Nano drug-carrying system, its preparation method, pharmaceutical composition and application in treating cancer

A nano-drug-loading and nano-carrier technology, applied in drug combinations, pharmaceutical formulations, anti-tumor drugs, etc., can solve problems such as aggravation of EMT, invasion and metastasis, and achieve the effect of preventing invasion and metastasis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] The preparation method of the HES-PLA graft copolymer can refer to, for example, the method disclosed in the patent application CN103467753A, which is incorporated herein by reference in its entirety.

[0088] According to a preferred embodiment, the preparation method of the nano drug-carrying system using HES-PLA grafted polymer as a carrier of the present invention includes:

[0089] It includes the following steps:

[0090] (1) Dissolve PLA and activate its terminal carboxyl group: Add the catalyst N-N'-dicyclohexylcarbodiimide and 4-dimethylaminopyridine to the carboxyl-terminated PLA, with anhydrous dimethyl sulfoxide as the solvent, 50 React for 25 to 45 minutes at ~70°C to completely dissolve it to obtain PLA with activated terminal carboxyl groups; the molecular weight of the PLA is 10-30kDa, preferably 10kDa, and the PLA, N-N'-dicyclohexyl carbon two The molar ratio of imine and 4-dimethylaminopyridine is 1:4:2;

[0091] (2) Dissolving HES: Under nitrogen protection,...

Embodiment 1

[0155] Example 1 Preparation of HES-PLA copolymer

[0156] Weigh 0.5g HES (Hua Keda Life Science & Technology Co., Ltd., hydroxyethylation rate is 0.5), put it in a drying oven at 105°C for 2h, take it out, and dissolve it in 20mL DMSO (60°C). At the same time, PLA (Mw 5kDa, Jinan Daigang Bioengineering Co., Ltd.), dicyclohexylcarbodiimide and dimethylaminopyridine were dissolved in 10 mL DMSO at a molar ratio of 1:4:2. After the two solutions were mixed, they were placed in a round-bottomed flask, protected by nitrogen, the temperature of the oil bath was maintained at 60°C, and the reaction was stirred for 24 hours. After the reaction is over, the product is collected, placed in a dialysis bag with an intercepted molecular weight of 3500, and dialyzed with ultrapure water for 3 days. After the dialysis product was freeze-dried, dichloromethane was added to purify it through a Soxhlet extractor (70°C, 24h) to remove unreacted PLA. The product obtained after extraction was vacu...

Embodiment 2

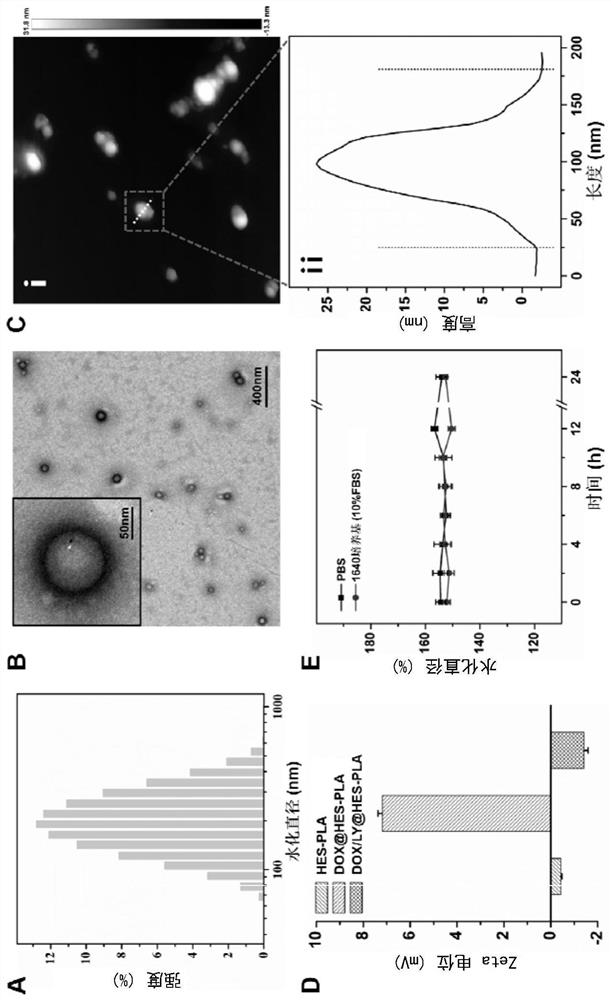

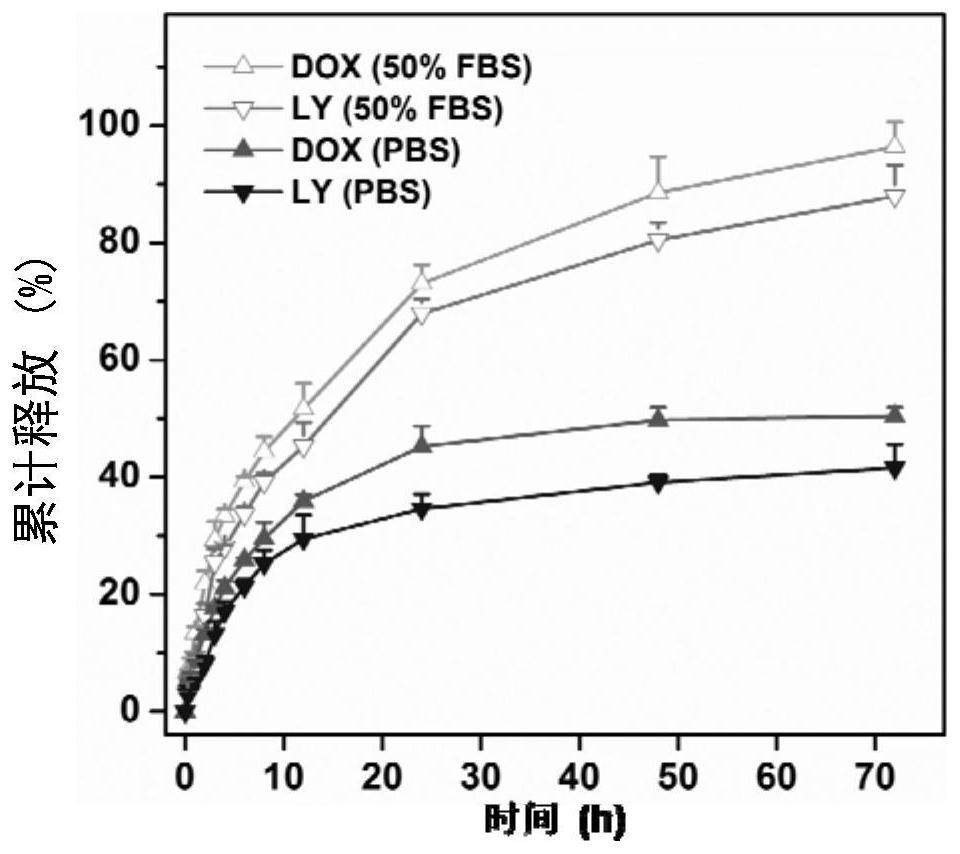

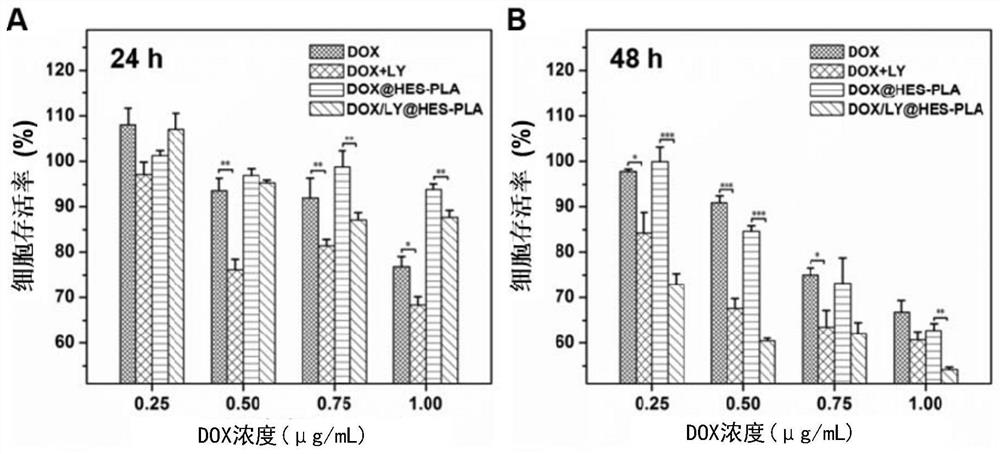

[0157] Example 2 Preparation of Nanoparticles (DOX / LY@ Nanoparticles) containing DOX and LY2157299 (hereinafter referred to as LY)

[0158] Weigh 6 mg of DOX hydrochloride (Beijing Huafeng Lianbo Co., Ltd.) and suspend and disperse it in 1 mL of chloroform. According to the molar ratio DOX: triethylamine=1:3, triethylamine was added to the suspension. After the suspension was sonicated for 1 hour, it was centrifuged at 3000 rpm for 10 minutes, and the supernatant was taken, which was the DOX trichloromethane solution with hydrochloric acid removed. Weigh 12 mg of LY and add it to the DOX chloroform solution, vortex and mix until there are no obvious particles in the solution.

[0159] Weigh 30 mg of the HES-PLA copolymer prepared in Example 1 and dissolve it in 20 mL of ultrapure water. In an ice bath, add the above 1 mL DOX / LY trichloromethane solution dropwise to the HES-PLA aqueous solution. During the dripping process, the solution was emulsified (power: 200W, working time: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com