Painting device for chain wheel type enameled wire

An enameled wire and sprocket type technology, applied in the direction of electrical components, circuits, conductors/cable insulation, etc., can solve problems affecting product quality, increasing costs, etc., and achieve the effect of solving uneven anisotropy and uniform paint thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

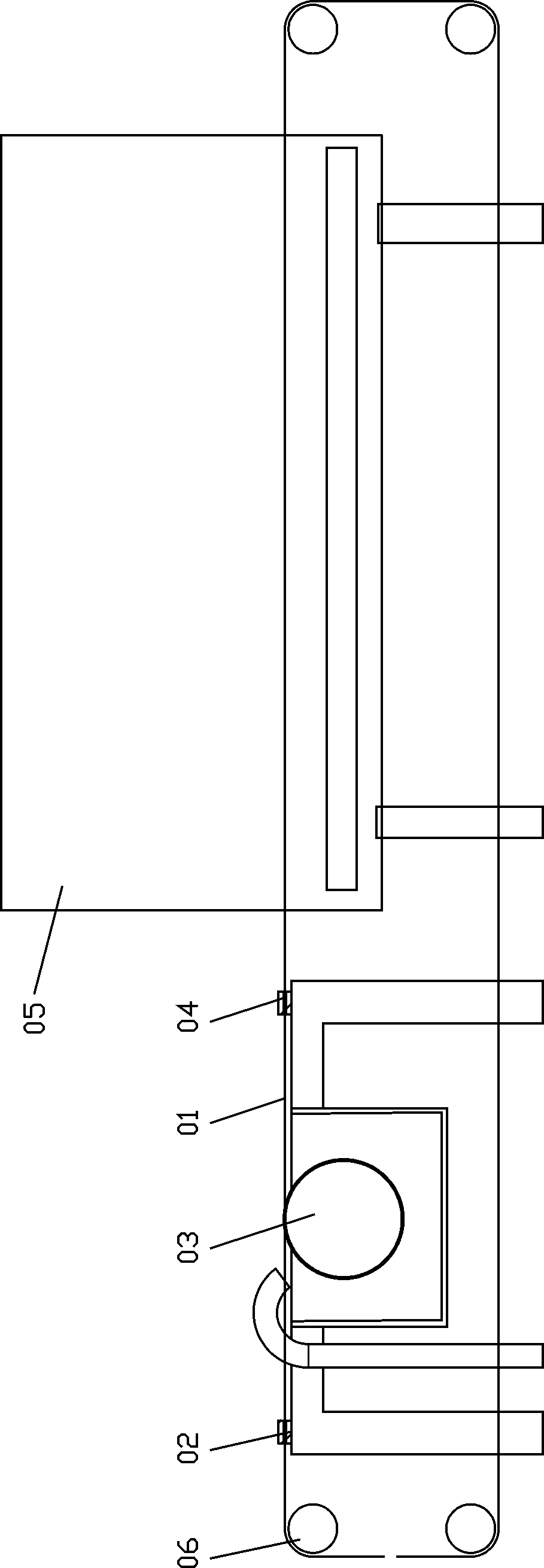

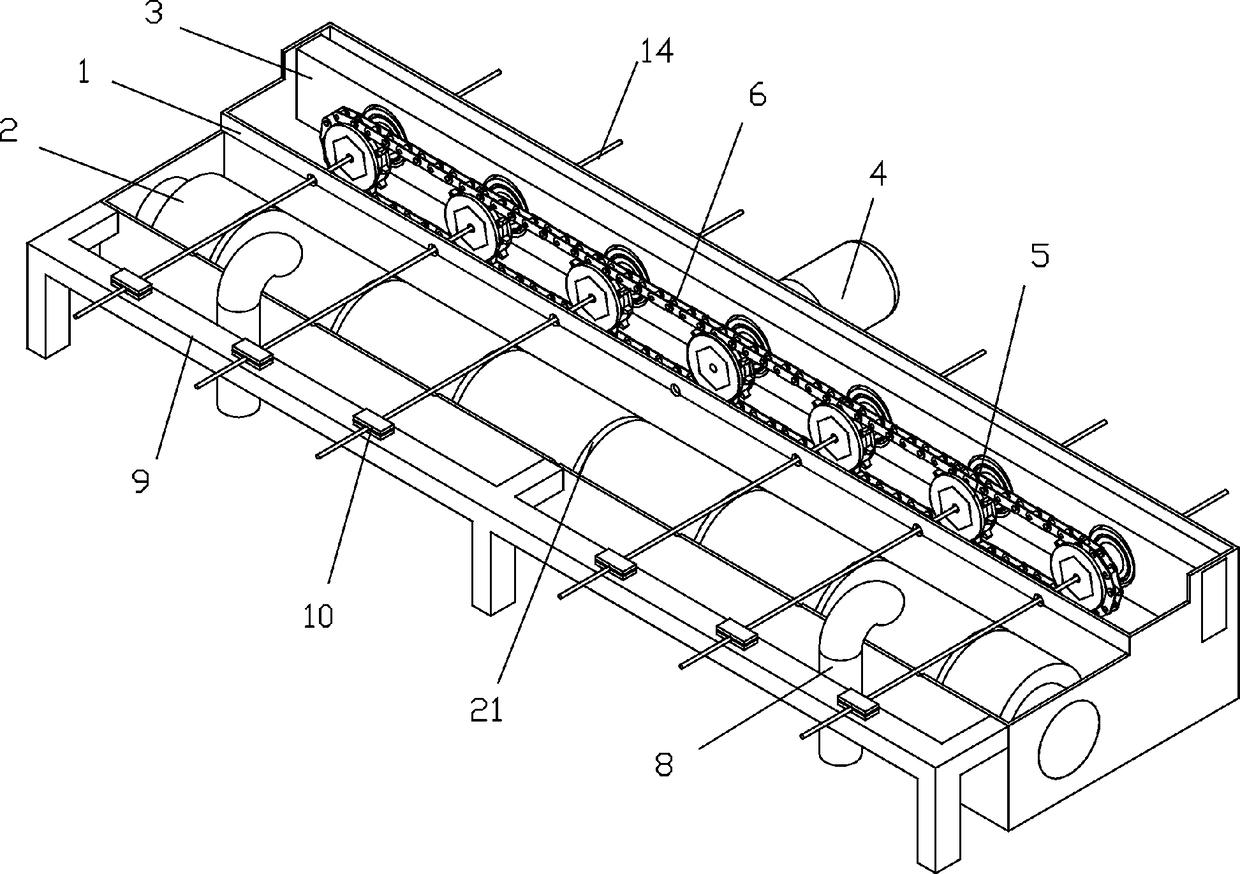

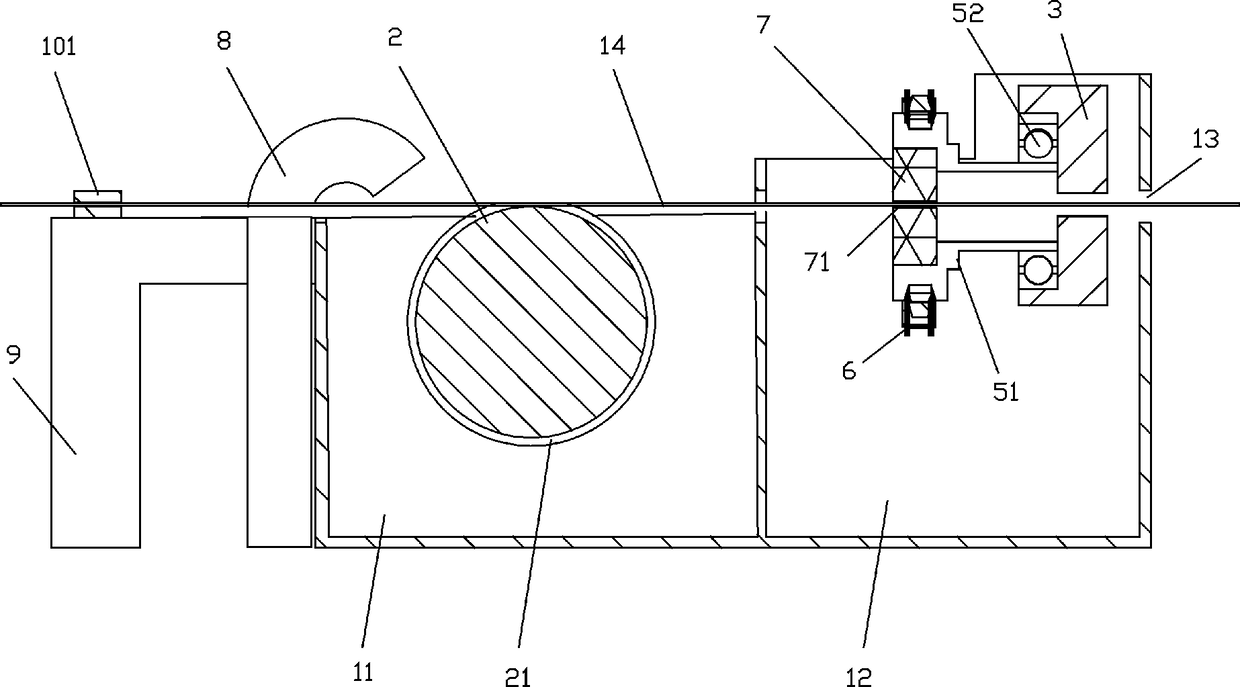

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1-4 As shown, mark as follows: paint tank 1, paint tank 11, empty tank 12, passage hole 13, paint turning roller 2, oil collection tank 21, gear frame 3, bearing hole 31, drive motor 4, drive wheel 41, sprocket Component 5, transmission chain 6, felt block 7, paint wiping hole 71, paint supply pipe 8, felt frame 9, felt plate assembly 10, felt plate 101, enameled wire 14.

[0018] The sprocket type enamelled wire painting device includes a paint tank 1, which is divided into a paint tank 11 and an empty tank 12. Two paint supply pipes 8 are arranged on the outside of the paint tank to facilitate the injection of paint into the paint tank. It can be adjusted; a felt frame 9 is arranged on the outside of the paint supply pipe, and a plurality of felt plate assemblies 10 are arranged on the felt frame. The felt plate assembly is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com