Efficient sticking and plugging prevention breaker

A crusher and anti-jamming technology, applied in the field of mechanical equipment, can solve the problems of the crusher stuck, the crushing efficiency is not high, and it is difficult to break, and the effect of preventing the crusher from being stuck is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

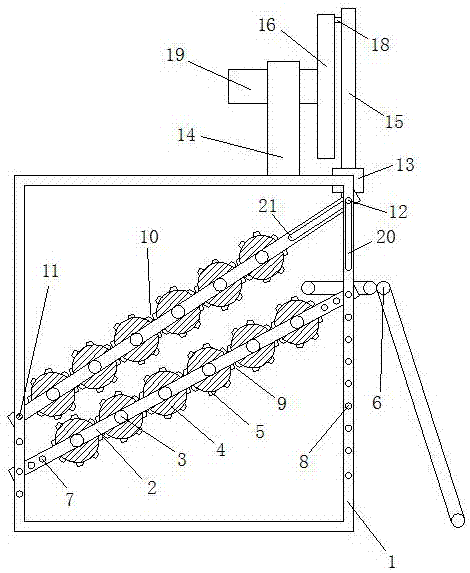

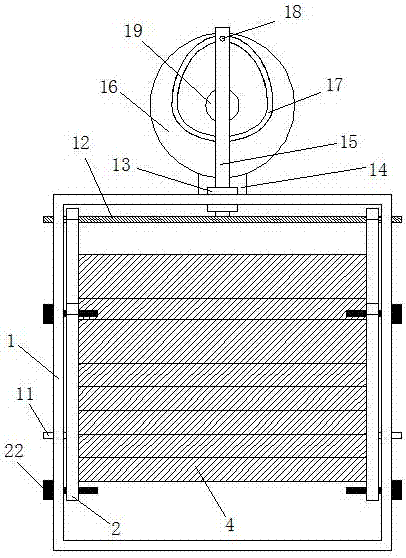

[0026] As a preferred embodiment of the present invention, with reference to the attached figure 1 And attached figure 2 , this embodiment discloses a high-efficiency anti-jamming crusher, this embodiment includes:

[0027] A high-efficiency anti-blocking crusher, comprising a bracket 1, a crushing roller group 1 9 is arranged on the bracket 1, a crushing roller group 2 10 is arranged above the crushing roller group 9, and one end of the crushing roller group 10 is connected to the bracket through a hinge point 11 1 is hinged, and the other end reciprocates around the hinge point 11; crushing roller group one 9 and crushing roller group two 10 are arranged side by side by multiple crushing rollers 4; crushing roller group one 9 and crushing roller group two 10 are arranged obliquely, and the crushing rollers The distance between group one 9 and crushing roller group two 10 is larger at one end and smaller at the other end, and the larger end is the feed end; the crushing rol...

Embodiment 2

[0035] As a preferred embodiment of the present invention, with reference to the attached figure 1 And attached figure 2 , this embodiment discloses a high-efficiency anti-jamming crusher, this embodiment includes:

[0036]A high-efficiency anti-blocking crusher, comprising a bracket 1, a crushing roller group 1 9 is arranged on the bracket 1, a crushing roller group 2 10 is arranged above the crushing roller group 9, and one end of the crushing roller group 10 is connected to the bracket through a hinge point 11 1 is hinged, and the other end reciprocates around the hinge point 11; crushing roller group one 9 and crushing roller group two 10 are arranged side by side by multiple crushing rollers 4; crushing roller group one 9 and crushing roller group two 10 are arranged obliquely, and the crushing rollers The distance between group one 9 and crushing roller group two 10 is larger at one end and smaller at the other end, and the larger end is the feed end; the crushing roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com