Multifunctional transverse flow type heat source tower device

A heat source tower, multi-functional technology, applied in the field of multi-functional cross-flow type heat source tower devices, can solve problems such as uneven liquid distribution, achieve stable operation, solve the problem of uneven liquid distribution, and reduce the effect of solution quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

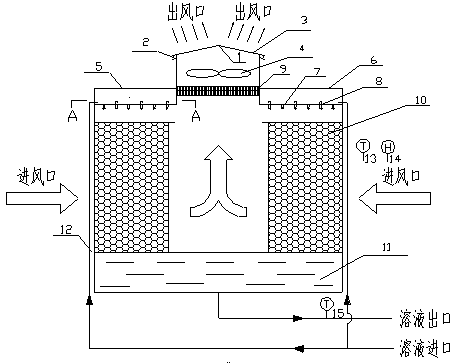

[0033]Further illustrate the specific embodiment of the present invention in conjunction with accompanying drawing: the multi-functional cross-flow type heat source tower device of the present invention comprises air flow loop and solution flow loop, and concrete connection method is: be provided with heat source tower tower body 12 in the air flow loop, be arranged on The air outlet at the top of the heat source tower body 12, the air inlets arranged on both sides of the middle part of the heat source tower body 12, the packing 10 arranged on both sides inside the heat source tower body 12 and located above the liquid collection tank 11, are arranged in sequence from bottom to top The anti-drift liquid device 9, the variable speed fan 4 and the self-opening rainproof device and the filler 10 are arranged directly against the air inlet below the air outlet.

[0034] The self-opening rainproof device includes an inner support device 1, an outer support device 2 and an arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com