Fast-sucking slow-discharging type air valve with filtration function

An air valve and slow-discharge technology, which is applied in the direction of filtration and separation, the device for absorbing fluid energy of the valve, and the details of the valve, can solve problems such as damage to pipelines and equipment, strong impact on pipelines, and water hammer when closing valves, etc. The effect of small resistance, large resistance to water, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

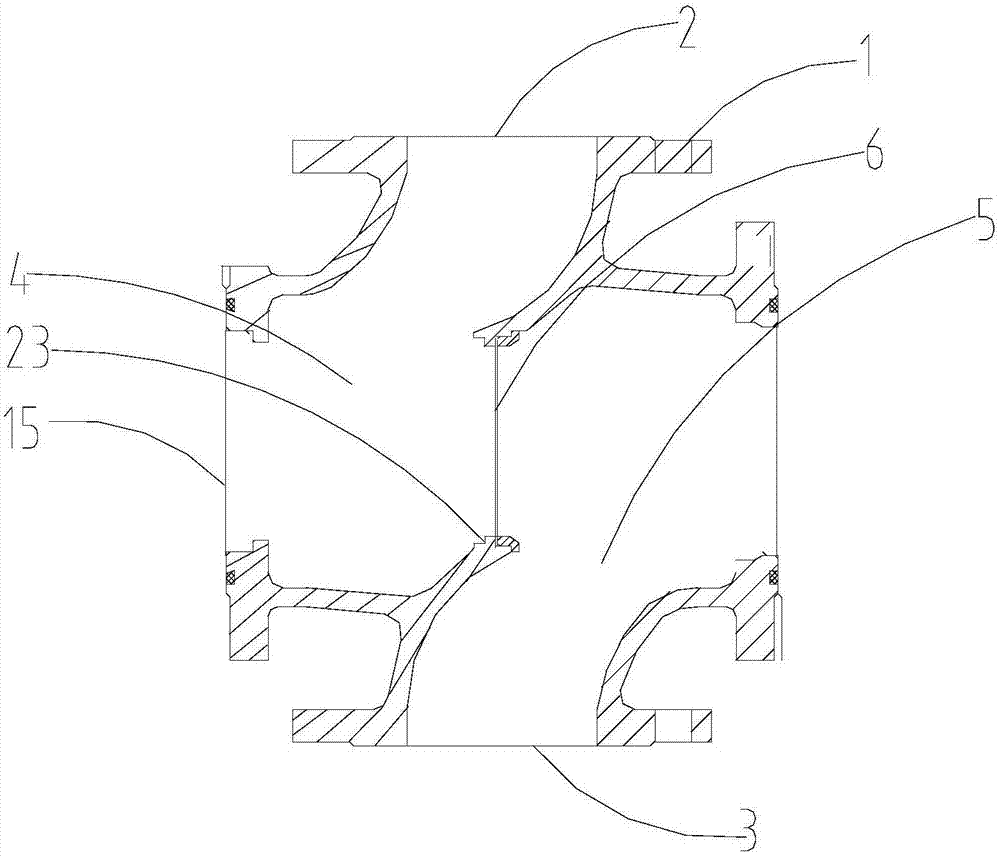

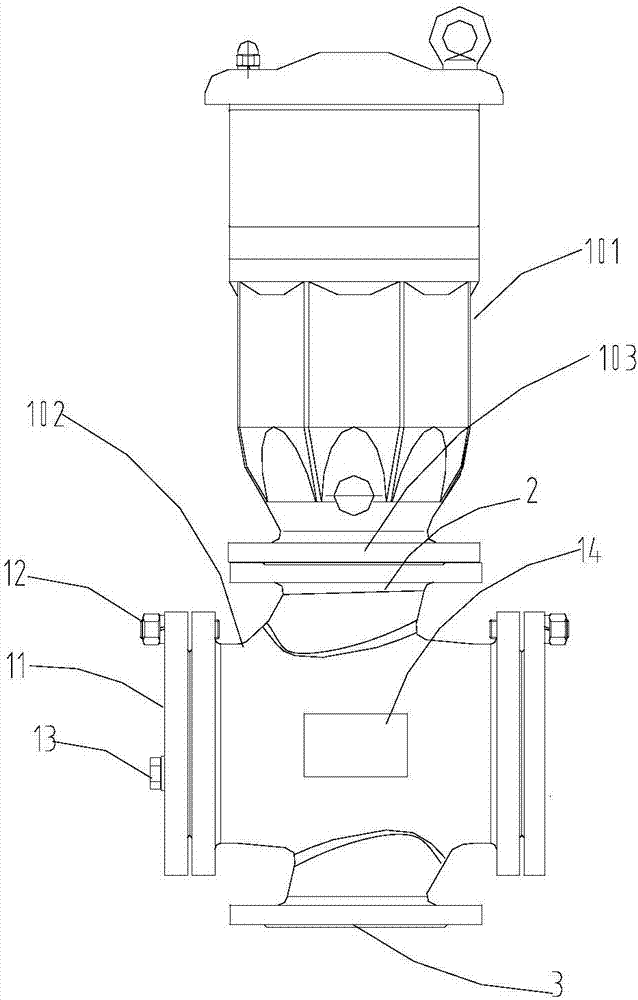

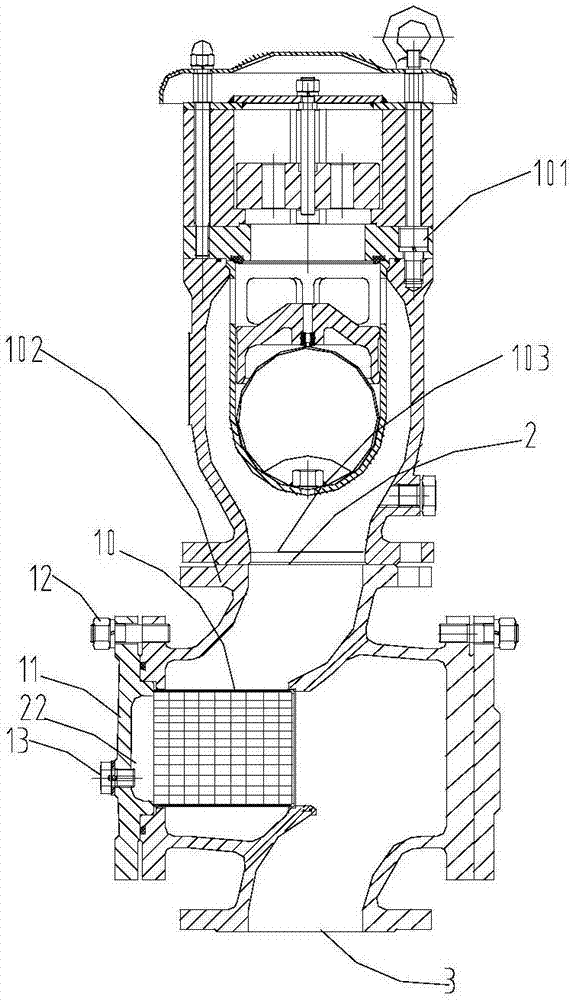

[0040] like Figure 1-8 As shown, the present embodiment provides a fast suction and slow discharge air valve with built-in filter, which is mainly used on pipelines with maintenance valves or shut-off valves, including the air valve main body 101 and the valve assembly 102, and the air valve main body 101 The valve opening 103 is connected to the valve assembly 102 through a flange seal, which is convenient for maintenance and replacement. The main body 101 of the air valve in this embodiment uses a water-proof air valve for further illustration. Specifically, the patent number 201520384037.9 applied by our company is used. The patent name is the anti-hammer air valve, and the specific structure and function will not be repeated one by one. This embodiment mainly integrates the air valve and the valve assembly without changing the structure of the air valve, and has the premise of having all the original functions of the air valve. Next, it has built-in filtration and quick s...

Embodiment 2

[0056] like Figure 9 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the number of reinforcing ribs 21 is at least two, and the two reinforcing ribs 21 cross each other and are fixed on the port of the filter cartridge close to the valve cover in a cross shape. It can play the role of Embodiment 1, and can further strengthen the strength and stability of the filter cartridge with double-layer structure through a plurality of reinforcing ribs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com