Wooden furniture plate machining device

A technology for sheet metal processing and wooden furniture, which is applied in the direction of manufacturing tools and workshop equipment, can solve problems such as inconvenient use, low production efficiency, and unclear shallow grooves, and achieve reduced production costs, accurate scribing accuracy, and improved scribing. The effect of line efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

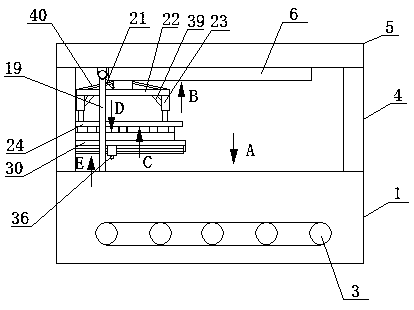

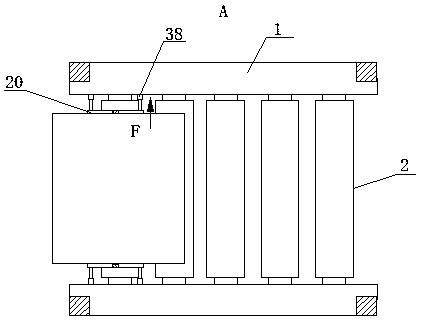

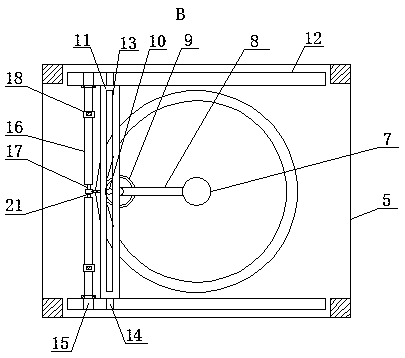

[0018] Embodiment 1: Place a plate with a width of 50mm on the roller 2, rotate the first screw rod 16 to make the two nuts 18 drive the vertical rod 19 to move relatively, and then drive the two fixed plates 20 to move relatively, so that the two fixed plates 20 Clamp the plate with a width of 50mm to prevent the plate from shaking in the marking line; when the second gear 28, the third gear 29 and the second ring gear 27 are in a static state, the second screw 31 and the roller 2 are perpendicular to each other state, the strip block 33 drives the marking pen 36 to move left and right, and then the marking operation is performed on the plate.

Embodiment 2

[0019] Embodiment 2: Place a plate with a width of 70mm on the roller 2, rotate the first screw rod 16 to make the two nuts 18 move relative to each other, and the nut 18 and the fixed plate 20 are fixedly connected by a vertical rod 19, which can drive two The fixed plates 20 move relative to each other, so that the two fixed plates 20 clamp the plate with a width of 70 mm to prevent the plate from shaking during the marking process; the second gear 28 and the third gear 29 rotate to drive the second ring gear 27 to rotate, and the second gear 28 and the third gear 29 rotate to drive the second ring gear 27 to rotate. The second ring gear 27 is fixedly connected with the third connecting plate 30, so that the third connecting plate 30 can be rotated, and then the second screw rod 31 and the roller 2 can be in a state parallel to each other, and then the second screw rod 31 rotates to make the strip block 33 drive The scribing pen 36 moves back and forth to perform a scribing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com