A micro gripper with a two-stage amplification mechanism

A technology of magnification mechanism and micro-clamp, which is applied in the direction of manipulators, manufacturing tools, micro-manipulators, etc., can solve the problems of air leakage and clamping failure of vacuum suction equipment, and achieve the effect of large magnification ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

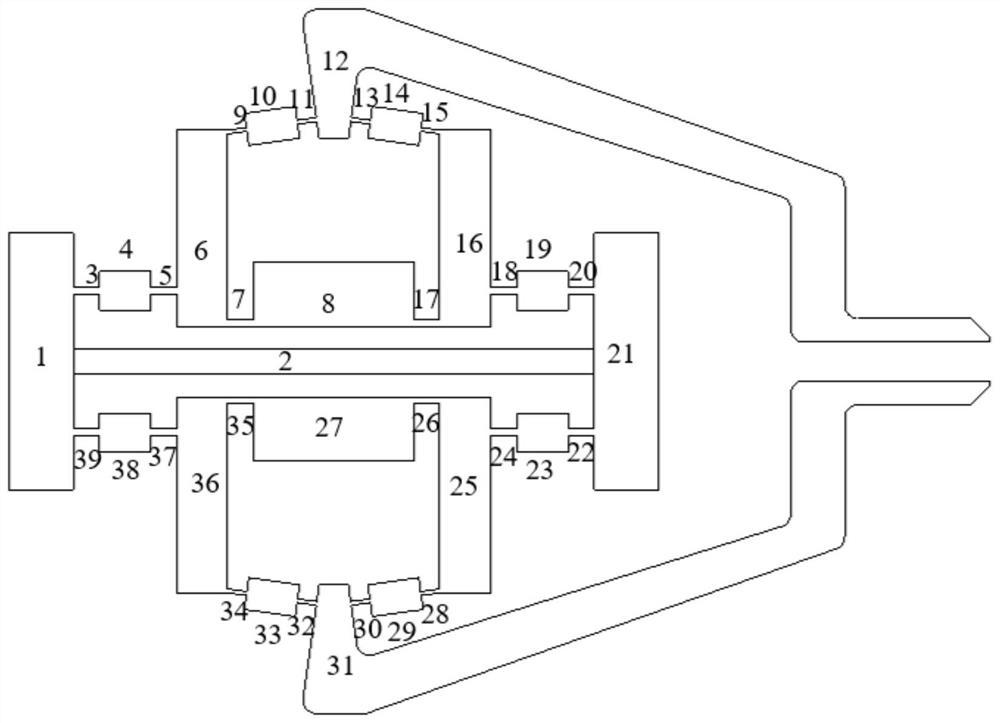

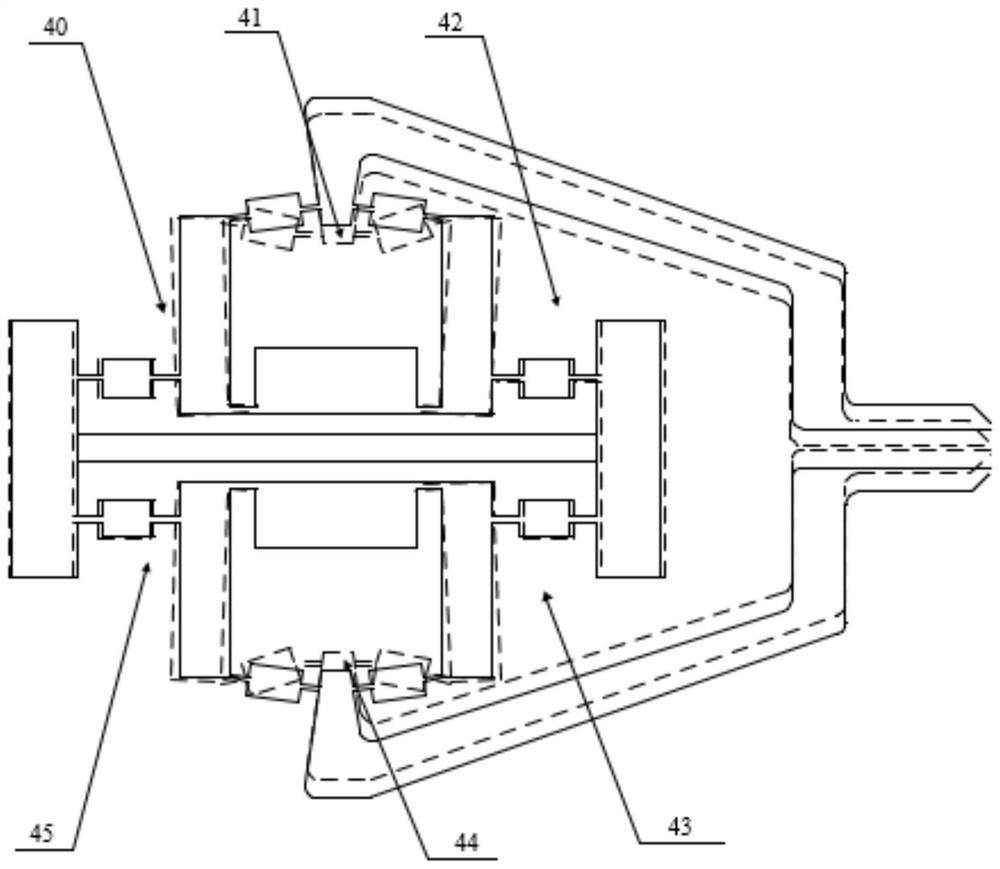

[0024] A micro-clamp with a two-stage amplification mechanism, such as figure 1 , 2 As shown, it includes a fixed frame (composed of a fixed frame 8 and a fixed frame 27), displacement input platforms 1 and 21, motion input mechanism 2 (this embodiment adopts piezoelectric ceramic driver), and four groups of first-level lever mechanisms (first-level lever mechanisms 40, 42, 43, 45) and two sets of bridge-type amplification mechanisms (bridge-type amplification mechanism 41 and bridge-type amplification mechanism 44), four groups of first-level lever mechanisms and two groups of bridge-type amplification mechanisms, respectively Symmetric, and the fulcrum of the first-level lever mechanism is connected with the fixed frame 8, 27 in a transmission, the two ends of the motion input mechanism 2 are respectively connected to the displacement input platform 1 and the displacement input platform 21, and the input ends of the four first-level lever mechanisms are respectively The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com