Multi-point locking mechanism

A locking mechanism, multi-point technology, applied in the direction of building locks, building structures, building fastening devices, etc., can solve the problems of high cost, low efficiency, complicated operation, etc., and achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

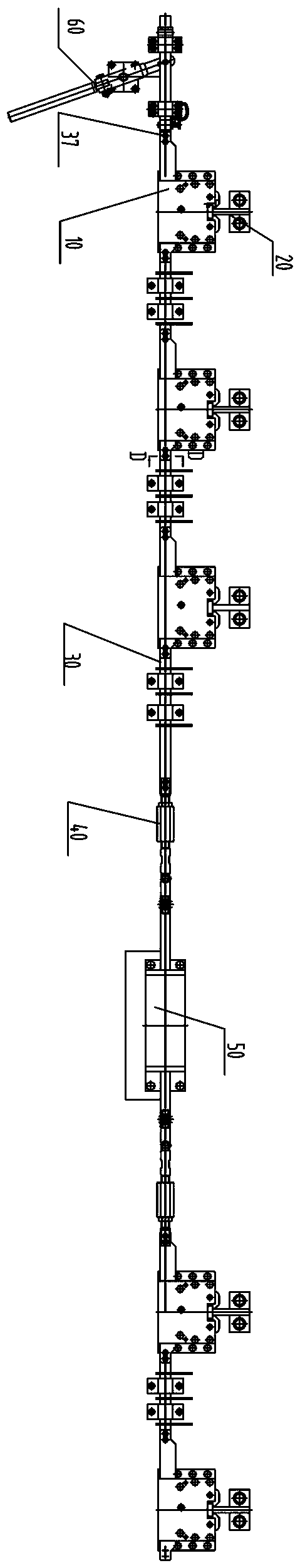

[0024] Such as Figure 1 to Figure 3 As shown, a multi-point locking mechanism is composed of at least two lock bodies 10 connected in a straight line, and every two adjacent lock bodies 10 are connected by a connecting rod 30 to realize linkage. Any lock body 10 connected in a straight line Connect with the power end of the electric cylinder 50 through the connecting rod 30, the release mechanism 40, or the lock body 10 at the end is connected with the manual unlocking mechanism 60 through the fixed pin 37; a lock corresponding to the position is provided outside each lock body 10 Tongue 20.

[0025] Such as Figure 4 to Figure 16 As shown, the lock body 10 includes the following structural parts: lock support 1, lock cover 2, pull hook 3, combined pull plate 4, cam 5, lock cylinder 6, long pull plate 7, lock tongue 20, wherein the lock support 1 is a groove-shaped structure, and the two sides of the lock support 1 are respectively provided with a mounting hole 9 and a fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com