Rotary distribution dry deslagging household waste pyrolysis gasifier

A technology for rotating cloth and domestic garbage, which is applied in the direction of rotary grate, incinerator, shaking grate, etc. Guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

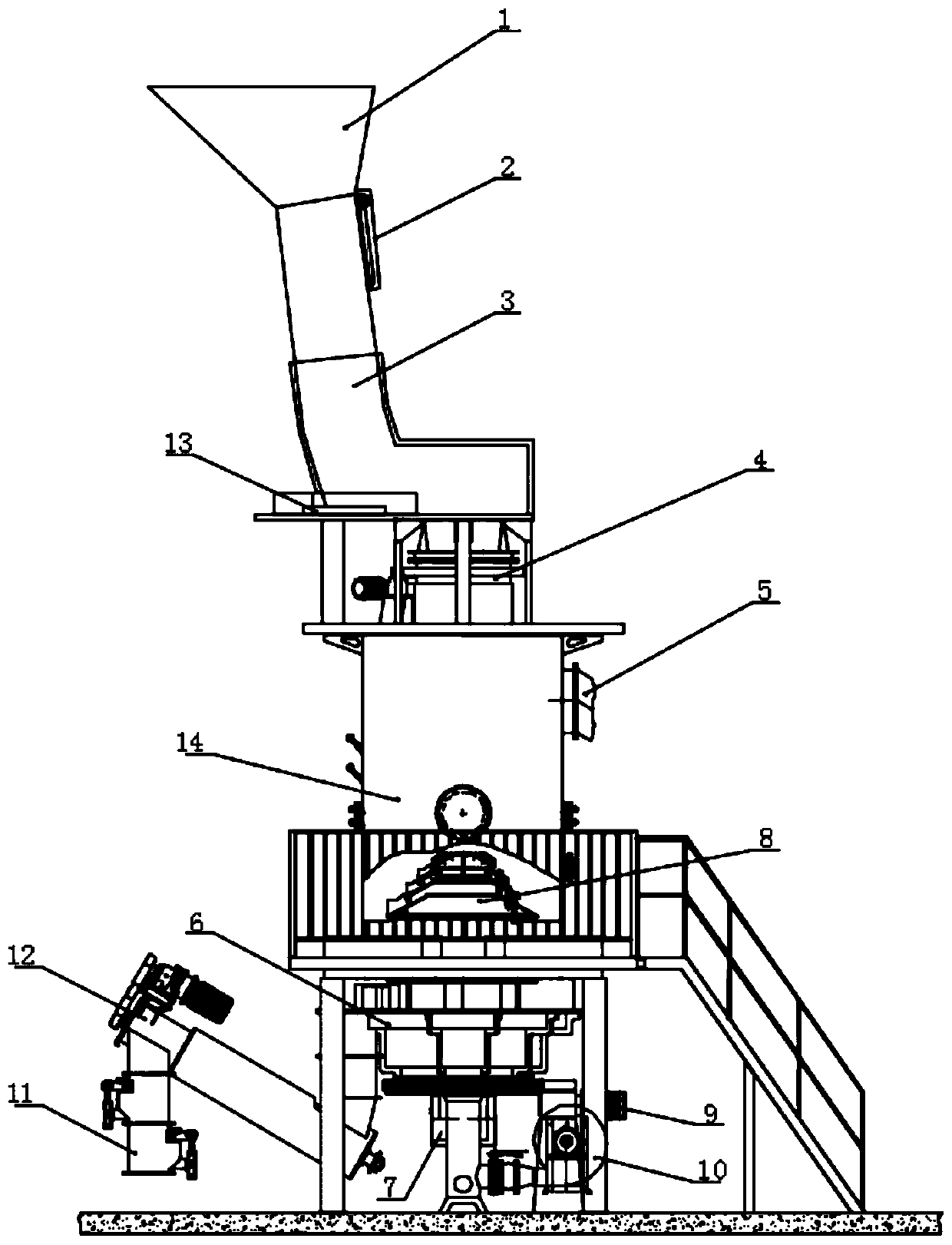

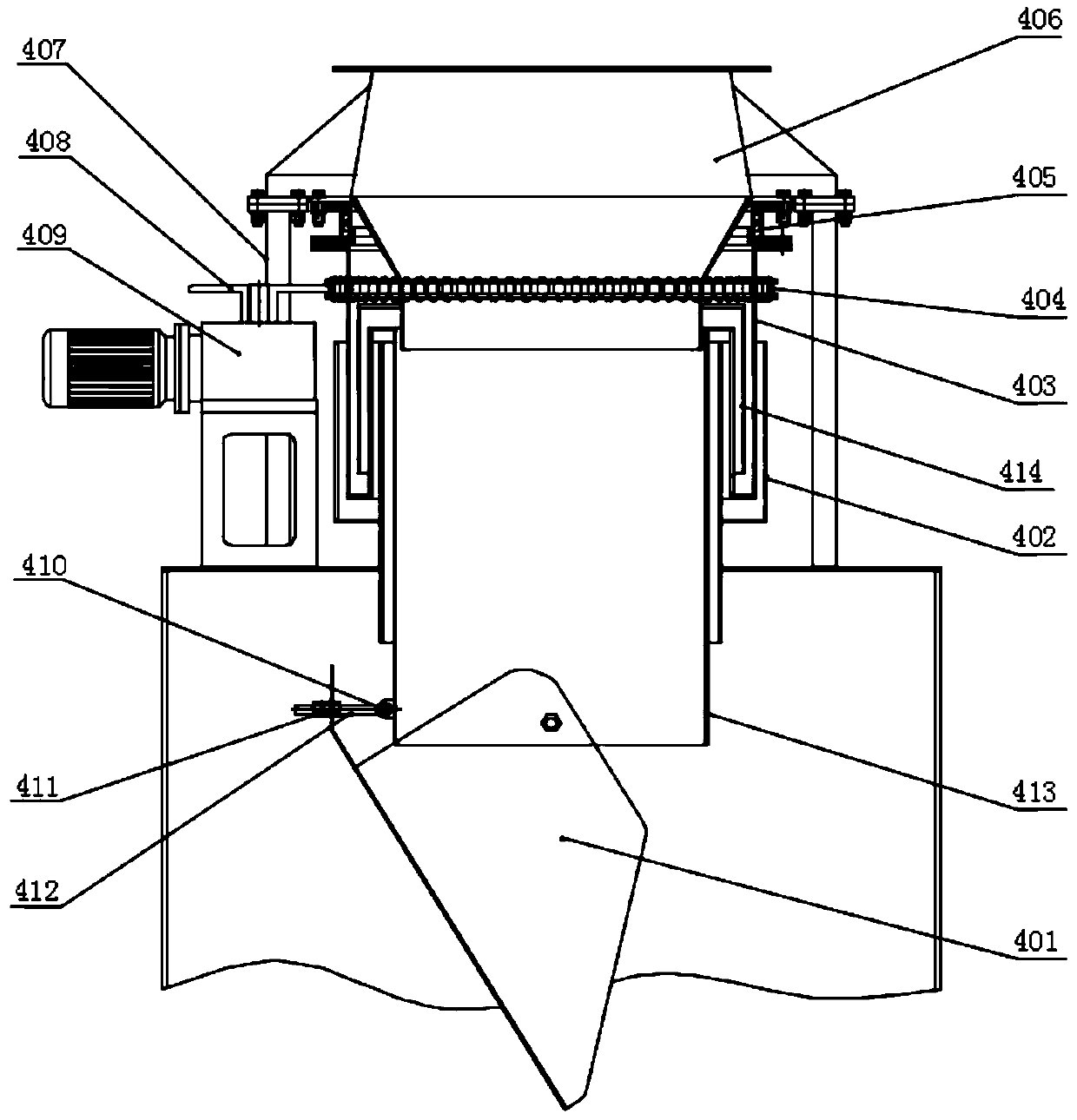

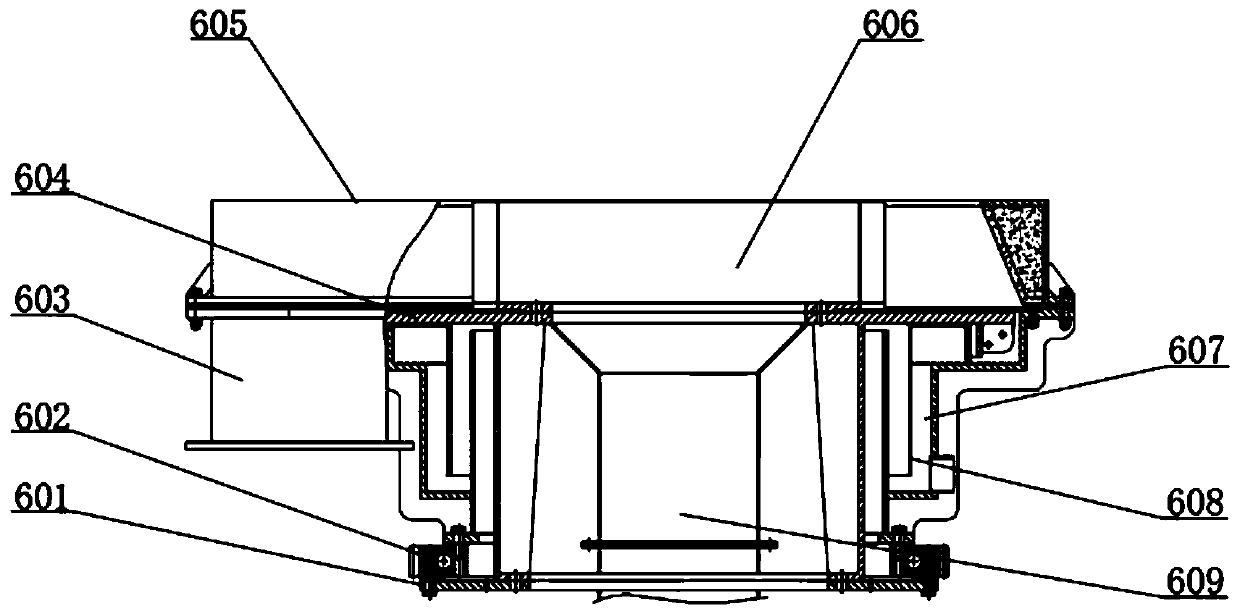

[0023] Such as Figure 1-4 As shown, a rotary distributing dry-type slagging domestic waste pyrolysis gasification furnace includes a furnace body 14, the upper part of the outer surface of the furnace body 14 is fixedly connected with a gas outlet 5, and the top of the furnace body 14 is provided with a rotary distributor 4, The input end of the rotary distributor 4 is fixedly connected with the upper chute 3, and the joint between the upper chute 3 and the rotary distributor 4 is provided with a hydraulic pusher 13. The hydraulic pusher 13 used in this application is a well-known device in the art. By setting the hydraulic pusher 13, its output end can assist in pushing the material inside the upper chute 3 to the inside of the rotary distributor 4, the other end of the upper chute 3 is fixedly connected with the feed hopper 1, and the inside of the feed hopper 1 is provided with Hydraulic gate 2, the bottom of the furnace body 14 is provided with a rotary grate 8 and a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com