Dry-wet separation mist dispersing water-saving type cooling tower

A separate and water-saving technology, applied in the field of cooling towers, can solve the problems of limited water-saving time, low average annual water-saving rate, and insignificant economic benefits in northern water-deficient areas, and achieve water-saving rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

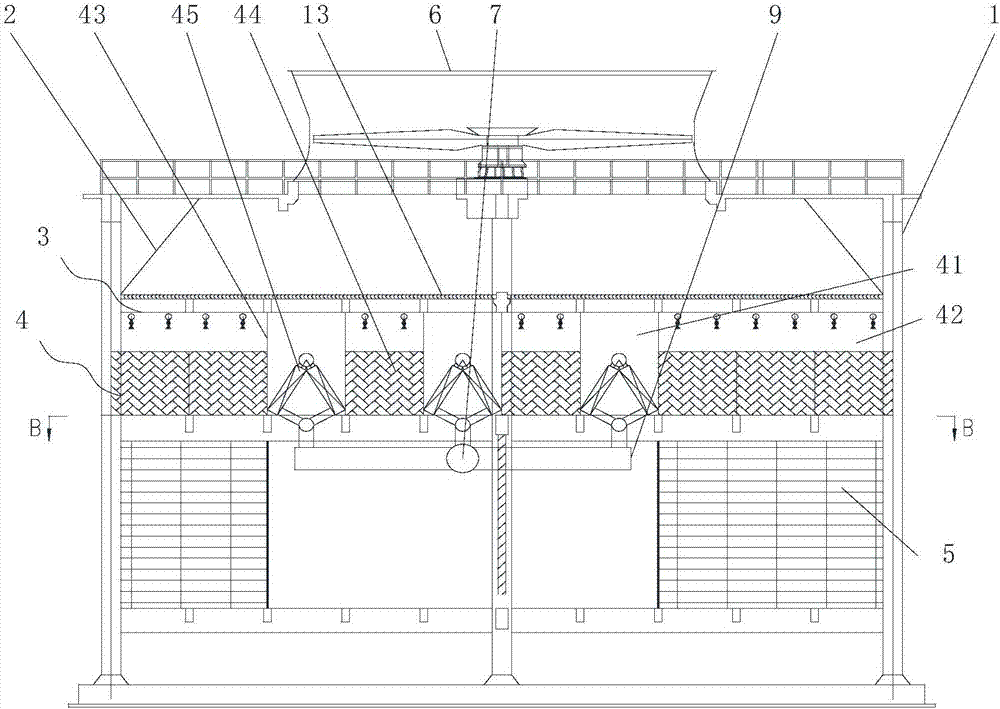

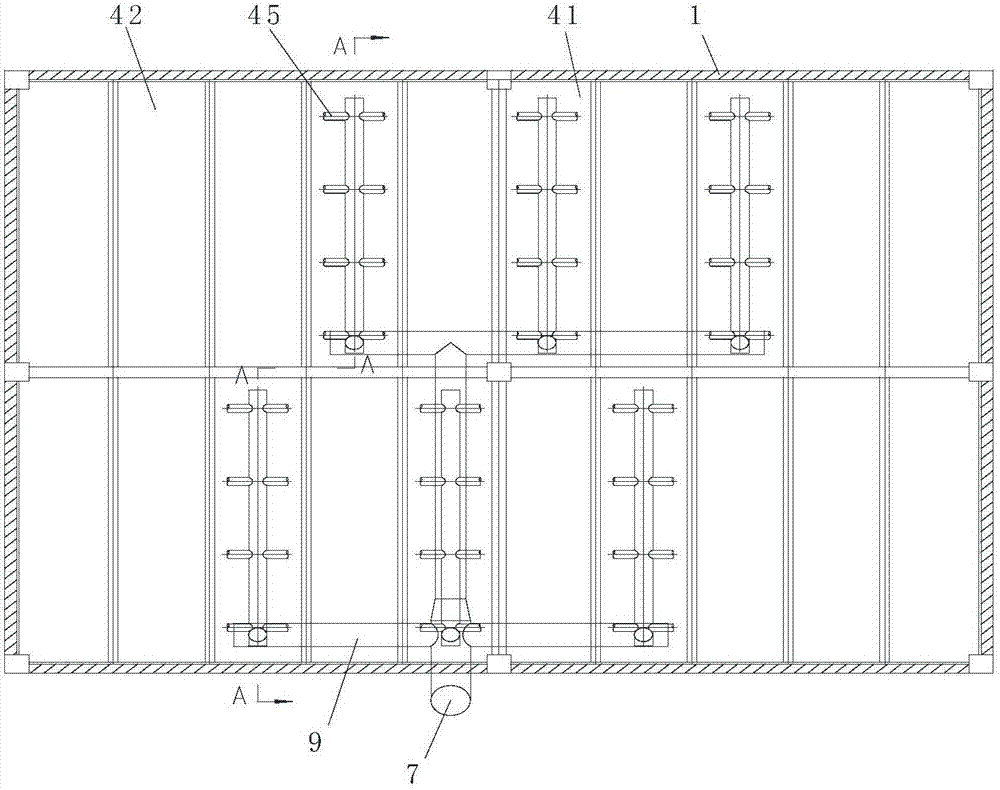

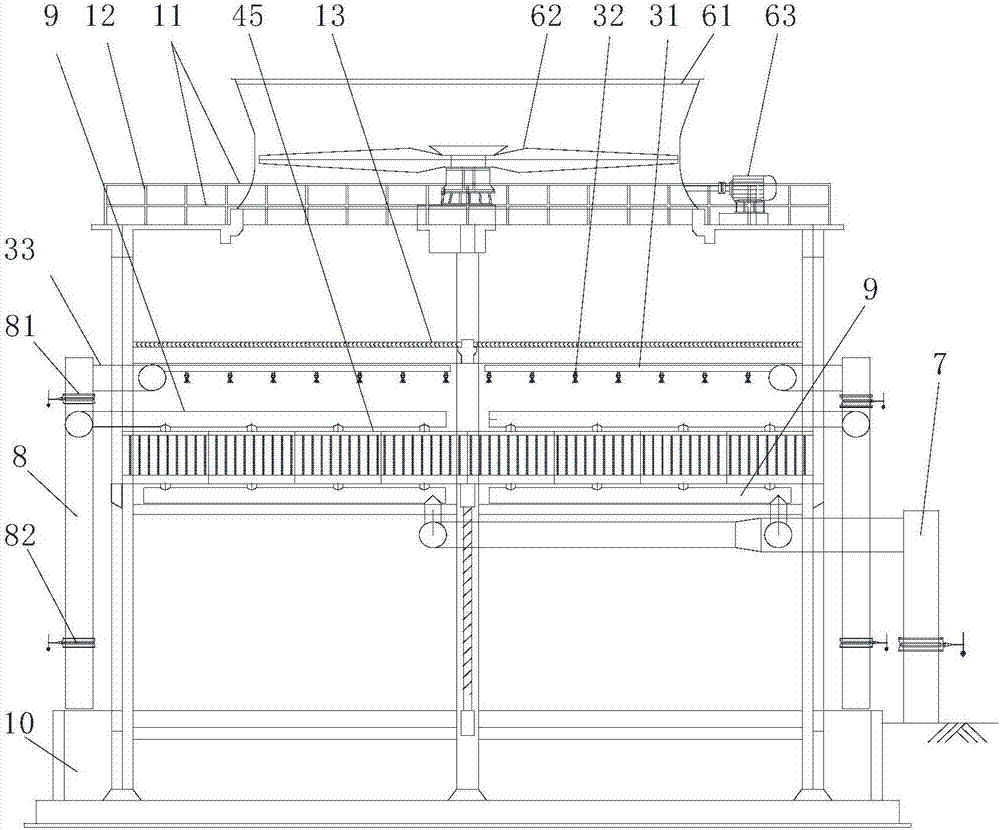

[0024] Example 1, such as Figure 1 to Figure 4 , a dry-wet separation type fog-eliminating and water-saving cooling tower, including a tower body 1 and a dry and wet air mixing device 2, a water spray system 3, a dry-wet separation Area 4 and the electric air regulating device 5 also include an exhaust system 6 arranged on the top of the tower body 1, a water inlet pipe 7 and an outlet pipe 8 arranged on one side of the tower body 1, the exhaust system 6 is connected with the dry and wet The air mixing device 2 communicates; the dry-wet separation area 4 includes a dry-cooling area 41 and a wet-cooling area 42 which are independent of each other, and the dry-cooling area 41 and the wet-cooling area 42 are sealed and separated by a partition 43, and the dry-cooling area 41 The quantity is set to 6, and the number of the wet and cold areas 42 is set to 14, which can realize water saving throughout the year. The described wet and cold areas 42 are provided with fillers 44, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com