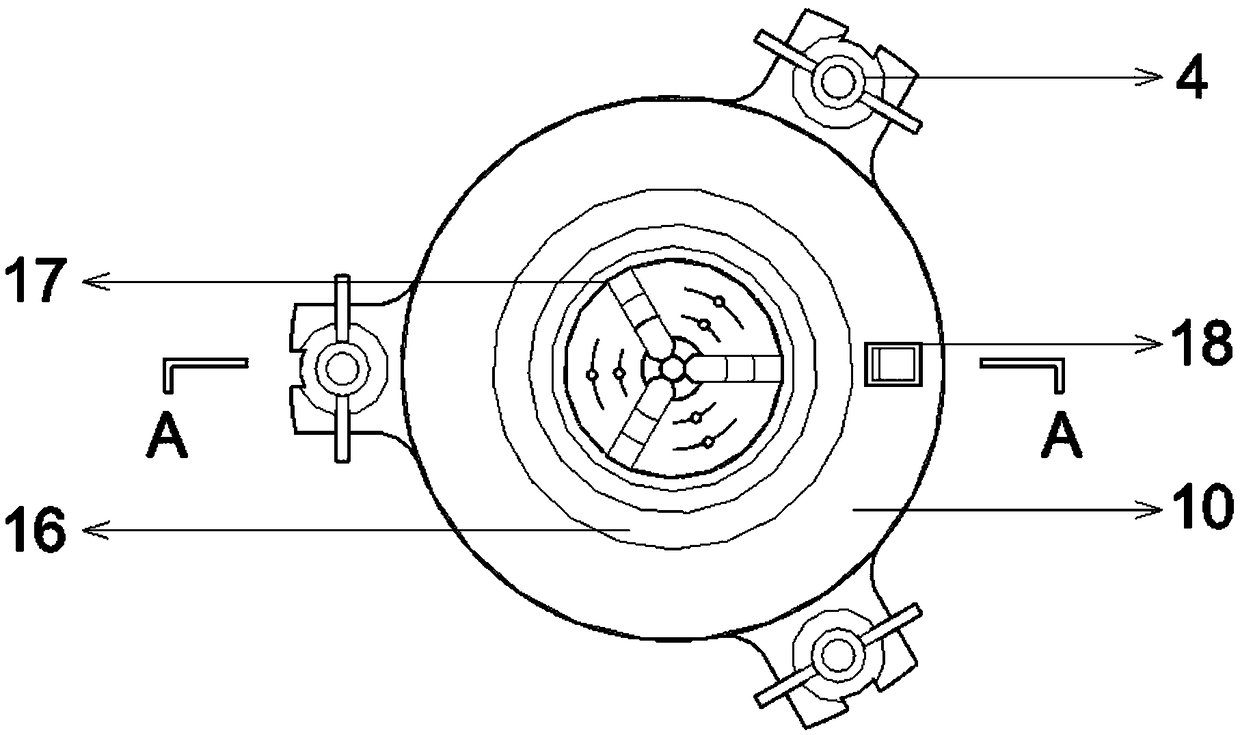

Rotary distribution dry deslagging household waste pyrolysis gasifier

PendingCN111473335AGuaranteed normal operationGuaranteed service lifeRevolving grateRocking grateElectric machineryProcess engineering

The invention discloses a rotary distribution dry deslagging household waste pyrolysis gasifier, and relates to the technical field of gasifiers. The rotary distribution dry deslagging household wastepyrolysis gasifier comprises a gasifier body. The upper portion of the outer side face of the gasifier body fixedly communicates with a gas outlet. A rotary distributor is arranged at the top of thegasifier body. The input end of the rotary distributor fixedly communicates with an upper chute. The other end of the upper chute fixedly communicates with a feeding hopper. A hydraulic gate is arranged in the feeding hopper. A rotary fire grate and a water seal type base are arranged at the bottom of the gasifier body. According to the rotary distribution dry deslagging household waste pyrolysisgasifier, a distribution gear motor is arranged, the output end of the distribution gear motor can drive a chain wheel, a transmission special-shaped chain, an inner water seal trough, a lower material falling barrel and the lower chute to rotate, materials located in an upper material falling barrel are evenly scattered into the gasifier body of the gasifier along with rotating of the lower chute, thickness-even material layers are formed, and the problem of uneven distribution of traditional gasifiers is solved.

Owner:河南省海琦环保科技有限公司

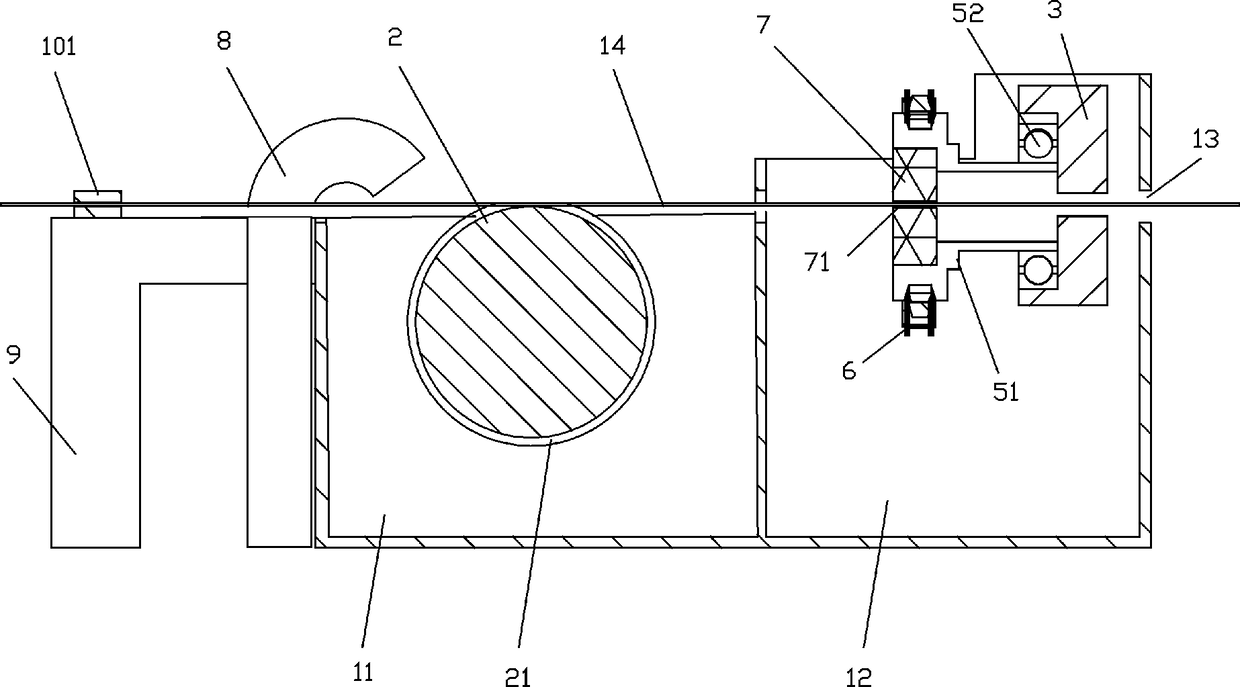

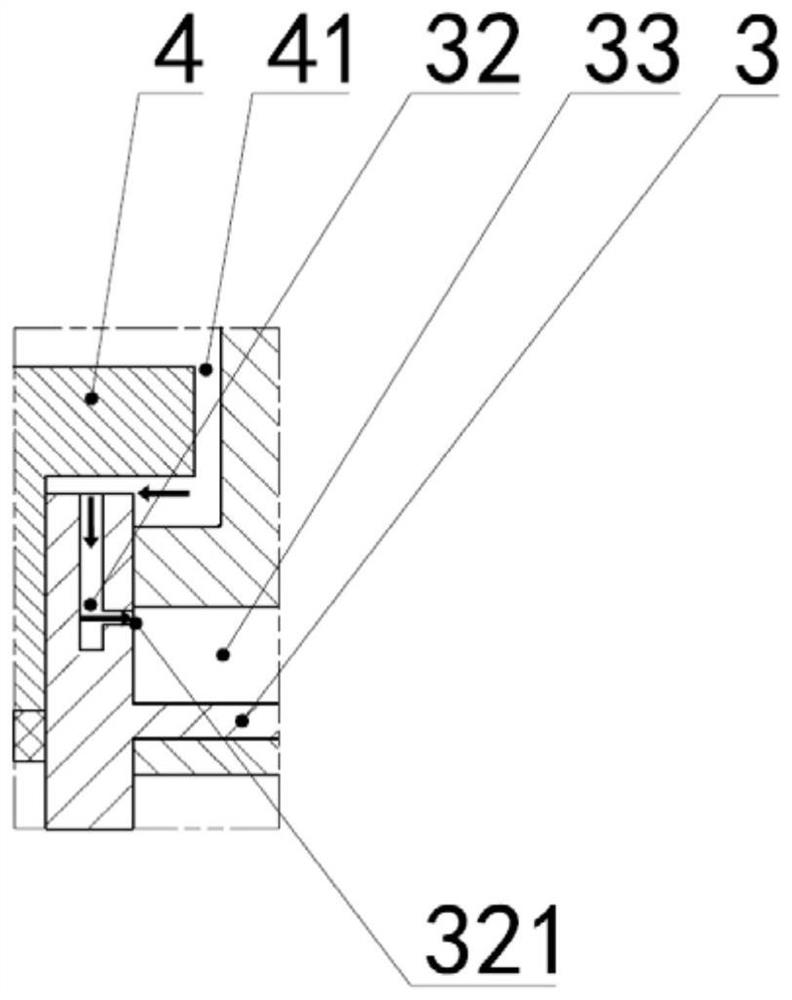

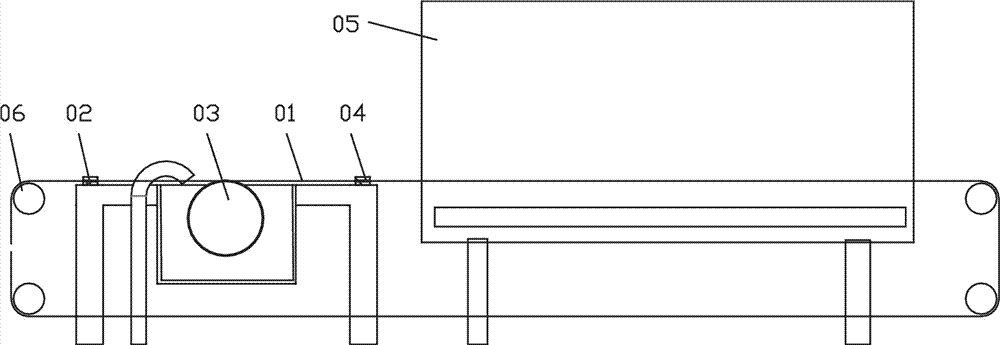

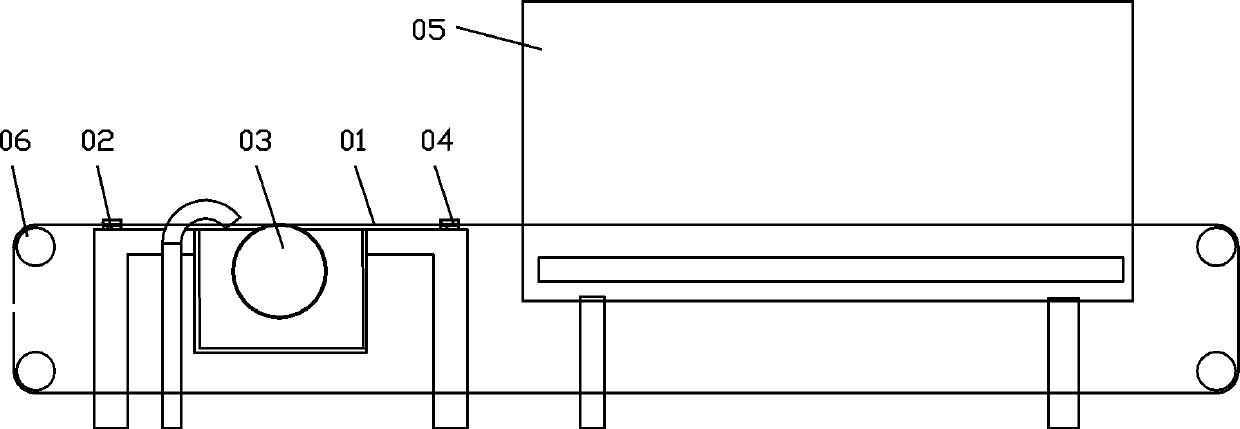

Painting device for chain wheel type enameled wire

InactiveCN108109774AUniform thicknessSolve the problem of unevennessInsulating conductors/cablesDrive wheelSprocket

Owner:宁波高新区布瑞恩科技有限公司

Enameled wire varnishing device

InactiveCN108133790AWipe off evenlyUniform thicknessInsulating conductors/cablesEngineeringMechanical engineering

Owner:宁波高新区布瑞恩科技有限公司

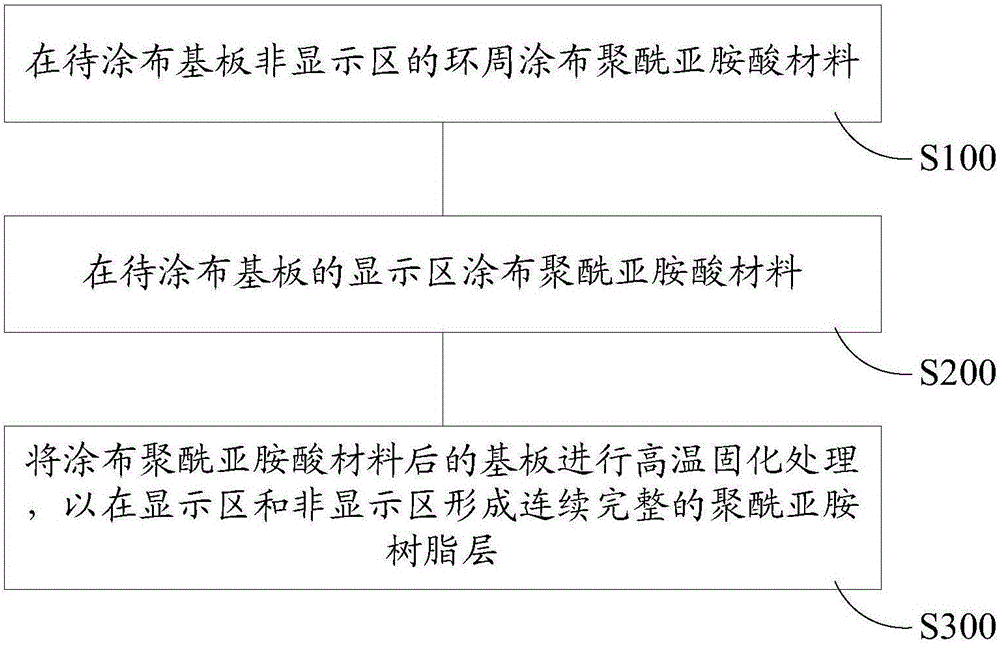

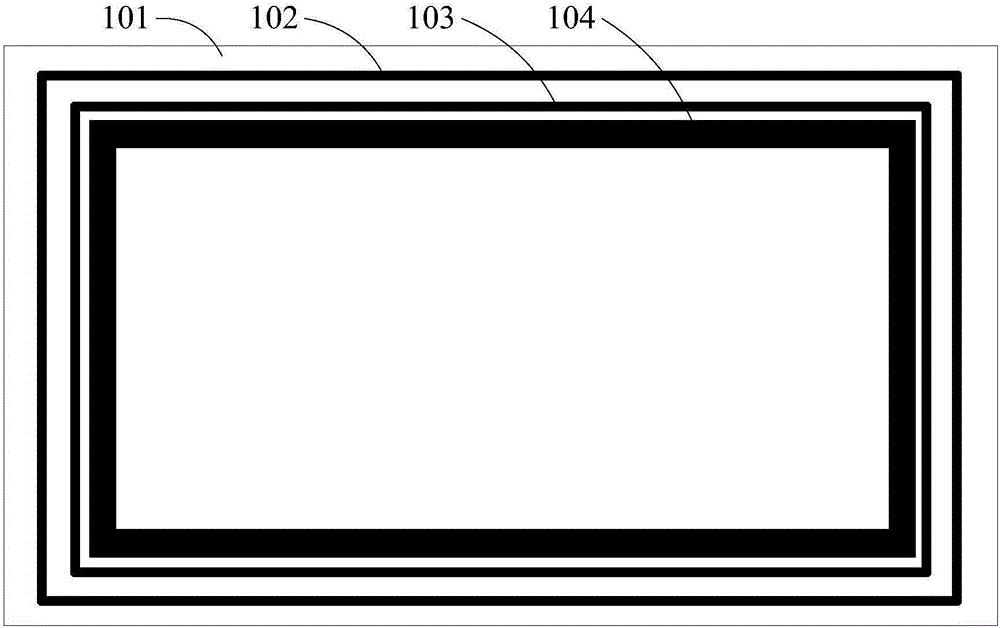

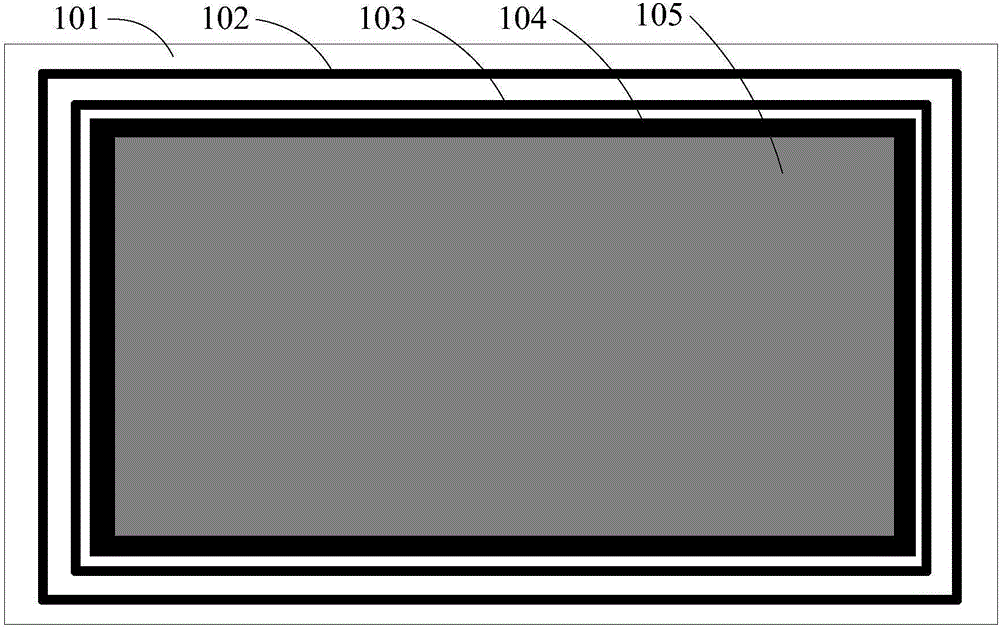

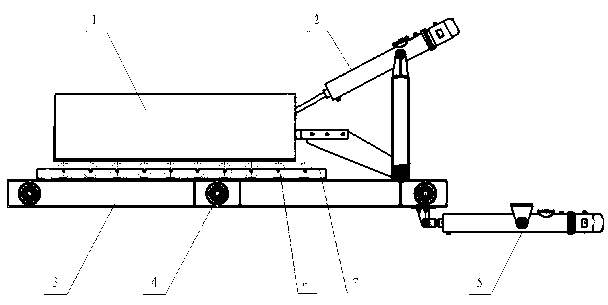

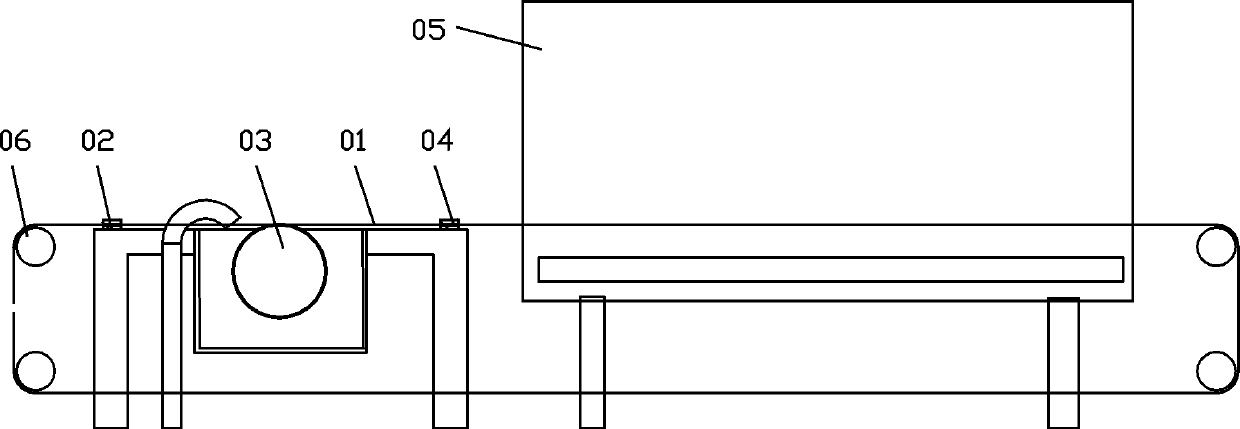

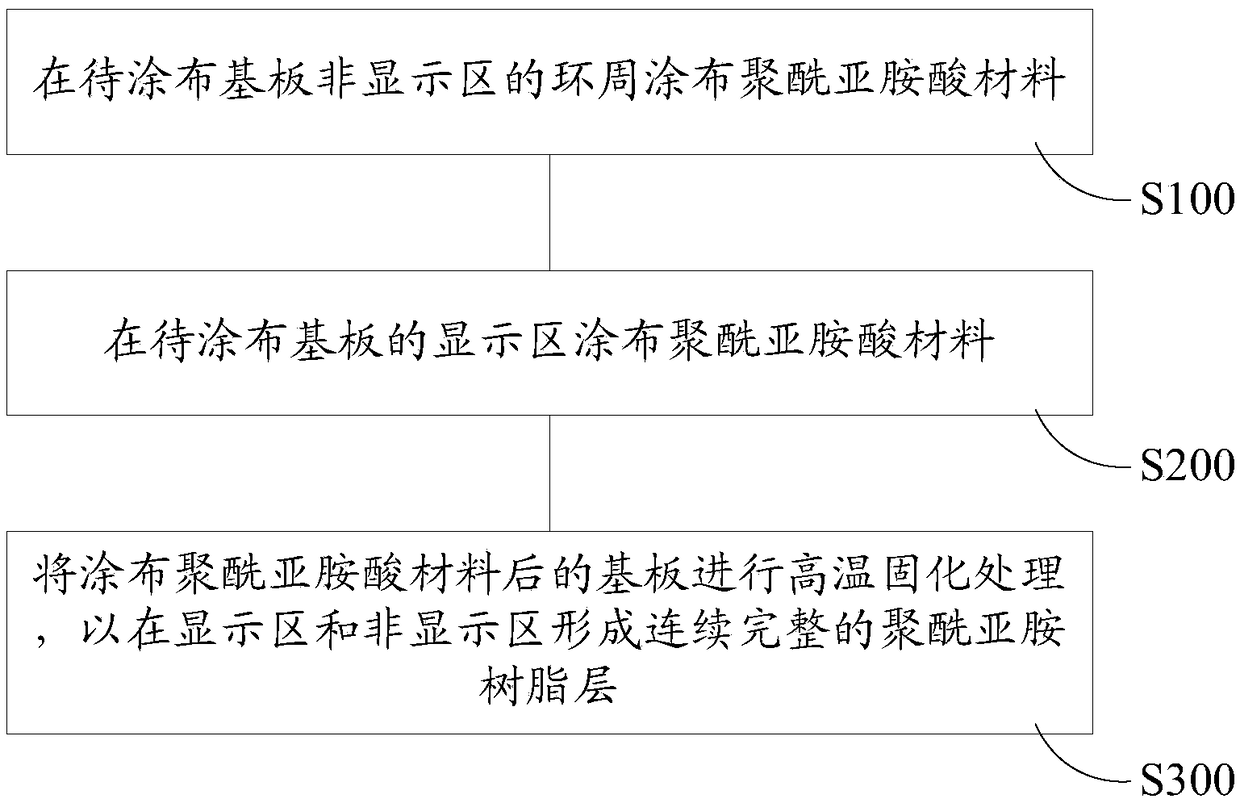

Display and coating method for polyimide resin layer in display module of display

ActiveCN105665247AImprove the level ofSolve the problem of unevennessPretreated surfacesCoatingsDisplay devicePolyimide

The invention provides a display and a coating method for a polyimide resin layer in a display module of the display.The coating method comprises the steps that a non-display area of a substrate to be coated is coated with a polyimide acid material, and a display area of the substrate to be coated is coated with the polyimide acid material, wherein the leveling property of the polyimide acid material coated to the non-display area is superior to that of the polyimide acid material coated to the display area, and an overlaying layer is formed between the polyimide acid material coated to the non-display area and the polyimide acid material coated to the display area; high-temperature curing is conducted on the substrate coated with the polyimide acid material so that the continuous and integrated polyimide resin layer can be formed on the display area and the non-display area.According to the coating method for the polyimide resin layer in the display module, under the situation that a flat layer is not used, the method that before normally coating a display area PI layer, the edge area is coated with a circle of PI layer easily and effectively solves the problem that the leveling property of the PI on the edge is not good.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

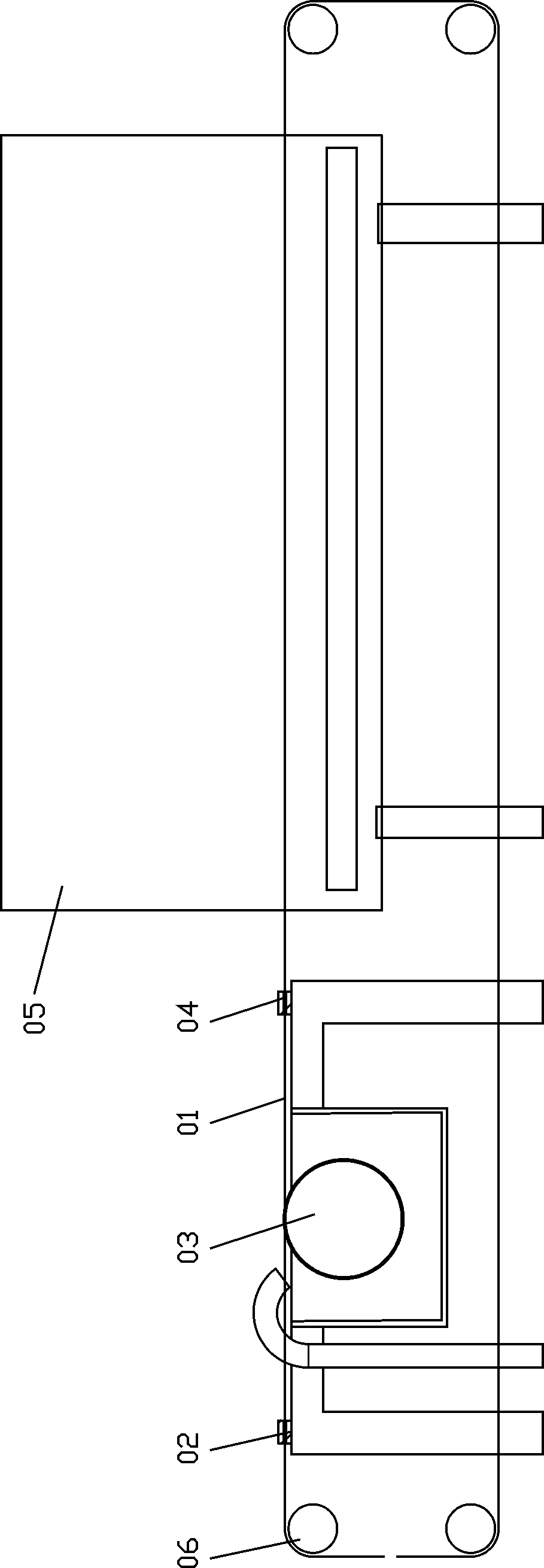

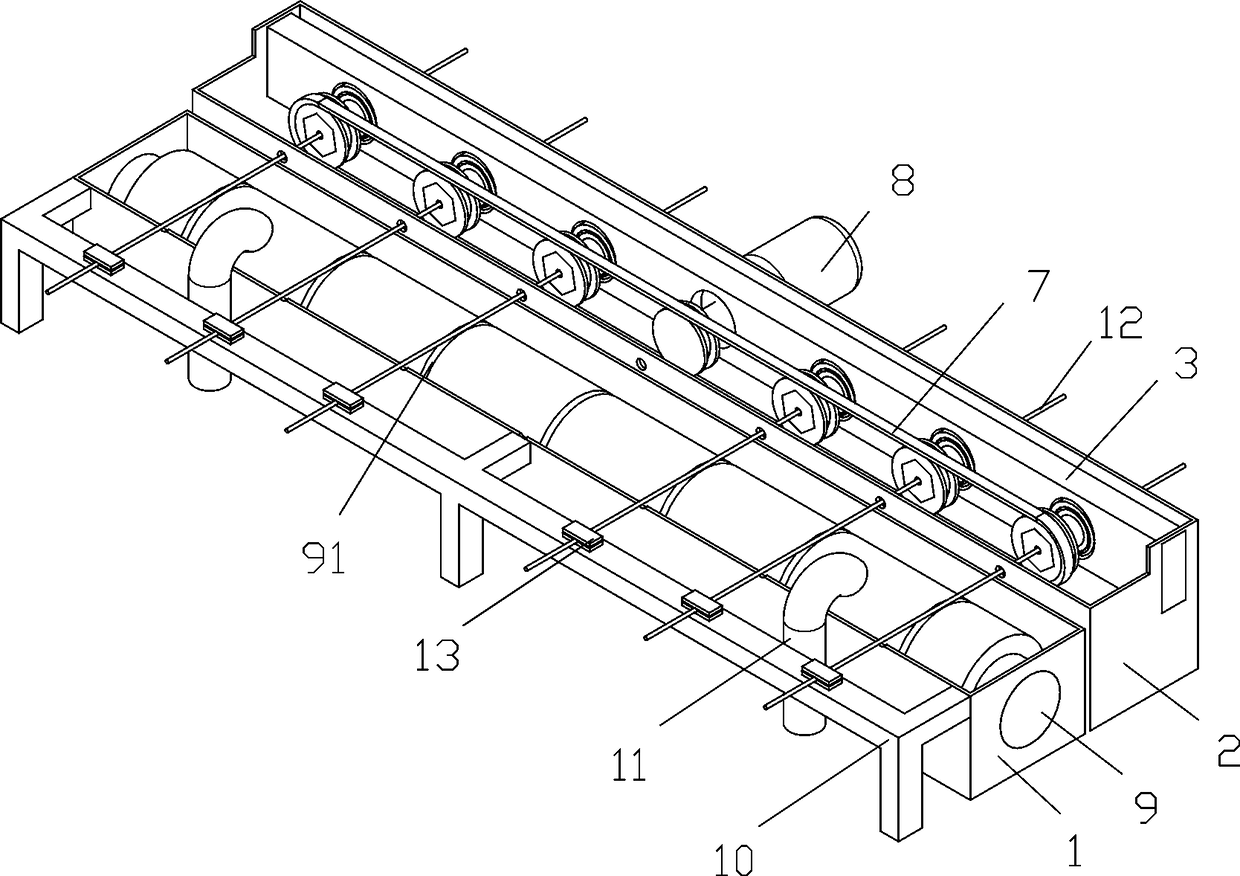

Movable plow discharger for biomass power generation

InactiveCN103264887APoor ability to overcome overloadOvercoming Burnable MotorsConveyor partsPower stationEngineering

The invention discloses a movable plow discharger for biomass power generation, which belongs to the technical field of heavy discharging. The plow discharger comprises a plowshare, a roller unit, a main frame and a hydraulic push rod, wherein the plowshare is connected with a plowshare drive push rod for driving the plowshare; a traveling wheel for driving the hydraulic push rod is arranged in the main frame; the roller unit is connected with a roller frame; and the roller frame is driven by the hydraulic push rod. According to the movable plow discharger for biomass power generation disclosed by the invention, the hydraulic push rod provided with a self-lock device is driven through the traveling wheel, so that multipoint even discharging can be realized, the problem of unevenness of distribution is solved, and meanwhile, the discharger has a simple structure, is stable to operate, is easy to maintain, and is suitable to be popularized and applied in biomass power stations.

Owner:ZHAOYANG PNEUAMTIC HYDRAULIC MECHANICAL EQUIP JIANGSU +1

Multifunctional transverse flow type heat source tower device

ActiveCN103292401BGuaranteed uptimeAvoid enteringSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringTower

The invention discloses a multifunctional transverse flow type heat source tower device which comprises a heat source tower body, an air flowing return circuit and a solution flowing return circuit, wherein the air flowing return circuit and the solution flowing return circuit are arranged in the heat source tower body. The air flowing return circuit comprises an air outlet which is formed in the top of the heat source tower body, air inlets which are formed in the two sides of the middle portion of the heat source tower body, fillings which are symmetrically arranged on the two sides of the inner portion of the heat source tower body and face towards the air inlets, liquor drifting resistant devices which are sequentially arranged below the air outlet from bottom to top, a speed changing draught fan and a self-open type rainproof device. The solution flowing return circuit comprises a liquor distributing system which is arranged above the fillings and placed inside the heat source tower body, fillings and a liquor collecting pool which is placed at the bottom of the heat source tower body, the liquor collecting pool is placed below the fillings, and a heat source tower solution outlet is formed in the bottom of the liquor collecting pool. The multifunctional transverse flow type heat source tower device can prevent rainwater from entering a heat source tower and diluting a solution, reduce solution mass loss caused by solution drifting, achieve the objective that a heat source tower can efficiently and stably operate.

Owner:SOUTHEAST UNIV

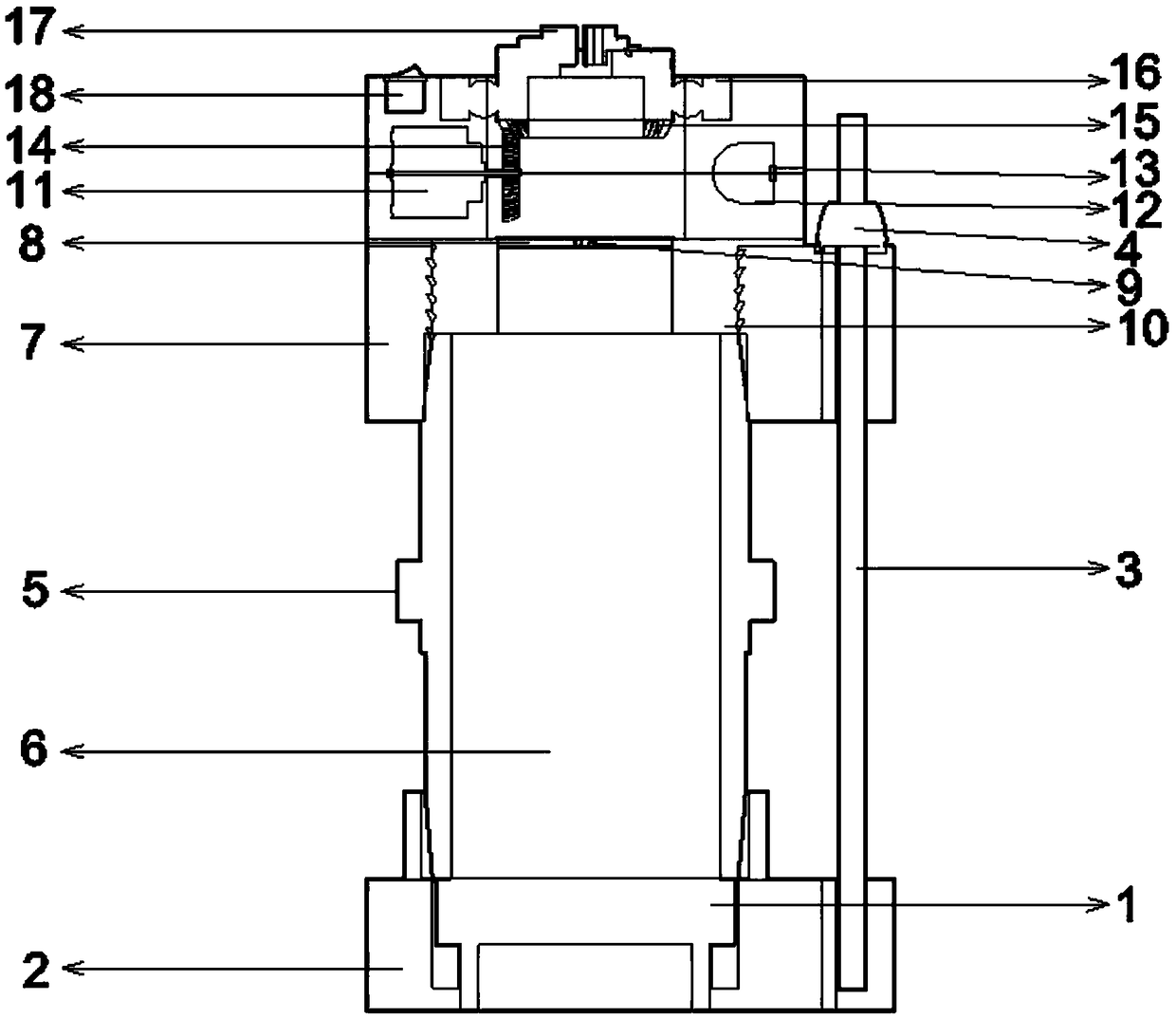

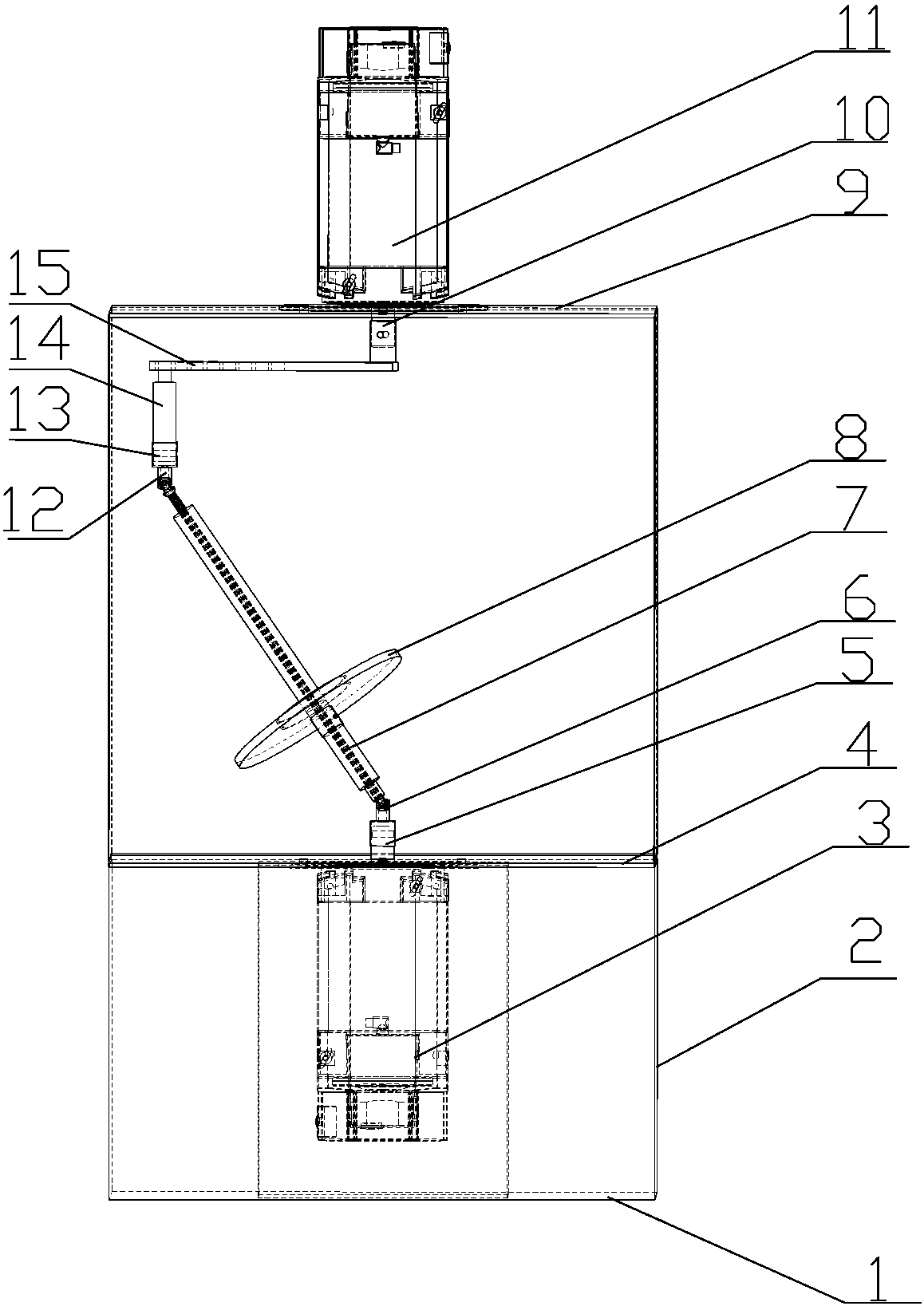

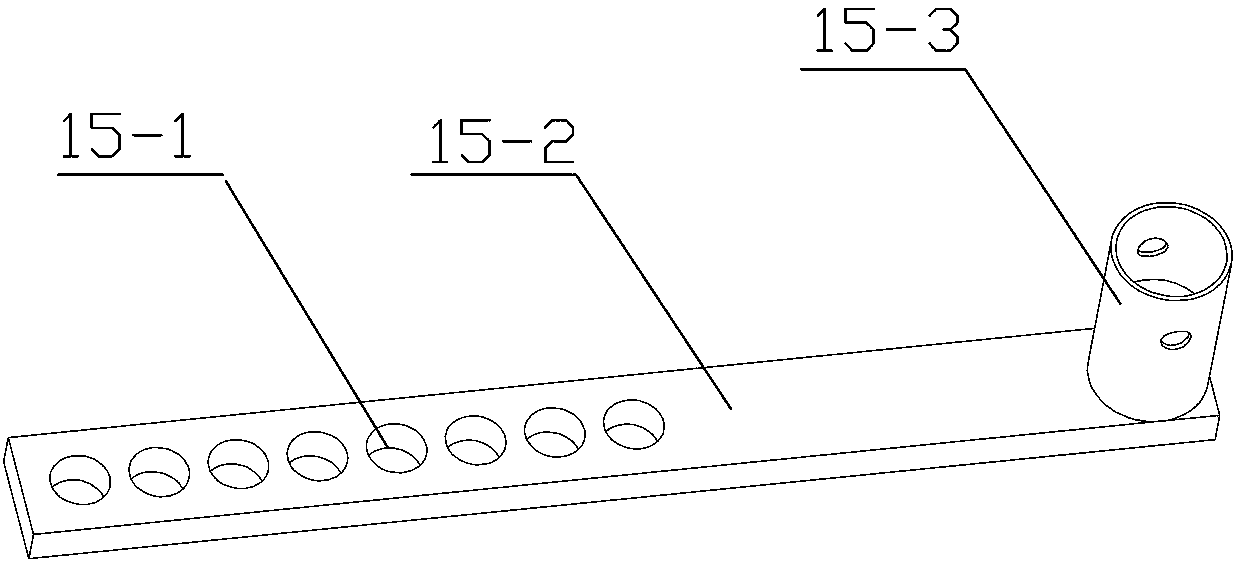

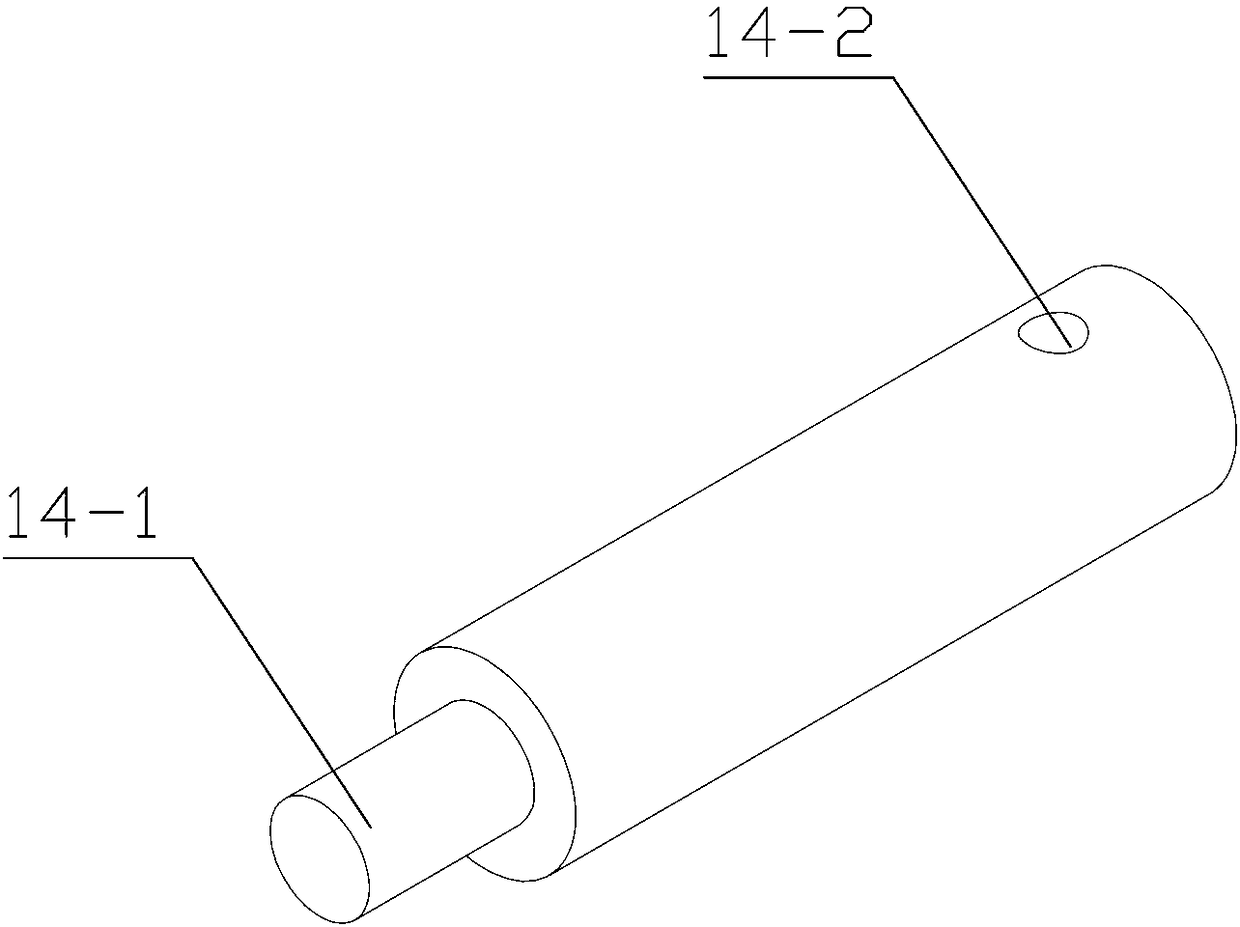

Three-axis sample preparation stirring and throwing device

InactiveCN109342148ASolve the problem of unevennessSolve the problem of not being able to connect wellPreparing sample for investigationPorosityTriaxial shear test

The invention discloses a three-axis sample preparation mixing and throwing device and a sample preparation method, relates to the technical field of preparation of mechanical three-axis test samplesof soil, and solves the problem of non-uniform soil property during the preparation of a remolded three-axis test sample with relatively high moisture content and porosity and the problem that inter-stratum soil layers cannot be well connected during layered sample preparation. The three-axis sample preparation mixing and throwing device comprises a fixer, a proofing cylinder, a clamping plate, astirrer and a stirring and throwing rod. The main technical scheme adopted by the invention is that the whole stirring and throwing device is integrally connected with the sample striking cylinder andthe base by means of threaded connection; the stirring and throwing rod is driven through the rotation of a direct current motor to stir and anchor the soil in the proofing cylinder; for each layer of soil sample, the depth of the stirring and throwing rod can be adjusted by a three-claw chuck, so that the soil layers of different depths can be stirred and anchored, and the quality of the test sample is greatly improved.

Owner:ANHUI UNIV OF SCI & TECH

An enamelled wire enamelling device

Owner:宁波高新区布瑞恩科技有限公司

Novel workpiece rotating stand device applied to magnetron sputtering

PendingCN108486542AOvercome the disadvantage of single rotation modeWide sputtering angleVacuum evaporation coatingSputtering coatingSputteringDegrees of freedom

The invention relates to a rotating stand device applied to magnetron sputtering. The rotating stand device comprises a reaction cavity, a working tray, a spindle and a working tray moving mechanism,wherein the reaction cavity is composed of side walls, a top plate and a bottom plate, and the working tray, the spindle and the working tray moving mechanism are arranged in the reaction cavity. Therotating stand device is characterized in that a base station is arranged in the reaction cavity and divides the reaction cavity into an upper cavity body and a lower cavity body, and the working trayis arranged on the spindle; and the working tray moving mechanism comprises a rotation mechanism and a revolution mechanism. The rotating stand device has the beneficial effects that the disadvantagethat a traditional workpiece rotating stand is simplex in rotating mode is overcome, the degree of freedom of workpiece movement is increased, thus all faces of a workpiece can be evenly covered withparticles sputtered by target materials, the problem that coatings of seamed edges of the workpiece are uneven is effectively solved, and the effect of the coatings is enhanced.

Owner:UNIV OF SCI & TECH LIAONING

Magic particle feature recognition anti-counterfeiting card and preparation method thereof

ActiveCN112150909ASolve the problem of indistinguishable authenticityReduce lossesStampsIdentification meansAdhesiveEngineering

The invention belongs to the technical field of anti-counterfeiting marks, and particularly relates to a magic particle feature recognition anti-counterfeiting card and a preparation method thereof. The card comprises a local covering layer, a first plastic film layer, a local uncovering layer, a first adhesive layer, a random identification mark layer, a second printing layer and a base materiallayer which are sequentially arranged from top to bottom. The random identification mark layer comprises a first printing layer, a second plastic film layer, a random physical characteristic layer, athird plastic film layer, a color ink layer and a second adhesive layer which are sequentially arranged from top to bottom, information of the first printing layer comprises variable information, andthe random physical characteristic layer is composed of random physical characteristics and an adhesive; a corresponding relationship exists between the variable information and the random physical characteristics; the second printing layer information comprises variable information, and the variable information of the second printing layer and the variable information of the first printing layerhave a corresponding relation; the local uncovering layer is arranged above the variable information of the second printing layer; and the partial covering layer covers part or all of the variable information of the second printing layer. The anti-counterfeiting effect is good, and the preparation method is simple.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

Voltage output method, device, controller and storage medium

ActiveCN111312167BImprove accuracySolve the problem of uneven display screenStatic indicating devicesDisplay deviceHemt circuits

The invention provides a voltage output method, device, controller and storage medium, which are applied to a pixel circuit including a driving thin film transistor, and the first voltage and the second voltage are respectively applied to the control terminal and the output terminal of the driving thin film transistor to obtain the driving The output voltage of the output terminal of the thin film transistor is stabilized, and it is judged whether the difference between the output voltage and the standard voltage satisfies the preset condition. When the preset condition is not met, the first voltage is updated according to the output voltage and the standard voltage, and the corresponding target is obtained. voltage, and return to the step of applying the first voltage and the second voltage to the control terminal and the output terminal of the driving thin film transistor, respectively, until the preset condition is met, then adding all the target voltages to obtain the threshold voltage of the driving thin film transistor, and Output threshold voltage; this solution can improve the detection accuracy of the threshold voltage of the driving thin film transistor, so as to better solve the problem of uneven display of the OLED display.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

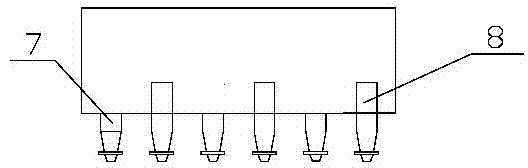

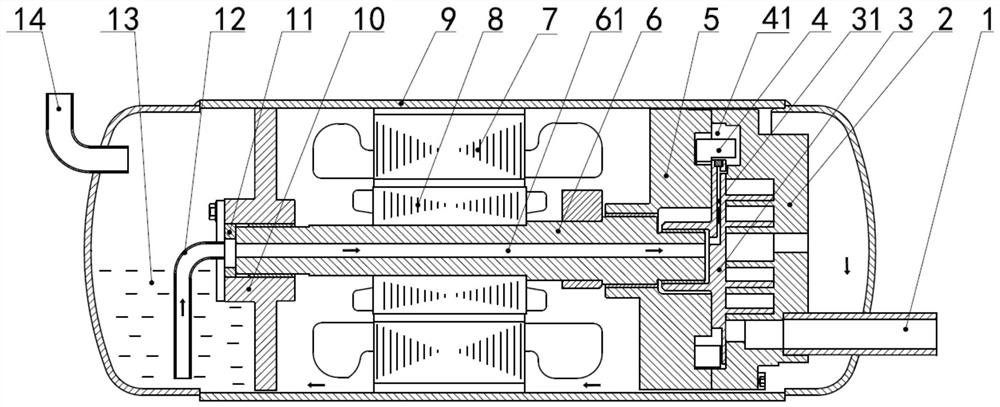

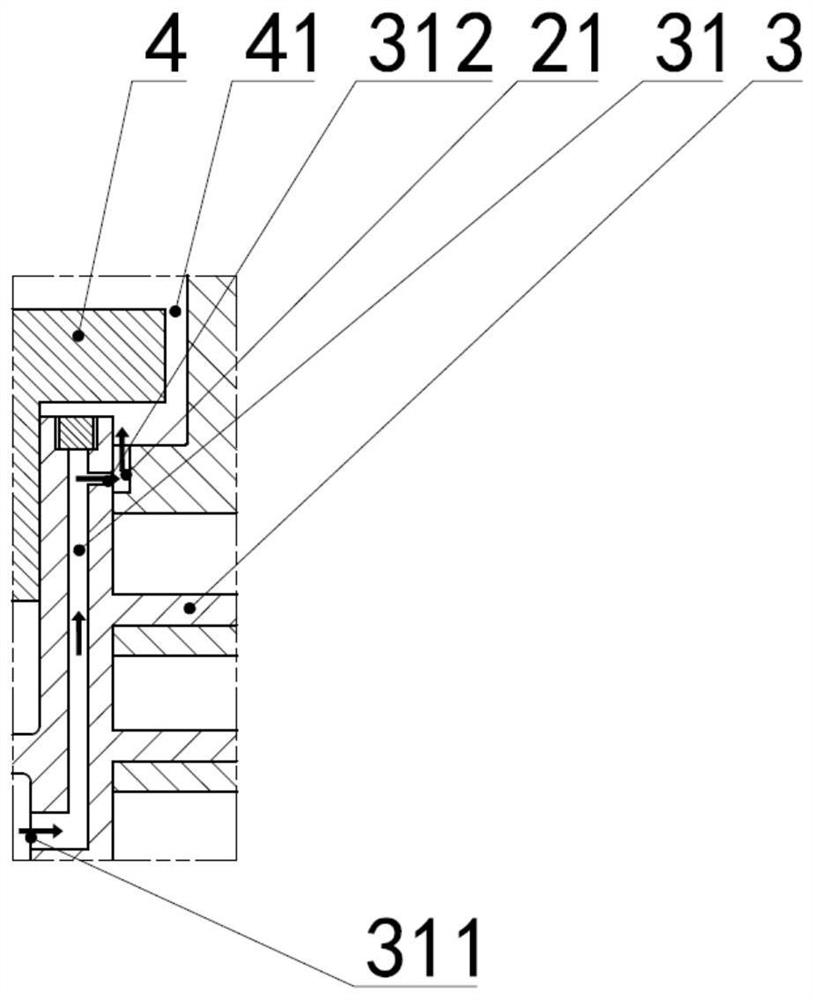

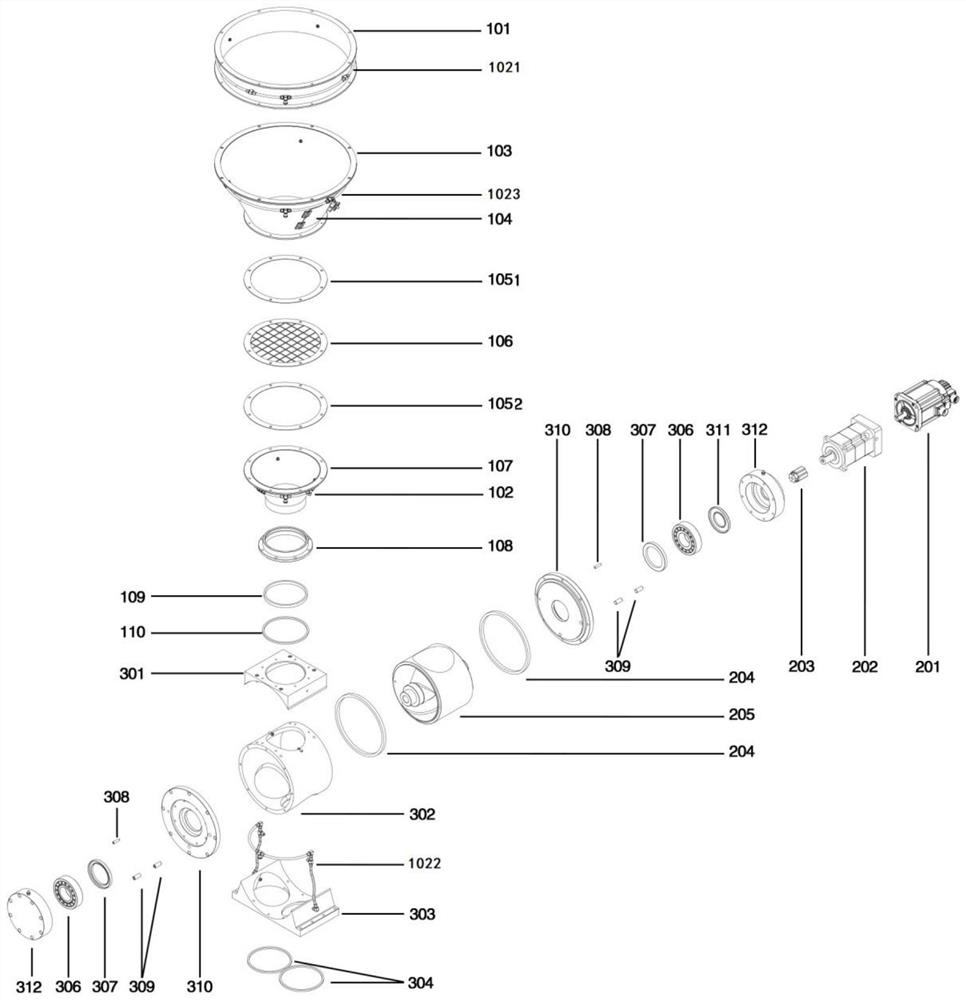

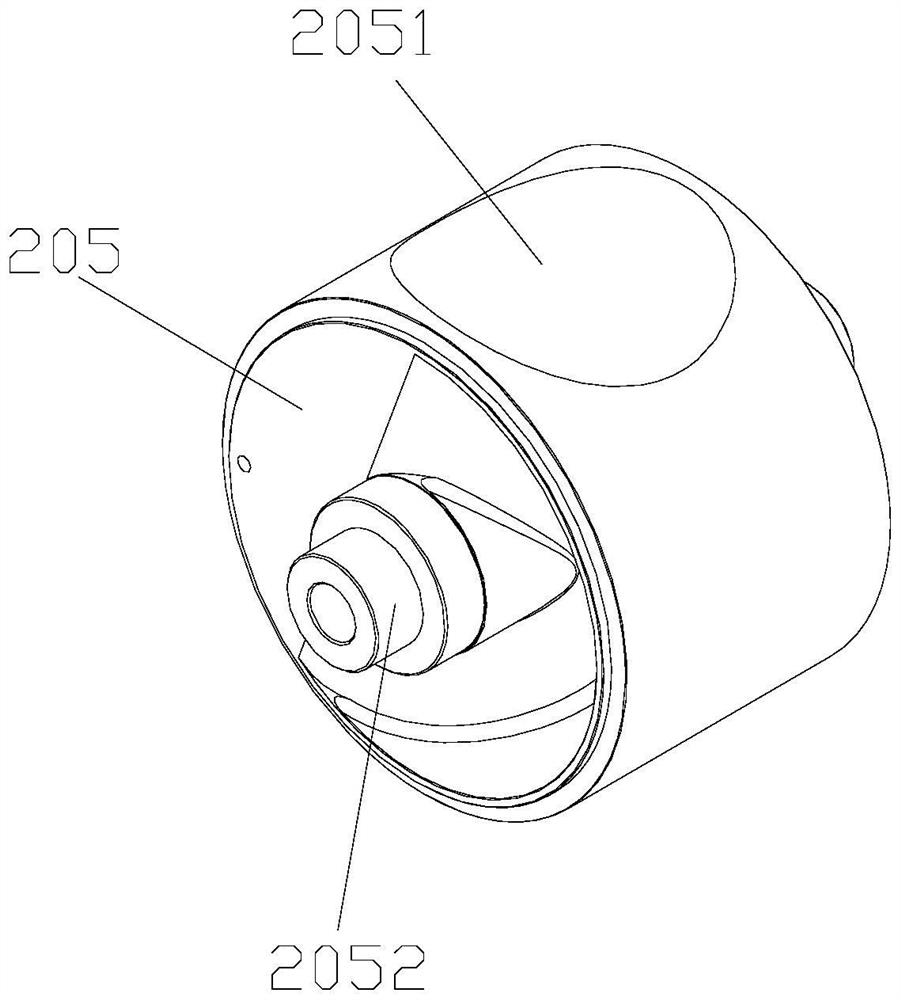

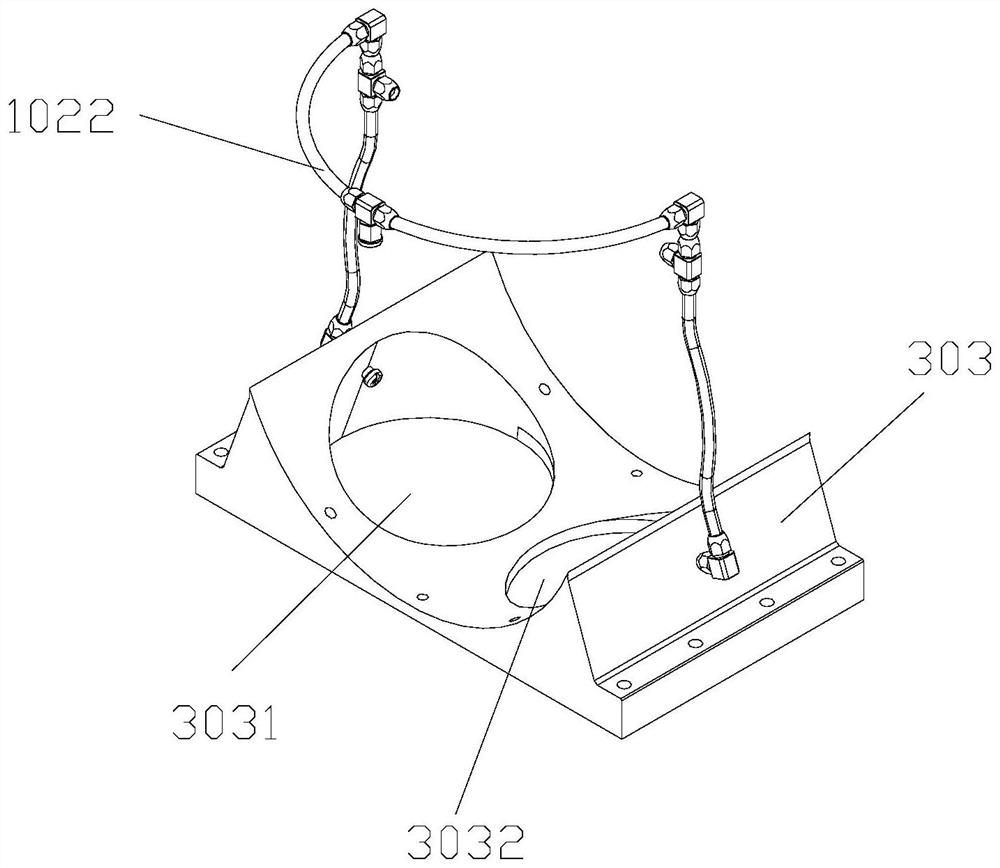

Scroll compressor with active oil supply system

PendingCN113606144AImprove reliabilitySolve uneven lubricating oilRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPhysicsSuction tubing

The invention discloses a scroll compressor with an active oil supply system, and relates to the technical field of scroll compressors for air conditioners, in particular to a horizontal scroll compressor with the active oil supply system. A movable scroll cross-shaped ring cavity oil supply structure is arranged between a cross-shaped ring cavity and a crankshaft oil way; a movable scroll compression cavity oil supply structure is arranged between the cross-shaped ring cavity and a compression cavity; lubricating oil in an oil pool is pumped into a crankshaft oil way by a positive displacement pump through an oil suction pipe assembly and enters the cross-shaped ring cavity through the movable scroll cross-shaped ring cavity oil supply structure, after the lubricating oil in the cross-shaped ring cavity reaches a certain height, the lubricating oil enters the compression cavity through the movable scroll compression cavity oil supply structure for lubrication, the lubricating oil is discharged out of a scroll cavity along with a refrigerant, and the oil returns to the oil pool. According to the technical scheme, the problem that in the prior art, the lubricating oil on all sliding faces of the compression cavity and a cross-shaped ring of the horizontal scroll compressor is not uniform is solved.

Owner:DALIAN SANYO COMPRESSOR

Sprocket type enameled wire painting device

InactiveCN108109774BUniform thicknessSolve the problem of unevennessInsulating conductors/cablesDrive wheelLacquer

Owner:宁波高新区布瑞恩科技有限公司

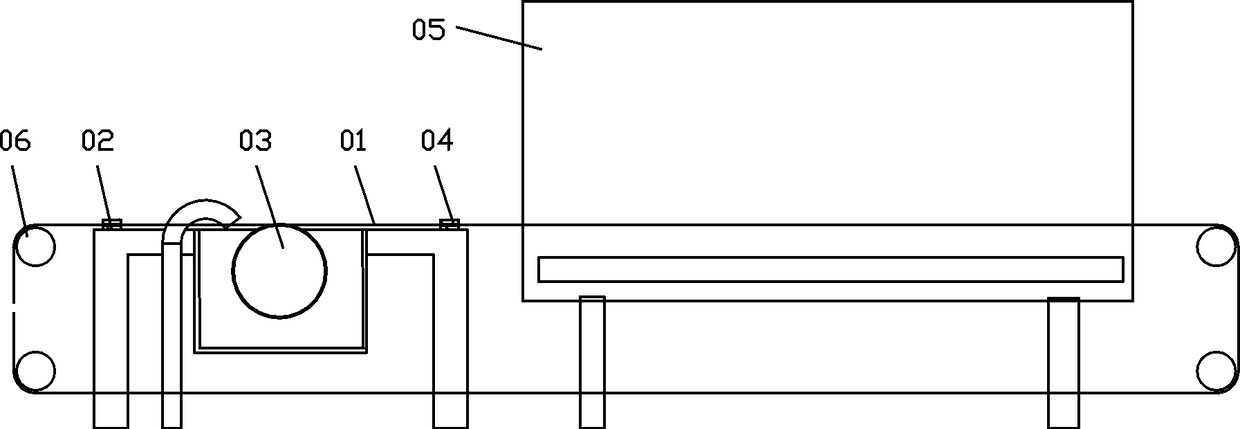

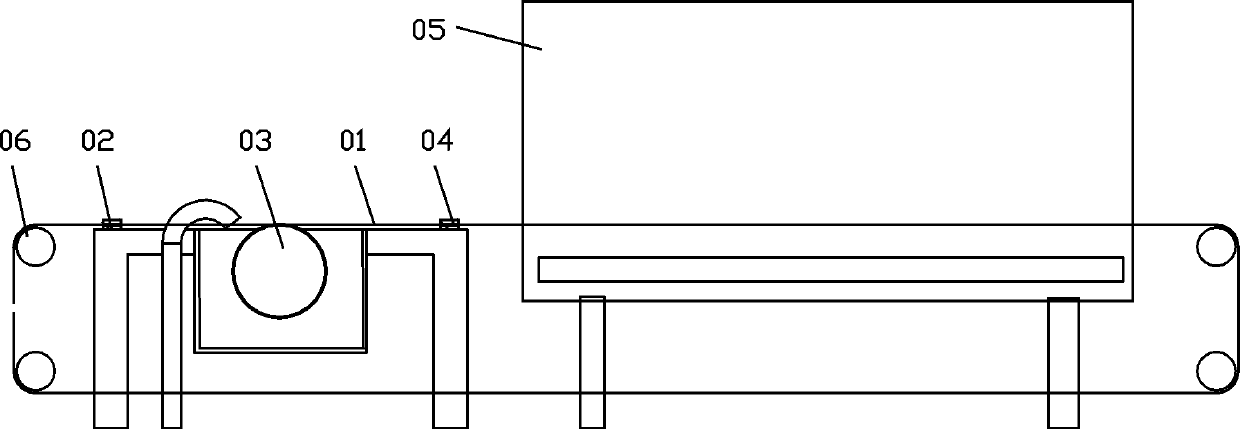

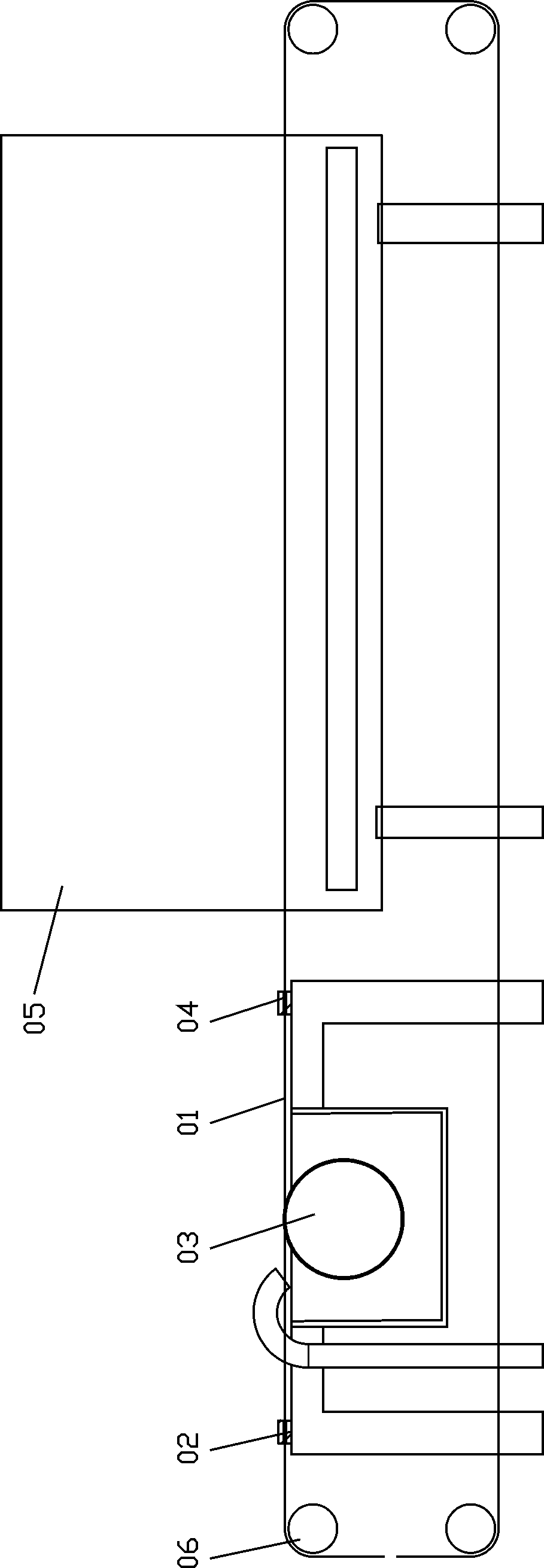

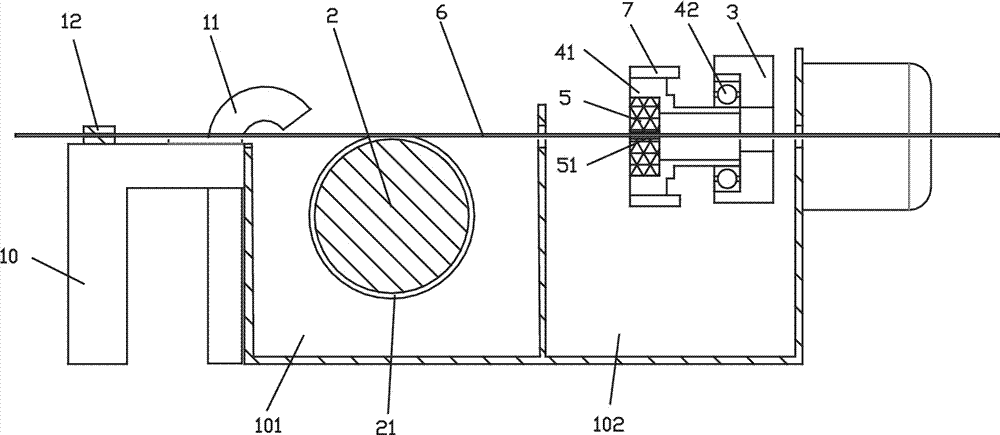

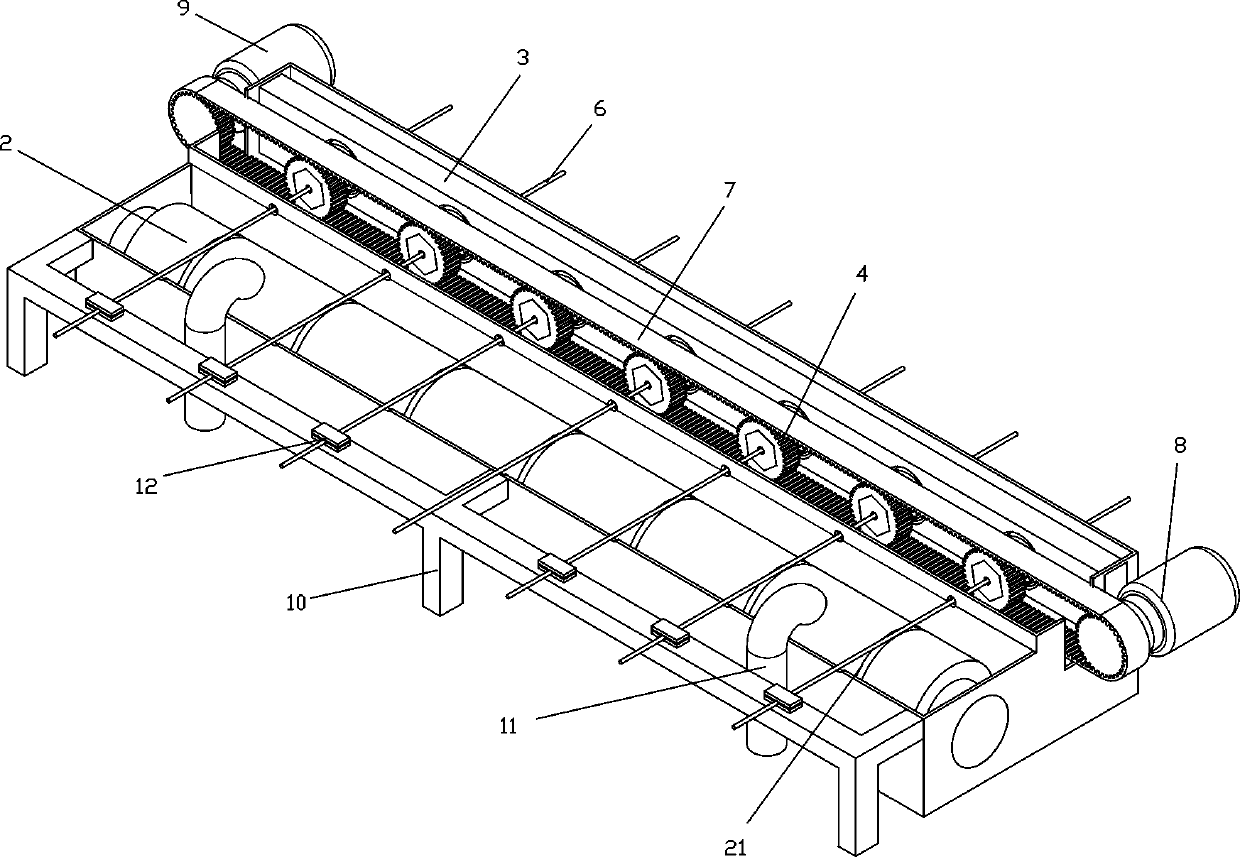

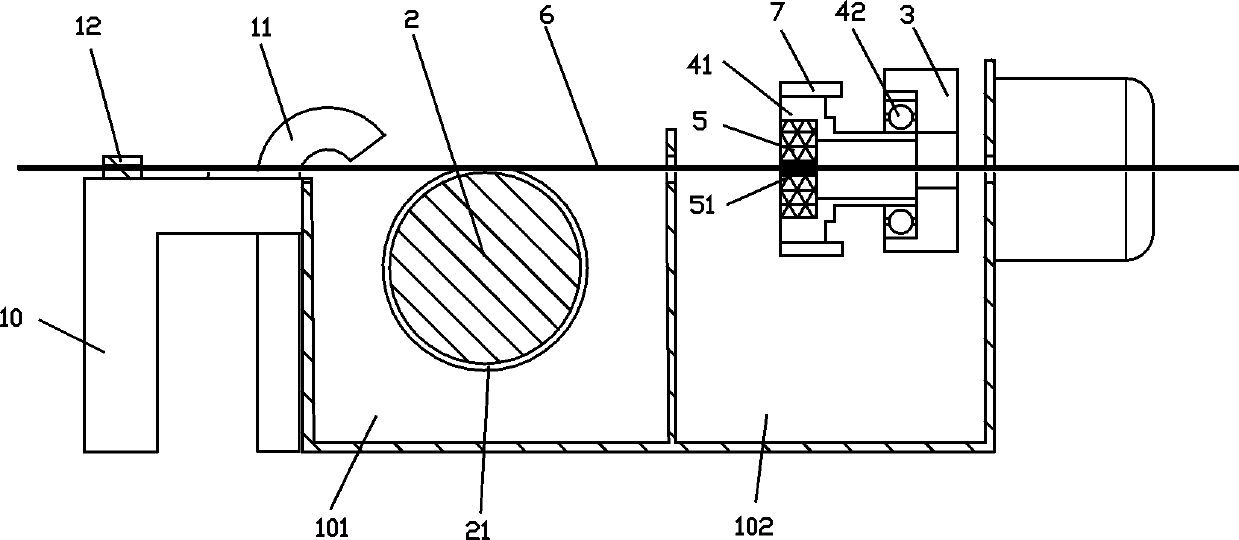

Crawler belt-driving painting device

InactiveCN107958749AWipe off evenlyUniform thicknessInsulating conductors/cablesEngineeringMechanical engineering

The invention discloses a crawler belt-driving painting device comprising a painting groove (1); the features are that the painting groove is divided into a paint slot and a hollow slot; a painting roller is arranged in the paint slot; the painting roller is provided with a plurality of oil gathering ring slots; a roller rack is arranged in the hollow slot, and provided with a plurality of step holes, wherein each step hole is provided with a rotatable roller assembly; the roller assembly is provided with a felt block; a wiping hole is arranged in the center of the felt block, and serves as the rotary center of the roller assembly; each wiping hole is matched with one oil gathering ring slot; a to-be-processed enamelled wire passes the oil gathering ring slot, and penetrates the wiping hole; the advantages are that in the process of the to-be-processed enamelled wire passing the rotating wiping hole, the excess paint material can be evenly wiped off, so the painting material thicknesscan be even in all directions of the to-be-processed enamelled wire, thus well solving the uneven problems in various directions.

Owner:宁波高新区布瑞恩科技有限公司

Multi-stage cutting machine for medicinal materials

InactiveCN108406873ASolve the problem of unevennessSimple structureMetal working apparatusEngineeringRotating disc

The invention relates to the technical field of medicine, and discloses a multi-stage cutting machine for medicinal materials. The multi-stage cutting machine for the medicinal materials comprises a shell. A feeding opening is formed in the left side surface of the shell. A fixed plate is located at the left side surface of the shell and arranged at the rear portion of the feeding opening. A firstmotor is fixedly installed at the front surface of the fixed plate. An output shaft of the first motor is fixedly connected with a first rotating shaft. A driving rod is fixedly connected to the rearportion of the inner wall of the shell. The one end, away from the first motor, of the first rotating shaft is sleeved with a rotating disc. The one end, away from the rear portion of the inner wallof the shell, is sleeved with a rotating disc. The surfaces of the two rotating discs are fixedly connected through conveying belts. A fixed block is fixedly connected to the top of the inner wall ofthe shell. A second motor is fixedly installed at the one end, away from the inner wall of the shell, of the fixed block. According to the multi-stage cutting machine for the medicinal materials, thestructure is simple, the operation is convenient, the cutting of the medicinal materials is more meticulous and more uniform, the medicinal value of the medicinal materials is maximized, and excessivewaste of the medicinal materials is avoided.

Owner:湖北茗萃农业科技有限公司

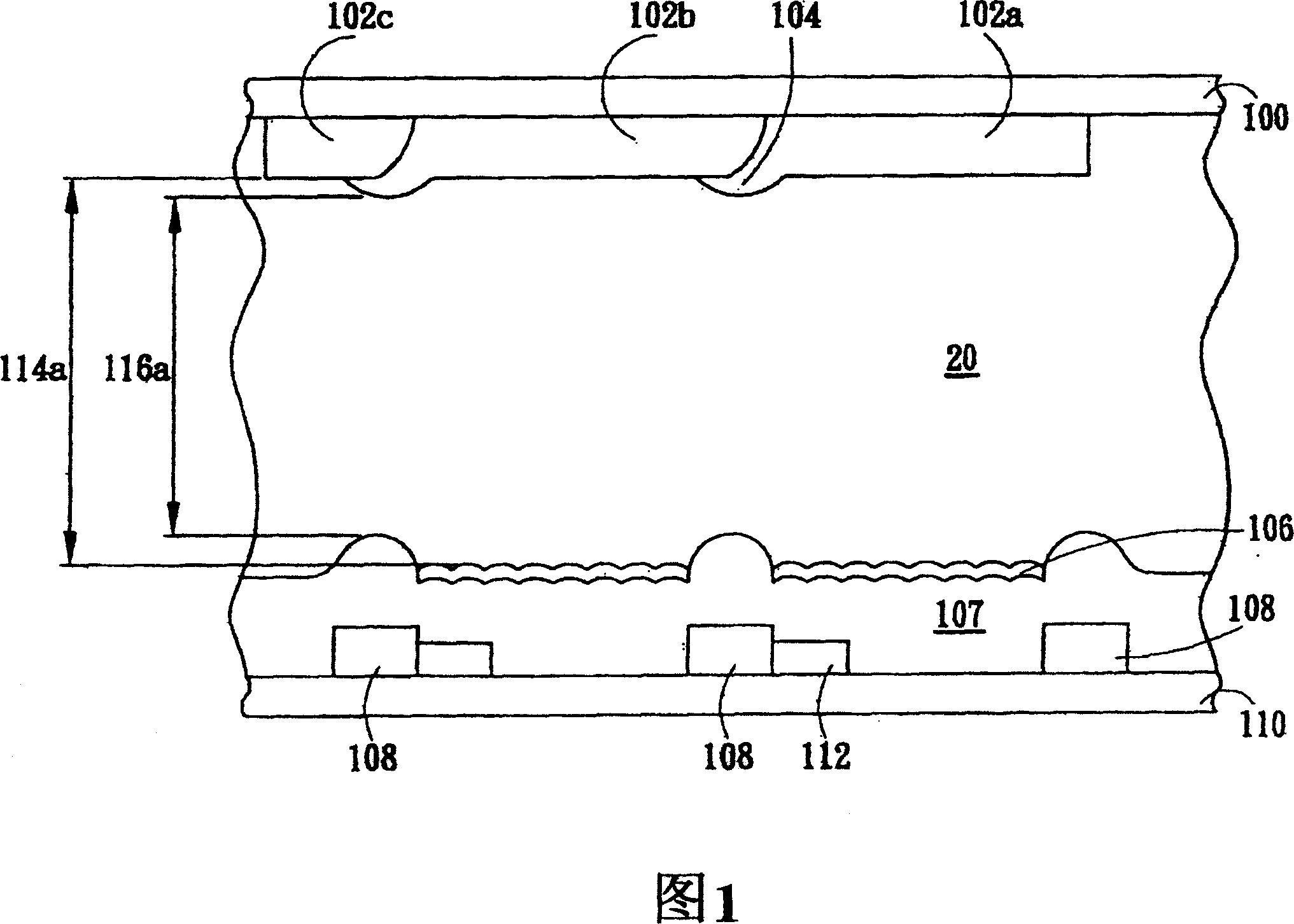

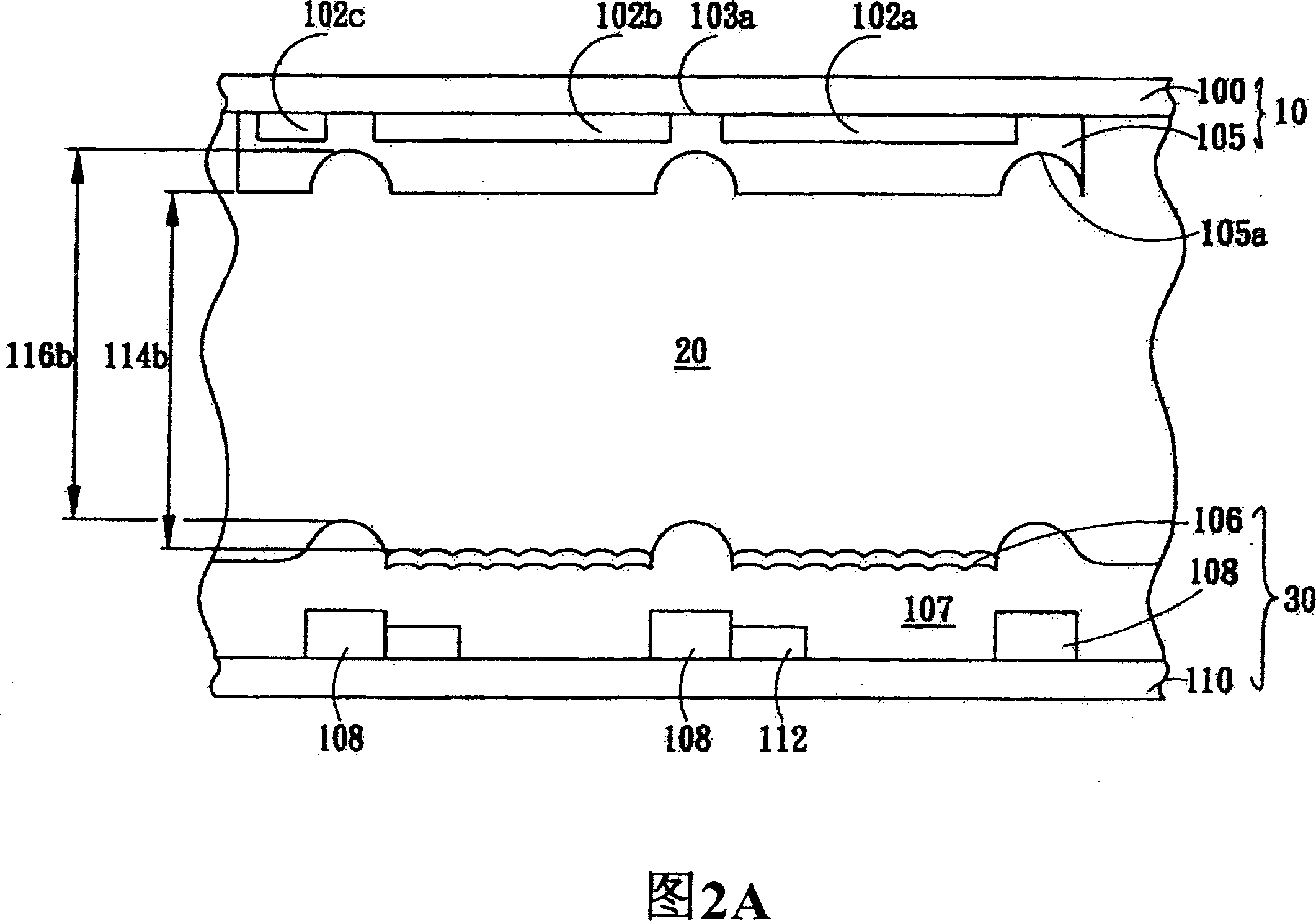

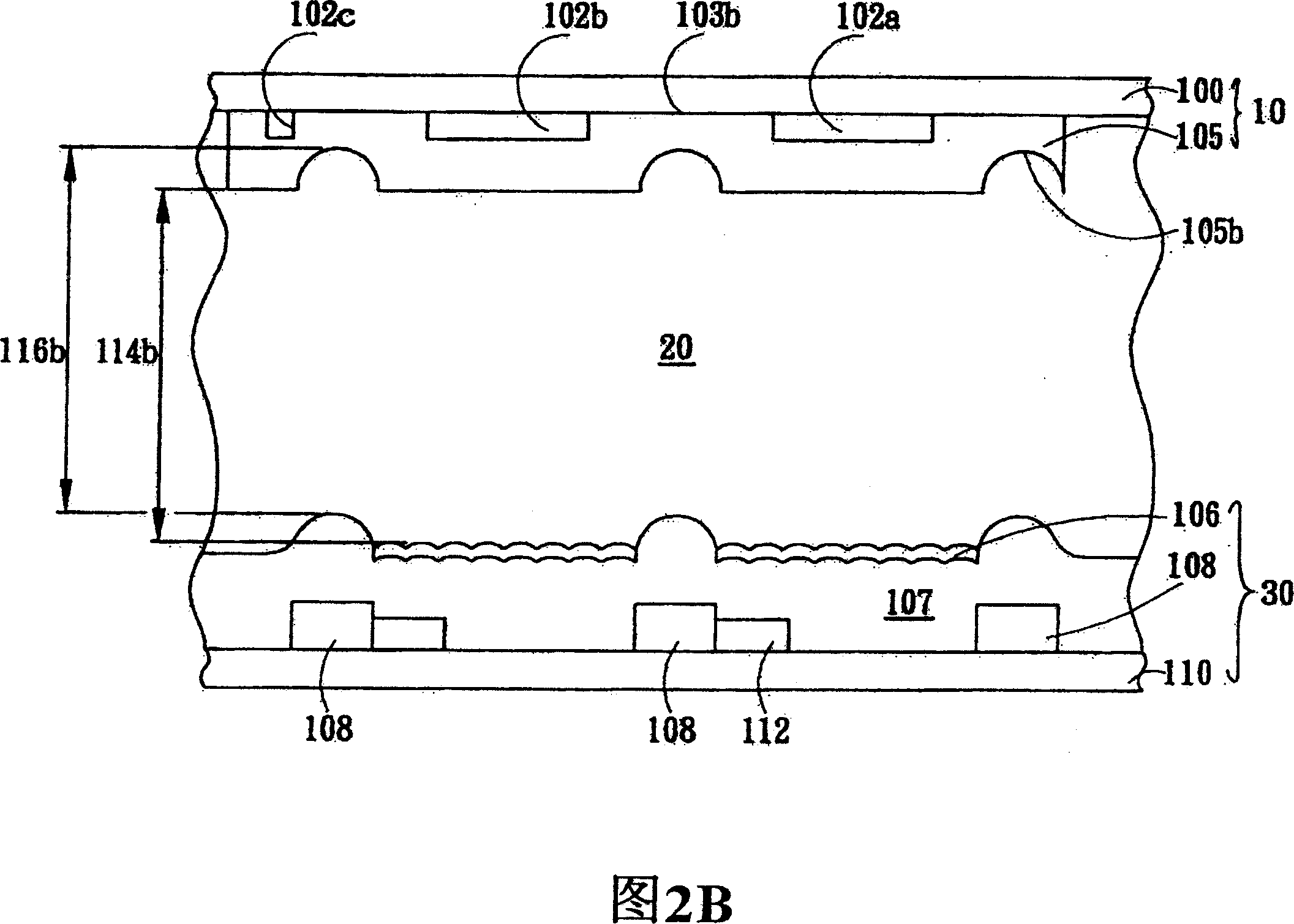

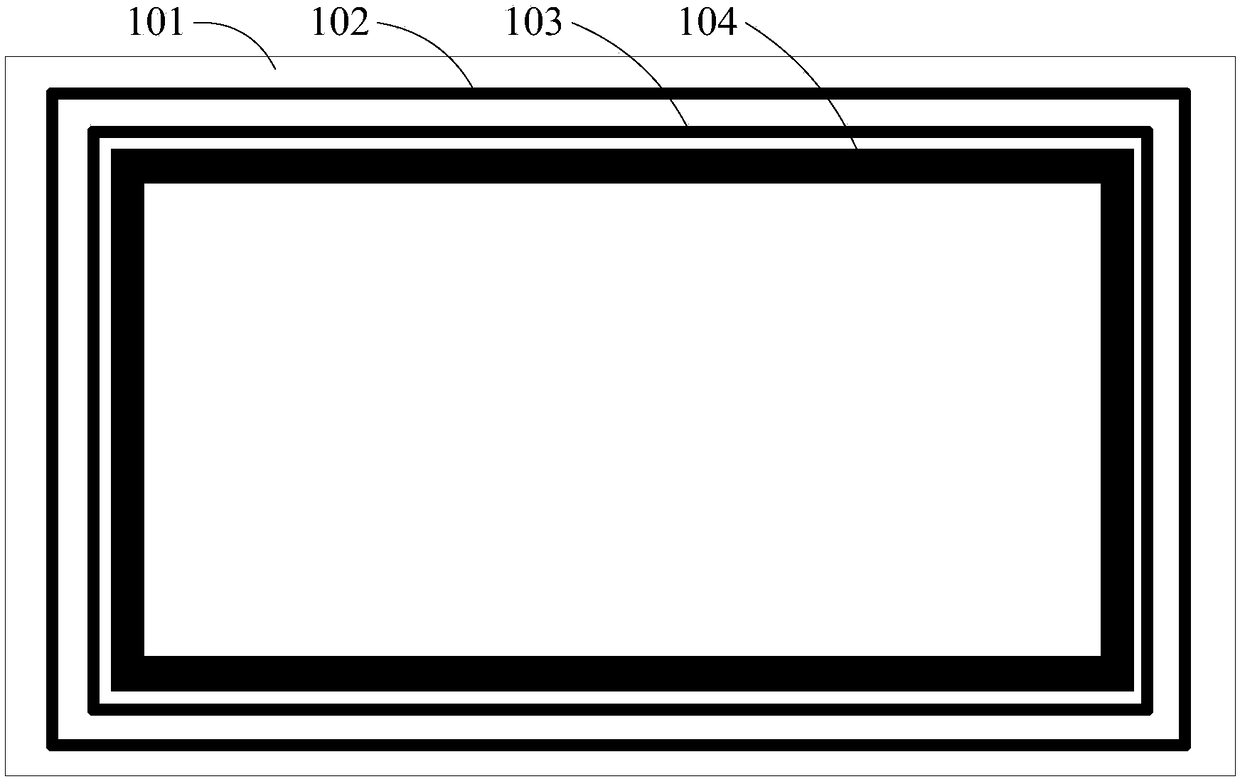

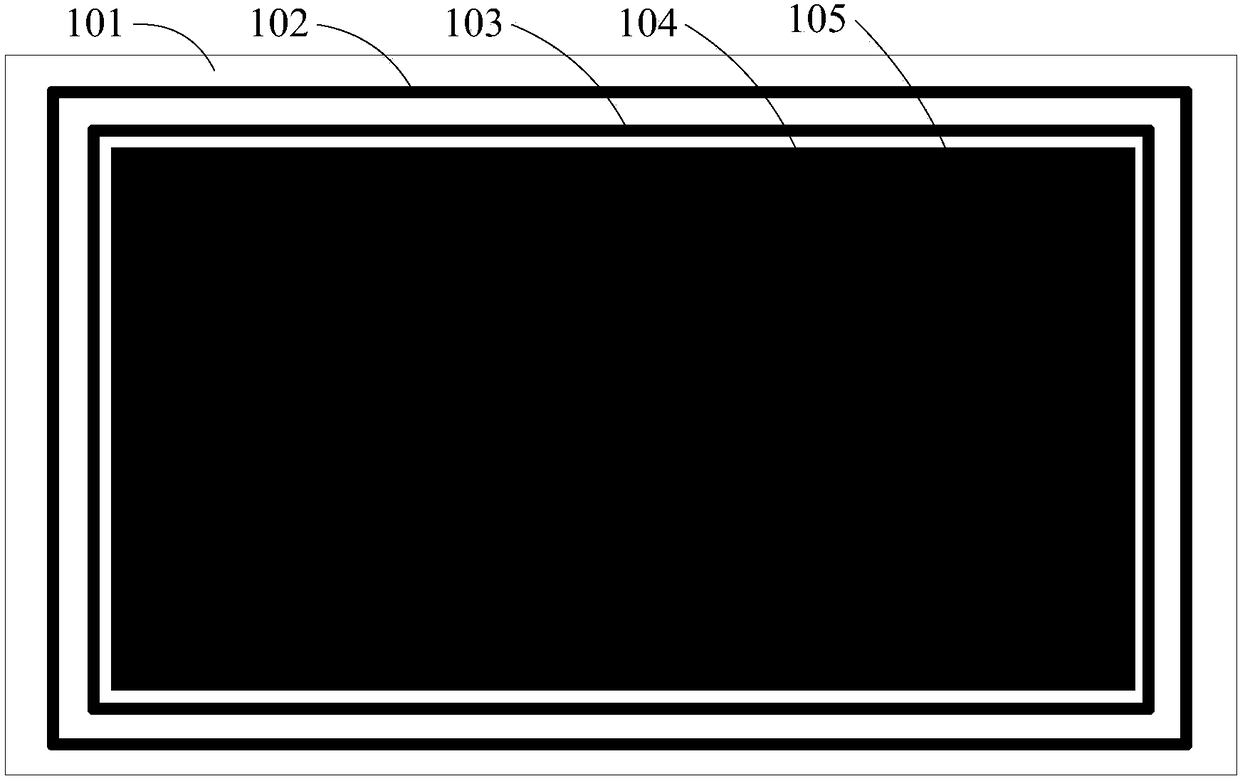

Faceplate of liquid crystal display

InactiveCN100373231CImprove yieldImprove qualityStatic indicating devicesNon-linear opticsConvex structureLiquid-crystal display

A faceplate of liquid crystal display sets opening on position of wire corresponding to colour filtering substrate to solve problem of convex structure formed by overlap of filtering layers and problem of nonuniformity of gap between liquid crystal particles caused by higher height of wire on bottom substrate corresponding to colour filtering substrate so that the on - specification rate and quality of liquid crystal faceplate can be raised.

Owner:AU OPTRONICS CORP

A track-driven painting device

InactiveCN107958749BWipe off evenlyUniform thicknessInsulating conductors/cablesEngineeringMechanical engineering

The invention discloses a crawler belt-driving painting device comprising a painting groove (1); the features are that the painting groove is divided into a paint slot and a hollow slot; a painting roller is arranged in the paint slot; the painting roller is provided with a plurality of oil gathering ring slots; a roller rack is arranged in the hollow slot, and provided with a plurality of step holes, wherein each step hole is provided with a rotatable roller assembly; the roller assembly is provided with a felt block; a wiping hole is arranged in the center of the felt block, and serves as the rotary center of the roller assembly; each wiping hole is matched with one oil gathering ring slot; a to-be-processed enamelled wire passes the oil gathering ring slot, and penetrates the wiping hole; the advantages are that in the process of the to-be-processed enamelled wire passing the rotating wiping hole, the excess paint material can be evenly wiped off, so the painting material thicknesscan be even in all directions of the to-be-processed enamelled wire, thus well solving the uneven problems in various directions.

Owner:宁波高新区布瑞恩科技有限公司

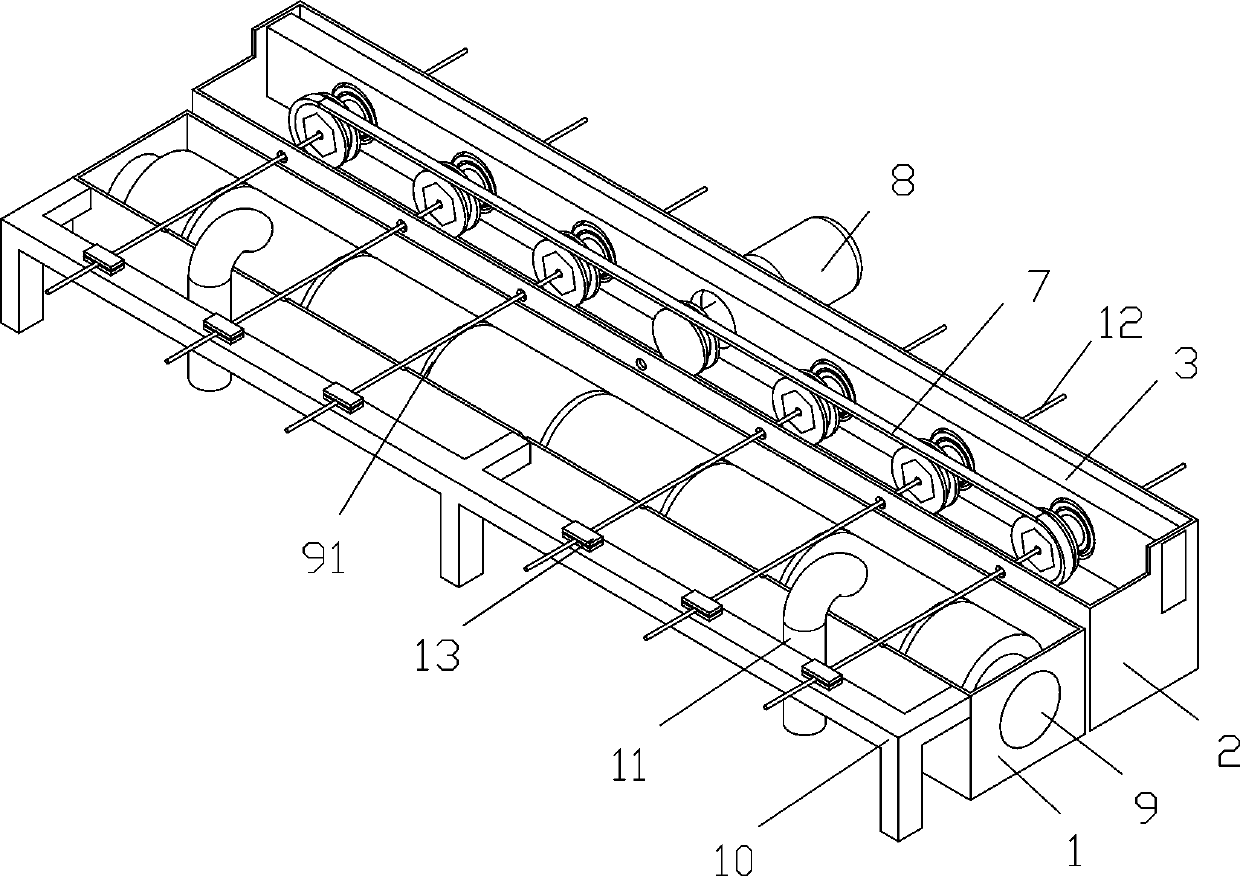

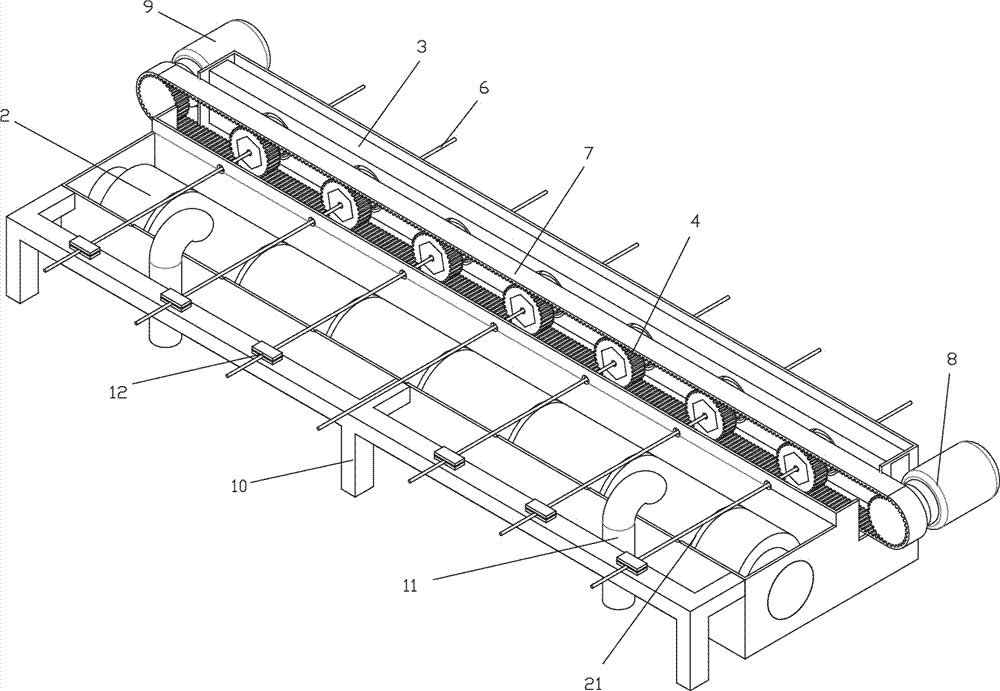

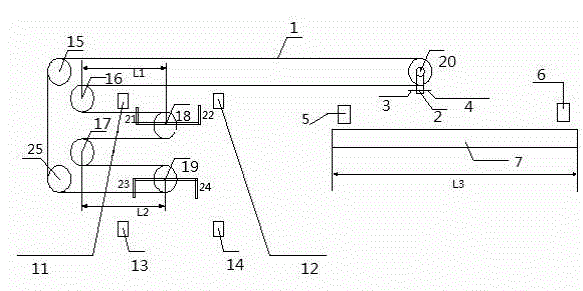

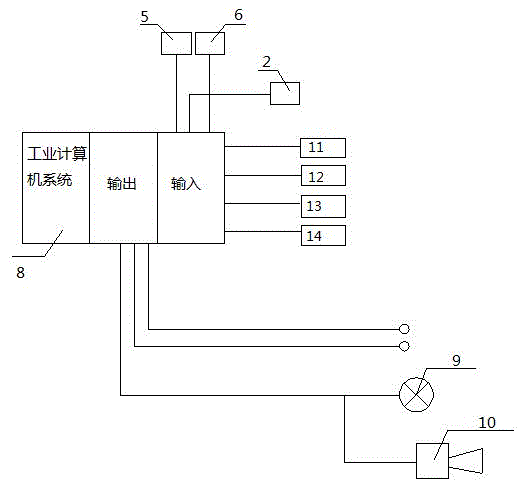

Material evenly-distributing device of horizontal type telescopic material distributing belt

InactiveCN103332510BSolve the problem of unevennessReduce workloadControl devices for conveyorsLoading/unloadingFixed bearingEngineering

The invention relates to a material evenly-distributing device of a horizontal type telescopic material distributing belt, and belongs to the field of belt logistic conveying. The material evenly-distributing device comprises the horizontal type telescopic material distributing belt, an optoelectronic switch, a shrunk pole limiting proximity switch induction sheet, an extended pole limiting proximity switch induction sheet, a shrunk pole limiting proximity switch, an extended pole limiting proximity switch, a material distributing platform, an industrial computer system, an alarm lamp, an alarm bell, ascended pole limiting proximity switches of sliding bearings I / II, descended pole limiting proximity switches of the sliding bearings I / II, a fixed bearing I, a fixed bearing II, a fixed bearing III, a fixed fixing IV, the sliding bearing I, the sliding bearing II, a sliding bearing III, ascended pole limiting proximity switch induction sheets of the sliding bearings I / II and descended pole limiting proximity switch induction sheets of the sliding bearings I / II. The material evenly-distributing device solves the problem of uneven material distribution of the horizontal type telescopic material distributing belt and reduces workloads, and the service life of the material evenly-distributing device of the horizontal type telescopic material distributing belt is prolonged..

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Dividing equipment

PendingCN114739772ASolve the problem of unevennessThe powder process is fastPreparing sample for investigationPlastic recyclingElectric machineryDrive motor

The invention provides division equipment which comprises a driving assembly, the driving assembly comprises a driving motor, an output shaft of the driving motor is connected with a rotary drum, and the rotary drum is provided with a containing cavity used for containing materials and a communicating opening communicating with the containing cavity; the shell assembly comprises a base, and a first material receiving opening and a second material receiving opening are formed in the base; the first material receiving port and the second material receiving port are arranged at an interval; the driving motor drives the communicating port to rotate in the first rotating direction or the second rotating direction, so that the communicating port is repeatedly communicated with the first material receiving port and the second material receiving port; wherein the first rotating direction is opposite to the second rotating direction, and the division equipment solves the problem that in the prior art, a motor of division equipment rotates in one direction, and division materials are not uniform easily.

Owner:SHENHUA SHENDONG COAL GRP +1

A straight-toothed paint tank

InactiveCN108109775BWipe off evenlyUniform thicknessInsulating conductors/cablesMechanical engineeringEngineering

Owner:宁波高新区布瑞恩科技有限公司

A kind of display and coating method of polyimide resin layer in display module

ActiveCN105665247BImprove the level ofSolve the problem of unevennessPretreated surfacesCoatingsDisplay devicePolyimide

The invention provides a display and a coating method for a polyimide resin layer in a display module of the display.The coating method comprises the steps that a non-display area of a substrate to be coated is coated with a polyimide acid material, and a display area of the substrate to be coated is coated with the polyimide acid material, wherein the leveling property of the polyimide acid material coated to the non-display area is superior to that of the polyimide acid material coated to the display area, and an overlaying layer is formed between the polyimide acid material coated to the non-display area and the polyimide acid material coated to the display area; high-temperature curing is conducted on the substrate coated with the polyimide acid material so that the continuous and integrated polyimide resin layer can be formed on the display area and the non-display area.According to the coating method for the polyimide resin layer in the display module, under the situation that a flat layer is not used, the method that before normally coating a display area PI layer, the edge area is coated with a circle of PI layer easily and effectively solves the problem that the leveling property of the PI on the edge is not good.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com