Water dispersible polymers and their applications

A dispersion and polymer technology, applied in the field of polymers, can solve problems such as bleeding, serious segregation, rapid loss over time, and serious concrete retardation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

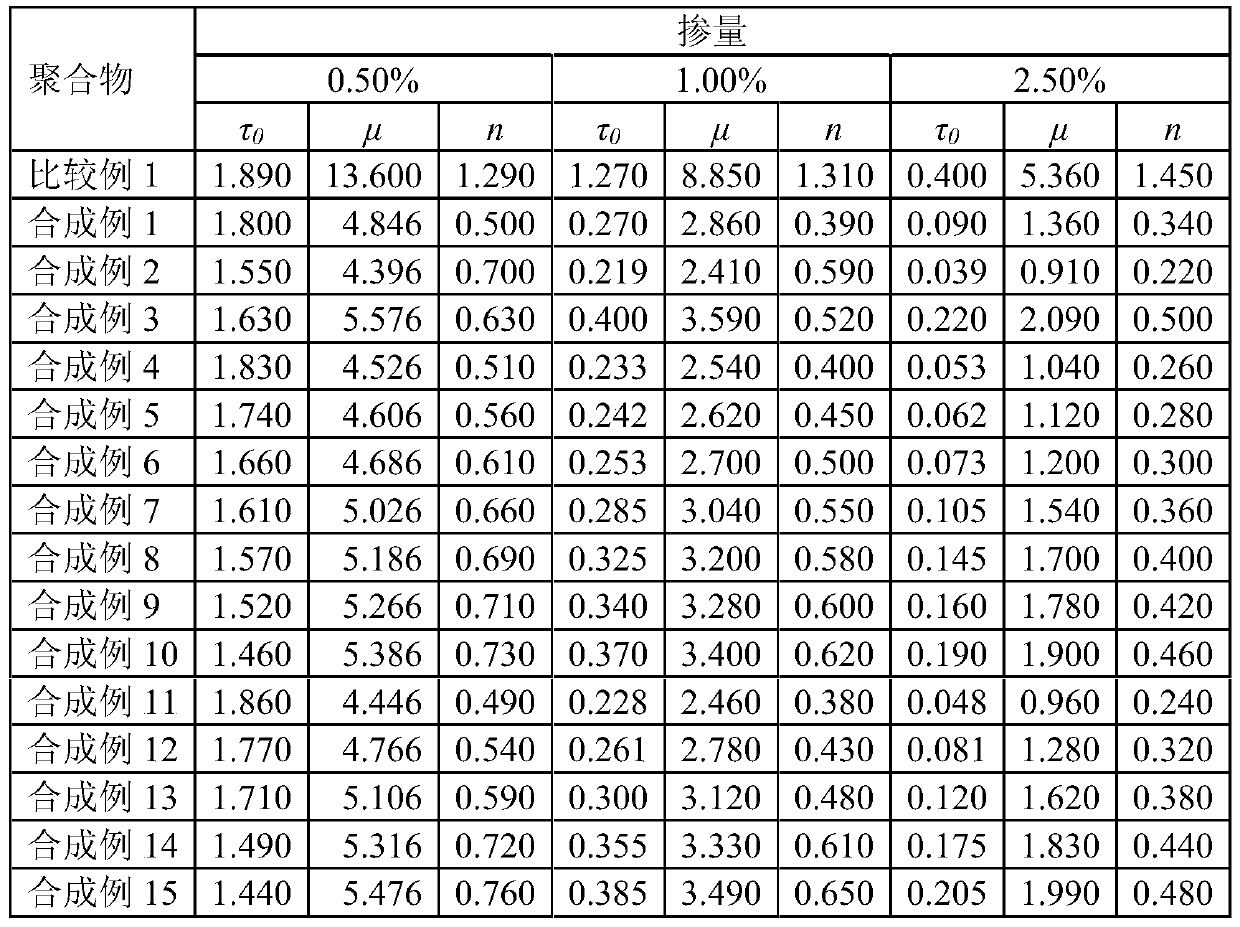

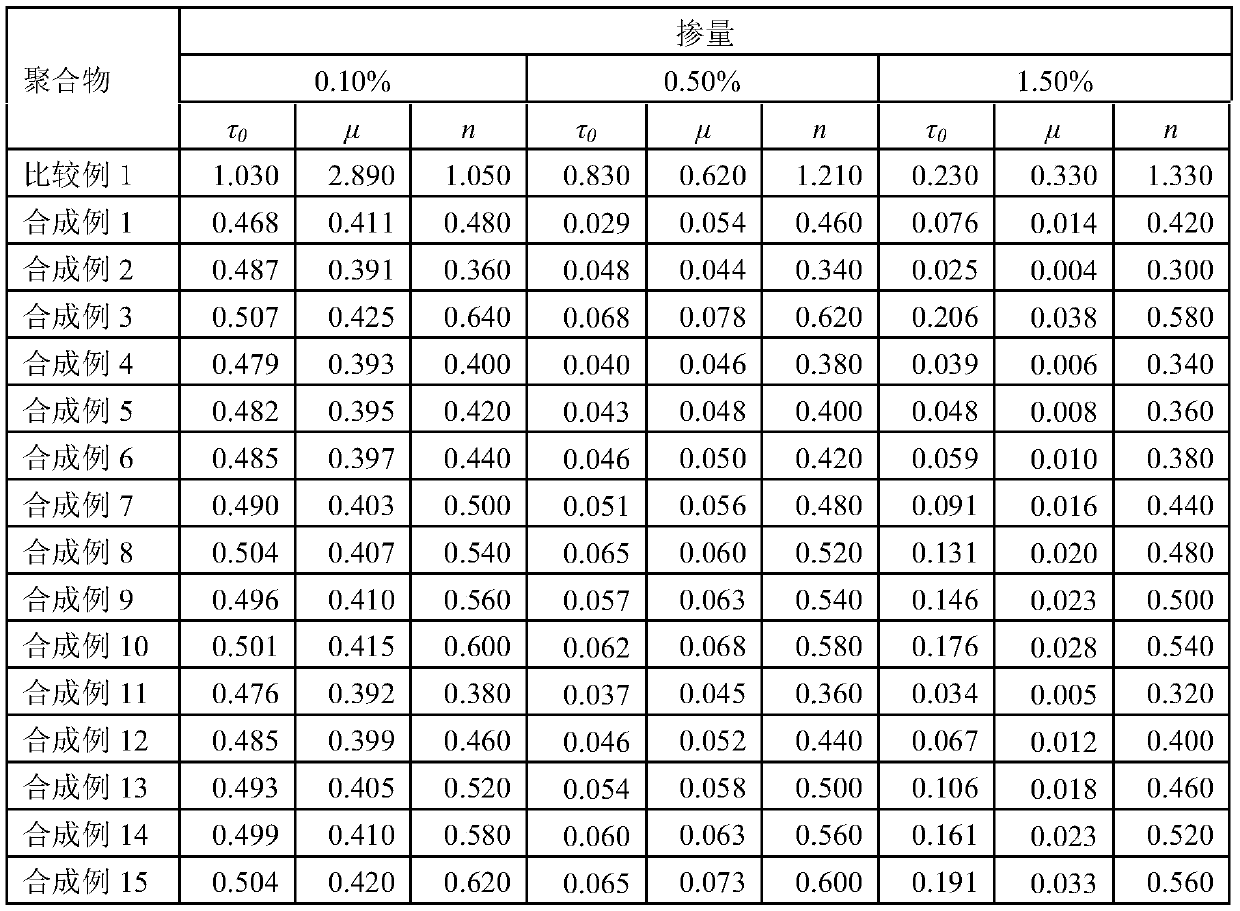

Synthetic example 1

[0062] 30kg tetrahydrofuran, 50kg isopentenyl polyoxyethylene ether (molecular weight 5000), 1.03kg (3-acrylamidopropyl) trimethylammonium chloride, 10.36kg 2-perfluorooctyl ethyl acrylate are mixed Add the solution into the reaction kettle, heat and stir until the temperature rises to 50°C; add 0.11kg of azobisisobutyronitrile dropwise to the bottom material, and the dropwise addition is completed within 3 hours. Afterwards, 20 kg of 2% sodium hydroxide solution was added dropwise and kept for 1 hour, and then kept for 1 hour, and water was added to adjust the solid content to obtain a 20% polymer solution.

Synthetic example 2

[0064] With 60kgN-methylpyrrolidone, 6kg methoxy polyethylene glycol methacrylate (molecular weight is 2400), 1.25kg methallyl polyoxyethylene ether (molecular weight is 500), 1.1kg methacryloyl propyl Trimethylammonium chloride, 18.31kg (perfluorocyclohexyl) methacrylate, and 77.73kg 2-perfluorooctyl ethyl acrylate were made into a mixed solution and added to the reactor, heated and stirred until the temperature rose to 60°C; 0.62kg of azobisisobutyronitrile was added dropwise to the base material, and the dropwise addition was completed within 3 hours. Then add 30kg of 2% sodium hydroxide solution dropwise for 1 hour, keep warm for 1 hour, cool down to less than 45°C, add water to adjust the solid content to prepare a 20% polymer solution.

Synthetic example 3

[0066] 30kg tetrahydrofuran, 0.30kg azobisisobutyronitrile, 45kg isopentenyl polyoxyethylene ether (molecular weight is about 1500), 12kg acryl polyoxyethylene ether (molecular weight is about 1200), 2.21kg methacrylic acid Trimethylammonium chloride, 2.09kg 1H, 1H, 2H, 2H-perfluorooctyl acrylate, 2.56kg methacrylate, 1.57kg styrene, 1 was made into a mixed solution and added to the reactor, heated and stirred until The temperature was raised to 50°C and kept for 4h. Afterwards, 30 kg of 2% sodium hydroxide solution was added dropwise for 1 h, kept warm for 1 h, and water was added to adjust the solid content to obtain a 20% polymer solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com