Novel workpiece rotating stand device applied to magnetron sputtering

A magnetron sputtering and working technology, applied in the field of magnetron sputtering, can solve the problems of inability to ensure the uniformity and consistency of the coating on the surface of the workpiece, reduce the coating effect, limit the development of the magnetron sputtering process, etc. Service life, enhance coating effect, solve the effect of uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

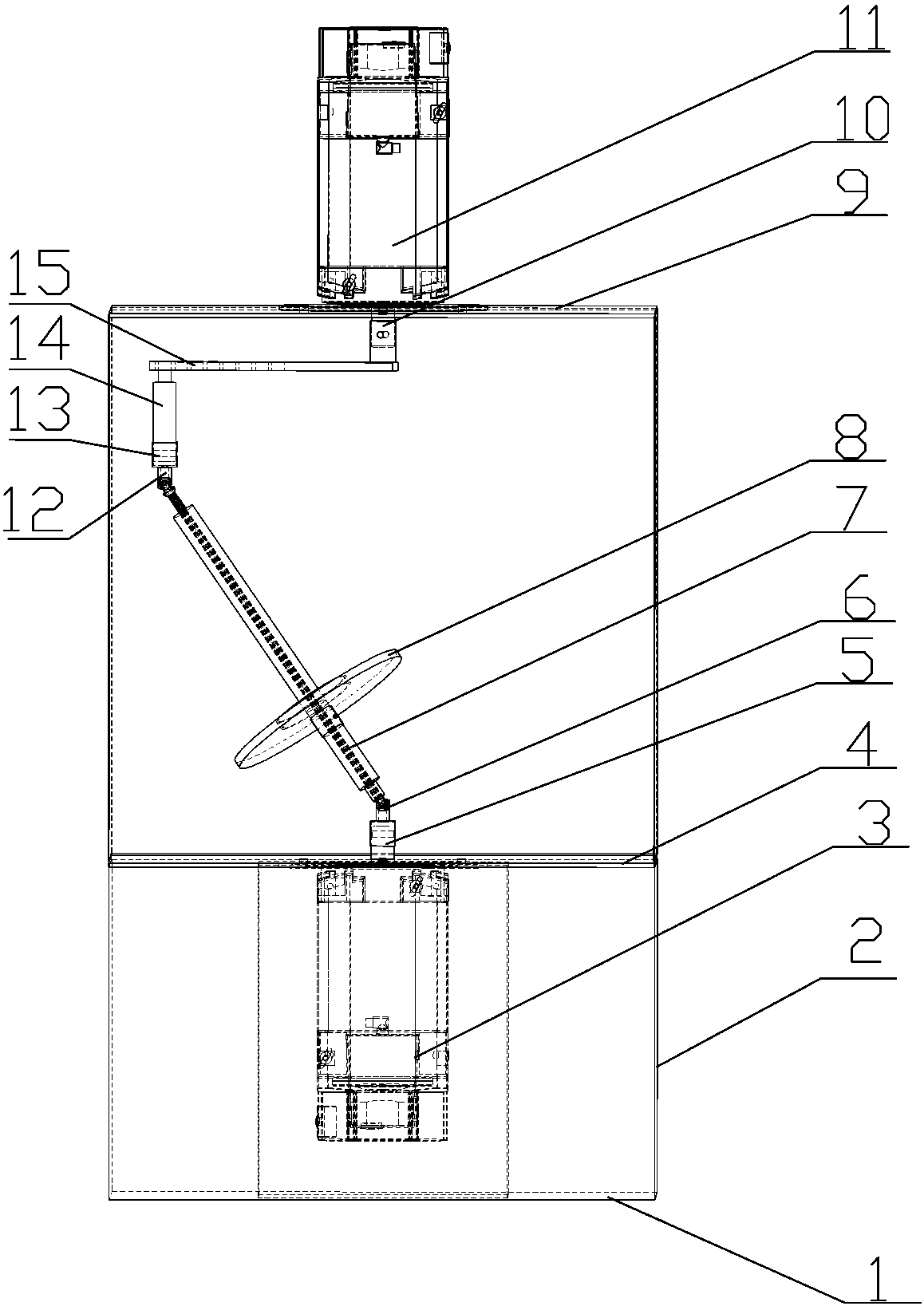

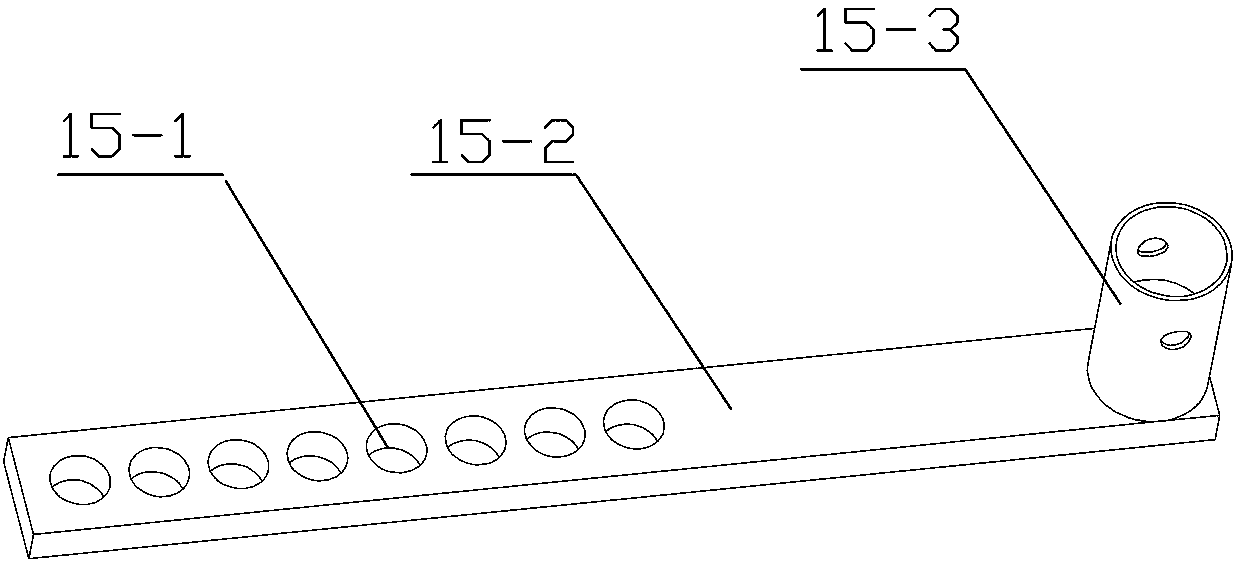

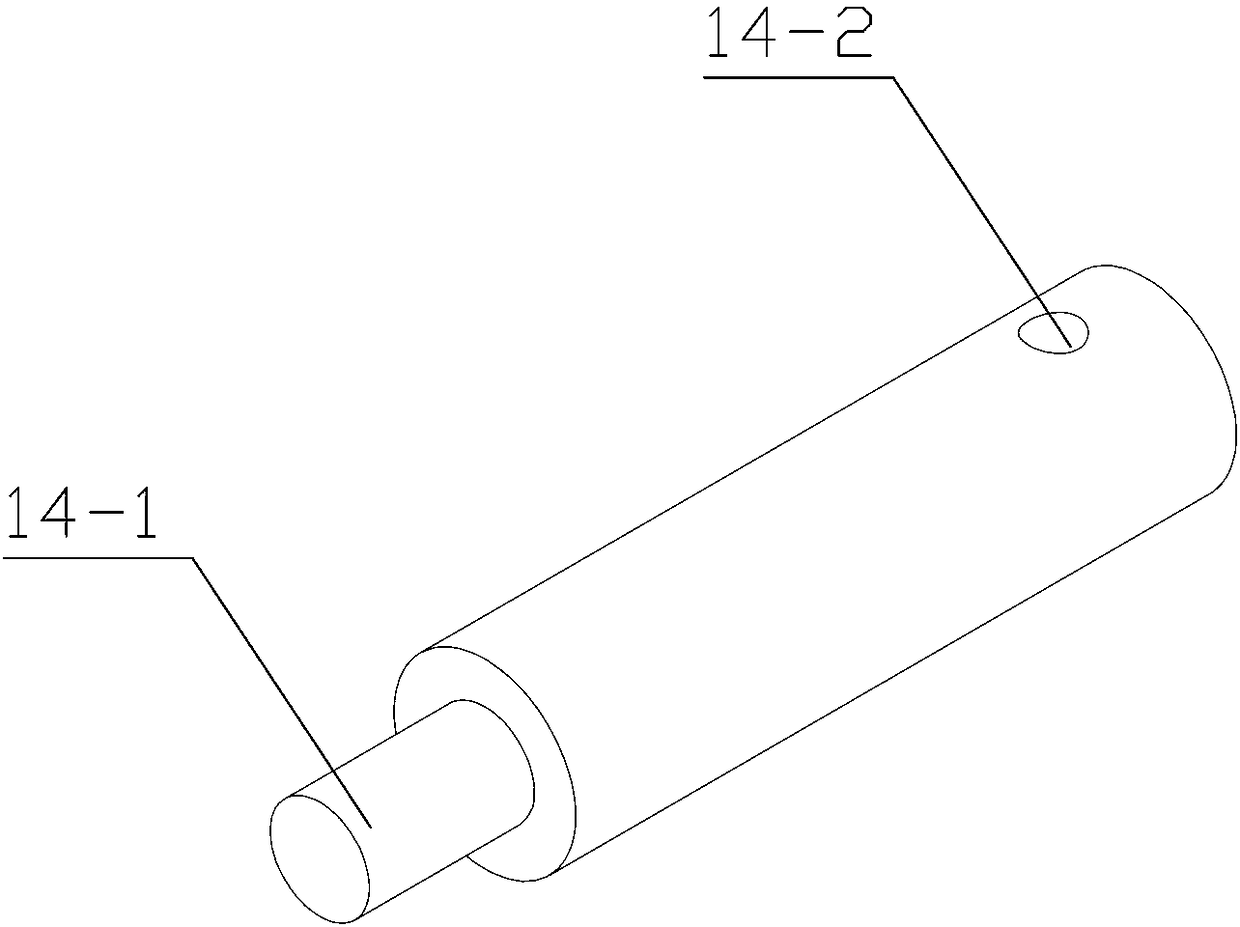

[0024] like Figure 1-5 As shown, a turret device for magnetron sputtering of the present invention includes a reaction chamber composed of a side wall 2, a top plate 9 and a bottom plate 1, a working tray 8, a spindle 7 and a working The tray movement mechanism is characterized in that a base 4 is provided in the reaction chamber, and the base 4 divides the reaction chamber into an upper chamber and a lower chamber, and the working tray 8 is arranged on the main shaft 7, so that Described workpiece tray 8 is that the upper end has the ring-shaped boss 8-1 that is used to fix the cylindrical workpiece, and the lower end has the disc of connecting sleeve 8-2, and its ring-shaped boss 8-1 is connected with the cylindrical workpiece. The inner diameter is an interference fit, and there is a pre-tightening screw hole 8-3 on the connecting sleeve 8-2. In this way, the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com