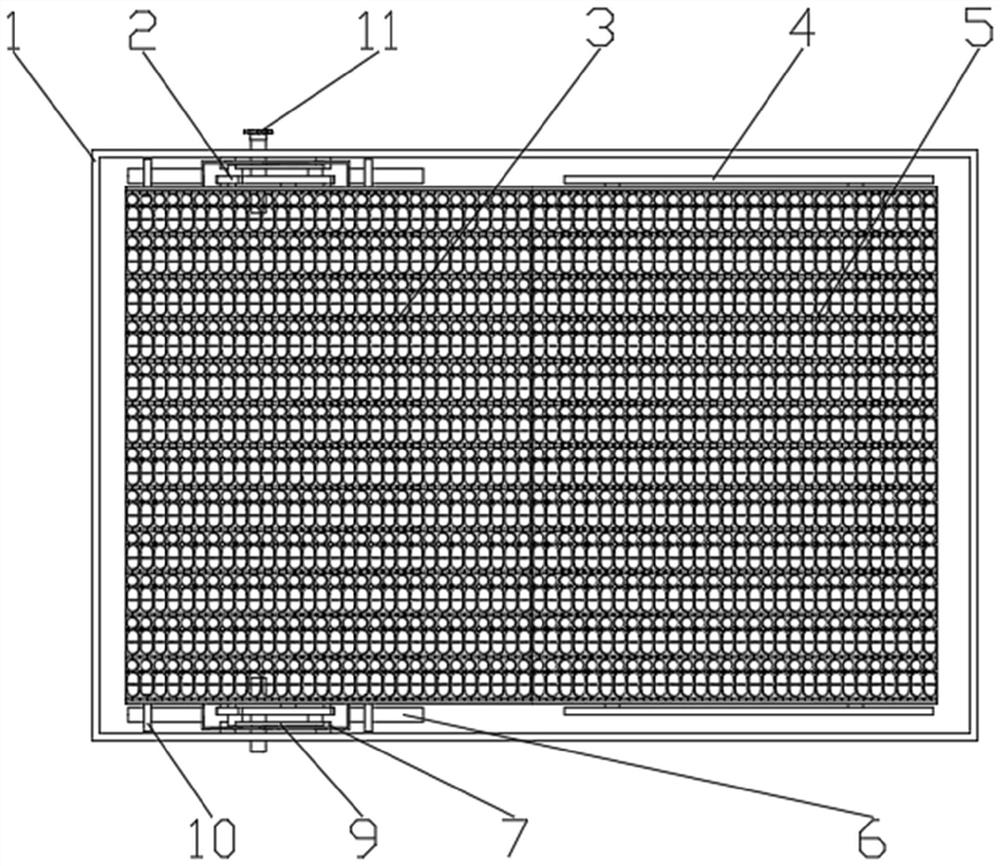

Sectional type corn kernel cleaning device imitating butterfly wing surface structure

A technology of butterfly wings and cleaning device, which is applied in the direction of solid separation, separation of solids from solids by air flow, and filtration and screening, etc., which can solve the problem of insufficient material dispersion, limit the opening rate of round hole sieves, and reduce the strength of the sieve body And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

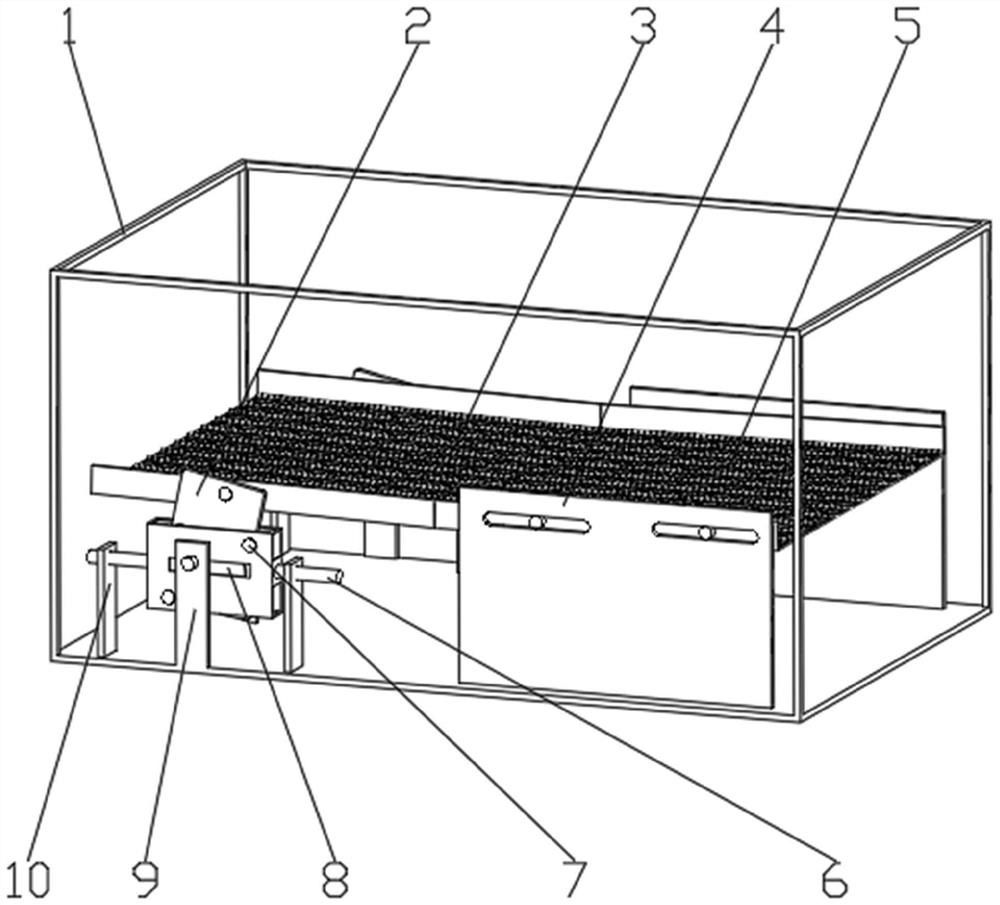

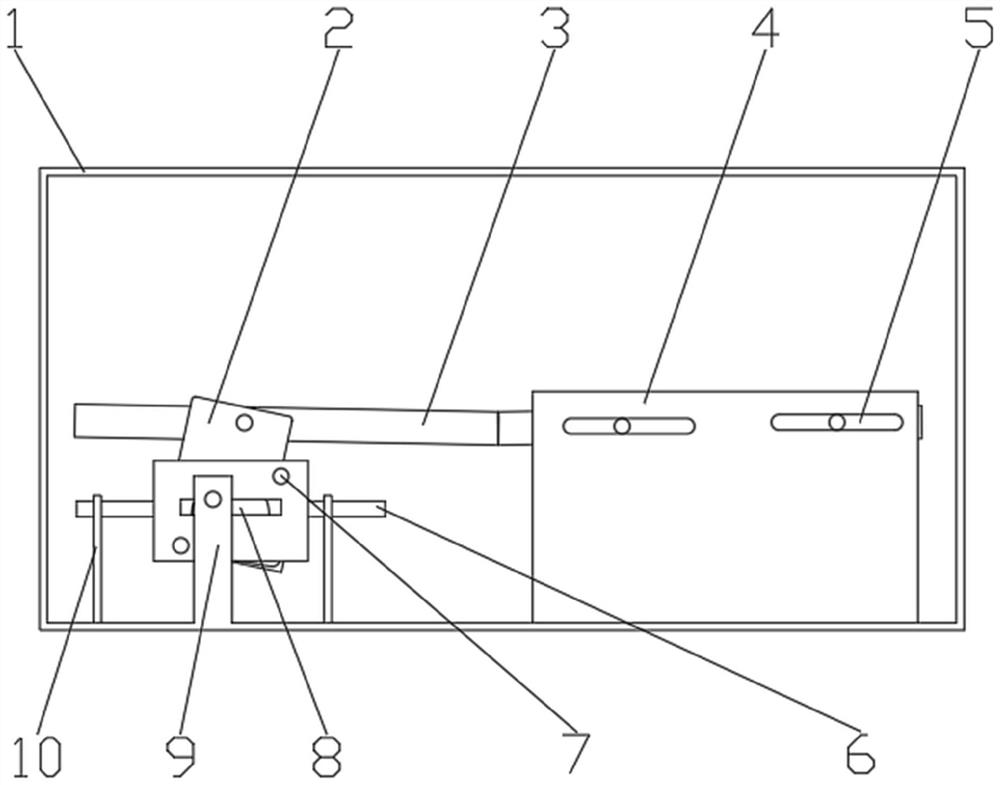

[0016] The embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, a segmented corn grain cleaning device imitating the surface structure of butterfly wings, two groups of first mounting brackets 10 are fixed on the bottom of the front end of the frame assembly 1, and the drive mechanism housing 6 The rotating shaft is slidably installed on the first mounting frame 10, two sets of second mounting frames 9 are fixed on the bottom of the front end of the frame assembly 1, and the rotating shaft driven by the disc type runner 8 in the driving mechanism is rotatably mounted on the second mounting frame 9, wherein one side of the rotating shaft of one inner disk type runner 8 is fixedly equipped with a driving sprocket 11, and the outer circle of the inner disk type runner 8 is rotatably installed with an outer circle rotating frame 2, and the outer circle rotating frame 2 passes through 2 groups The connecting rod 7 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com