Human body recognition system above the railway tracks

A technology of human body recognition and railway track, applied in the field of target recognition, can solve the problems of lack of detection mechanism and difficulty of human body recognition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the human body recognition system above the rails of the present invention will be described in detail below with reference to the drawings.

[0023] In order to overcome the above shortcomings, the present invention builds a human body recognition system above the rails, implements targeted image acquisition and image processing mechanism processing, and sends out an emergency alarm signal when it is determined that a human body is present.

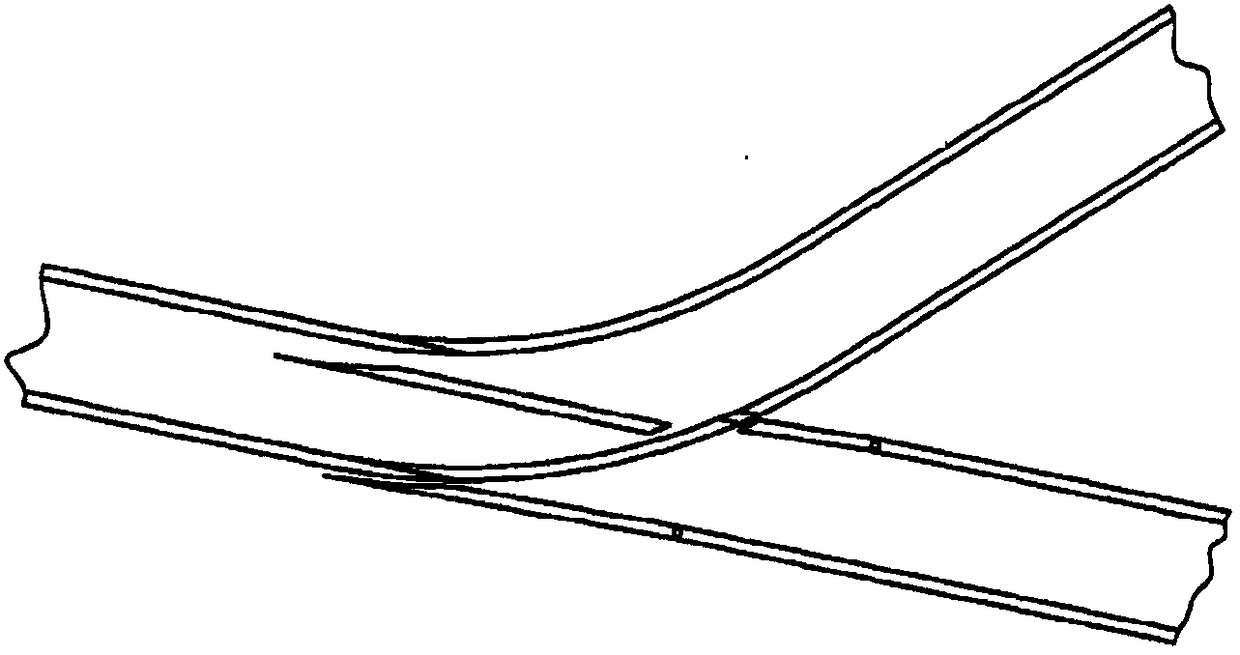

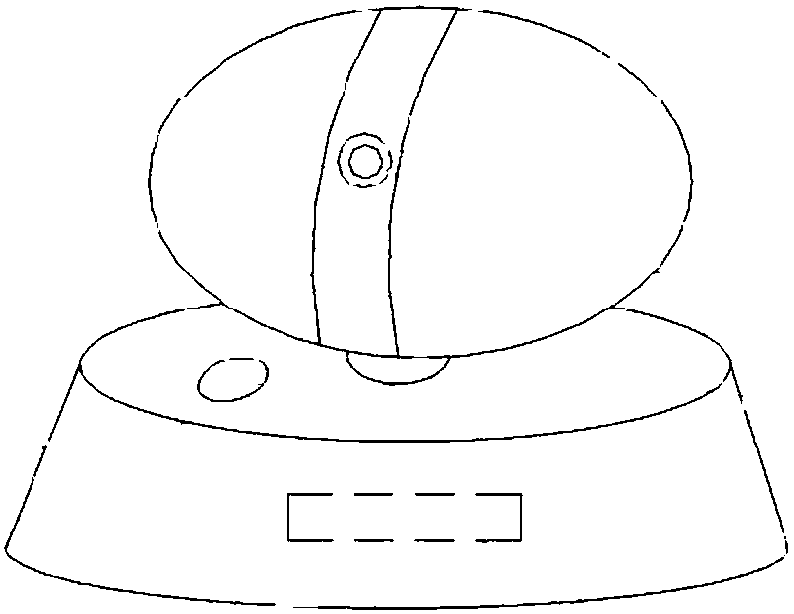

[0024] figure 1 Is a schematic diagram showing the structure of the rail above the rail where the human body recognition system is located according to the embodiment of the present invention, figure 2 It is a schematic structural diagram of a fixing mechanism of a human body recognition system above a rail according to an embodiment of the present invention. As shown in the figure, the system includes:

[0025] Force detection equipment, set at the rail transfer joints, used to detect and output the real-time forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com