Apparatus for additive manufacturing of three-dimensional objects

A three-dimensional object, additive technology, applied in additive manufacturing, metal processing equipment, manufacturing tools, etc., to solve problems such as changes, the impact of the quality of manufactured objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

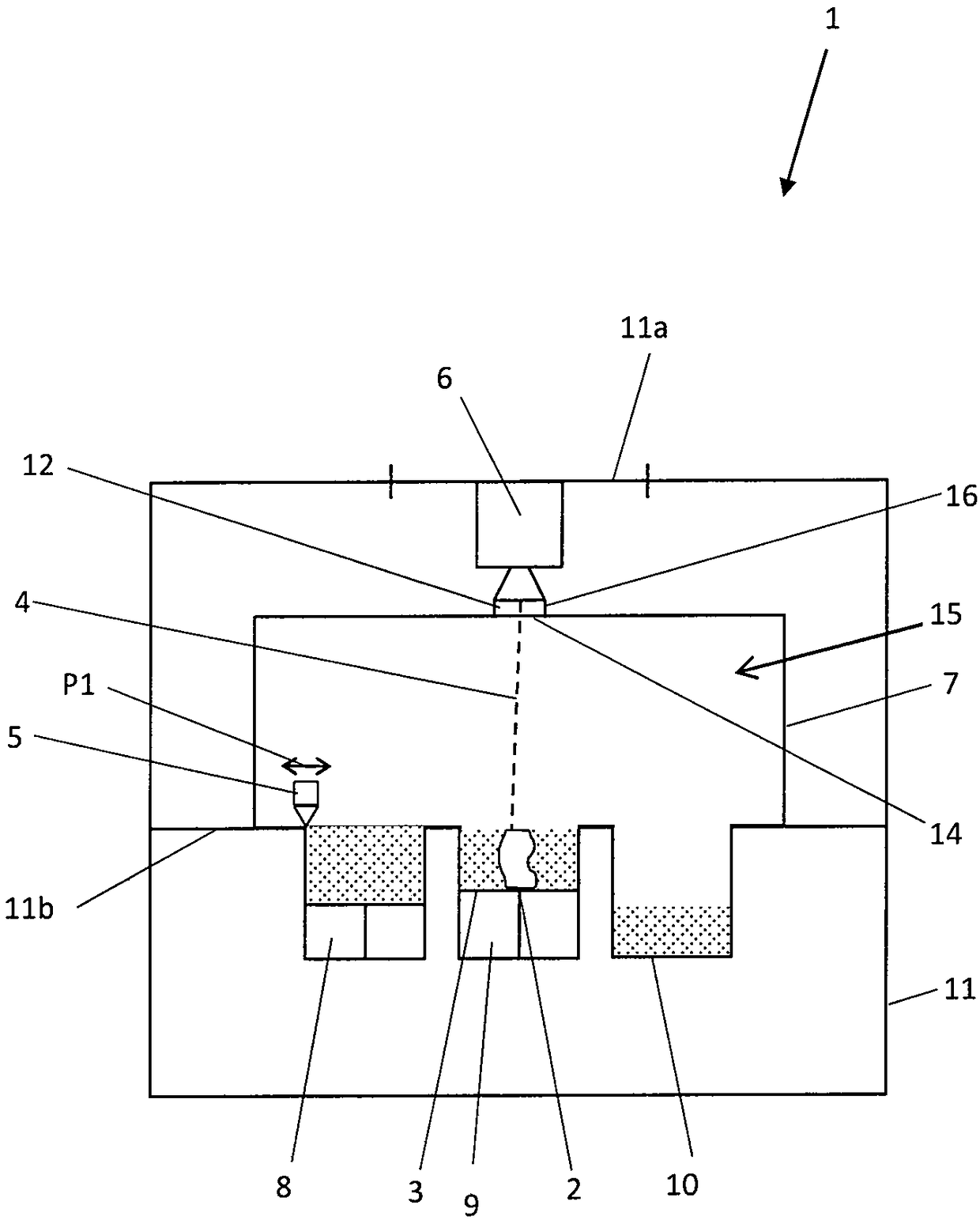

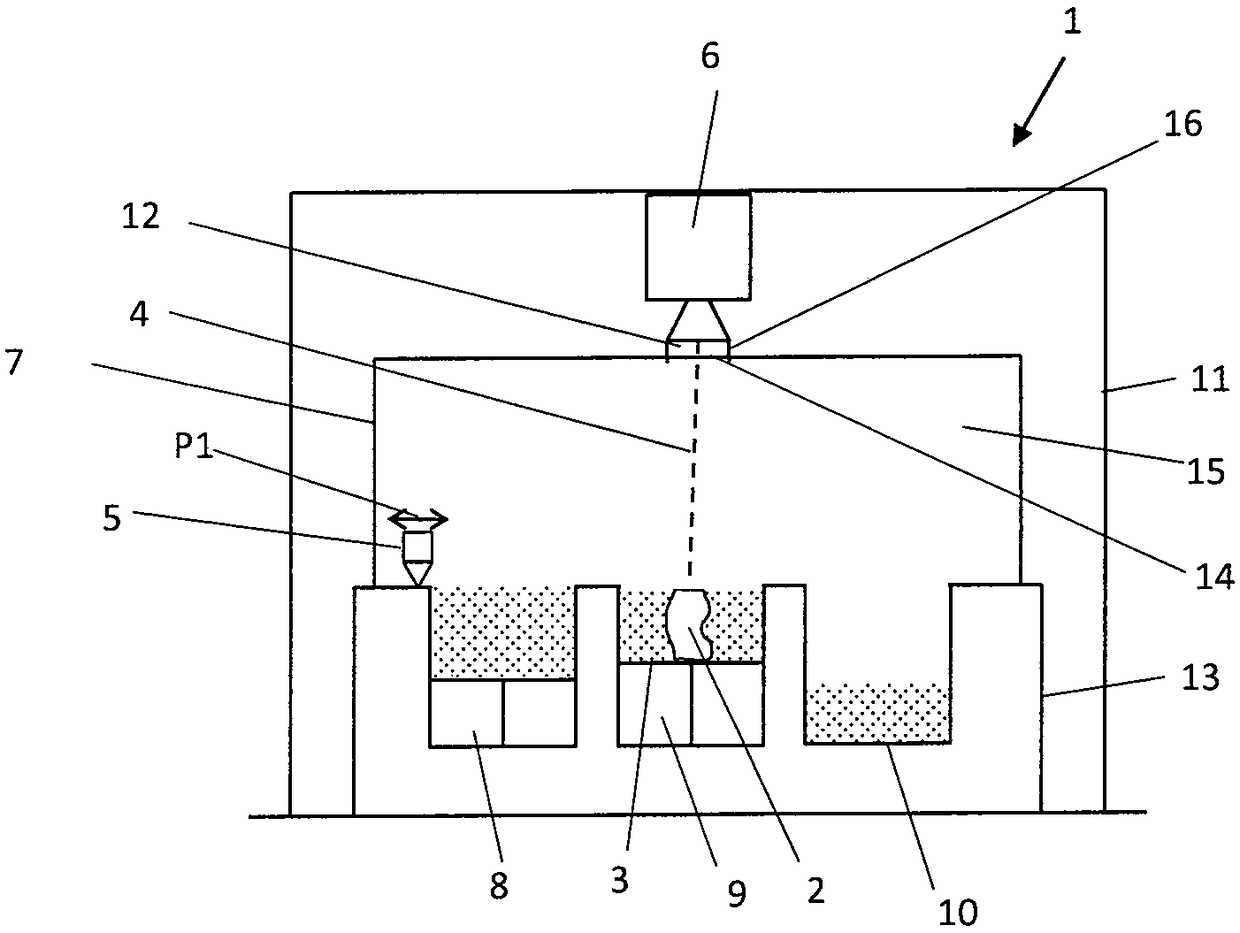

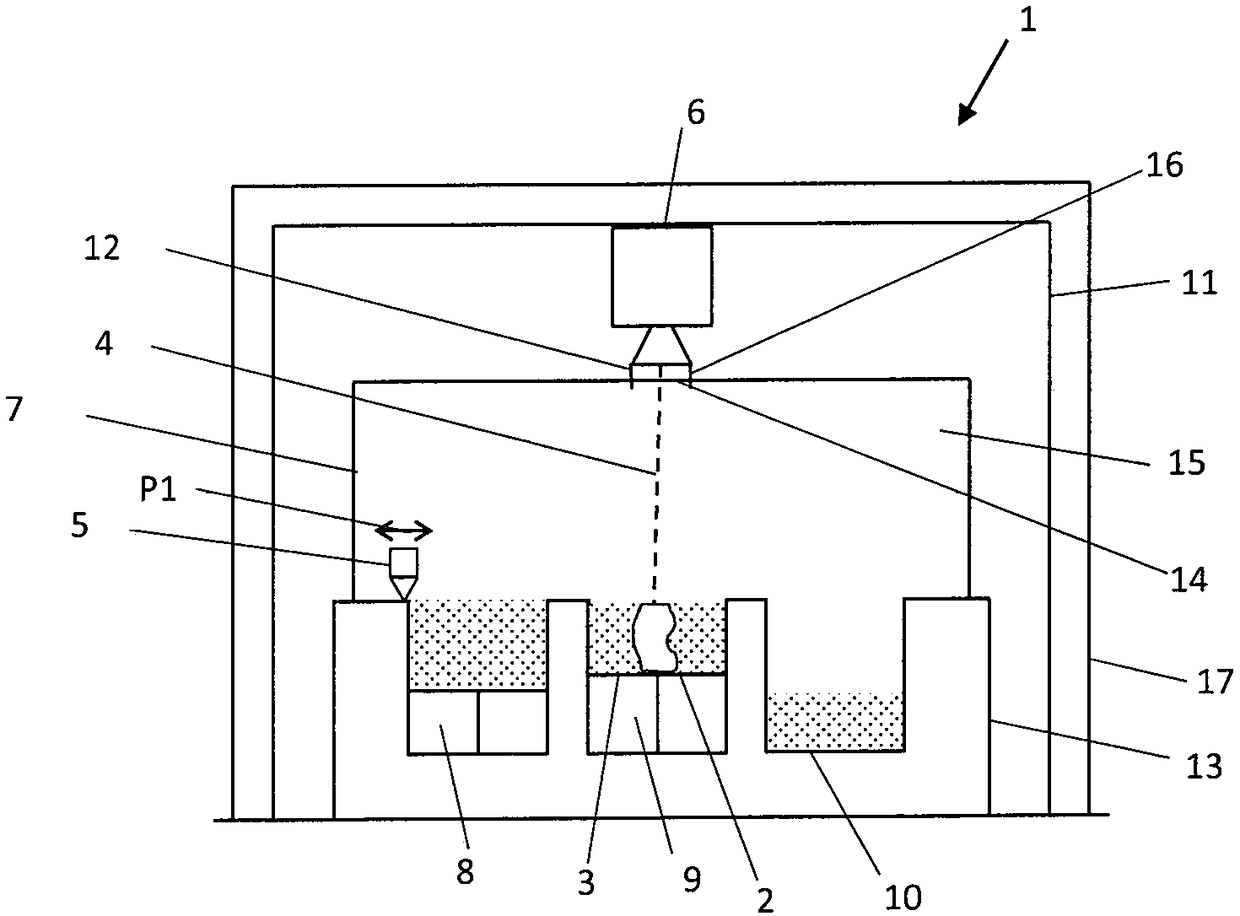

[0024] Figure 1 to Figure 3 A schematic diagram of the device 1 according to an exemplary embodiment of the device 1 is shown in each case.

[0025]The device 1 is used to selectively irradiate layer by layer and then selectively cure layer by layer, consisting of a construction material 3 that can be cured by means of laser radiation, or laser beam 4 , that is to say, for example, metal powder. Layers of construction material for the additive production of three-dimensional objects 2 , that is to say in particular technical components or groups of technical components. The selective curing of the individual layers of construction material to be cured takes place on the basis of object-related construction data. The corresponding construction data describe the geometrical or geometrical design of the object 2 to be additively produced in each case and can contain, for example, “sliced” CAD data of the object 2 to be produced. Device 1 can be designed as Equipment, that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com