A preparation method of GaN-based horizontal nano cylindrical shell-core structure array LED

A gallium nitride nanometer, core-shell structure technology is applied in the field of preparation of gallium nitride-based horizontal nanocolumn core-shell structure array LEDs, which can solve the problems of inhomogeneity limitation, nanocolumn size, random distribution, and high cost, and achieve The effect of reducing the difficulty of subsequent processes, uniform device aspect ratio, and improving injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means and functions adopted by the present invention to achieve the predetermined invention objectives, the specific implementation manners of the present invention will be described below in conjunction with the drawings. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

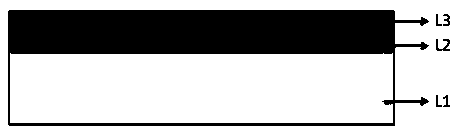

[0037] Such as figure 1 As shown, a high-quality gallium nitride film was deposited on a sapphire substrate L1 as a substrate by MOCVD. The thickness of buffer layer and non-doped gallium nitride film L2 is 2.5 microns; silane SiH is introduced during the growth process 4 As a dopant source, the epitaxy of the n-type gallium nitride film L3 is completed, and the thickness is 1.5 microns.

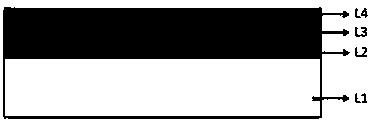

[0038] Such as figure 2 As shown, using PECVD equipment to deposit SiO 2 The mask layer L4 has a thickness of 100 nm.

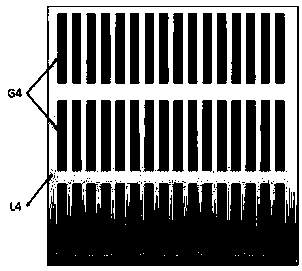

[0039] As shown in Figure 3, using nanoimprint technology co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com