Material evenly-distributing device of horizontal type telescopic material distributing belt

A technology for evenly distributing and distributing materials, applied in the direction of conveyor control devices, transportation and packaging, loading/unloading, etc., can solve problems such as uneven distribution of materials, achieve the effect of reducing workload and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

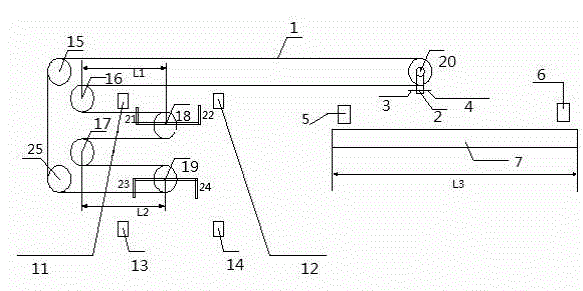

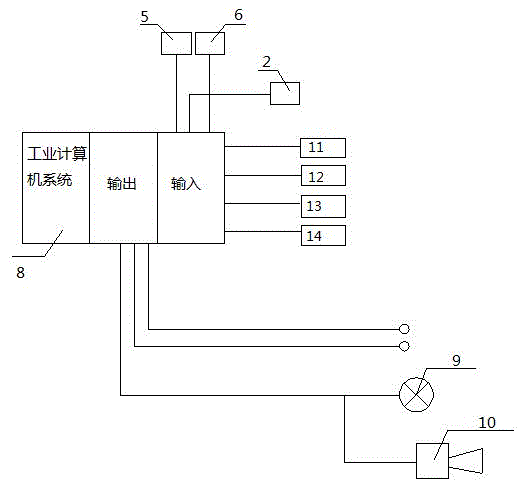

[0018] Embodiment 1: as Figure 1-2 As shown, a uniform distribution device for a horizontal retractable distribution belt, including a horizontal retractable distribution belt 1, a photoelectric switch 2 located above the distribution platform 7, and a contraction limit proximity switch sensor 3 located on the left side of the photoelectric switch 2 , the extension limit proximity switch sensor 4 located on the right side of the photoelectric switch 2, the contraction limit proximity switch 5 located on the left side above the cloth platform 7, the extension limit proximity switch 6 located on the right side above the cloth platform 7, and the cloth platform 7 , industrial computer system 8, alarm light 9, alarm bell 10, sliding bearing I rising limit position proximity switch 11, sliding bearing I falling limit position proximity switch 12, sliding bearing II rising limit position proximity switch 13, sliding bearing II falling limit position proximity switch Proximity switc...

Embodiment 2

[0019] Embodiment 2: as Figure 1-2 As shown, a uniform distribution device for a horizontal retractable distribution belt, including a horizontal retractable distribution belt 1, a photoelectric switch 2 located above the distribution platform 7, and a contraction limit proximity switch sensor 3 located on the left side of the photoelectric switch 2 , the extension limit proximity switch sensor 4 located on the right side of the photoelectric switch 2, the contraction limit proximity switch 5 located on the left side above the cloth platform 7, the extension limit proximity switch 6 located on the right side above the cloth platform 7, and the cloth platform 7 , industrial computer system 8, alarm light 9, alarm bell 10, sliding bearing I rising limit position proximity switch 11, sliding bearing I falling limit position proximity switch 12, sliding bearing II rising limit position proximity switch 13, sliding bearing II falling limit position proximity switch Proximity switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com