Insulator iron cap facilitating mounting of angular ball

A technology of insulators and iron caps, applied in the field of power grid equipment, can solve the problems of inconvenient installation of iron caps and corner balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

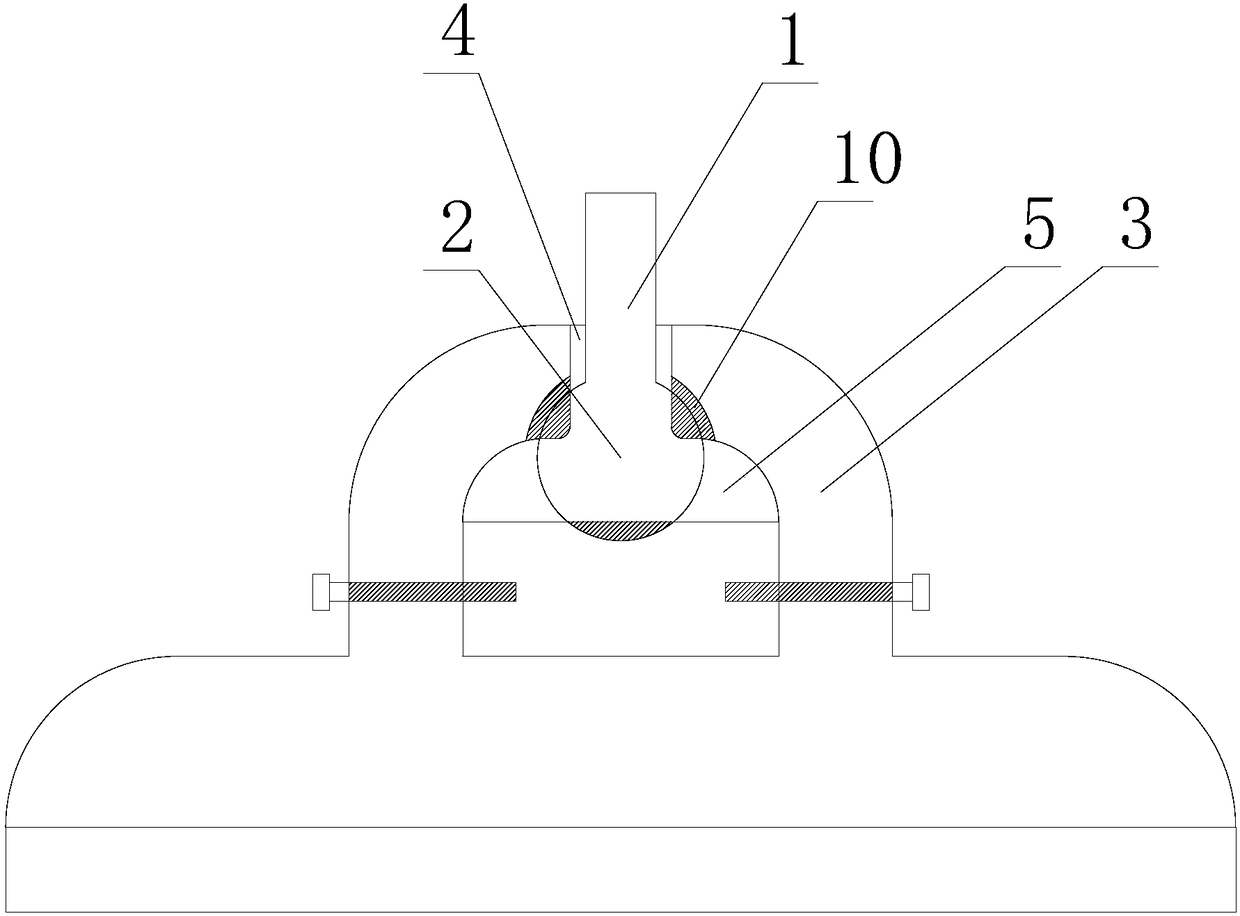

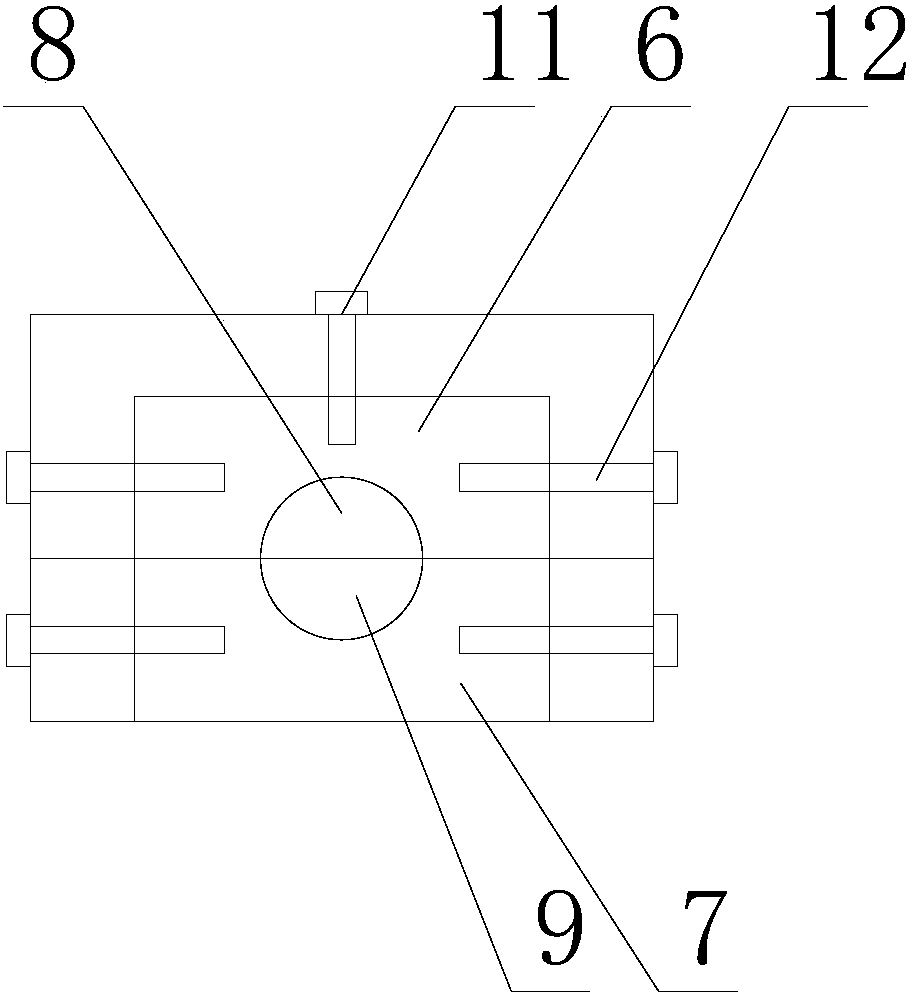

[0021] Such as figure 1 , 2 As shown, the present invention proposes an insulator iron cap that is convenient for corner ball installation. The corner ball is composed of a ball head 2 and a rod portion 1. It is characterized in that it includes: an iron cap body 3 and a stopper. Position block 6, the second limit block 7, the first limit block 6 offers the first limit groove 8, the second limit block 7 offers the second limit groove 9, and the iron cap body 3 offers the first guide groove 4, The transition groove 10, the second guide groove 5, the first guide groove 4, the transition groove 10, and the second guide groove 5 are sequentially connected and communicated, and the notches are directed in the same direction; the first limit block 6 and the second limit block 7 are spliced into the second limit groove 9, the iron cap body 3 fixes the first limit block 6 through the first screw 11, and fixes the second limit block 7 through the second screw 12; the rod part 1 is put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com