Three-axis sample preparation stirring and throwing device

The technology of agitator and hair dryer is applied in the field of three-axis sample preparation, agitator and hair thrower, and achieves the effect of reducing cost input and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

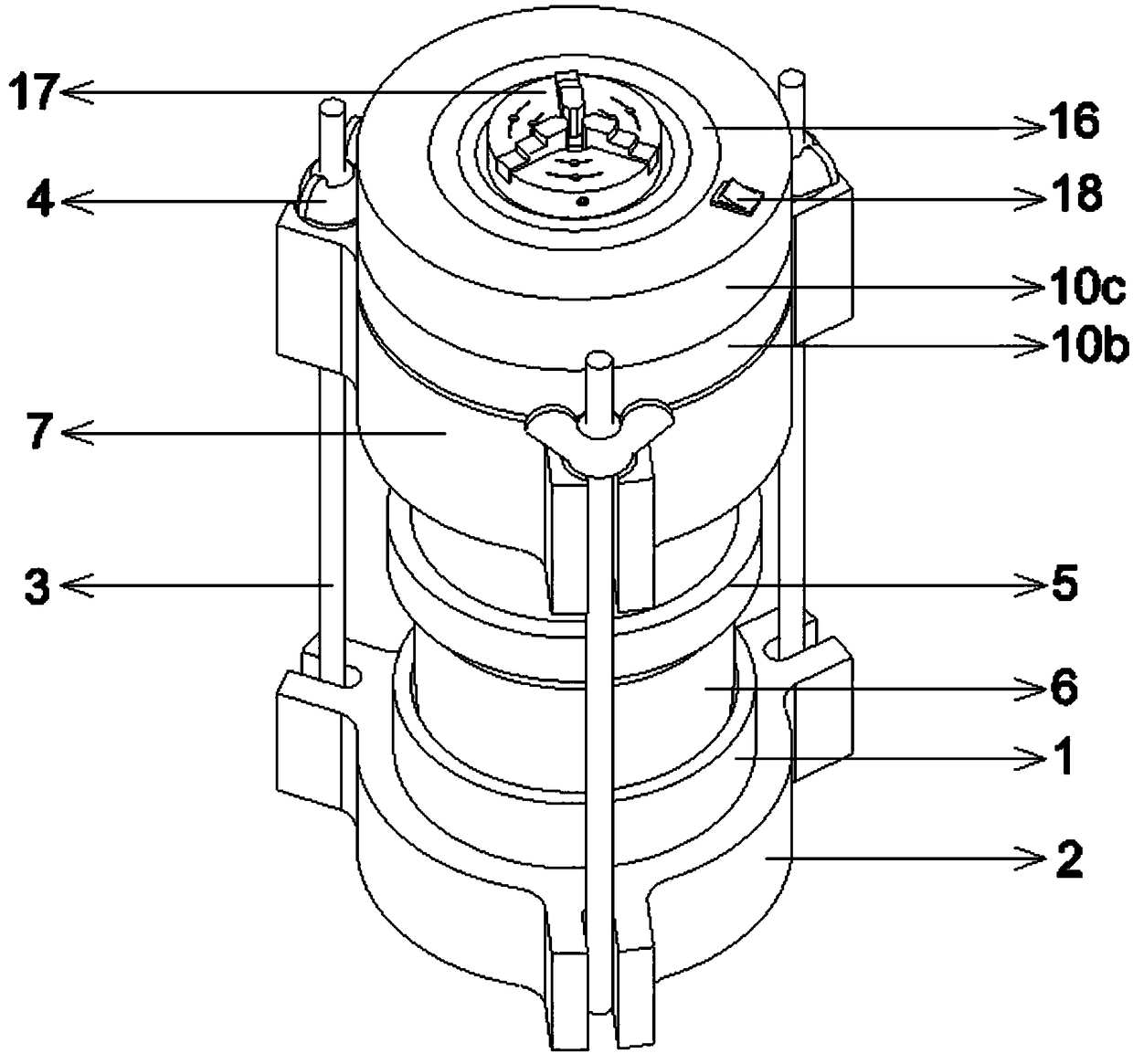

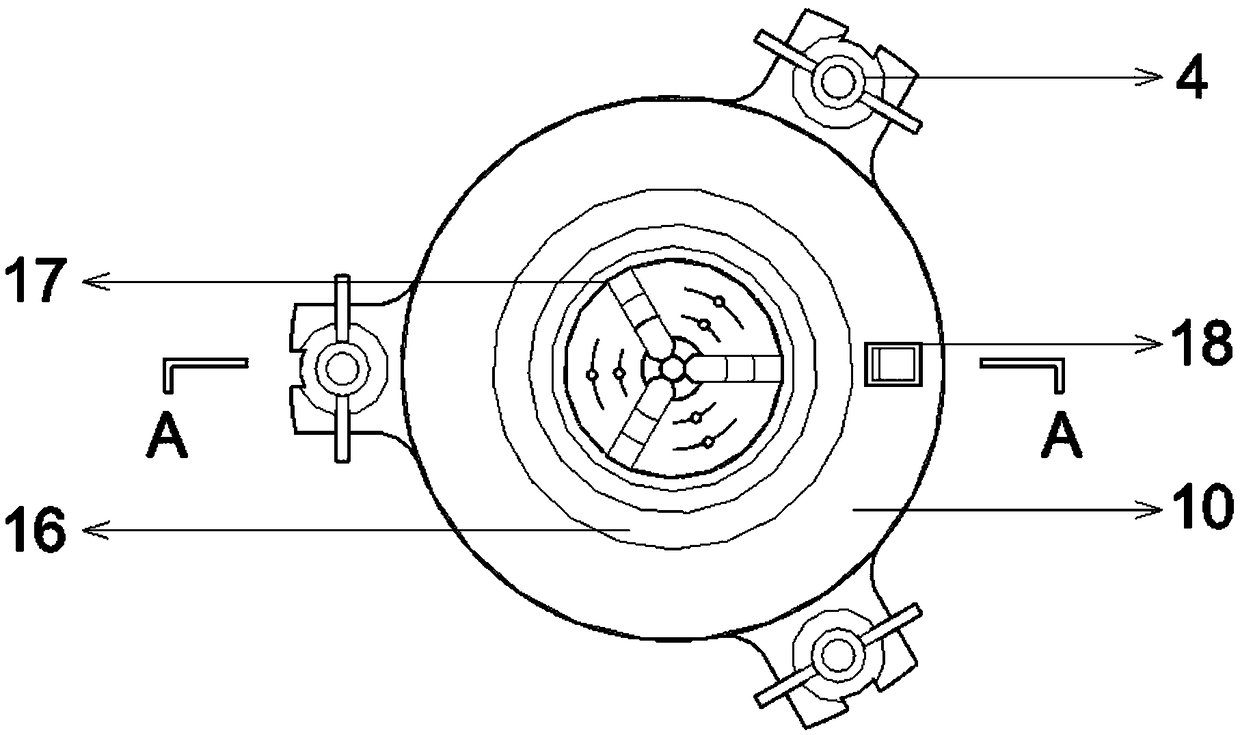

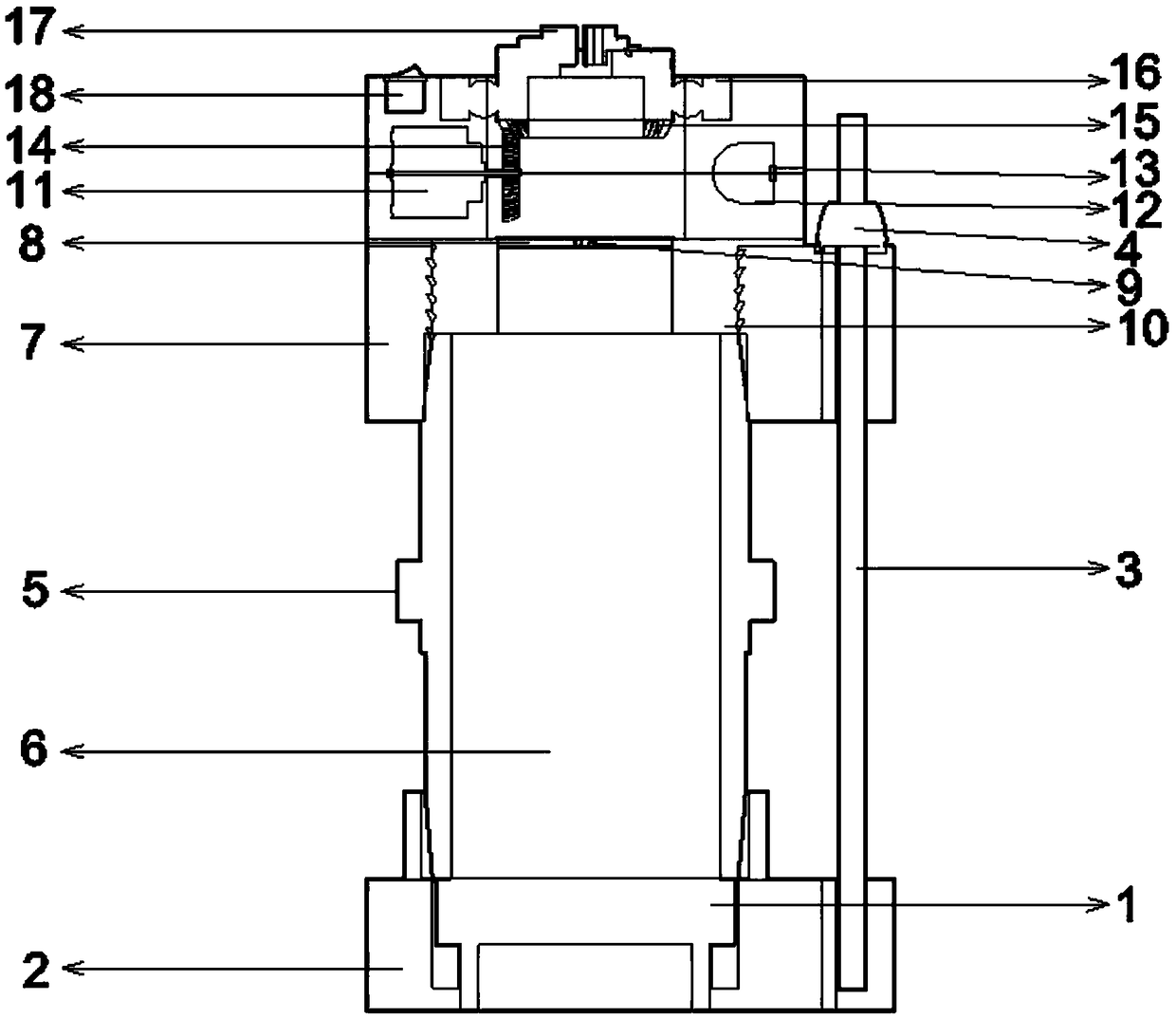

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] The present invention is a three-axis sample-making stirring and throwing device, comprising: a fixer, a sample beating cylinder, a splint, an agitator, and a stirring and throwing rod;

[0029] Described fixture further comprises: Sampling seat 1, base 2, pull bar 3, nut 4; Base 2 and pull bar 3 are all matched with the size of Sampling seat 1, upper threaded device 7 and stirring thrower, Sampling seat 1 is set in the base 2; the nut 4 fixes the sample cylinder through the pull rod 3;

[0030] The sample striking cylinder further comprises: a tight hoop 5 and a circular mold cylinder 6 composed of three circular arc sheets; the tight hoop 5 is set on the round mold cylinder 6 for fixing;

[0031] The splint further includes: an upper threaded device 7; the upper threaded device 7 increases the height on the basis of the traditional splint, and adds a threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com