Improved type unhairing assembly used during slaughtering of pigs

An improved and component technology, applied in the direction of slaughtering accessories, slaughtering, slaughtering devices, etc., can solve the problems of unclean hair removal, affecting the consumption of pigskin, troublesome and other problems, achieve uniform gas distribution, good clamping reliability, and reduce use cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

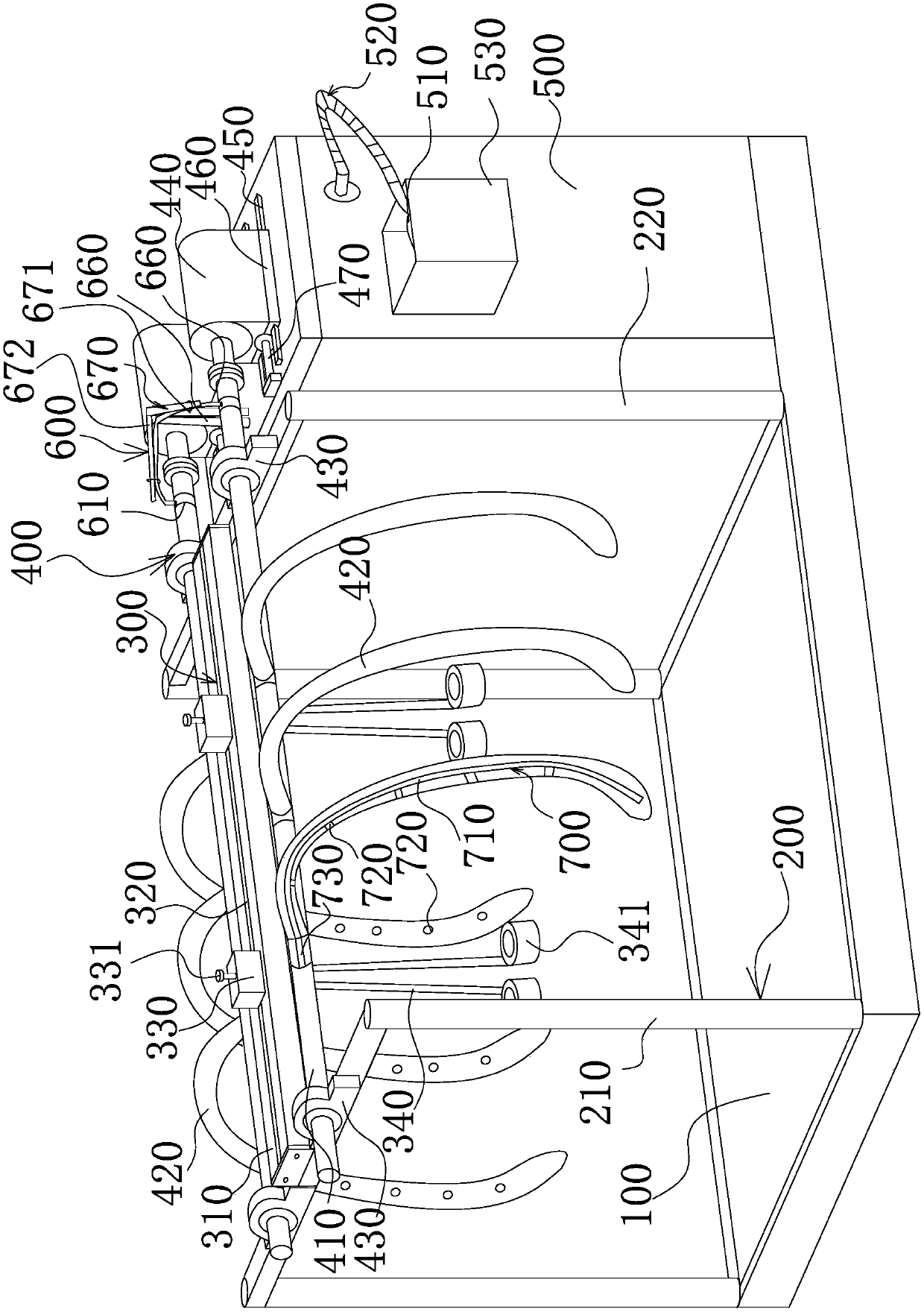

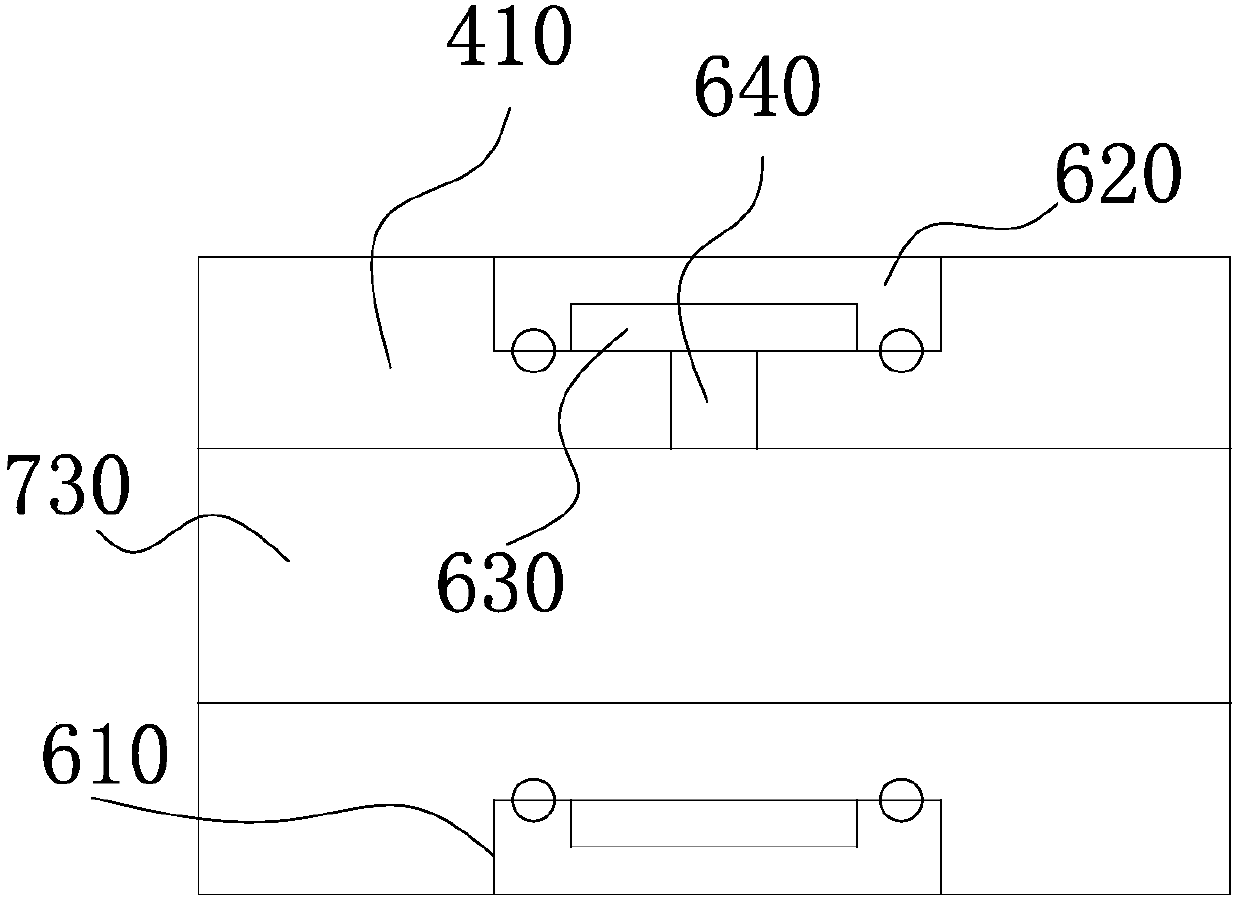

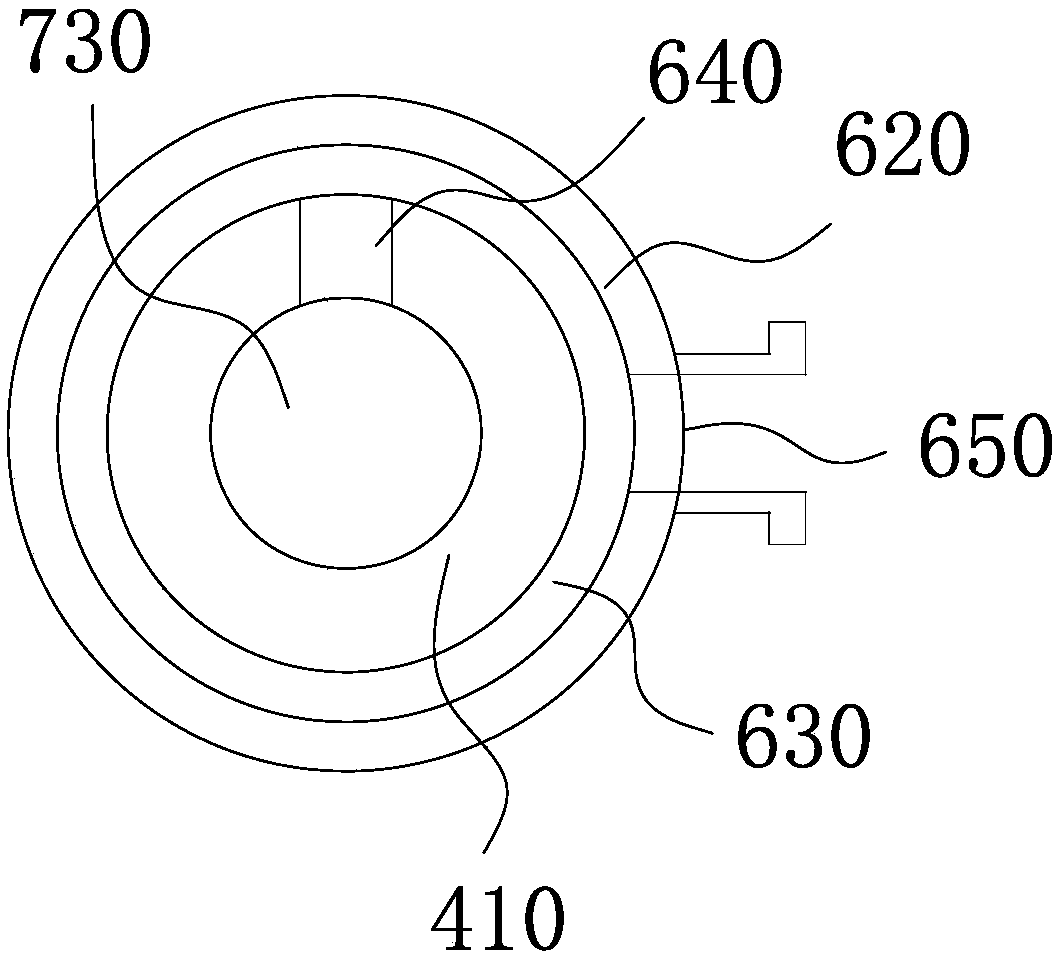

[0025] Such as Figure 1-9As shown, the improved hair removal assembly for slaughtering pigs includes a base 100 on which a frame body 200 and an inflatable assembly 300 are arranged. The frame body 200 includes an inverted front U-shaped frame 210 and a rear U-shaped frame 220. A hoisting assembly 300 is provided between the U-shaped frame 210 and the rear U-shaped frame 220. The hoisting assembly 300 includes a beam 310 arranged between the front U-shaped frame 210 and the rear U-shaped frame 220. The bar-shaped through groove 320 that is set is also provided with two I-shaped sliders 330 that can move along the bar-shaped through-groove 320 on the crossbeam 310, and the I-shaped slider 330 is provided with a slider bolt 331 for positioning. Two suspenders 340 are fixed on the lower end of the sliding block 330, and the suspenders 340 are provided with a universal binding belt 341 for binding the pig's feet, and both sides of the crossbeam 310 are provided with a slapping me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com