Container for transporting steel coils

A technology for containers and steel coils, applied in the field of containers, can solve problems such as accidents and jumping out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

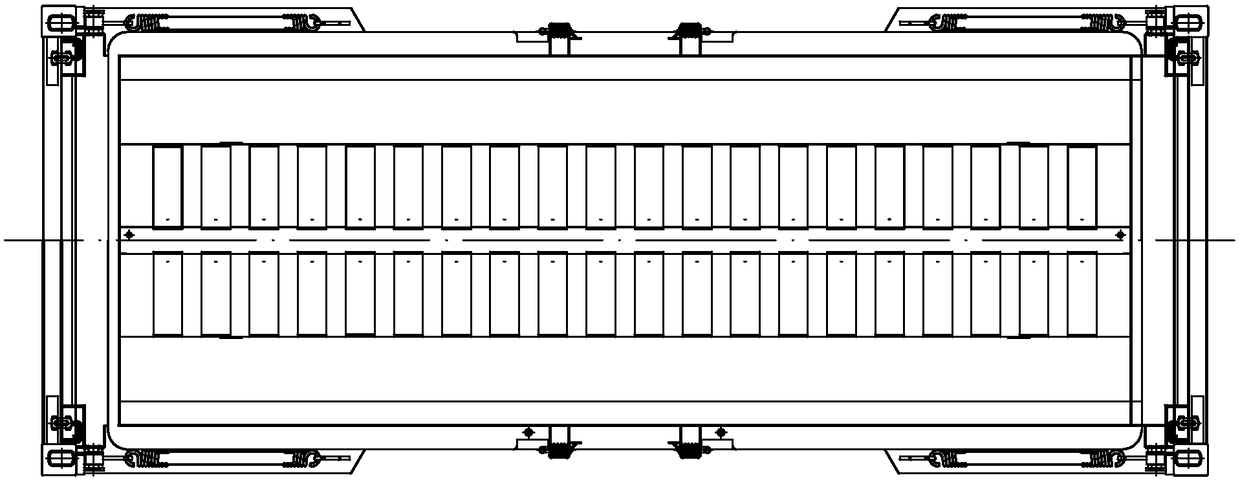

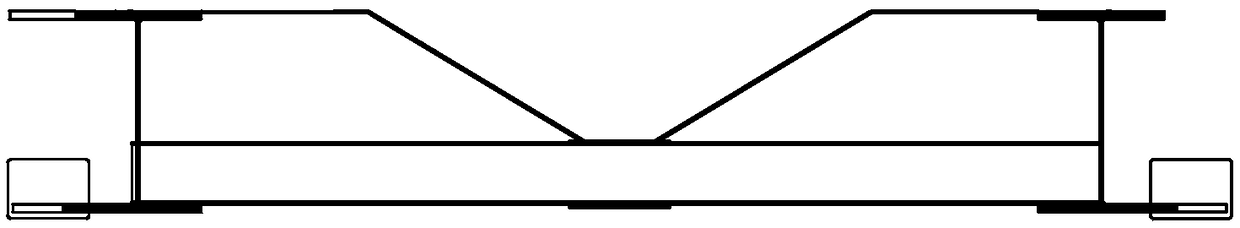

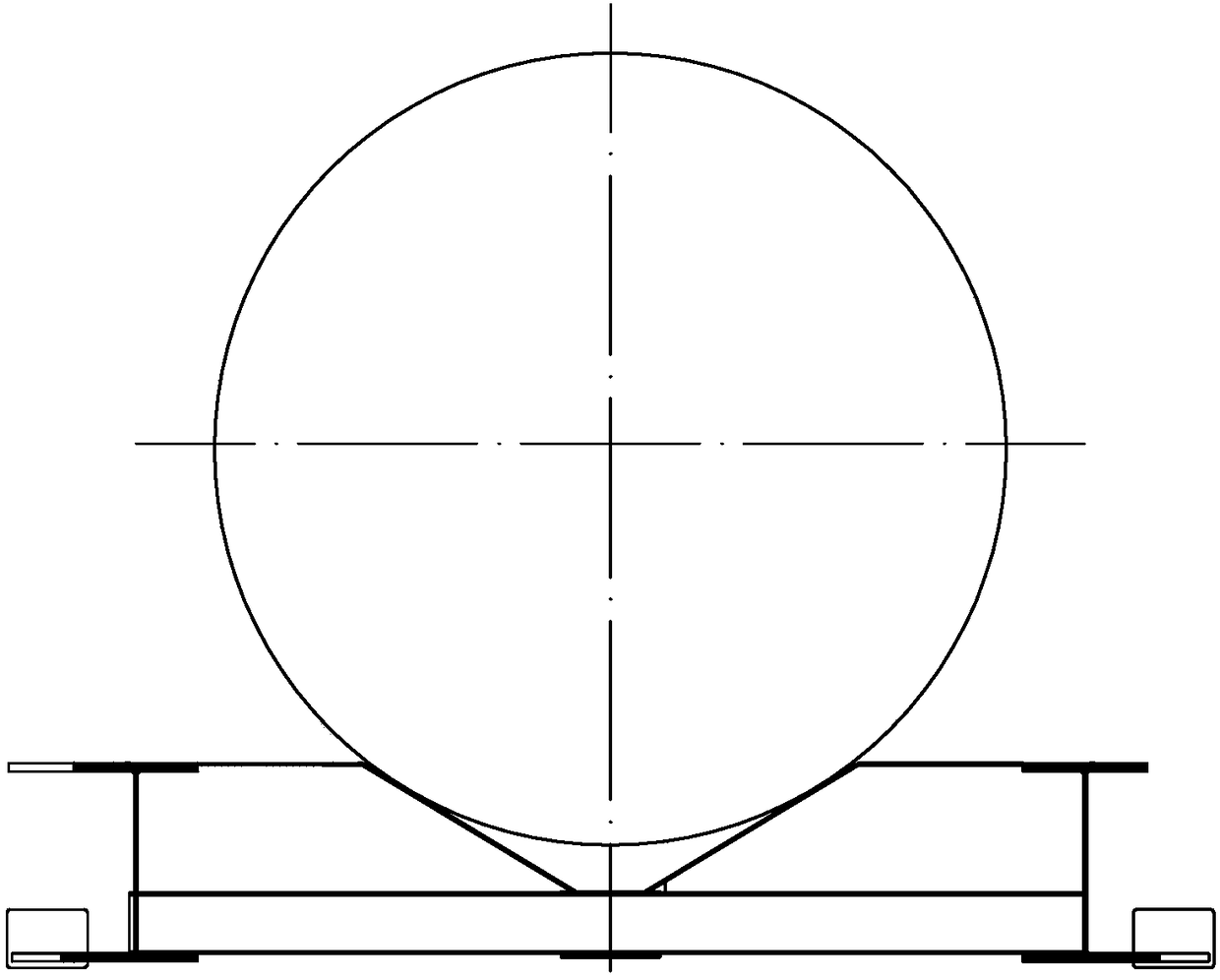

[0034] Figure 4 to Figure 8 It is a structural schematic diagram of a container for shipping steel coils. As can be seen from the figure, it includes a front end wall 1, a rear end wall 2 and an underframe 3, and a bracket 4 is installed on the underframe 3, and the bracket 4 is provided with three parallel grooves 6 for placing steel coils 5. . Usually, each container can be provided with 1-4 grooves according to the size of the steel coils to be shipped. The groove 6 is a circular arc with different curvatures or a plurality of broken lines connected to form an open arc surface. The front and rear ends of the groove 6 are respectively provided with an opening groove 7, and the opening groove 7 is located below the opening groove. There is a row of six retaining rods 9 connected in series by pin shafts 8 in the middle (the number of retain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com