Movable plow discharger for biomass power generation

A plow unloader, biomass power generation technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of uneven distribution of unloading bins, achieve stable operation, easy maintenance and maintenance, and overcome poor overload capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

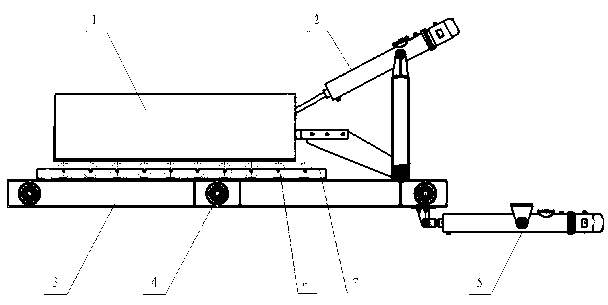

[0011] Such as figure 1 As shown, the movable plow unloader for biomass power generation includes plowshare 1, idler roller group 6, main frame 3 and hydraulic push rod 5, plowshare 1 is connected with plowshare driving pushrod 2 that drives plowshare 1 ; The main frame 3 is provided with a traveling wheel 4 for driving the hydraulic push rod 5; the idler group 6 is connected with the idler frame 7, and the idler frame 7 is driven by the hydraulic push rod 5, and the hydraulic push rod 5 is equipped with a multi-point Unloading pressure self-locking device.

[0012] Working process: when working, the hydraulic push rod 5 is extended to act on the plow share to drive the push rod 2, to drive the frame forward, complete the fall of the plow share 1, and support the flat roller group 6, so that the working surface of the belt is straight, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com