Faceplate of liquid crystal display

A liquid crystal display panel, liquid crystal layer technology, applied in static indicators, optics, instruments, etc., can solve the problems of uneven cell gap and high wire height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

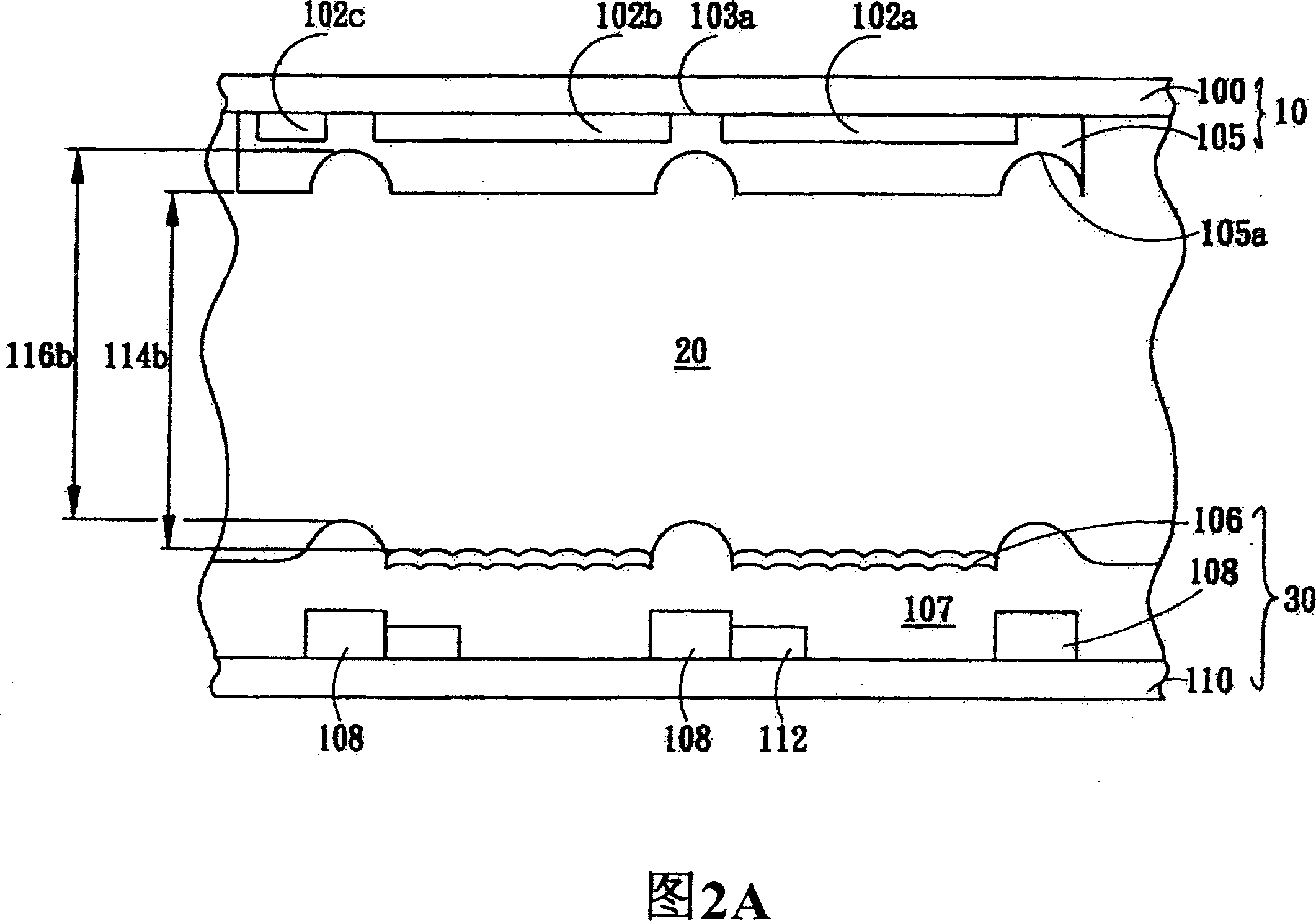

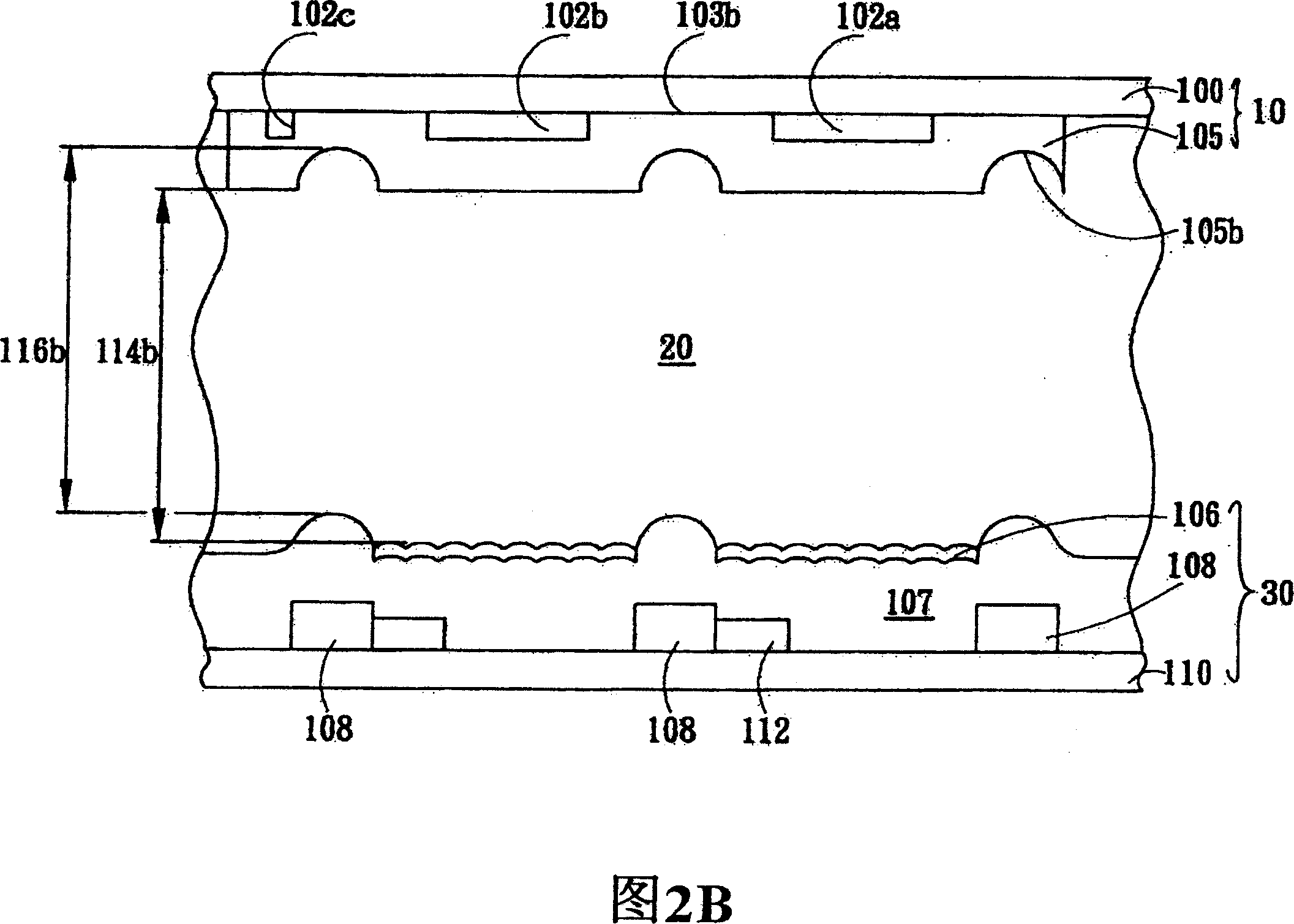

[0033] 2A is a schematic cross-sectional view of an embodiment of the present invention, including a lead substrate 30 with several wires 108, a color filter substrate 10 arranged in parallel above the lead substrate 30, and the color filter substrate 10 has an opening 105a Corresponding to the wire 108 , and a liquid crystal layer 20 fills the gap between the wire substrate 30 and the color filter substrate 10 .

[0034] The lead substrate 30 is composed of a plurality of leads 108 on the lower substrate 110, including data lines and scan lines perpendicular thereto, and a plurality of transistors 112 electrically connected to the data lines and the scan lines. And an insulating layer 107 is formed on the lower substrate 110 to cover the transistor 112 , the wire 108 and the surface of the lower substrate 110 , and the material of the insulating layer 107 can be an organic material. And a reflective layer 106 is formed on the insulating layer 107 in the area defined as the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com