Built-in cup bracket for car

A cup holder and automobile technology, which is applied in special positions of vehicles, vehicle parts, transportation and packaging, etc., can solve the problems of reduced storage space of cup holders, low self-adaptation, occupied storage space, etc. The effect of convenience, high degree of self-adaptation and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

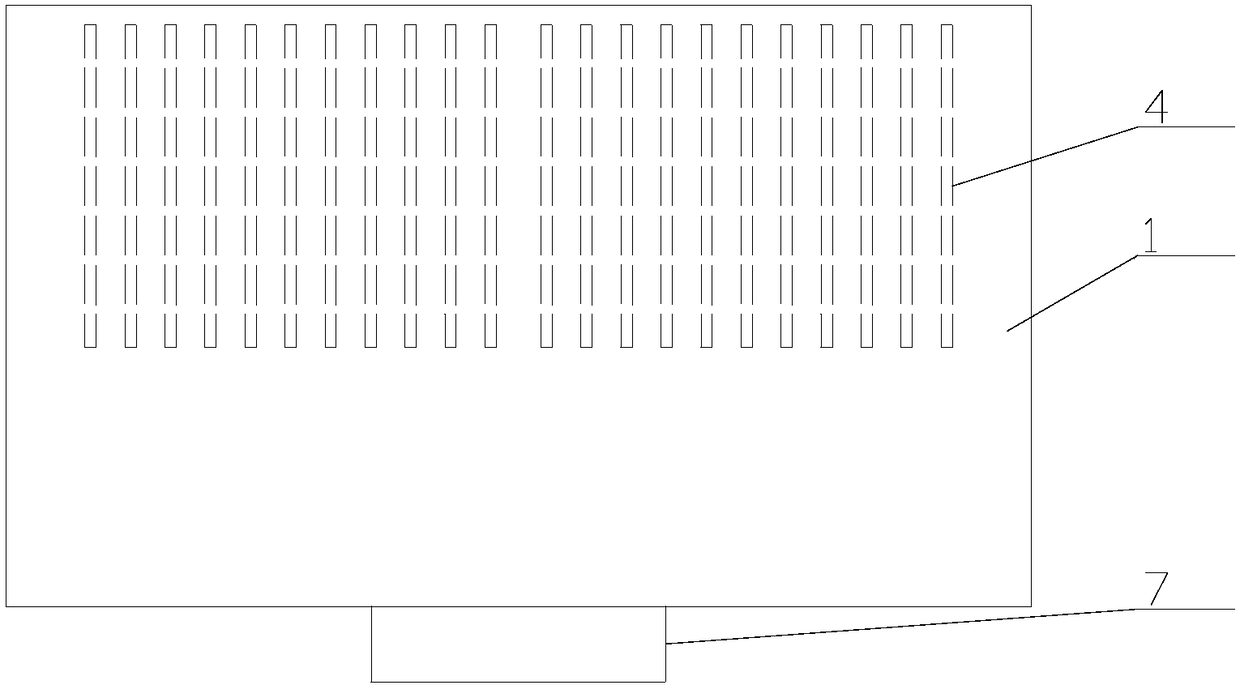

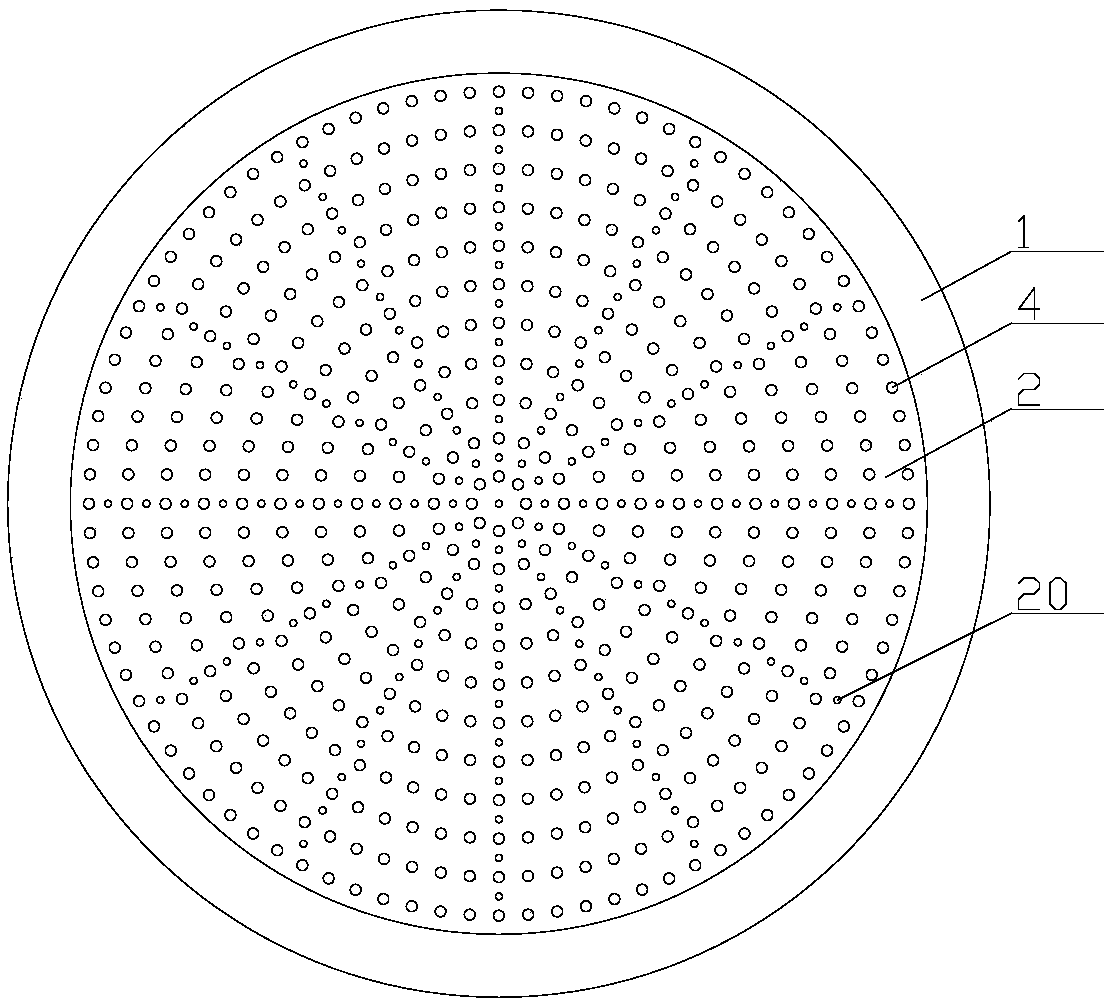

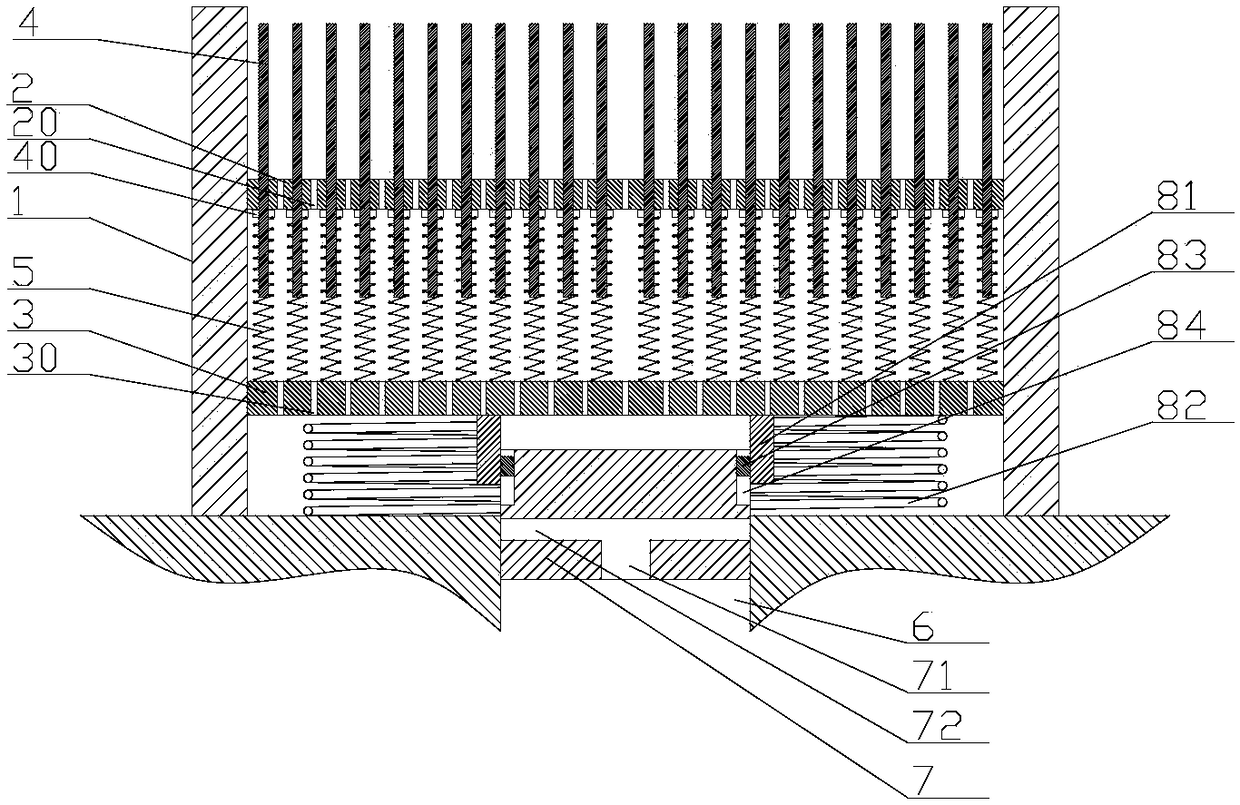

[0028] Embodiment one, such as Figure 3-5 As shown: the linkage assembly includes a sleeve 81 and a compression spring 82, the bottom plate 3 is connected to the inner wall of the base 1 through threads, the air blocking column 7 is connected to the air outlet 6 of the air conditioner through threads, and the blocking The screw thread on the wind post and the screw thread on the bottom plate have the opposite direction of rotation. The sleeve 81 is fixedly connected to the bottom surface of the bottom plate 3 and socketed on the wind blocking post 7. The sleeve 81 and the air blocking post 7 are connected by a synchronous rotation mechanism, and the compression spring 82 is vacantly sleeved outside the sleeve 81 and is pressed between the outer side of the top edge of the air outlet of the air conditioner and the bottom surface of the bottom plate. In this way, when the user further presses down on the cup body, the bottom plate will overcome the force of the compression spri...

Embodiment 2

[0031] Embodiment two, such as Figure 6-8 As shown: the linkage assembly includes an active lever 85, a linkage disk 86, a torsion spring and a driven lever 87. The linkage disk 86 is vertically arranged below the bottom plate 3 and is hinged in the base 1 through a rotating shaft. The two ends of the torsion spring are respectively fixedly connected to the linkage disc 86 and the rotating shaft, the top of the active rod 85 is slidably connected to the bottom surface of the base plate 3, and the bottom end is hinged on the surface of the linkage disc 86, and the driven rod 87 can be A telescopic rod, one end of the driven rod 87 is fixedly connected to the side wall of the wind blocking column 7, and the other end is hinged on the surface of the linkage plate 86, and the active rod 85 and the driven rod 87 are located on the linkage plate 86 respectively. sides of the center. In this way, when the user further presses down on the cup body, the active lever will go down toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com