Method for calibrating a temperature sensor located in an automation technology process

A technology of temperature sensor and automation technology, applied in the field of temperature measurement equipment, to achieve the effect of reliable on-site calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

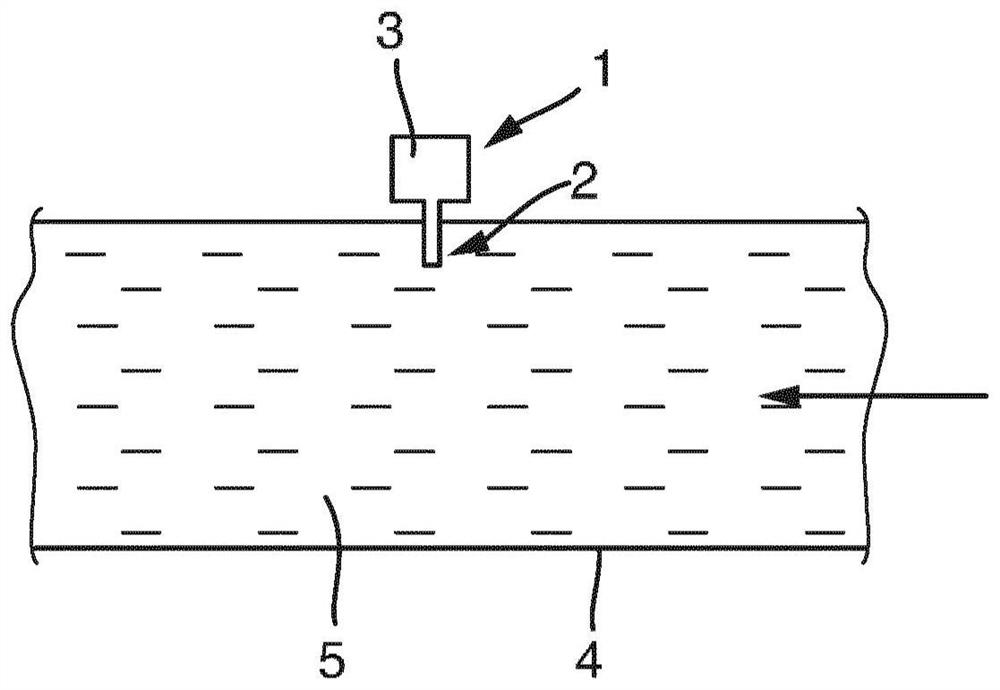

[0030] figure 1 It is a schematic representation of the in-situ calibratable temperature measuring device 1 of the present invention in the process. In the case shown, the temperature measuring device 1 determines the temperature T of the medium 5 which flows through the pipeline 4 in the direction of the arrow. The temperature measuring device 1 is composed of a temperature sensor 2 (with a temperature sensitive element) and a control / evaluation unit 3. While the temperature sensor 2 is in thermal contact with the medium 5, the control / evaluation unit 3 is arranged to be removed from the pipeline 4 and therefore from the actual process. Medium 5 is any fluid medium. Examples of temperature sensitive elements and corresponding temperature sensors 2 have been mentioned above non-exclusively. A large number of temperature measuring devices 1 are produced and sold by the applicant for use in diversified automation technology applications. Generally speaking, the known temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com