Elevator starting torque compensation method

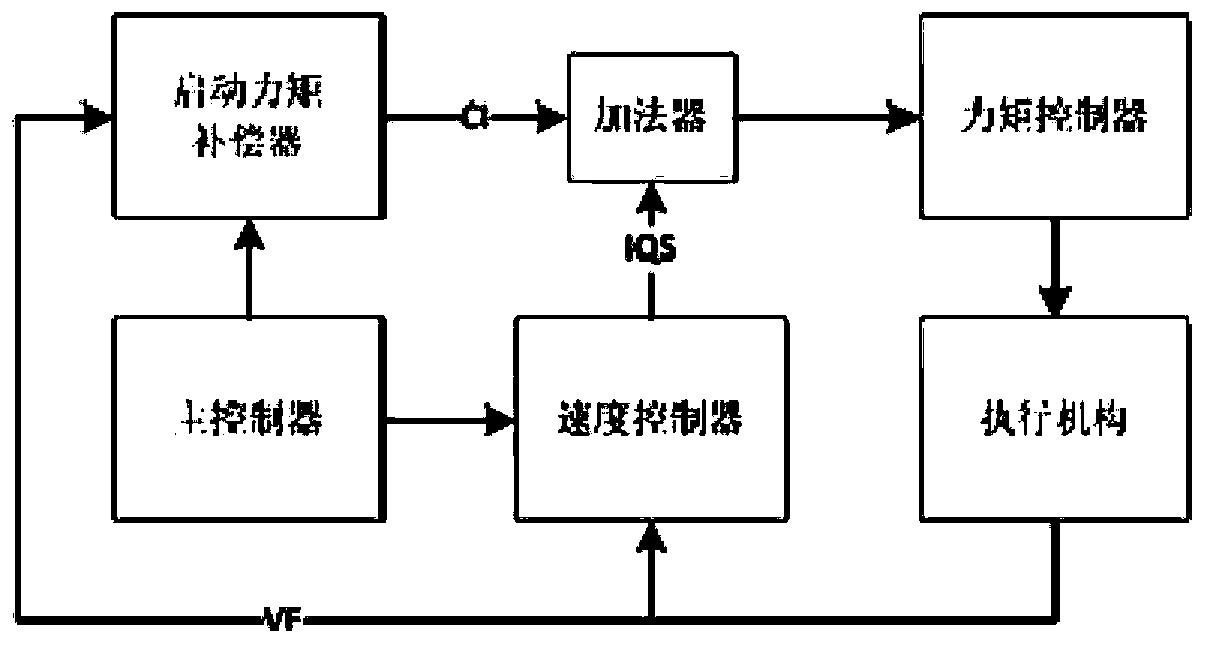

A technology of starting torque and compensation method, which is applied to elevators, elevators, transportation and packaging in buildings, etc. It can solve the problems of slow elevator movement, fast opening of elevator brakes, and deviation of torque compensation value from the actual required value, etc., to achieve The effect of fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

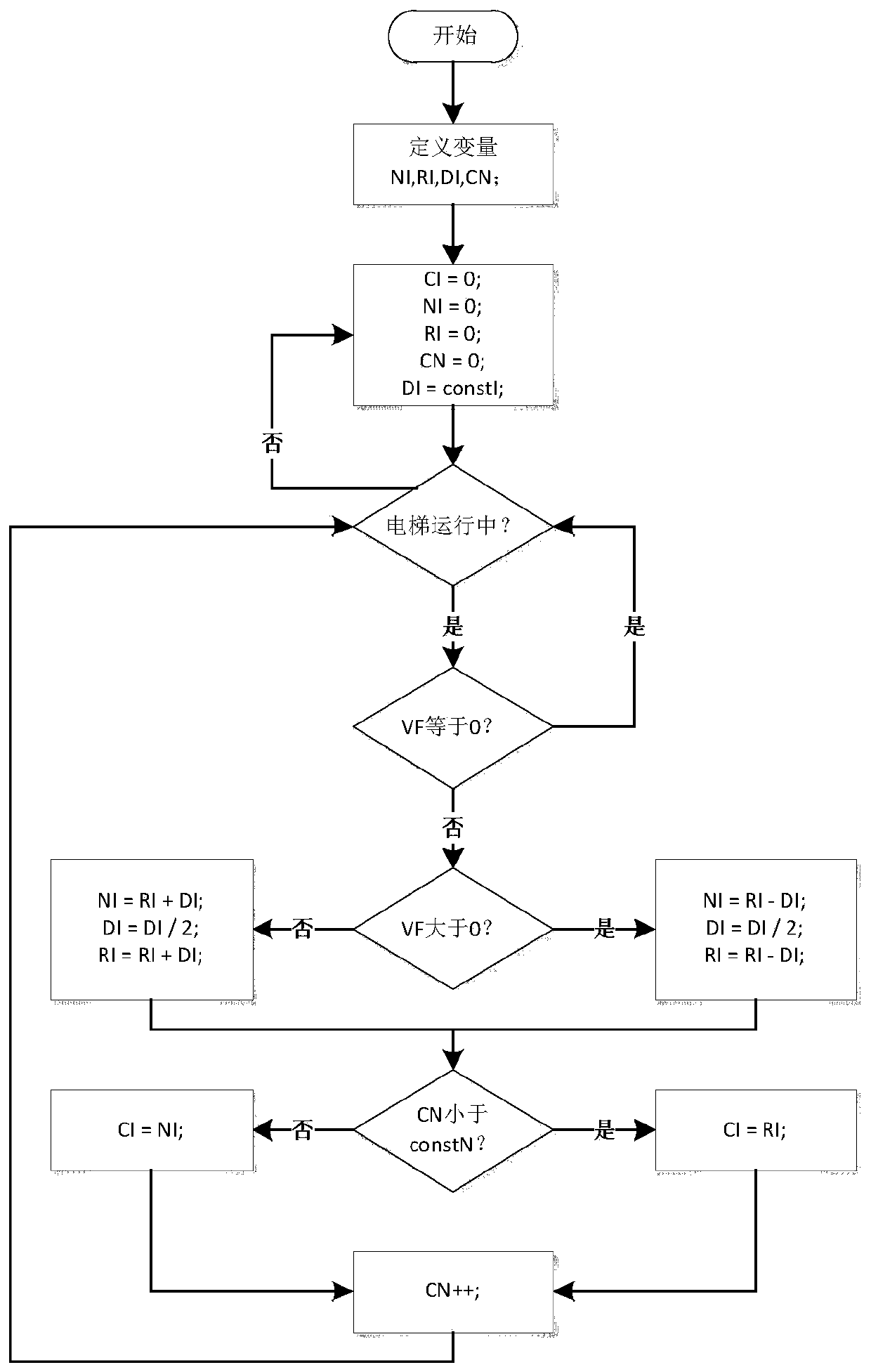

[0068] This embodiment is suitable for elevators without weight sensors, and the steps are as follows:

[0069] Step 1: Define variables RI and DI.

[0070] Step two, assign the following variables to:

[0071] CI=0;

[0072] RI=0;

[0073] DI=ratedI;

[0074] among them:

[0075] ratedI is the torque value required to maintain the force balance when the rated load is placed in the car.

[0076] Step 3: If the elevator is running, monitor the elevator speed feedback signal VF; otherwise, perform step 2.

[0077] If VF=0, perform step 3 again;

[0078] Otherwise, perform the following calculations:

[0079] If VF> 0, then:

[0080] DI=DI / 2;

[0081] RI=RI-DI;

[0082] If VF <0, then:

[0083] DI=DI / 2;

[0084] RI=RI+DI;

[0085] Step 4: Assign a value to the torque compensation value CI:

[0086] CI=RI;

[0087] Step five, perform step three.

[0088] Obviously, this embodiment is figure 2 A special case of the flow chart shown is that the constant constI is selected as ratedI; the constant constN is...

Embodiment 2

[0093] This embodiment is suitable for elevators without weight sensors, and the steps are as follows:

[0094] Step one, define the variables NI, RI, DI.

[0095] Step two, assign the following variables to:

[0096] CI=0;

[0097] NI=0;

[0098] RI=0;

[0099] DI=ratedI;

[0100] among them:

[0101] ratedI is the torque value required to maintain the force balance when the rated load is placed in the car.

[0102] Step 3: If the elevator is running, monitor the elevator speed feedback signal VF; otherwise, perform step 2.

[0103] If VF=0, perform step 3 again;

[0104] Otherwise, perform the following calculations:

[0105] If VF> 0, then:

[0106] NI=RI-DI;

[0107] DI=DI / 2;

[0108] RI=RI-DI;

[0109] If VF <0, then:

[0110] NI=RI+DI;

[0111] DI=DI / 2;

[0112] RI=RI+DI;

[0113] Step 4: Assign a value to the torque compensation value CI:

[0114] CI=NI;

[0115] Step five, perform step three.

[0116] Obviously, this embodiment is figure 2 A special case of the flow chart shown is that the cons...

Embodiment 3

[0121] This embodiment is suitable for elevators without weight sensors, and the steps are as follows:

[0122] Step one, define variables NI, RI, DI, CN.

[0123] Step two, assign the following variables to:

[0124] CI=0;

[0125] NI=0;

[0126] RI=0;

[0127] CN=0;

[0128] DI=ratedI;

[0129] among them:

[0130] ratedI is the torque value required to maintain the force balance when the rated load is placed in the car.

[0131] Step 3: If the elevator is running, monitor the elevator speed feedback signal VF; otherwise, perform step 2.

[0132] If VF=0, perform step 3 again;

[0133] Otherwise, perform the following calculations:

[0134] If VF> 0, then:

[0135] NI=RI-DI;

[0136] DI=DI / 2;

[0137] RI=RI-DI;

[0138] If VF <0, then:

[0139] NI=RI+DI;

[0140] DI=DI / 2;

[0141] RI=RI+DI;

[0142] Step 4: Assign a value to the torque compensation value CI according to the value of the variable CN:

[0143] If CN <1, then:

[0144] CI=RI;

[0145] otherwise:

[0146] CI=NI;

[0147] Step five, increase t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com