Method for calibrating a temperature sensor present in an automation technology process

A technology of temperature sensor and automation technology, applied in the field of temperature measurement equipment, to achieve the effect of reliable on-site calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

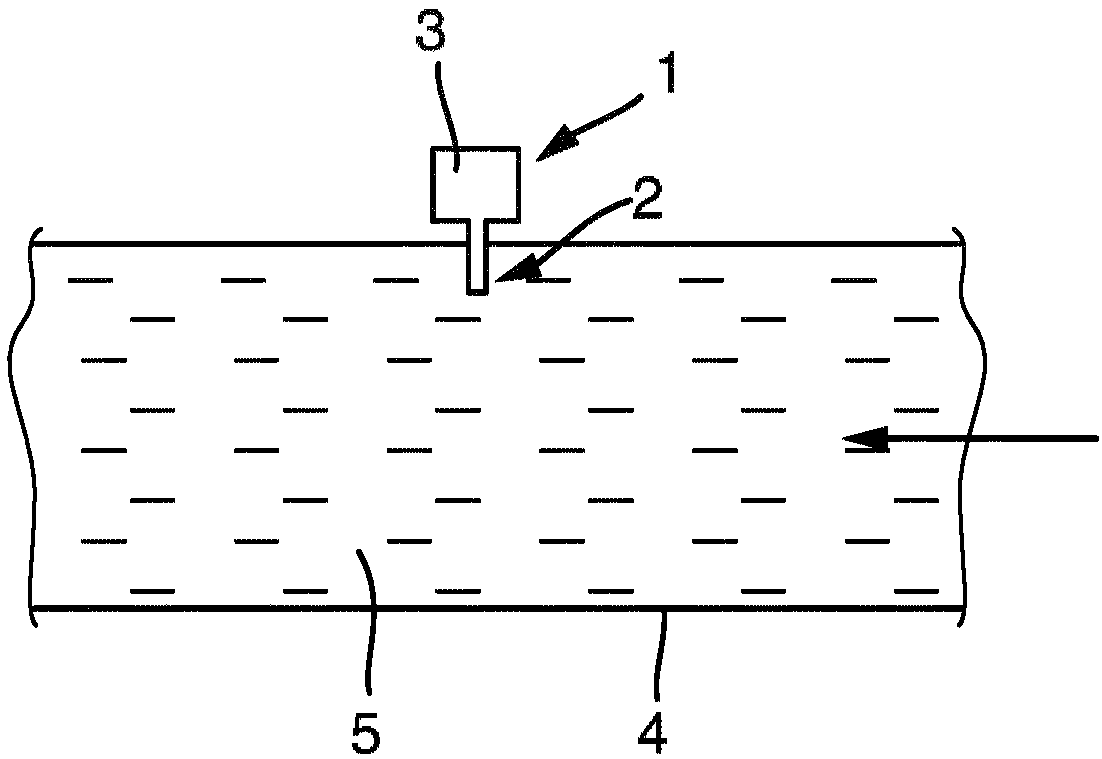

[0030] figure 1 is a schematic representation of an in situ calibratable temperature measuring device 1 of the present invention located in a process. In the case shown, the temperature measuring device 1 determines the temperature T of a medium 5 which flows through the line 4 in the direction of the arrow. The temperature measuring device 1 consists of a temperature sensor 2 (with a temperature sensitive element) and a control / evaluation unit 3 . While the temperature sensor 2 is in thermal contact with the medium 5, the control / evaluation unit 3 is arranged to be removed from the line 4 and thus from the actual process. Medium 5 is any fluid medium. Examples of temperature sensitive elements and corresponding temperature sensors 2 have been mentioned above but not exclusively. A large number of temperature measuring devices 1 are produced and sold by the applicant for use in a wide variety of automation technology applications. In general, known temperature sensors 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com